Silicon carbide reinforced metal matrix composite with micro orientated structure and preparation method thereof

A composite material, silicon carbide technology, used in magnesium alloy and aluminum alloy matrix composite materials and their preparation, the field of metal magnesium, can solve the problem of reducing the integrity and coherence of the matrix alloy, reducing the plasticity and toughness of the material, and having no toughening mechanism, etc. problems, to achieve considerable application prospects, enhanced mechanical properties, and excellent comprehensive mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

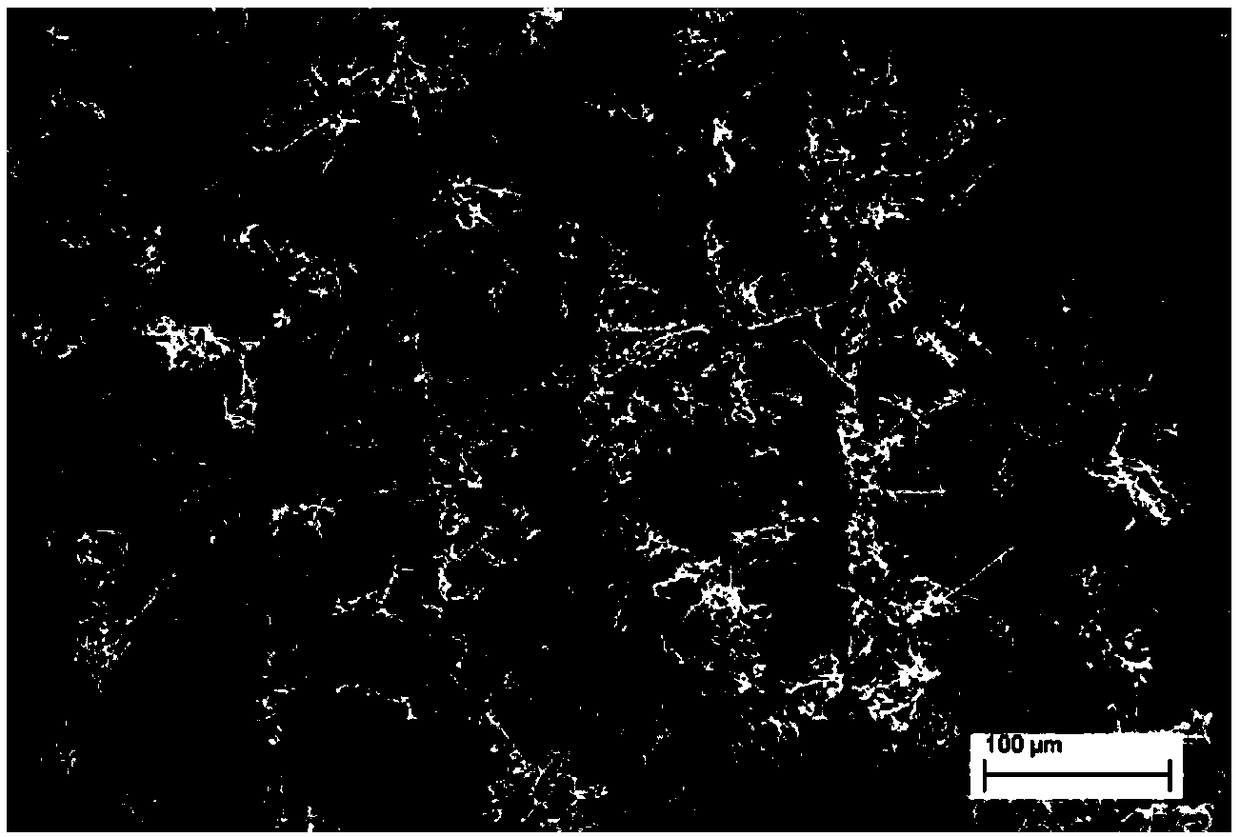

[0036] In this example, a silicon carbide whisker-reinforced magnesium-based composite material with a microscopic oriented structure was prepared. The raw materials used mainly include silicon carbide whiskers (average diameter 2.5μm, length 50-200μm), silicon oxide powder (average particle size 20nm), deionized water, polyvinyl alcohol, hydroxypropyl methylcellulose powder (average particle size 180 μm), polyacrylic acid and pure metal magnesium, the specific preparation process is as follows:

[0037] (A) Preparation of slurry

[0038] Add 700g of deionized water to a 1000ml plastic jar, add 90g of silicon carbide whiskers, 3.6g of silicon oxide powder, 31.5g of polyvinyl alcohol and 1.8g of polyacrylic acid into the bottle, and stir at a speed of 60rpm until solid The powder is evenly dispersed in water. Place the jar in a constant temperature water bath at 70°C, keep it warm for 30 minutes, slowly add 12.6g of hydroxypropyl methylcellulose powder into the bottle, and st...

Embodiment 2

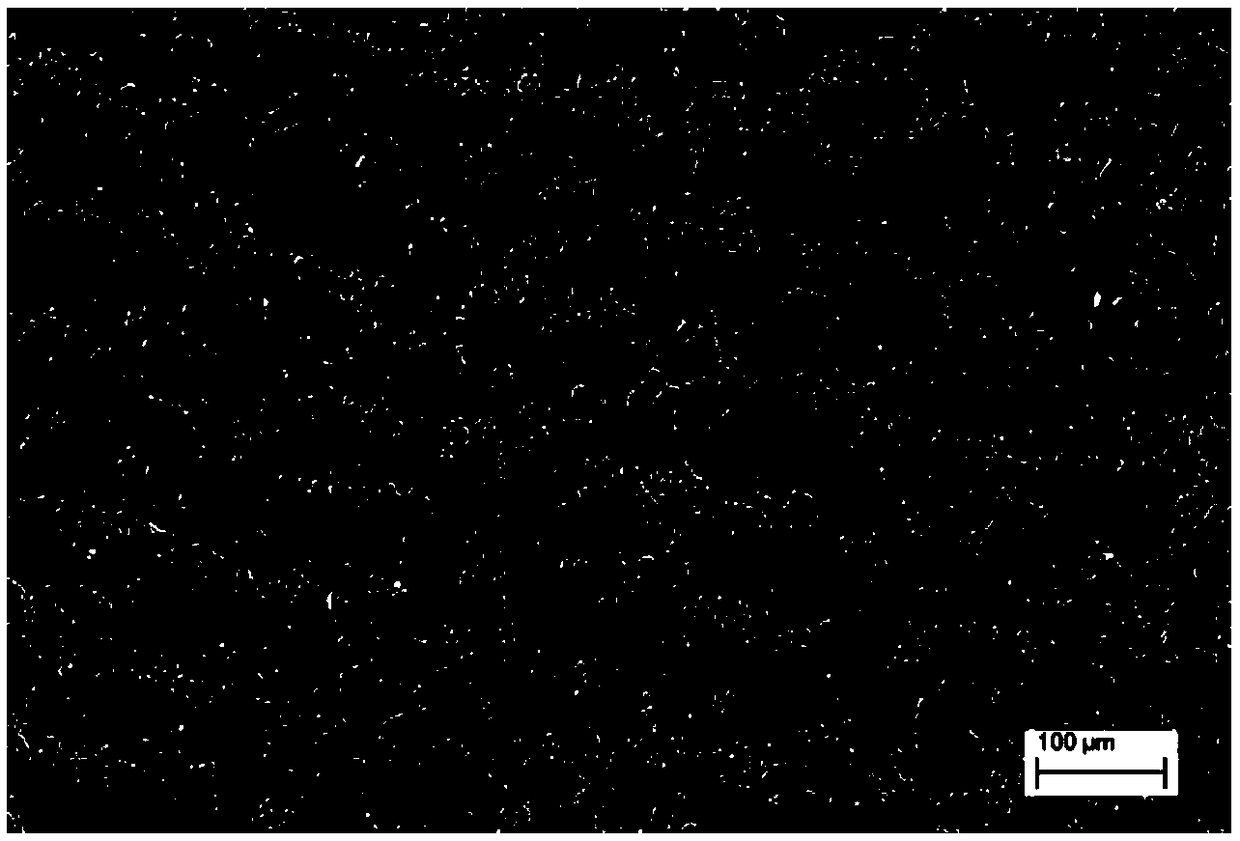

[0049] In this example, a silicon carbide sheet-reinforced magnesium alloy-based composite material with a microscopic oriented structure was prepared. The raw materials used mainly include nano-silicon carbide powder (average particle size 100nm), nano-yttrium oxide powder (average particle size 30nm), nano-alumina powder (average particle size 20nm), deionized water, polyvinyl alcohol, hydroxyl Propyl methyl cellulose powder (average particle diameter 180 μm), polyacrylic acid and AZ91D type magnesium alloy (in terms of mass percentage, the composition is 9.0% aluminum, 0.5% zinc, 0.2% manganese, the rest is magnesium), the specific preparation process is as follows :

[0050] (A) Preparation of slurry

[0051] Add 185g of deionized water to a 500ml plastic jar, add 45g of nano-silicon carbide powder, 2.853g of nano-yttrium oxide powder, 2.147g of nano-alumina powder, 8g of polyvinyl alcohol and 1g of polyacrylic acid into the bottle , stirring at a speed of 60rpm until th...

Embodiment 3

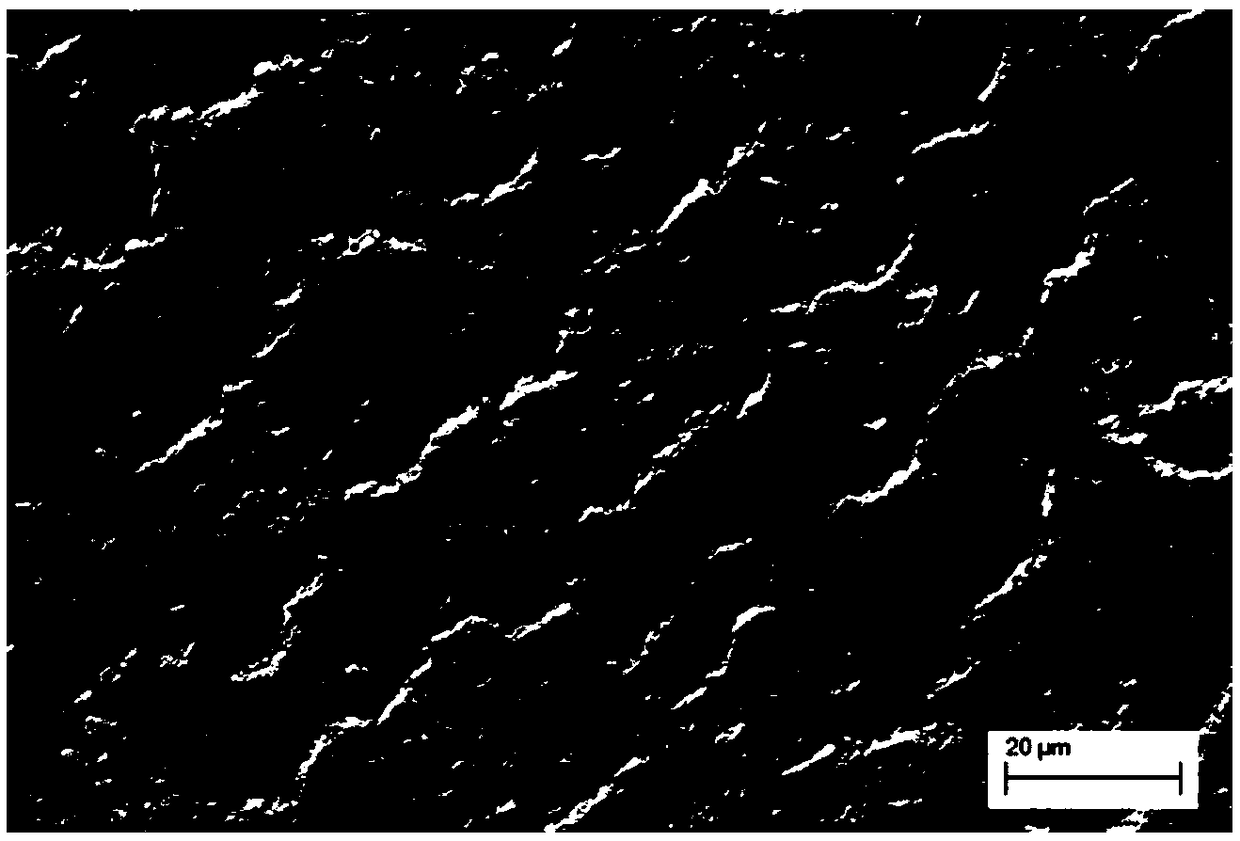

[0062] In this example, a silicon carbide sheet-reinforced aluminum alloy matrix composite material with a microscopic oriented structure was prepared. The raw materials used mainly include nano-silicon carbide powder (average particle size 100nm), nano-yttrium oxide powder (average particle size 30nm), nano-alumina powder (average particle size 20nm), deionized water, polyvinyl alcohol, hydroxyl Propylmethylcellulose powder (average particle size 180 μm), polyacrylic acid and ZL303 aluminum alloy (by mass percentage, the composition is 1.0% silicon, 0.2% manganese, 5.2% magnesium, and the rest is aluminum), the specific preparation process is as follows:

[0063] (A) Preparation of slurry

[0064] The operation of this step is the same as step (A) in Example 2.

[0065] (B) Preparation of porous body

[0066] The operation of this step is the same as step (B) in Example 2.

[0067] (C) Body compression treatment

[0068] The operation of this step is similar to that of st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com