Copper-based contact material with microscopic orientation structure and preparation method of copper-based contact material

A contact material, copper-based technology, applied in contacts, electrical components, circuits, etc., can solve the constraints of plasticity and toughness of copper-based contact materials, performance advantages cannot be fully utilized, electrical conductivity and thermal conductivity cannot be realized, etc. problems, to achieve considerable application prospects, excellent electrical and thermal conductivity, and good high-temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

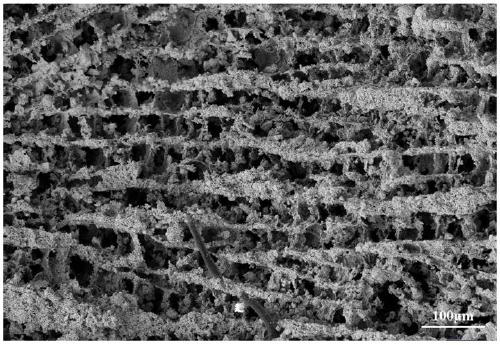

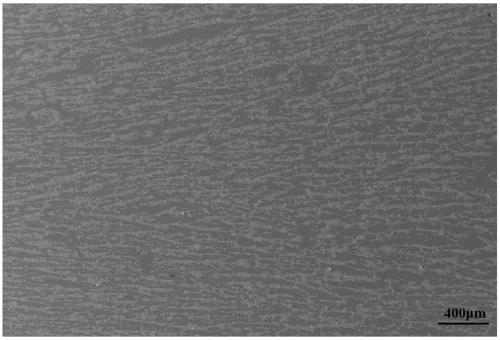

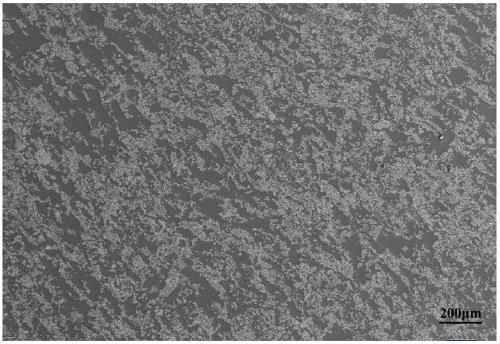

Image

Examples

Embodiment 1

[0029] In this example, a copper / chromium contact material with a microscopic oriented structure is prepared, and the raw materials used include metal chromium powder (average particle diameter is 600 nm), water, hydroxypropyl methylcellulose powder (average particle diameter is 180 μm ), polyethyleneimine and pure copper block for infiltration, the specific preparation process is as follows:

[0030] (A) slurry preparation

[0031] Weigh 120g of water and add it to a 500ml plastic jar, add 480g of metal chromium powder, 6g of hydroxypropyl methylcellulose powder and 9.6g of polyethyleneimine to the jar in turn, and drop 5 drops of Foaming agent (about 0.3ml), this defoaming agent is the XPM-120 type defoaming agent that Nanjing Huaxing Defoamer Co., Ltd. produces, stirs 5min to make slurry evenly disperse, then in slurry, add diameter is 3mm, 6mm, 6 zirconia grinding balls of 10mm and 12mm respectively, after sealing the bottle cap on the jar, place it on a roller ball mill ...

Embodiment 2

[0040] In this example, the copper / chromium contact material with a microscopic oriented structure is prepared, the raw materials used are the same as in Example 1, and the specific preparation process differs from Example 1 in that the amount of water added in the slurry preparation process The mass is 100g, the mass of the metal chromium powder is 600g, the mass of the hydroxypropyl methylcellulose powder is 5g, and the mass of polyethyleneimine is 12g, and the rest of the operations are the same as in Example 1.

[0041] The copper / chromium contact material with microscopic directional structure can be prepared through the above process, and its microstructure can be seen in image 3 , the volume fraction of chromium in this material is 52%, and the corresponding mass fraction is 47%.

Embodiment 3

[0043] In this example, a copper / tungsten carbide contact material with a microscopic oriented structure was prepared, and the raw materials used included tungsten carbide powder (average particle size: 1 μm), water, polyvinyl alcohol (average particle size: 100 μm), polyacrylic acid And pure copper block for infiltration, the specific preparation process is as follows:

[0044] (A) slurry preparation

[0045] The operation of this step is basically the same as step (A) in Example 1, except that the type and amount of raw materials used are specifically: 400 g of tungsten carbide powder, 100 g of water, 5 g of polyvinyl alcohol, and 8 g of polyacrylic acid.

[0046] (B) Freeze casting and vacuum freeze drying

[0047] The operation of this step is the same as step (B) in Example 1.

[0048] (C) Organic matter removal and skeleton sintering

[0049] According to the same operation of step (C) in Example 1, the organic matter in the green body obtained after vacuum freeze-dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com