Metal-matrix bionic composite material reinforced by carbon nanomaterials, and preparation method thereof

A technology of nano-carbon materials and composite materials, which is applied in the field of metal-based biomimetic composite materials and their preparation, can solve problems such as difficulty in popularization, difficulty in effective regulation of microstructure, and complicated preparation process of composite materials. Easy to promote and achieve performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

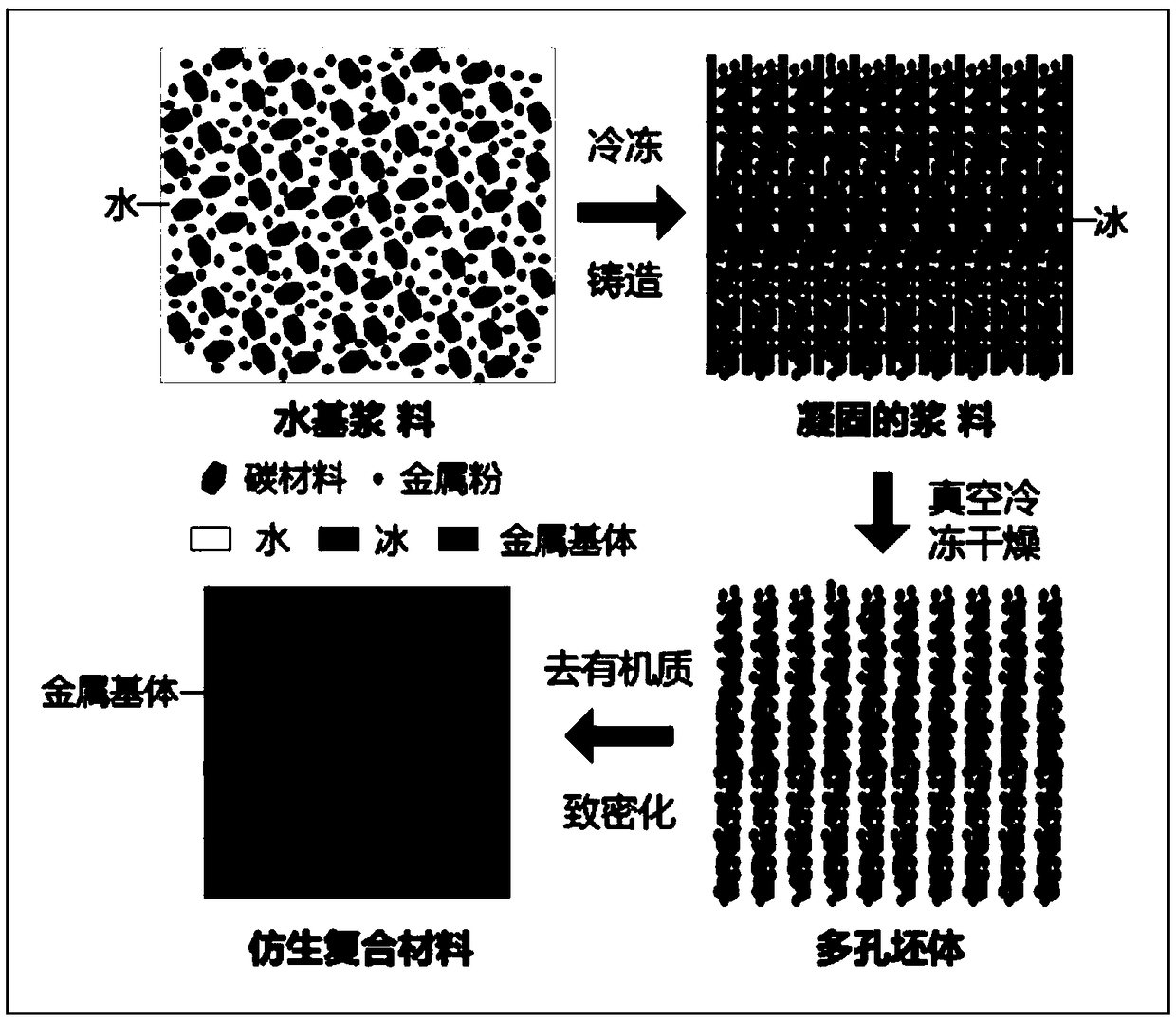

[0034] In this example, the graphene-reinforced metal aluminum-based biomimetic composite material is prepared. The raw materials used mainly include graphene (diameter 5-10 μm, thickness 3-10 nm), flake aluminum powder (average sheet diameter 10 μm, average thickness 0.5 μm), deionized water, sodium lauryl sulfate, hydroxypropyl methylcellulose powder (average particle size 180 μm), polyvinyl alcohol, sucrose, and polyacrylic acid. Such as figure 1 As shown, the specific preparation process is as follows:

[0035] (A) prepare the water-based slurry of graphene and flake aluminum powder

[0036] Take 180g of deionized water and add it to a 500mL plastic jar, add 0.36g of sodium lauryl sulfate powder into the jar, and stir at a speed of 100rpm until the powder is evenly dispersed in the water. Take 0.378g of graphene and slowly add it into a jar, place the jar in an ultrasonic disperser, and perform ultrasonic treatment on it for 2 hours at a power of 100W. Take out the jar ...

Embodiment 2

[0043] In this example, the metal nickel-based biomimetic composite material reinforced with graphene is prepared, and the raw materials used mainly include graphene (diameter 5-10 μm, thickness 3-10 nm), nano-nickel powder (average particle size 50 nm), deionized water , sodium lauryl sulfate, hydroxypropyl methylcellulose (average particle size of 180 μm), polyvinyl alcohol, sucrose and polyacrylic acid. Such as figure 1 As shown, the specific preparation process is as follows:

[0044] (A) water-based slurry for preparing graphene and nano-nickel powder

[0045] The difference between this step and step (A) in Example 1 is the type and consumption of raw materials, specifically: changing the flaky aluminum powder into nano-nickel powder, the consumption is 14.7g, and the consumption of deionized water is 200g, ten The consumption of sodium dialkyl sulfate is 0.4g, the consumption of graphene is 0.3g, the consumption of hydroxypropyl methylcellulose is 1.5g, the consumptio...

Embodiment 3

[0052] In this example, the metal cobalt-based biomimetic composite material reinforced with graphene is prepared, and the raw materials used mainly include graphene (diameter 5-10 μm, thickness 3-10 nm), nano-cobalt powder (average particle size 40 nm), deionized water , sodium lauryl sulfate, hydroxypropyl methylcellulose (average particle size of 180 μm), polyvinyl alcohol, sucrose and polyacrylic acid. Such as figure 1 As shown, the specific preparation process is as follows:

[0053] (A) prepare the water-based slurry of graphene and nano-cobalt powder

[0054] The difference between this step and step (A) in Example 1 is the type and consumption of raw materials, specifically: changing the flake aluminum powder into nano cobalt powder, the consumption is 40g, and the consumption of deionized water is 100g, 12 The consumption of sodium alkyl sulfate is 0.2g, the consumption of graphene is 0.1g, the consumption of hydroxypropyl methylcellulose is 1.5g, the consumption of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com