Ceramic powder preparation method based on freeze casting molding

A technology of freezing casting and ceramic powder, which is applied in ceramic molding machines, manufacturing tools, etc., can solve the problem of difficult preparation of ceramic powder in large quantities, achieve airflow control and anti-pollution functions, facilitate handling, and increase furnace capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

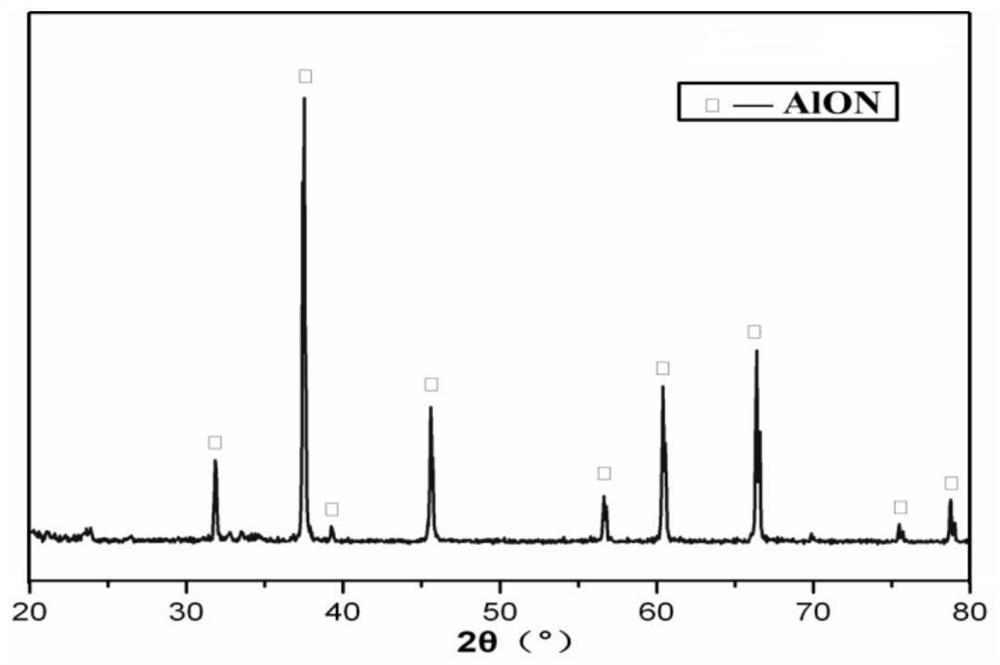

[0037]The Alon powder was prepared using a ceramic powder preparation method based on frozen casting, and specifically includes the following steps:

[0038](1) Weigh a certain amount of micron γ-A12O3Powder, high-purity carbon black powder, polyvinylpyrrolidone, ammonium citrate, tert-butanol, and alumina grinding balls, borne mill mill grinding in a polyurethane ball grinding tank, and obtains a solid phase content of 45 % Slurry;

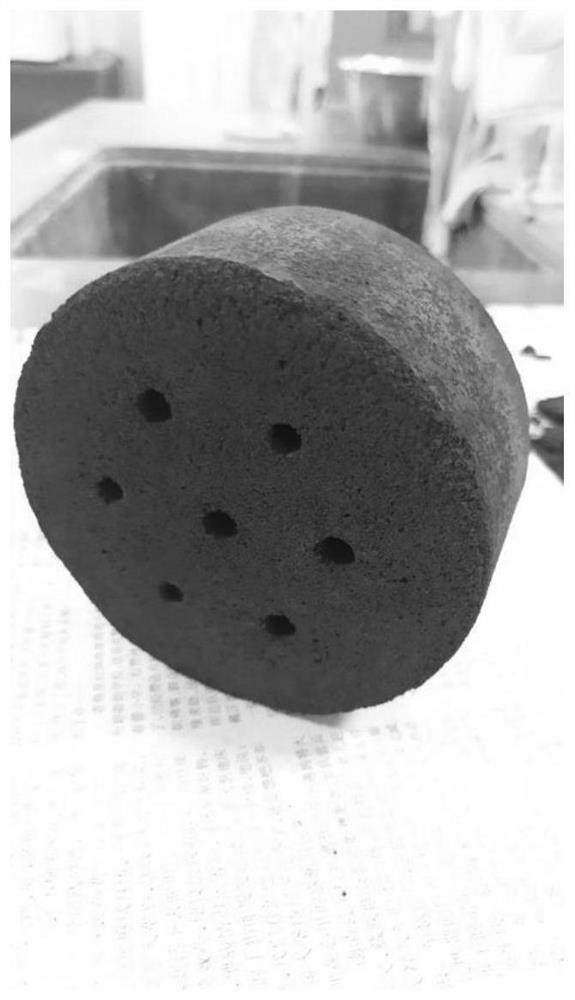

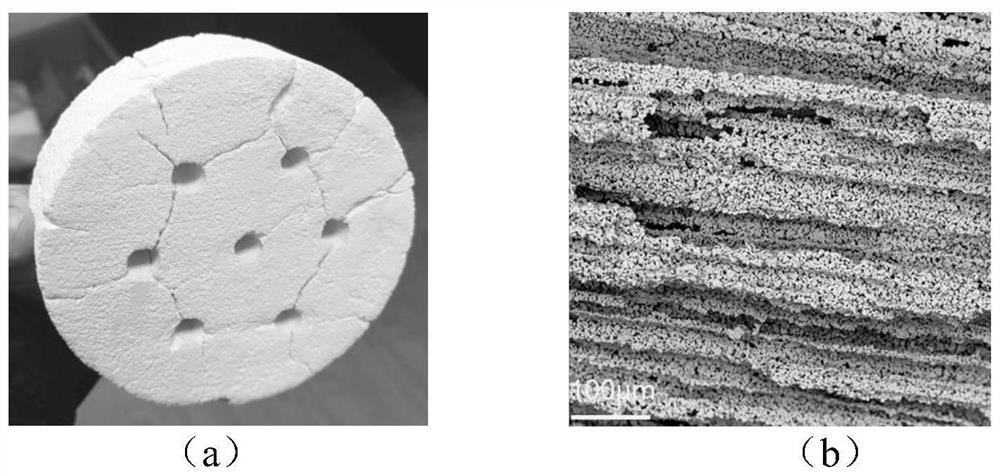

[0039](2) Injecting the slurry into the molded mold (the heat transfer bottom plate of the mold is a steel sheet, the insulation is nylon, and the occupying rod is polytetrafluoroethylene), and the molded mold is placed in an alcohol cooling medium of -80 ° C. Placed in 4 h, then releases the feed blank of the condensed condensate into a cryogenic dryer to dry the temperature of -30 ° C for 24 h, resulting in a raw material blank having an internal via structure (seefigure 1 );

[0040](3) The above-mentioned raw material blank is placed in a ceramic powder rea...

Embodiment 2

[0043]ALN powder was prepared using a ceramic powder preparation method based on frozen casting, and specifically includes the following steps:

[0044](1) Weigh a certain amount of nanoscale α-A12O3Powder, high purity carbon black powder, polyvinyl alcohol, tetramethylammonium hydroxide, deionized water and alumina grinding ball, loaded into a polyurethane spherical grinding tank, a rod mill mill mill mill mill mill, obtained Phase content is 50% slurry;

[0045](2) Injecting the slurry injecting the molded mold (the mold is identical to the first embodiment), the molding die is placed in an alcohol cooling medium having a temperature of -60 ° C, then removes the raw material blank of the condensed solid. The inlet dryer was dried in a freeze dryer at -20 ° C for 24 h to obtain a raw material blank having an internal via structure;

[0046](3) The above-mentioned raw material blank is placed in a ceramic powder reaction apparatus in the high temperature graphite sintered furnace to perform ...

Embodiment 3

[0049]Mgalon powder was prepared using a ceramic powder preparation method based on frozen casting, including the following steps:

[0050](1) Weighing nanoscale γ-Al2O3 powder, nanoscale MgO powder, high purifu carbon black powder, carboxymethylcellulose, ammonium polyacrylate, water, tert-butanol, and alumina grinding ball, is loaded into a polyurethane sphere, The ball milling of the solid phase content of 40% was obtained at a rough mill of 500r / min.

[0051](2) Injecting the slurry into the molding mold (the mold is identical to the first embodiment), the molding die is placed in an alcohol cooling medium having a temperature of -40 ° C, and then removes the raw material blank of the condensed solid. The inlet dryer was dried in a freeze dryer at -20 ° C for 24 h to obtain a raw material blank having an internal via structure;

[0052](3) The above-mentioned raw material blank is placed in a ceramic powder reaction apparatus in the high temperature ink sintered furnace to perform high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com