Biomimetic construction method of g-C3N4/BiOI-pDA@PVDF photocatalytic membrane and application thereof

A technology of photocatalytic film and construction method, which is applied in the field of environmental functional material preparation, can solve the problems of reduced catalytic active sites of catalysts, uneven distribution of nano-photocatalysts, and reduced photocatalytic activity, so as to reduce film pollution and improve photocatalytic activity. Catalytic activity, the effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

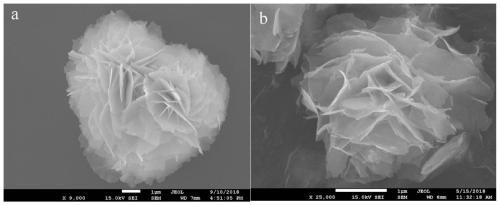

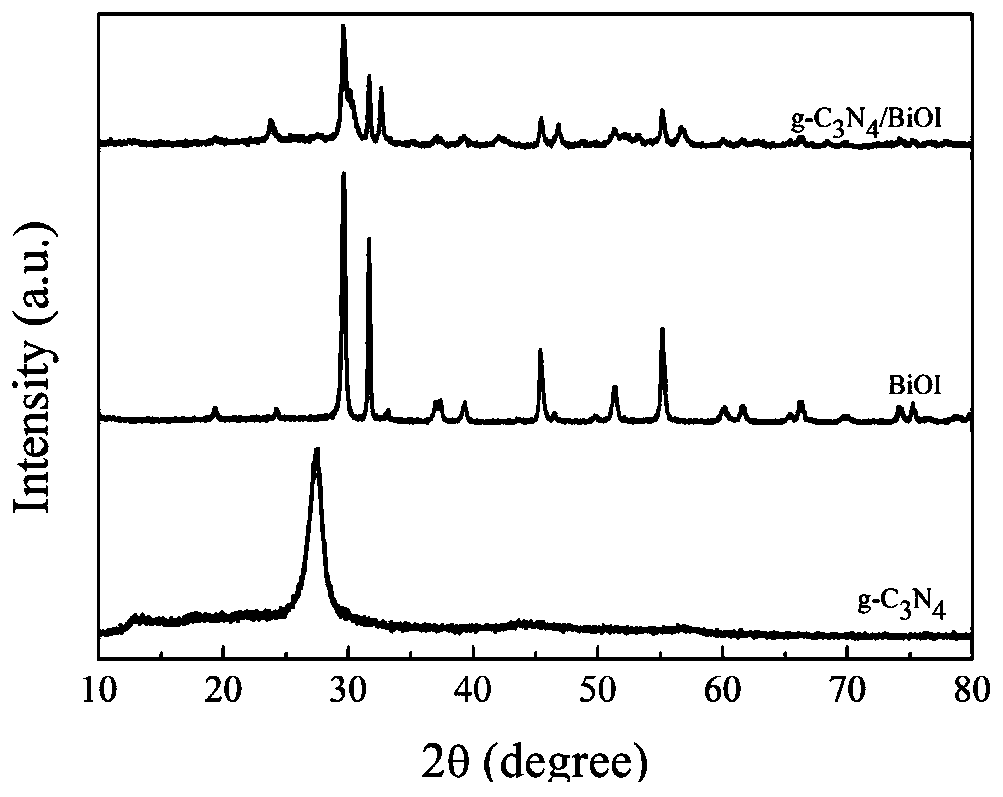

[0032] Example 1g-C 3 N 4 / Preparation of BiOI-pDA@PVDF photocatalytic film

[0033] (1) Weigh a certain amount of melamine in a semi-closed crucible, dry it overnight, then wrap it with tin foil and transfer it to a temperature-programmed muffle furnace, and heat it to 550°C for 4.0h at a heating rate of 2.3°C / min. , after naturally cooling to room temperature, take it out, grind it into powder, and get g-C 3 N 4 ;

[0034] (2) Take a certain quality of Bismuth Nitrate Pentahydrate Bi(NO 3 ) 3 ·5H 2 O and g-C 3 N 4 Disperse in absolute ethanol, ultrasonic for 30min; then dissolve a certain mass of KI in deionized water, add dropwise to the above mixed solution under vigorous stirring, after stirring for 1h, transfer the obtained solution to an autoclave at 180°C for hydrothermal After reacting for 12 hours, the obtained product was centrifuged, washed, and dried to obtain a composite photocatalyst, denoted as g-C 3 N 4 / BiOI;

[0035] (3) Preparation of pDA@PVDF ...

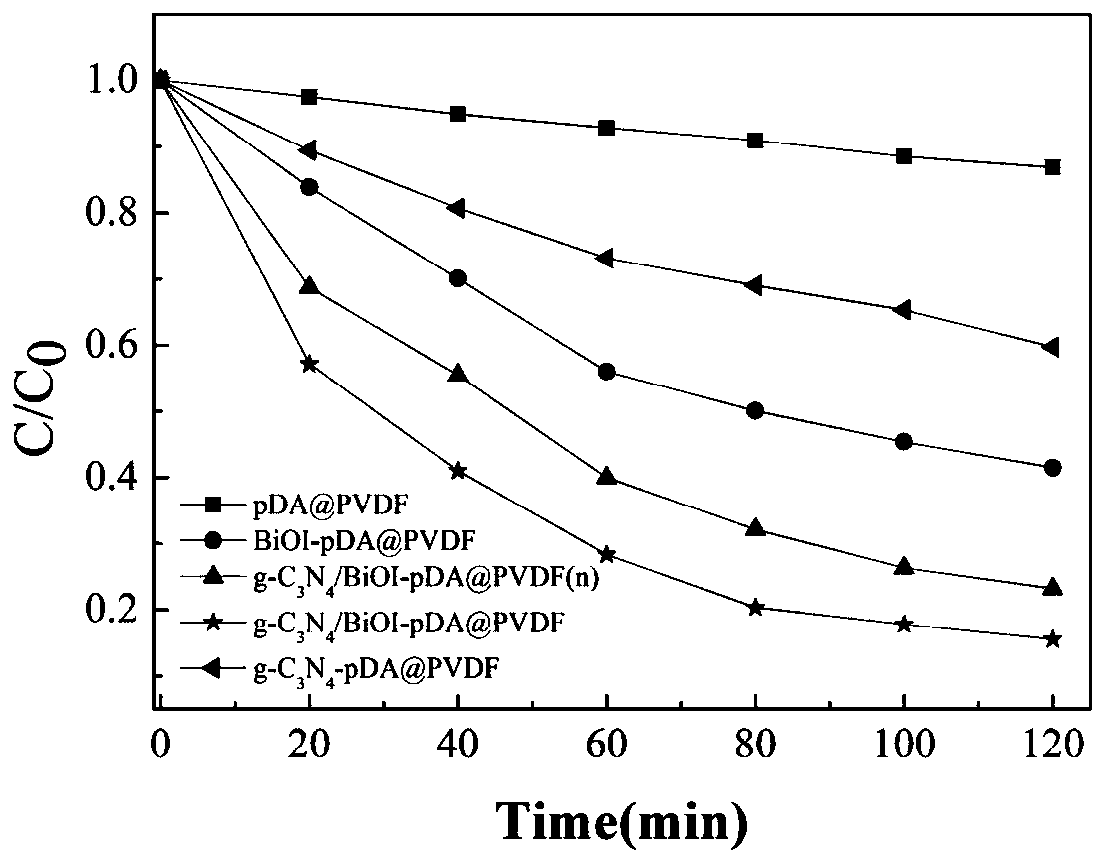

Embodiment 2

[0043] Under the condition that embodiment 2 guarantees that other conditions are constant, set up comparative experiment as follows: in step (4), take 0.2gBiOI catalyst to replace g-C 3 N 4 / BiOI, added to the casting solution.

Embodiment 3

[0044] Under the situation that embodiment 3 guarantees that other conditions are constant, set up comparative experiment as follows: in step (4), take by weighing 0.2gg-C 3 N 4 The catalyst was replaced by g-C3N4 / BiOI and added to the casting solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com