Method for preparing oriented porous structure of precursor conversion type ceramic

A technology of precursor transformation and porous structure, which is applied in ceramic products, ceramic molding machines, manufacturing tools, etc., can solve the problems of different ceramic sizes and poor green body strength, and achieve low cost, low preparation temperature, and minimal material defects effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

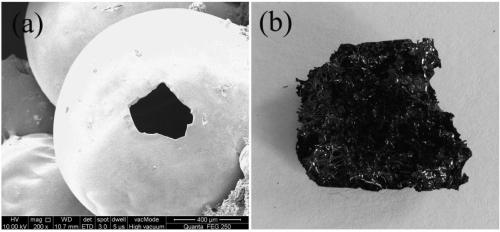

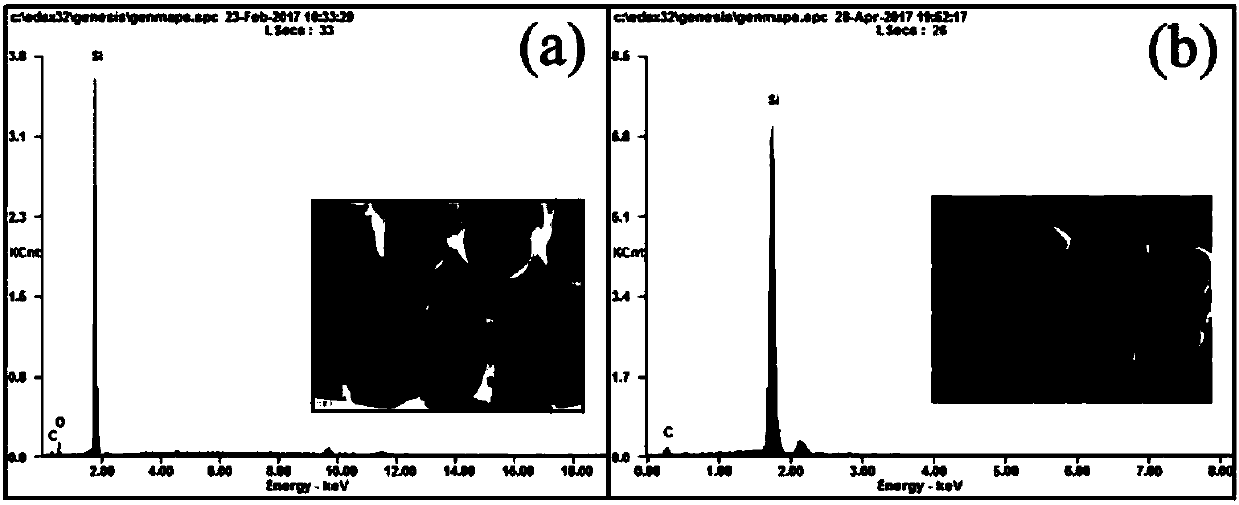

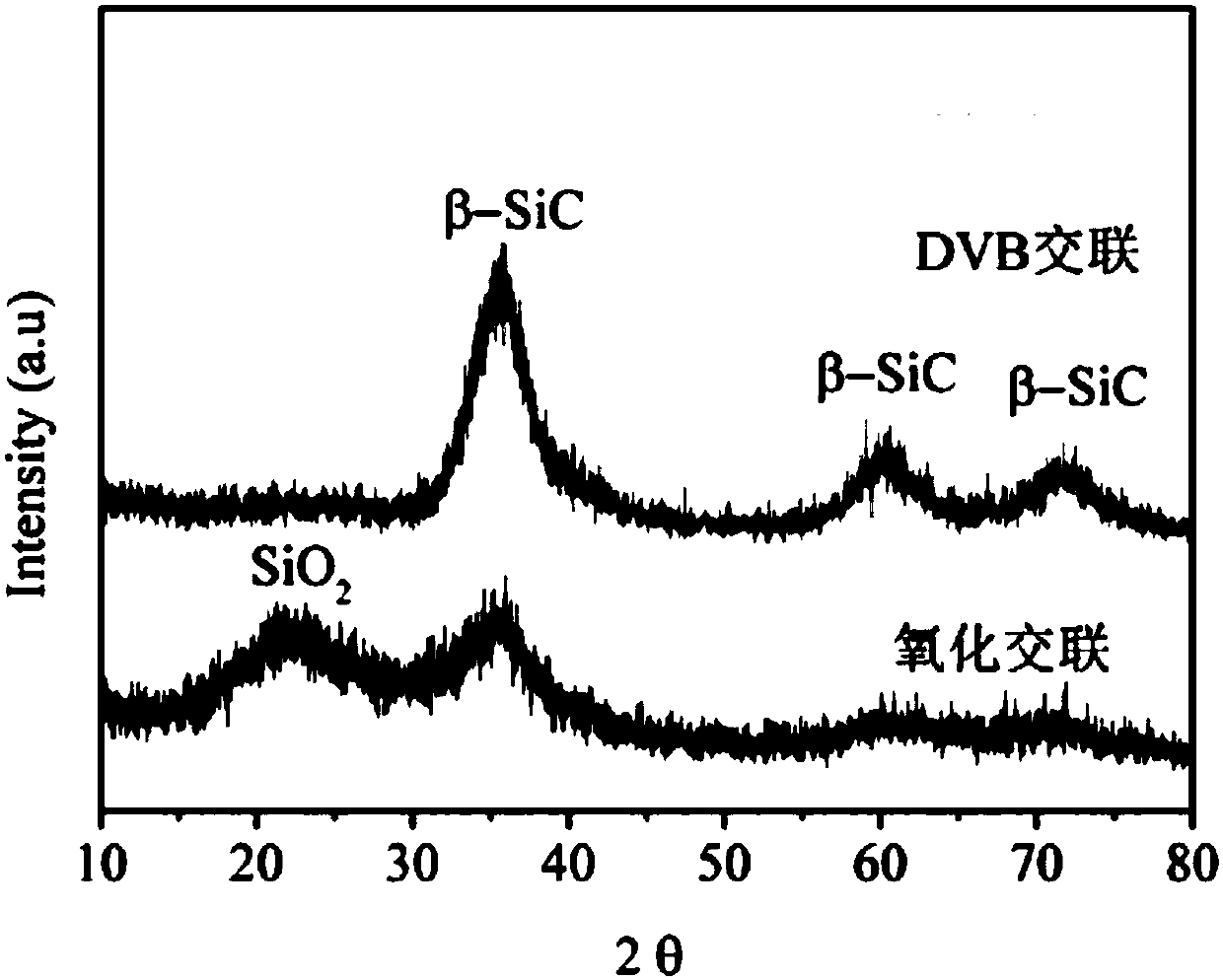

[0055] Oriented porous silicon carbide fiber composite ceramics were prepared by freeze casting method using polycarbosilane as ceramic precursor.

[0056] Taking camphene as a solvent, adding the quality of the ceramic precursor powder / (the quality of the ceramic precursor powder+solvent quality)=0.2, adding carbon fibers with a length of 10-20 μm, the addition is 10wt% of the precursor powder, and Add 0.1wt.% organic dispersant (relative to the precursor powder), and stir magnetically at 60°C for 3h until a uniform and stable slurry is obtained.

[0057] Pour the slurry into a mold (aluminum mold) with a set temperature, and freeze and solidify under the control of the temperature field. The freezing rate was 20°C / min, respectively.

[0058] The solvent in the sample was removed by freeze drying to obtain a green body. The vacuum used in the freeze-drying process is 1 Pa, and the freezing and heating conditions are: -50-30°C, with an interval of 5°C as a temperature sectio...

example 2

[0064] Other conditions are uniform and identical to Example 1, the difference is that, when freezing and pouring, the mold used is a silicone mold. The compressive strength of the resulting product is higher than that of the sample obtained in Comparative Example 1, but lower than that of the sample obtained in Example 1. This exceeded experimental expectations.

example 3

[0066] Oriented porous silicon carbide ceramics were prepared by freeze-casting method using polycarbosilane as ceramic precursor.

[0067] Take camphene as solvent respectively, add the quality of ceramic precursor powder / (the quality of ceramic precursor powder+solvent quality)=0.1, add the silicon carbide micropowder of 0.5 μm, its addition is the ceramic precursor powder used 5wt.%, and 0.3wt% Texaphor 963 dispersant (relative to the ceramic precursor powder) was added, and magnetically stirred at 60°C for 3h until a uniform and stable slurry was obtained.

[0068] Pour the slurry into a mold (silicone mold) with a set temperature, and freeze and solidify under the control of the temperature field. The freezing rate was 20°C / min, respectively.

[0069] The solvent in the sample was removed by freeze drying to obtain a green body. The vacuum used in the freeze-drying process is 1 Pa, and the freezing conditions are: -50-30°C, with an interval of 5°C as a temperature secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com