Bionic cement with oriented porous structure and preparation method thereof

A porous structure and cement technology, which is applied in the field of porous cement, can solve the problems of multiple preparation processes, prolong the production cycle, and complex processes, and achieve the effects of simple and easy-to-obtain raw materials, excellent comprehensive performance, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

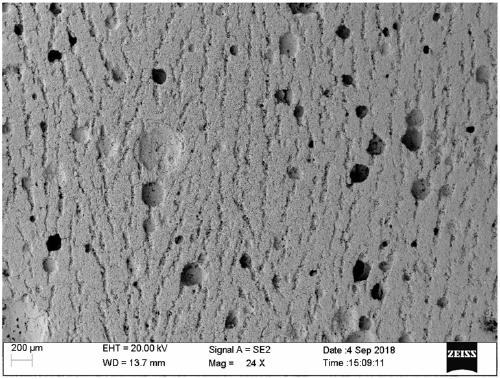

Embodiment 1

[0033] In this example, the biomimetic cement with a directional porous structure was prepared by using a slurry with a mass ratio of water to cement powder of 0.4. The raw materials used include ordinary Portland cement powder (the fineness is 80 microns, the sieve residue is 0.9 wt%, and the specific surface area is 342m 2 / kg), water and polycarboxylate high-performance water reducer, the specific preparation process is as follows:

[0034] 1) Slurry preparation

[0035] Weigh 750g of ordinary Portland cement powder, 300g of water and 3g of DH-4005 polycarboxylate high-performance water reducer, add them into a 1000mL plastic jar and perform mechanical stirring at a stirring rate of 100rpm. The time is 30 minutes to obtain uniformly dispersed cement slurry.

[0036] 2) Freeze casting

[0037] Pour the evenly stirred slurry into a cuboid polymethyl methacrylate mold with an inner cavity size of 30mm×30mm×70mm. The lower end of the mold is sealed with a polydimethylsiloxan...

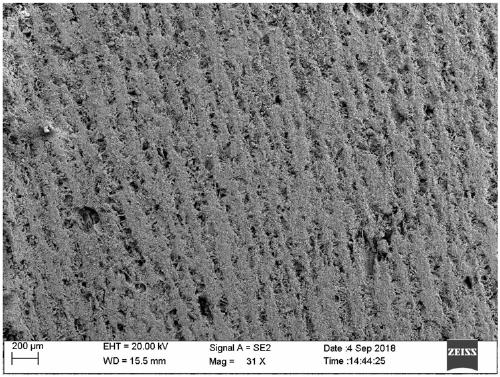

Embodiment 2

[0042] In this example, the biomimetic cement with a directional porous structure was prepared by using a slurry with a mass ratio of water to cement powder of 0.7. Used raw material is identical with embodiment 1, and concrete preparation process is as follows:

[0043] 1) Slurry preparation

[0044] Weigh 400g of ordinary Portland cement powder, 280g of water and 1g of DH-4005 polycarboxylate high-performance water reducer, add them to a 1000mL plastic jar, and add 3mm, 6mm in diameter to the bottle , 6 zirconia grinding balls of 10mm and 12mm respectively, after the bottle cap is sealed on the jar cap, be placed on the roller type ball mill and carry out ball milling. The ball milling speed was 150 rpm, the ball milling time was 10 min, and the mass ratio of the balls to the slurry was 0.5 to obtain uniformly dispersed cement slurry.

[0045] 2) Freeze casting

[0046] The difference between this step and step 2) in Example 1 is that the cooling medium of the copper rod ...

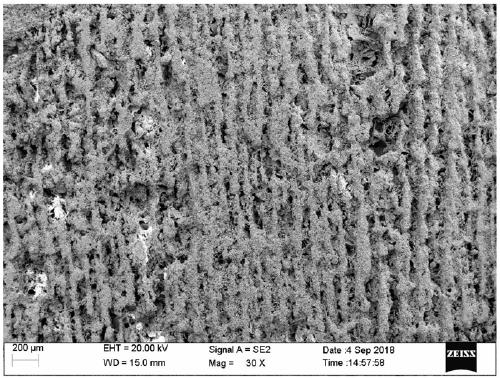

Embodiment 3

[0051] In this embodiment, the biomimetic cement with directional porous structure is prepared by using the slurry with the mass ratio of water to cement powder of 1.1. The raw materials used include fly ash Portland cement powder (fineness is 80 microns, sieve residue 1.6wt%, specific surface area 315m 2 / kg), water and hydroxypropyl methylcellulose powder (average particle size 180 μm), the specific preparation process is as follows:

[0052] 1) Slurry preparation

[0053] Weigh 333.3g of ordinary Portland cement powder, 300g of water and 1.3g of hydroxypropyl methylcellulose powder, and add them into a 1000mL plastic jar for mechanical stirring. The stirring rate is 30rpm and the stirring time is 1h. , to obtain a uniformly dispersed cement paste.

[0054] 2) Freeze casting

[0055] This step operation is identical with step 2) in embodiment 1.

[0056] 3) Body maintenance

[0057] The solidified cement slurry was removed from the copper plate and placed in an environm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com