Liftable expansion rope wind wave resistant cultivation method for pearl oyster

A breeding method and wind and wave resistance technology, applied in fish farming, application, climate change adaptation, etc., to achieve strong wind and wave resistance, increase growth speed, and avoid impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparatory work: Prepare various ropes, floating balls and anchors; make sliding rings, positioning blocks, and cement sinkers.

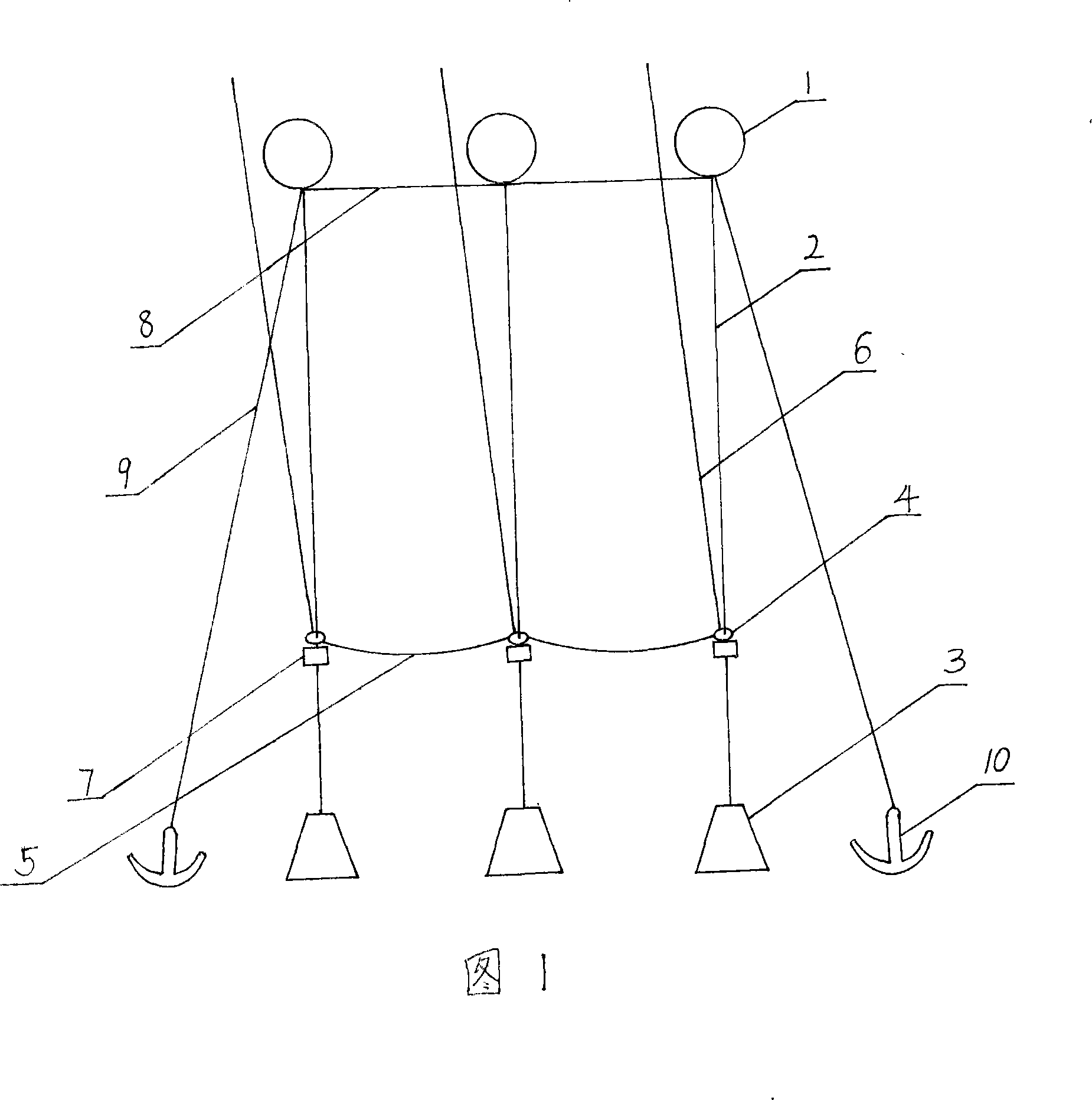

[0027] 2. Set a series of floats 1 arranged in a straight line every 5-10m on the water surface. The floats 1 are connected by fixed ropes 8 .

[0028] 3. Connect the cement sinker 3 to one end of the dry rope 2, then fix the positioning block 7 about 5m away from the sinker 3, and sink the sinker 3 into the seabed at the position of the float.

[0029] 4. Connect a lifting rope 6 to each sliding ring 4, and fix the lifting rope 6 on the buoy 1 or the fixed rope 8 between the buoys 1.

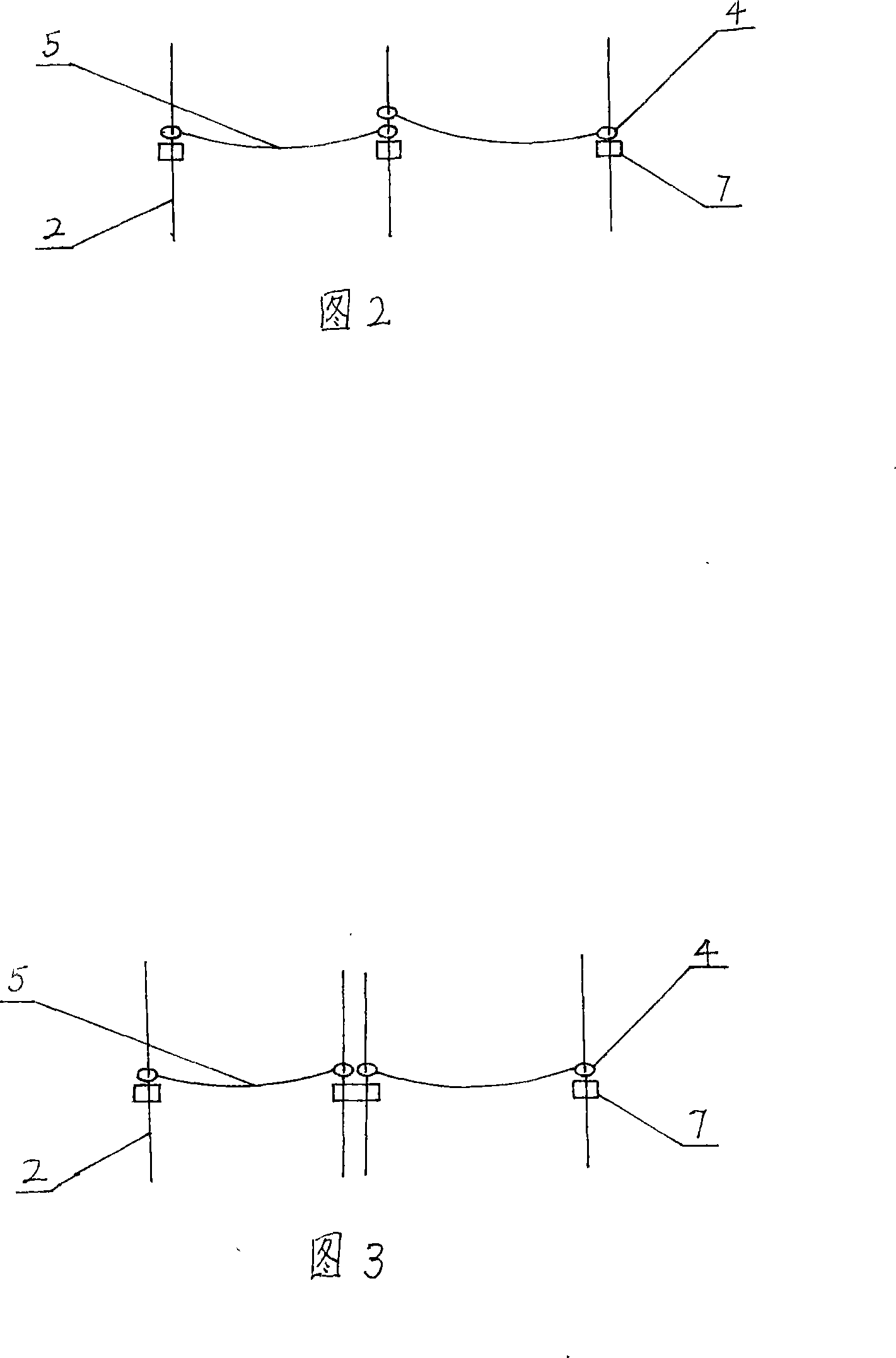

[0030] 5. Pass the water surface end of the dry rope 2 through the sliding ring 4, and each dry rope 2 passes through a sliding ring 4, and then connect the dry rope 2 with the buoy 1.

[0031] 6. Connect the adjacent sliding rings 4 with the long rope 5, pull the lifting rope 6 upward to lift the whole long rope 5 to the water surface and fix it to the f...

Embodiment 2

[0035] 1. Preparation: Prepare various ropes and stakes; make sliding rings and positioning blocks; fix the positioning blocks at a position about 5m away from the lower end of the stakes.

[0036] 2. Set up a series of wooden stakes in a straight line every 5-10m in the water.

[0037] 3. Connect a lifting rope 6 to each sliding ring 4, put the sliding ring 4 in the wooden pile, and fix the lifting rope 6 on the water surface part of the wooden pile.

[0038] 4. The wooden stakes are connected with fixed ropes 8 on the water surface, and the two ends are fixed on the anchor fixtures 10 on the seabed through anchor ropes 9 .

[0039] 5. Connect the adjacent sliding rings 4 with the longline 5, pull the lifting rope 6 upward to raise the whole longline 5 to the water surface and fix it to the fixed rope 8 between the wooden stakes on the water surface; the pearl oyster is hung on the longline 5 on.

[0040] 6. When the typhoon comes, loosen the lifting rope 6 fixed on the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com