Processing method of ionized calcium water-soluble preparation and product

A processing method and water-soluble technology, applied in the processing method and product field of ionic calcium water-soluble preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

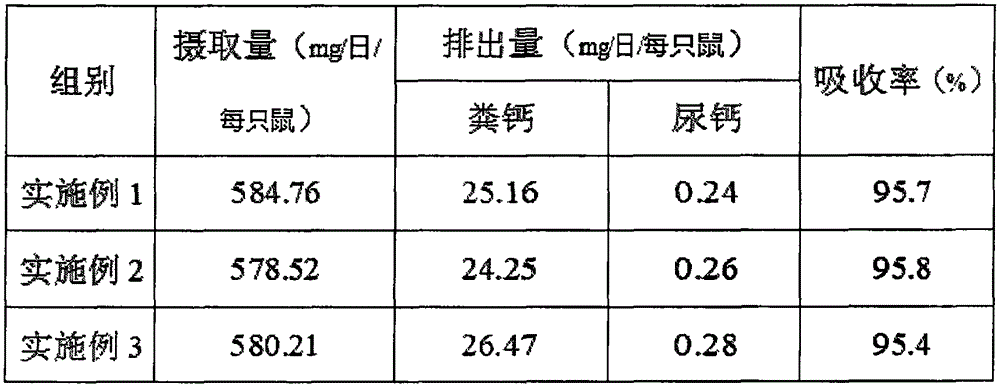

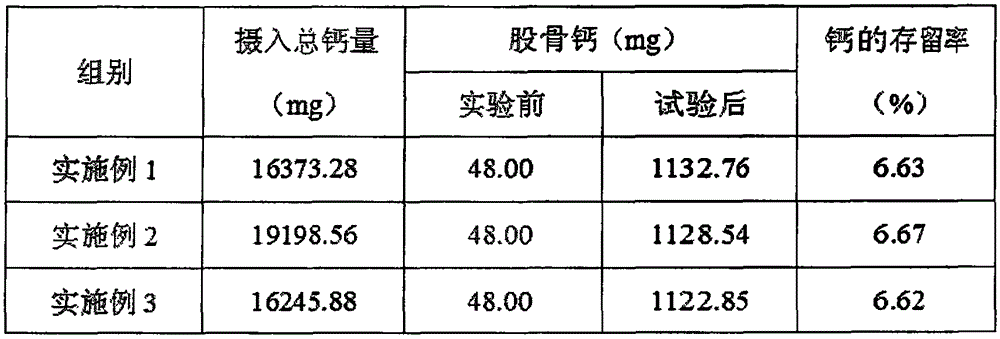

Examples

Embodiment 1

[0023] The preparation process of the ionized calcium water-soluble preparation of this embodiment is as follows:

[0024] Prepare the corresponding raw materials: 100kg oyster shells, 28kg stalactites, 68kg pearl oysters, 55kg heptagonal shells, 35kg castor, 25kg salvia, 20kg prunella, 12kg hawthorn, 13kg wild jujube kernels, 32kg lemon, 40kg donkey bones, 26kg eggs protein.

[0025] Remove the oyster shells, pearl oysters, and heptagonal scallops from the meat pillars, descaling the outside, and rinse and drain. After immersing in a strong alkali solution for 3-5 days, deacetylation is performed, and then neutralized to make the pH value 6.5-7. Then soak in hydrogen peroxide solution for 4-6 days, hydrolyze and purify.

[0026] The above-mentioned shell materials are broken by the existing technology; the stalactite, keel, castor, salvia, prunella, hawthorn, jujube kernels, lemon, donkey bone, egg protein and other raw materials are cleaned, screened, and then combined with the a...

Embodiment 2

[0032] The preparation of the ionized calcium water-soluble preparation of this example is basically the same as that of Example 1, except that the raw material weight ratio is as follows: 120kg oyster shell, 20kg stalactite, 60kg pearl oyster, 65kg hectagon, 70kg keel, 32kg castor, 30kg salvia, 17kg prunella vulgaris, 18kg hawthorn, 15kg jujube seed, 25kg lemon, 55kg donkey bone, 23kg egg protein.

Embodiment 3

[0034] The preparation of the ionized calcium water-soluble formulation of this example is basically the same as that of Example 1, except that the raw material weight ratio is as follows: 110kg oyster shell, 25kg stalactite, 72kg pearl oyster, 60kg hectagon, 85kg keel, 28kg castor, 34kg salvia, 22kg prunella, 16kg hawthorn, 10kg jujube seed, 28kg lemon, 62kg donkey bone, 20kg egg protein.

[0035] Instructions:

[0036] The ionic calcium water-soluble preparation of the present invention is used as daily drinking water to infuse 1000-1200 ml of purified water per 0.4 g, which can supplement calcium and various trace elements and minerals.

[0037] The ionic calcium water-soluble preparation of the present invention has a calcium weight percentage of more than 55%, and also contains iron, potassium, sodium, zinc, magnesium, phosphorus, copper and many other trace elements and minerals. The product is in powder form and has a fineness of powder. Above 3500 mesh, the water-soluble cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pulverization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com