Forming die and method for preparing pressed billet of non-oriented neodymium iron boron cylindrical magnet

A molding die and cylindrical technology, which is applied in the field of molding dies for compacts, can solve problems such as inability to suppress oval compacts, and achieve the effect of simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

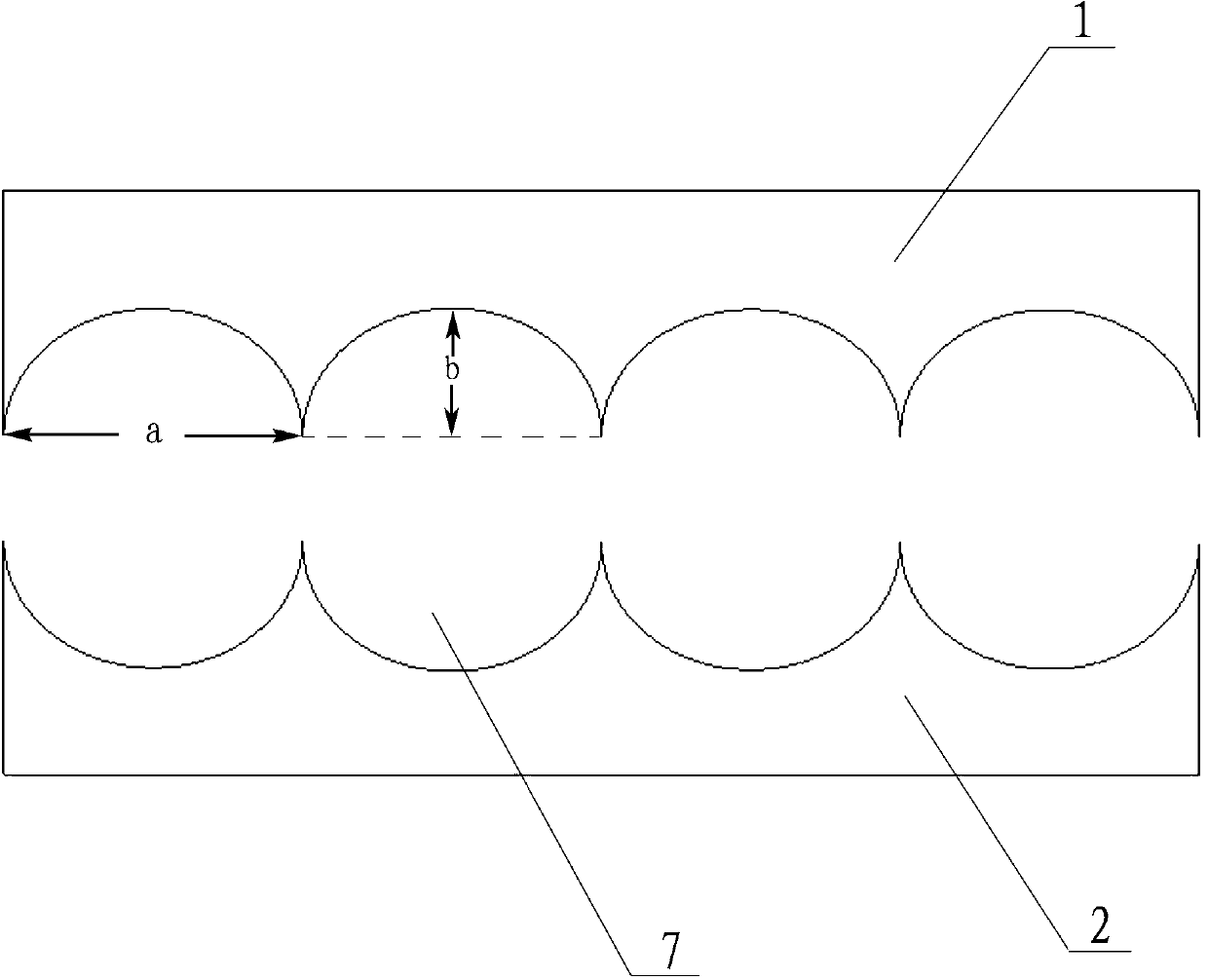

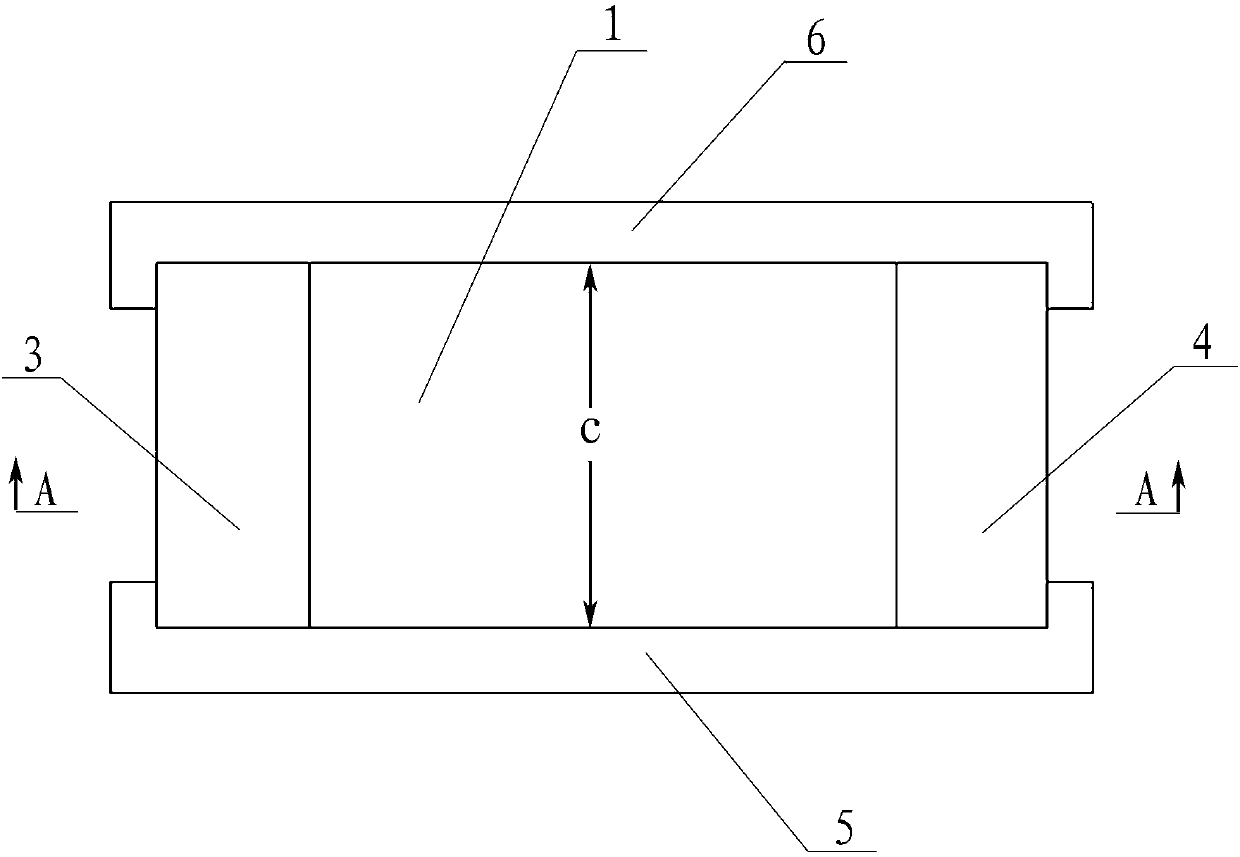

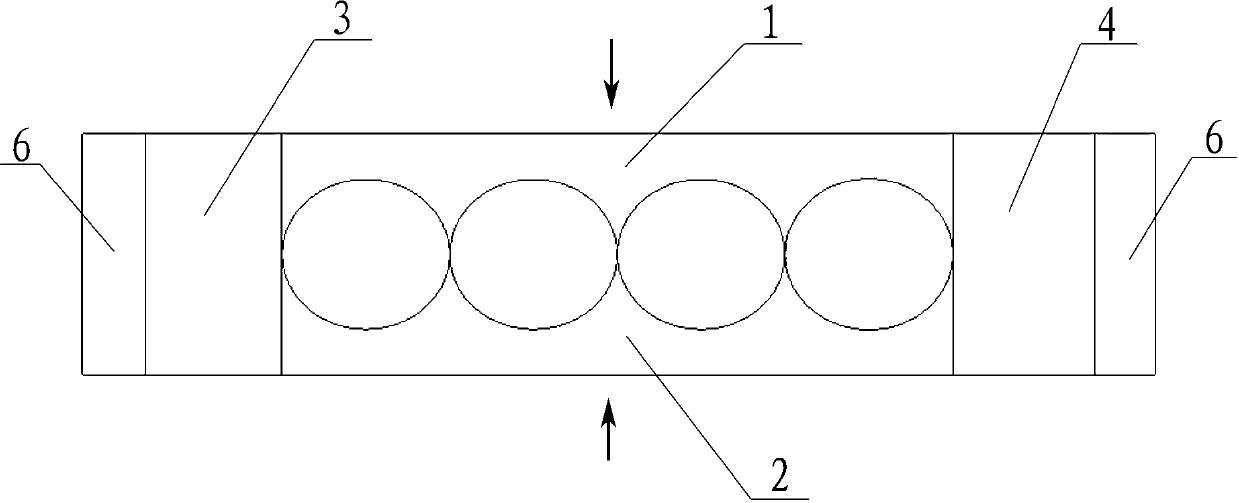

[0017] Such as figure 1 , 2 , shown in 3, a kind of molding die that prepares the green compact of non-oriented NdFeB cylindrical magnet, comprises cavity, and described cavity is divided into upper cavity 1 and lower cavity 2, and described upper and lower cavity The contact surfaces of 1 and 2 are respectively formed with several parallel semi-elliptical grooves 7 that can be combined into an elliptical cavity. The cross-sectional size of the elliptical cavity is: long axis of the ellipse = magnet diameter ÷ (0.75 ~0.77), ellipse minor axis = magnet diameter ÷ (0.825 ~ 0.835), semi-elliptical groove 7 length = magnet length ÷ (0.75 ~ 0.76), the magnet refers to the final non-oriented NdFeB cylindrical magnet .

[0018] For example figure 1 As shown, the elliptical cavity is evenly divided along the long axis of the ellipse, and the cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com