Brake pad

A technology of brake pads and skeleton, which is applied in the field of brake pads, can solve the problems of insufficient performance of brake pads and potential safety hazards, and achieve the effects of excellent overall bonding force, overall performance optimization, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

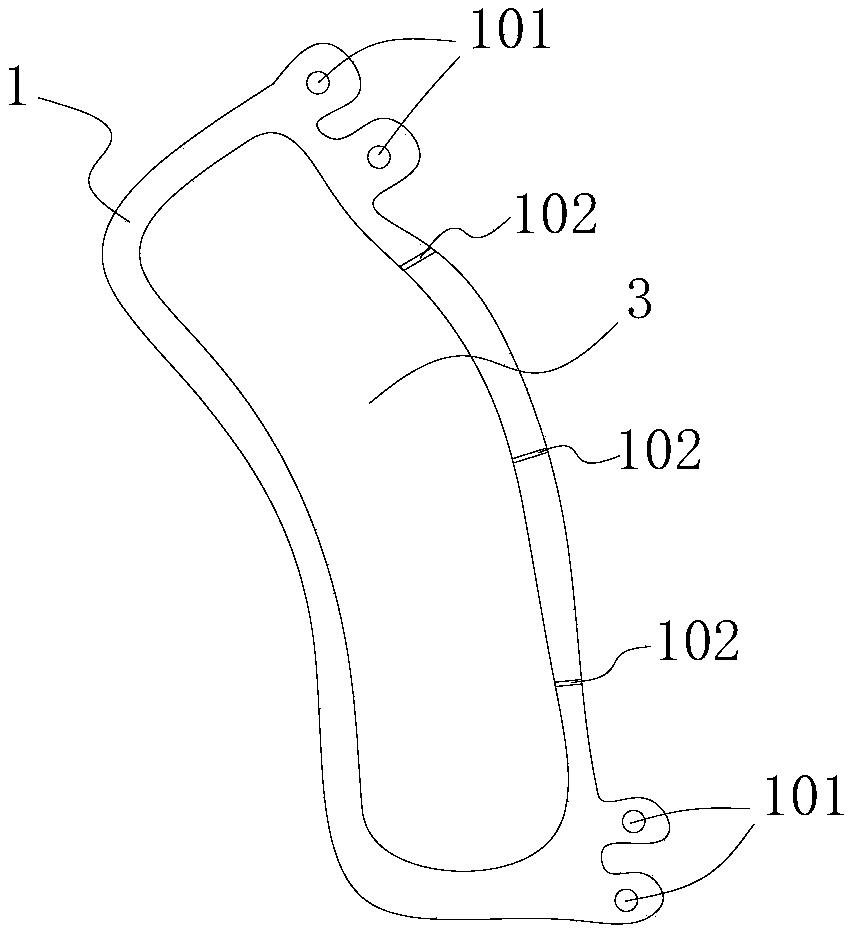

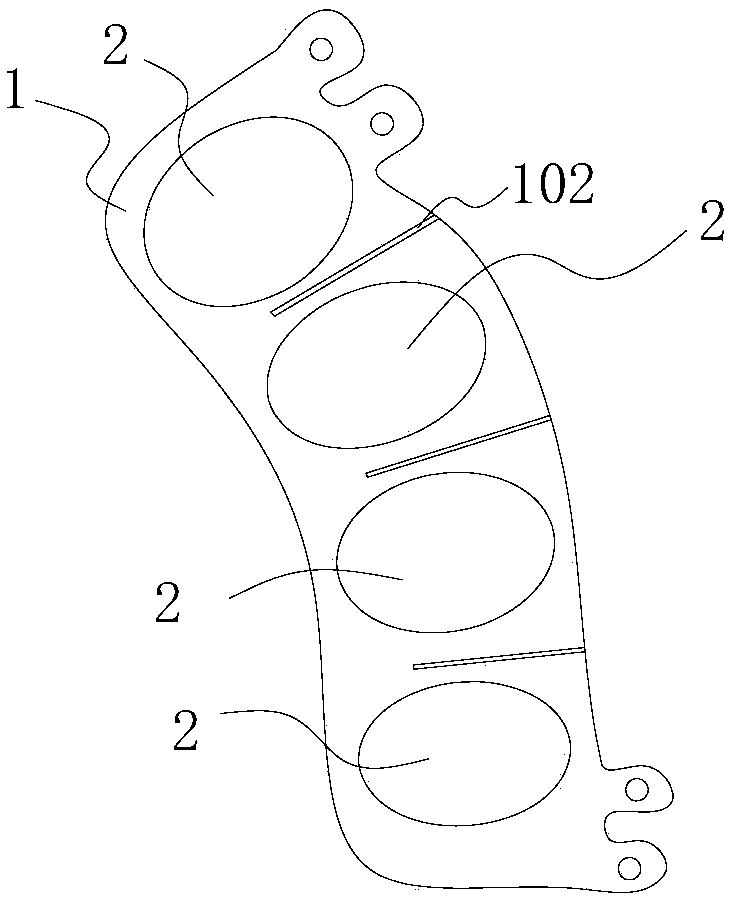

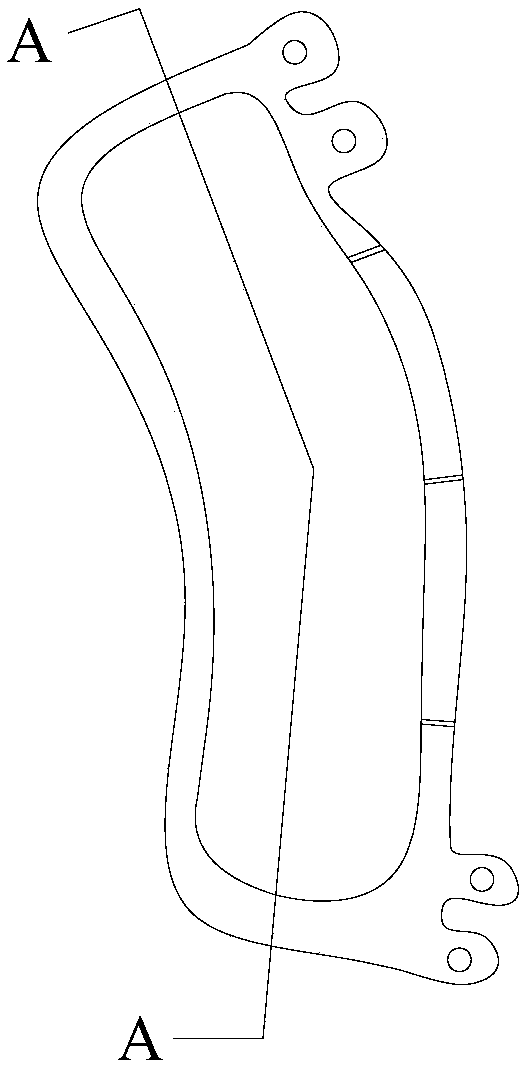

[0030] Such as figure 1 As shown in the brake pad, the skeleton 1 of the brake pad is in the shape of an arc-shaped sheet, and an installation hole 101 is provided on the outer edge side of the arc-shaped sheet-shaped skeleton 1, and the installation hole is provided at the outer end of the arc-shaped sheet. There are two mounting holes (for a total of four mounting holes). A friction block 3 is combined on the surface of the skeleton 1, and the friction block 3 is a main friction member, which provides braking friction resistance. Slag discharge grooves 102 are arranged on the frame 1, distributed in the rear direction of the frame, and leading to the side edge of the frame. Such as figure 2 As shown, when the brake pad frame 1 is not combined with the friction block 3, it can be clearly seen that there are four grooves 2 on the friction block frame, and the thickness of the grooves is 2-5 mm. A slag discharge groove 102 is arranged between adjacent grooves, and the slag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com