Concrete block slotting equipment

A technology for concrete blocks and grooving equipment, applied in the field of aerated concrete block grooving equipment, can solve the problems of dust pollution, difficult to guarantee accuracy, and inability to reserve staggered butt grooves, etc. The effect of high tank efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

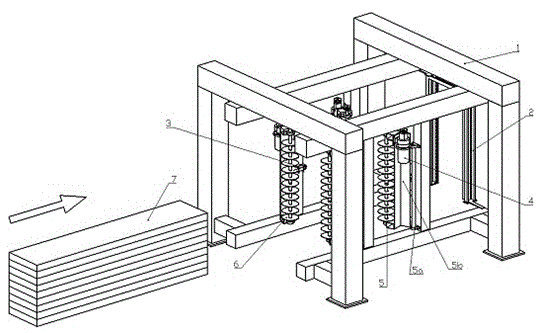

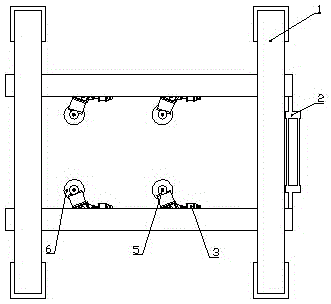

[0012] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 and figure 2 As shown, the concrete block slotting equipment provided by the present invention includes a vertical frame 1, along the direction of transportation of the green body 7, a channel for allowing the green body 7 to pass is provided in the frame 1, and on both sides of the channel A plurality of vertical cutter shafts 5 are arranged symmetrically, and the cutter shafts 5 are rotatably connected to the tool seat 5b, and the motor reducer 4 is connected to the cutter shafts 5 through a transmission chain to provide a power base. The tool seat 5b is hingedly installed with the mounting seat 5a on the frame 1, so that the tool seat 5b drives the tool shaft 5 to move, thereby realizing the adjustment of the feeding amount of the blade 6 extending into the blank 7. The air cylinder 3 connected with the frame 1 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com