Ellipsoidal groover

A technology of ellipsoid and slotting machine, which is applied in the direction of earth mover/shovel, construction, etc., which can solve the problems of high equipment cost and low slotting efficiency, and achieve the effect of low equipment cost and high slotting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

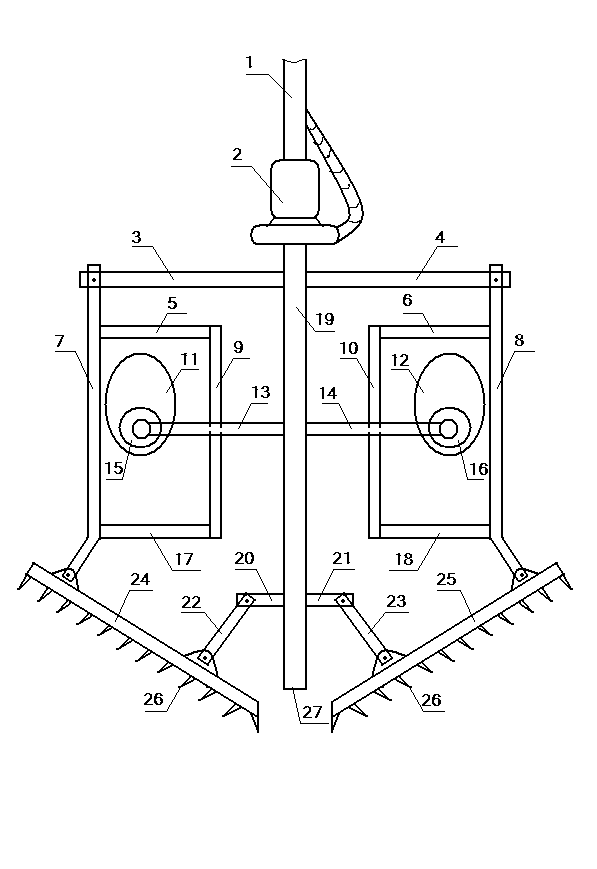

[0011] Accompanying drawing is a kind of specific embodiment of the present invention, and the upper part of this embodiment excavator is provided with outlet pipe 1, and the lower end of outlet pipe is provided with mud pump 2, and the lower end of mud pump is provided with suction pipe 19, and the left and right sides of suction pipe top are respectively fixed with Upper arm A3 and upper arm B4, the left end of upper arm A is hinged to the upper end of crank arm A7, the lower end of crank arm A is hinged to the left end of arm rod A24, the right end of upper arm B is hinged to the upper end of crank arm B8, the lower end of crank arm B is hinged to the right end of arm rod B25; the left and right ends of the suction pipe are respectively fixed The middle arm A13 and the middle arm B14, the left end of the middle arm A is equipped with a hydraulic driver A15, the hydraulic driver A is fixed with an ellipsoid A11, the right end of the middle arm B is equipped with a hydraulic dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com