Ultrahigh-strength rock layer wall forming method

An ultra-high-strength, rock formation technology, applied in excavation, sheet pile walls, construction, etc., can solve problems such as inability to form grooves, rock formations that cannot be milled, and obstacles to the construction of underground diaphragm walls, so as to reduce the difficulty and cost of groove formation. Groove cost, increase the effect of the construction field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] A construction method for forming a wall in an ultra-high-strength rock formation, comprising the steps of:

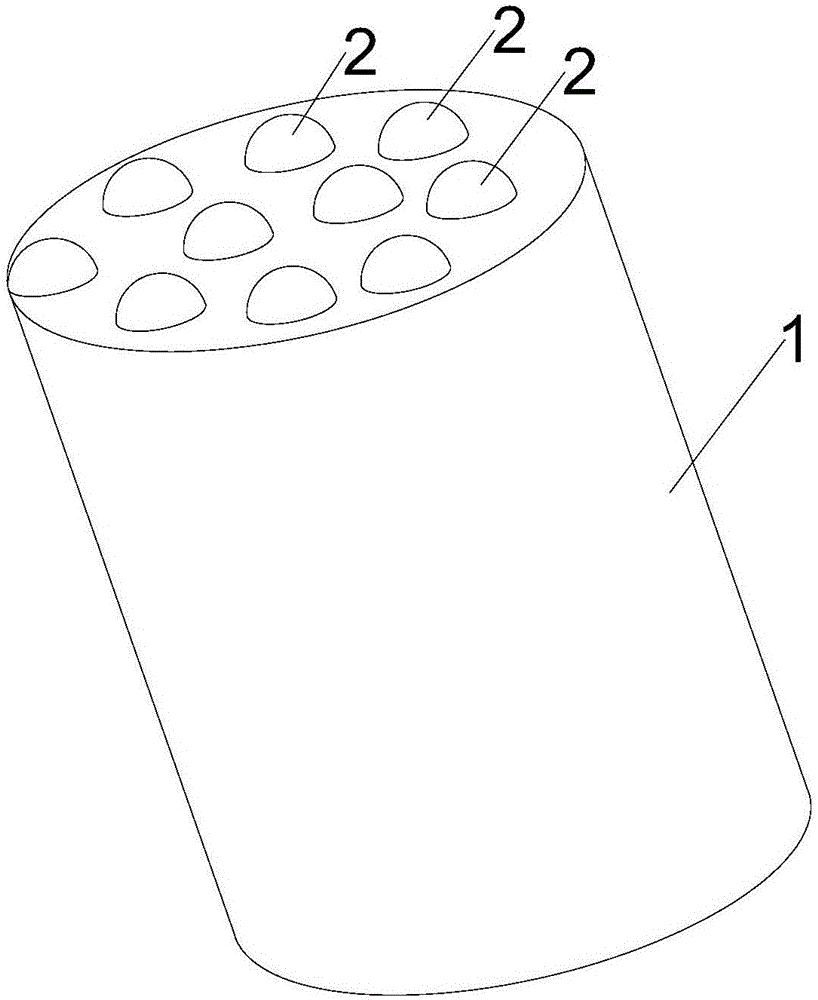

[0017] 1), a plurality of holes are drilled at intervals on the rock formation; in the present invention, it is preferred to use a down-the-hole hammer to hammer the rock formation to hammer out a plurality of holes in the rock formation. Such as figure 1 The structure schematic diagram of the down-the-hole hammer is shown, and the down-the-hole hammer includes a hammer body 1 . A plurality of protrusions 2 are arranged on the surface of the hammer body 1 . A plurality of protrusions are arranged at intervals. The hammer body 1 and the protrusion 2 are made of suitable materials. The hammer body 1 impacts the rock formation, and the protrusions 2 can be used to form a plurality of spaced holes on the rock formation surface.

[0018] 2), milling an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com