Pipe burying and grooving device for water conservancy construction of hard soil

A kind of soil and hard technology, which is applied in the direction of earth mover/excavator, construction, etc., can solve the problems of low slotting efficiency and difficulty of slotting, so as to improve slotting efficiency, reduce the difficulty of pipe laying, and reduce the difficulty of opening. The Effect of Slot Difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

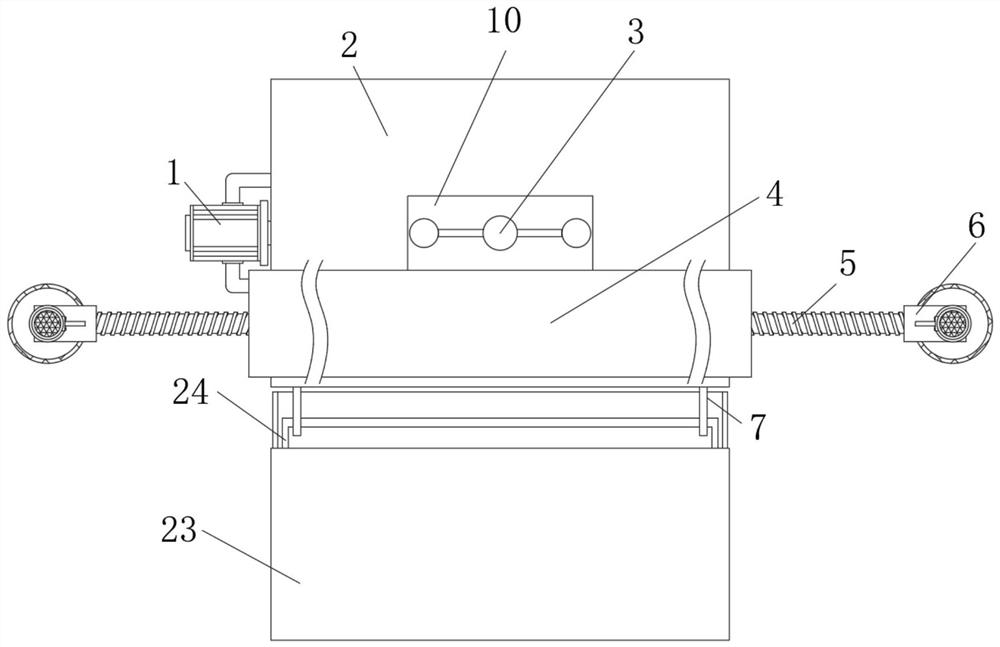

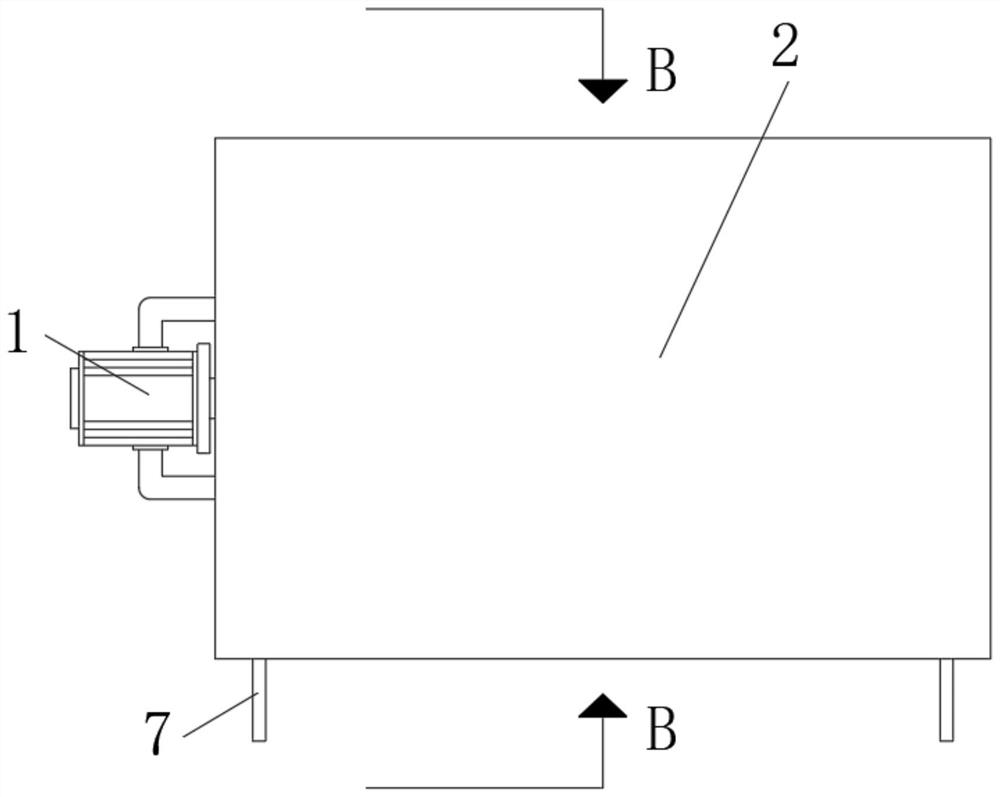

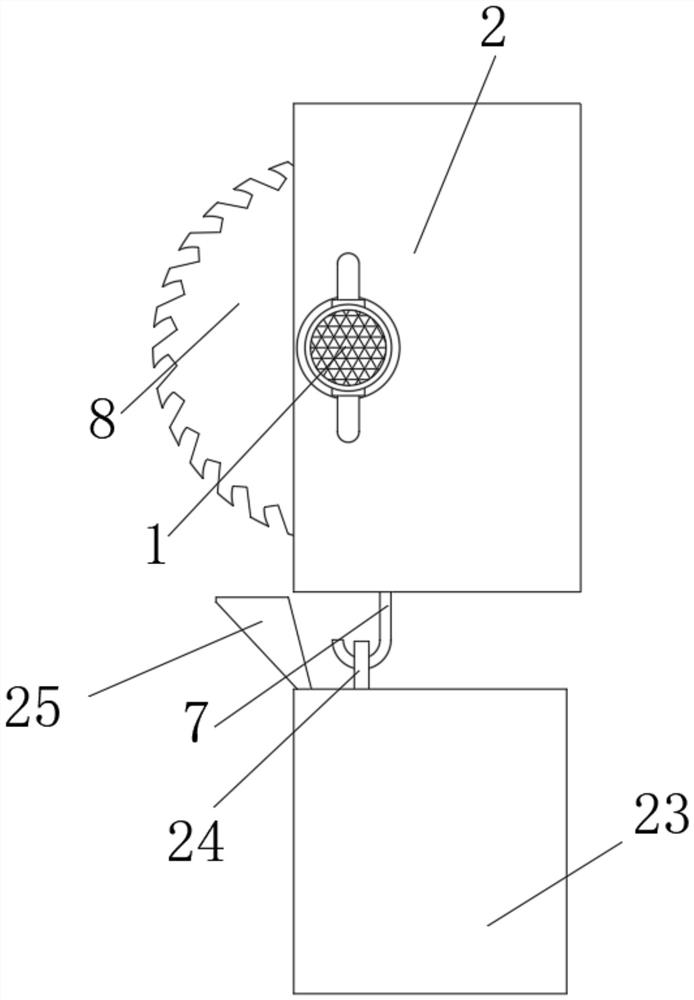

[0034] Embodiment 1: A buried pipe slotting device for water conservancy construction in hard soil, including a base frame 2, a rotatable rotating shaft 14 is installed inside the base frame 2, and two cutting blades 8 are installed on the rotating shaft 14, And the both sides of the rotating shaft 14 close to the two cutting discs 8 are screwed and connected with a spiral ring 16, the circumferential surface of the rotating shaft 14 is provided with external threads 15, the base frame 2 is equipped with the first motor 1, the output end of the first motor 1 Connect with the rotating shaft 14, pull the two cutting pieces 8, so that the two cutting pieces 8 move on the rotating shaft 14, after the two cutting pieces 8 move to the position required by the user on the rotating shaft 14, turn the spiral rings on both sides of the cutting piece 8 16. Through the cooperation of the external thread 15, the spiral ring 16 is pressed against the cutting piece 8, so that the cutting piec...

Embodiment 2

[0035] Embodiment 2: A buried pipe slotting device for water conservancy construction in hard soil, including a base frame 2, a rotatable rotating shaft 14 is installed inside the base frame 2, and two cutting blades 8 are installed on the rotating shaft 14, And the both sides of the rotating shaft 14 close to the two cutting discs 8 are screwed and connected with a spiral ring 16, the circumferential surface of the rotating shaft 14 is provided with external threads 15, the base frame 2 is equipped with the first motor 1, the output end of the first motor 1 Connected with the rotating shaft 14;

[0036] Also comprises support frame 4, and top frame 10 is installed on support frame 4, and electric push rod 3 is installed on top frame 10, and electric push rod 3 comprises telescopic end and fixed end, and fixed end is fixedly connected with top frame 10, and telescopic end is connected with top frame 10. The base frame 2 is connected, and the two cutting pieces 8 are pulled to ...

Embodiment 3

[0037] Embodiment 3: A buried pipe slotting device for water conservancy construction in hard soil, including a base frame 2, a rotatable rotating shaft 14 is installed inside the base frame 2, and two cutting blades 8 are installed on the rotating shaft 14, And the both sides of the rotating shaft 14 close to the two cutting discs 8 are screwed and connected with a spiral ring 16, the circumferential surface of the rotating shaft 14 is provided with external threads 15, the base frame 2 is equipped with the first motor 1, the output end of the first motor 1 Connected with the rotating shaft 14;

[0038] Also comprises support frame 4, and top frame 10 is installed on support frame 4, and electric push rod 3 is installed on top frame 10, and electric push rod 3 comprises telescopic end and fixed end, and fixed end is fixedly connected with top frame 10, and telescopic end is connected with top frame 10. pedestal 2 connection;

[0039] The interior of the support frame 4 is sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com