Dragging-saw grooving machine without sticking drill

A stick-drill saw-saw-type slotting machine technology, which is applied in the directions of earthmoving machines/shovels, construction, etc., can solve the problems of unusability and low slotting efficiency of saw-saw slotting machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

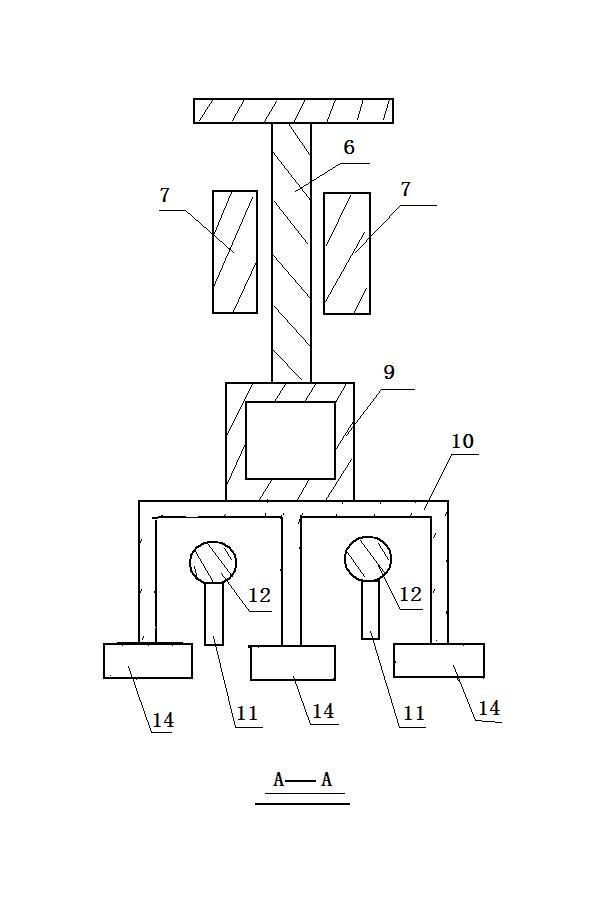

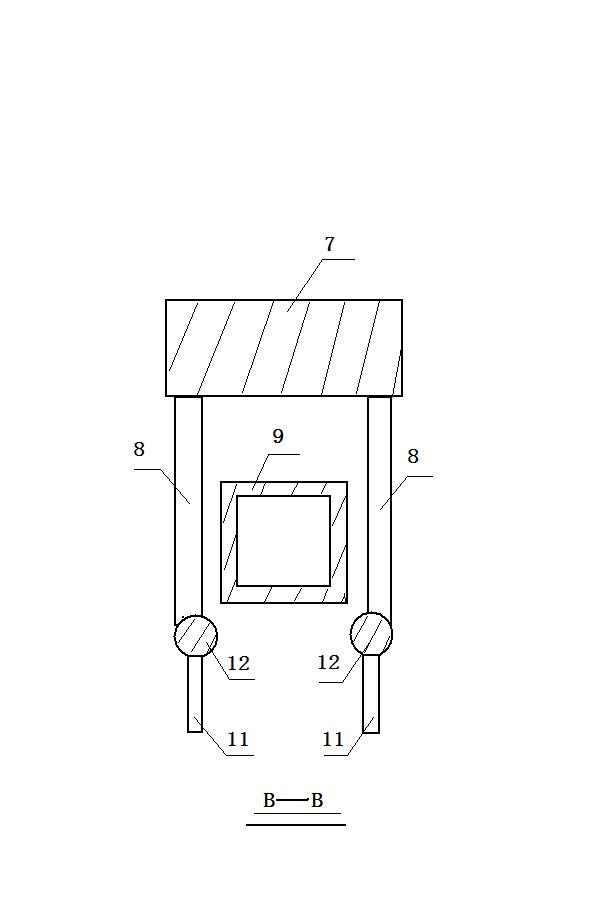

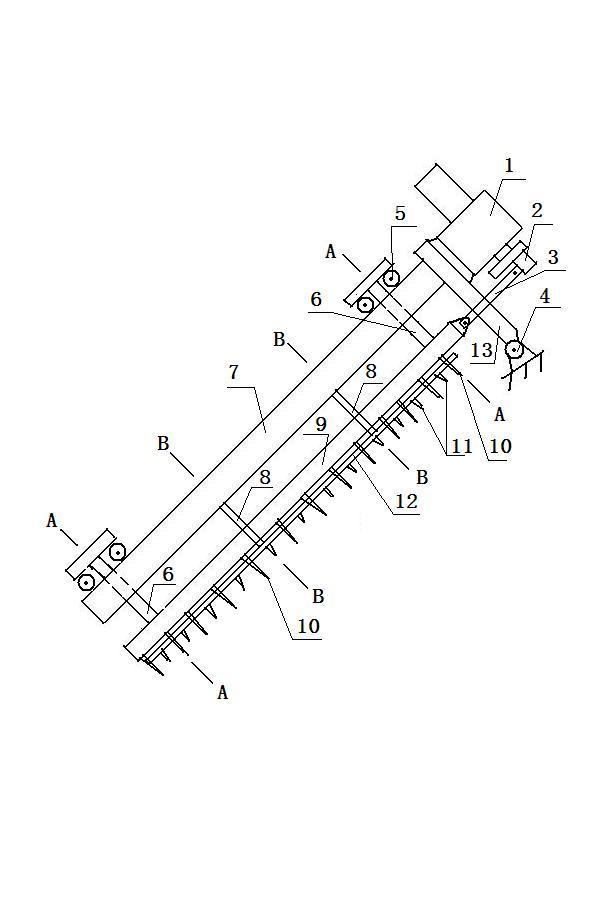

[0013] Accompanying drawing is a kind of specific embodiment of the present invention, and this embodiment speed reducer 1 is fixed on the right end of vertical arm 13, and the lower end of speed reducer is provided with crank 2, and crank is hinged on the right end of support arm 9 by connecting rod 3, and vertical arm 13 The left end of the support arm A7 is fixed, the lower ends of the two pull rods 6 are fixed on the support rod B9, the upper end of the pull rod is hung on the support arm A7 through two rollers 5, and the lower part of the support rod B is provided with two support rods C12, each support rod C is fixed on the support arm A through two connecting rods 8. The lower end of the support rod C is provided with a plurality of cutter teeth B11, and the lower end of the support rod B is provided with a plurality of cutter teeth A10. A knife edge 14 is provided, and two support rods C12 pass through the knife teeth A10 of the inverted mountain structure.

[0014] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com