Rock trenching machine and trenching method

A trough machine, rock technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of reservoir water leakage, unable to form a continuous wall, and not fundamentally solve the leakage, etc., to achieve anti-seepage. The effect of high height, strong wall continuity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

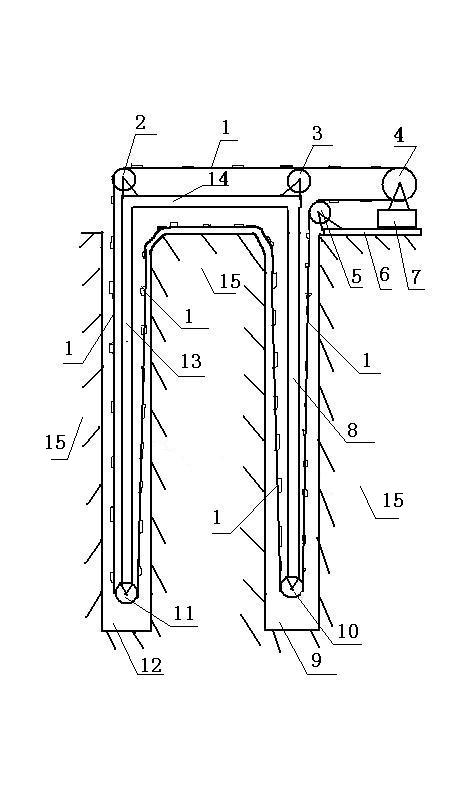

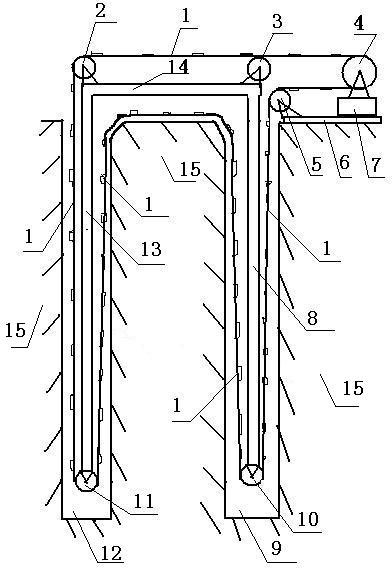

[0011] Accompanying drawing is a kind of concrete embodiment of the present invention, and this embodiment comprises slotting machine track 6 and the dolly 7 on the track, driving wheel 4 is installed on the dolly, cross bar 14 left lower end is provided with upright bar A13, upright bar A The lower end is provided with a rotating wheel E11, the upper end of the vertical rod A is provided with a rotating wheel A2, the lower right end of the cross bar 14 is provided with a vertical rod B8, the lower end of the vertical rod B is provided with a rotating wheel D10, and the upper end of the vertical rod B is provided with a rotating wheel B3. C5 is located at the left end of the track and the upper right end of hole B9; the steel wire 1 starts from the driving wheel, goes around the turning wheel B, turning wheel A, turning wheel E, cuts into the rock 15, enters turning wheel D, and then walks around turning wheel C Enter the driving wheel.

[0012] When the present invention work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com