Lining steel arch frame installing groove grooving machine for treating existing railway tunnel defects

A technology for tunnel diseases and existing railways. It is used in tunnel lining, tunnel, shaft lining and other directions. It can solve the problems of unreported grooving equipment, and achieve the effect of high grooving efficiency and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

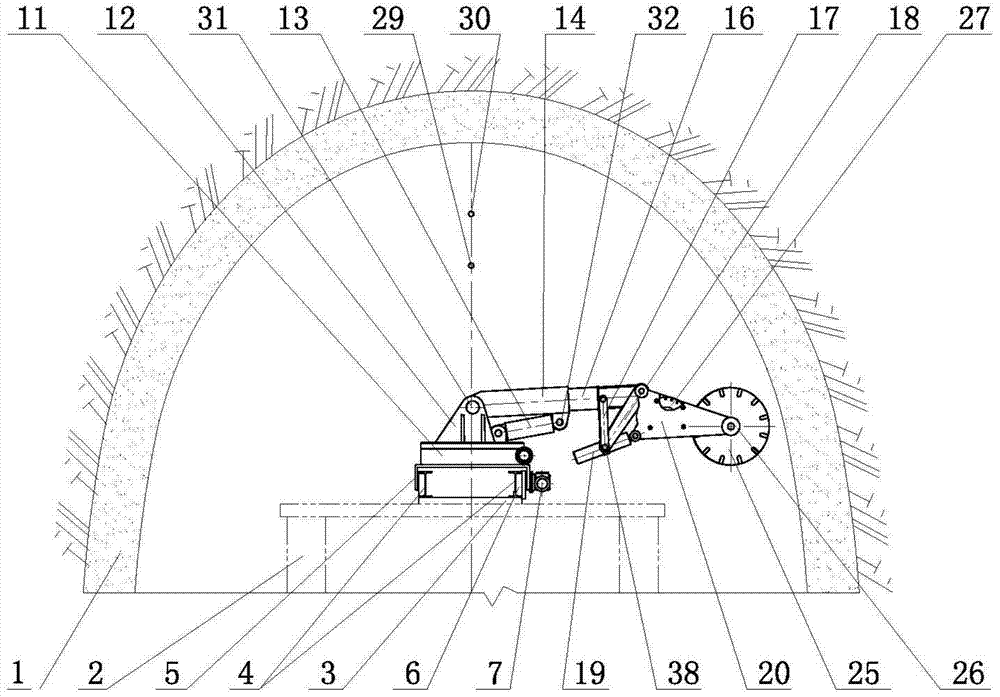

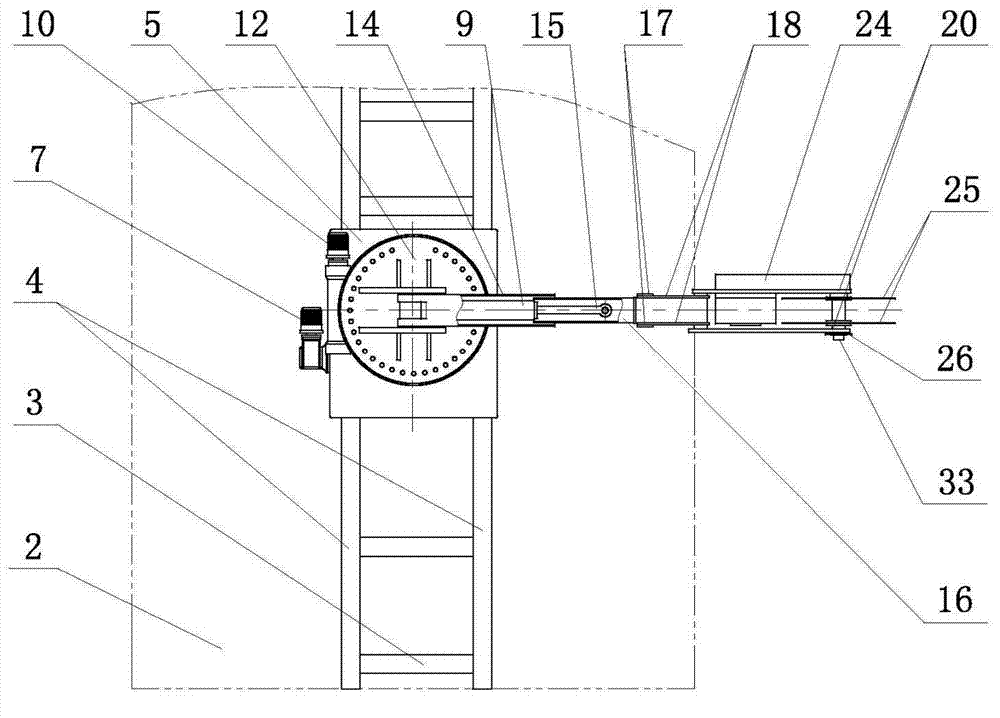

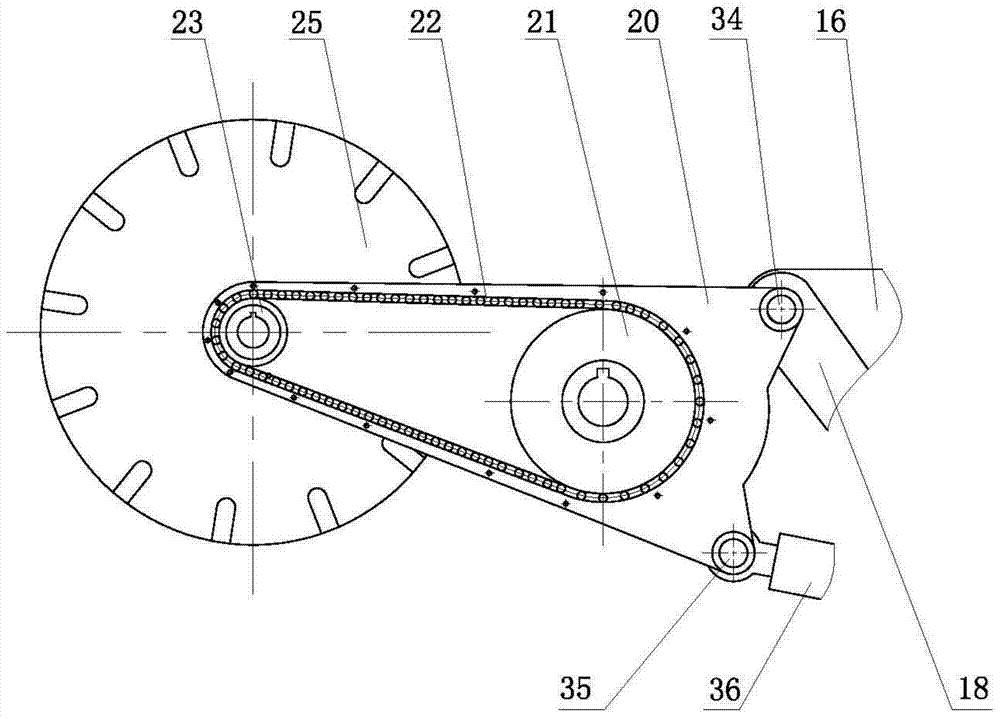

[0028] see Figure 1-7 , In this embodiment, the frame 12 is a frame that can rotate and move vertically, and is installed on the rotary mechanism served by the rotary support device 11 of the worm and worm gear. Worm screw and worm gear rotary supporting device 11 is installed on the longitudinal movement mechanism that is made of longitudinal movement support 5, track bolster 3, shaped steel track 4, road wheel 6 and longitudinal movement motor 7. 10 among the figure is the rotary motor of the worm gear rotary support device 11. The worm wheel and worm gear rotary support device and the longitudinal movement mechanism all continue to use the prior art structure. The telescopic arm is hinged to the telescopic arm outer frame 14 on the machine base 12 by the hinge shaft 31 at its tail, the telescopic hydraulic cylinder 9 with a pressure maintaining circuit set in the telescopic arm outer frame 14 and the piston installed in the telescopic hydraulic cylinder 9 The telescopic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com