Wood plate grooving machine for furniture

A slotting machine and wood board technology, applied in the field of furniture manufacturing, can solve problems such as low efficiency, trouble, and poor quality, and achieve the effect of high efficiency and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

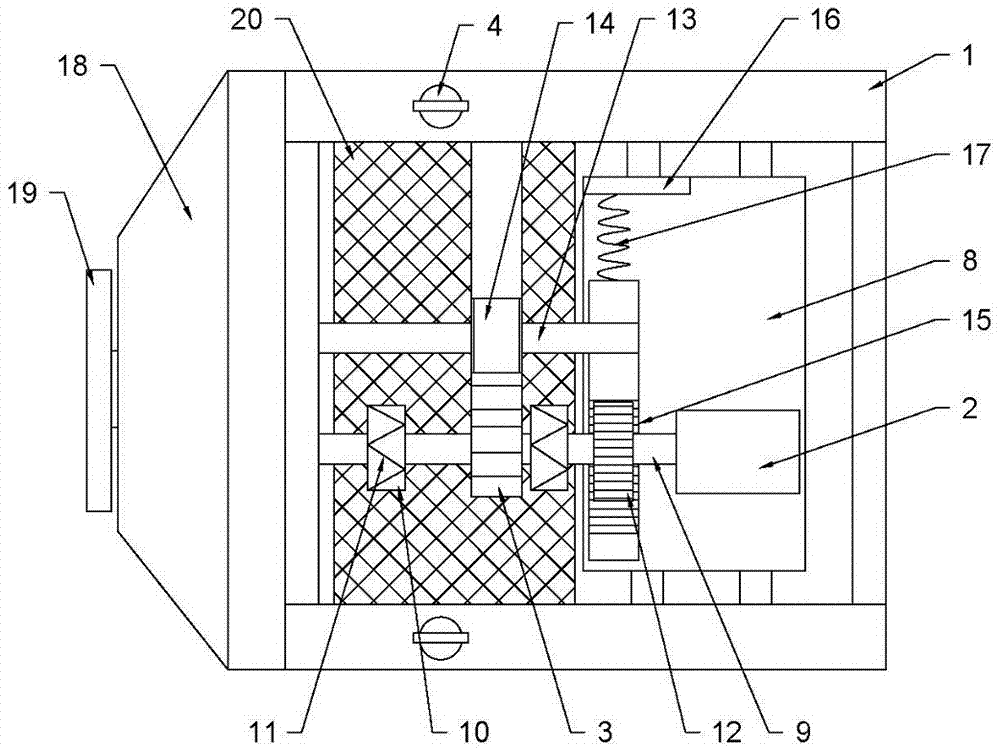

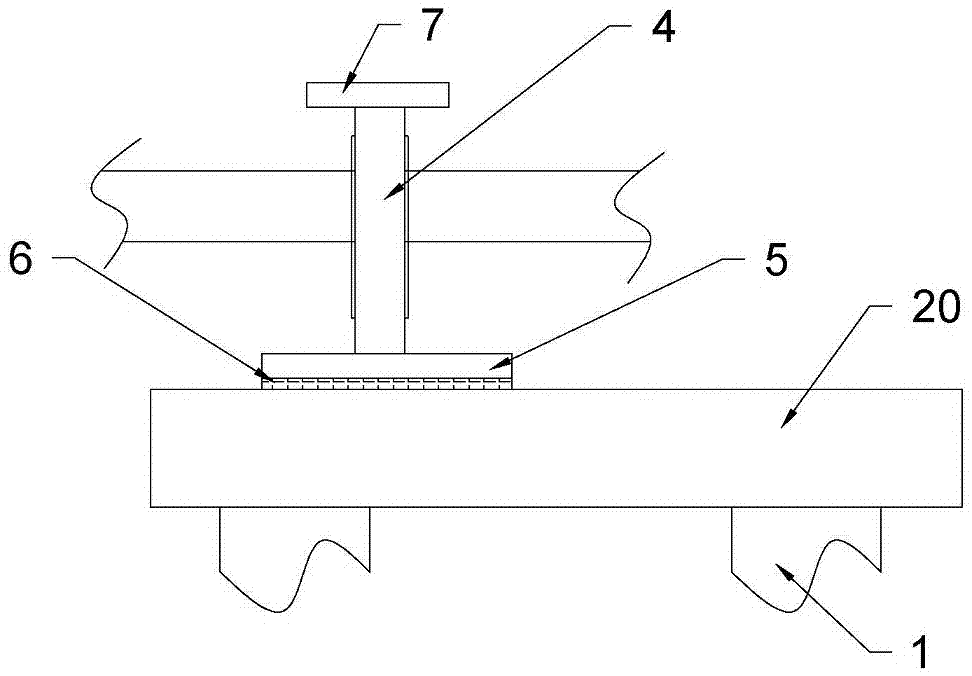

[0017] The reference signs in the drawings of the description include: frame 1, motor 2, rotary cutter 3, screw rod 4, pressure plate 5, rubber layer 6, handle 7, slide plate 8, rotating shaft 9, roller 10, anti-skid pattern 11, sector gear 12 , Slide bar 13, planer 14, rack 15, boss 16, extension spring 17, conical cover 18, rotary impeller 19, plank 20.

[0018] Example basic reference figure 1 with figure 2 Shown: furniture plank slotting machine, including frame 1, motor 2 and rotary cutter 3, frame 1 is provided with fixtures for fixing planks 20, the fixtures include threaded holes, threaded holes are provided on frame 1, and threaded holes are internally threaded A screw 4 is connected, the lower end of the screw 4 is welded with a pressure plate 5, the lower side of the pressure plate 5 is bonded with a rubber layer 6, and the upper end of the screw 4 is welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com