Advertisement typeface side trip full automatic numerical control grooving bending machine and grooving method

A fully automatic, bending machine technology, applied in the control of workpiece feed movement, grinding feed movement, grinding drive device, etc., to reduce manual operation errors, improve perception accuracy and anti-interference, and ensure grooving effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

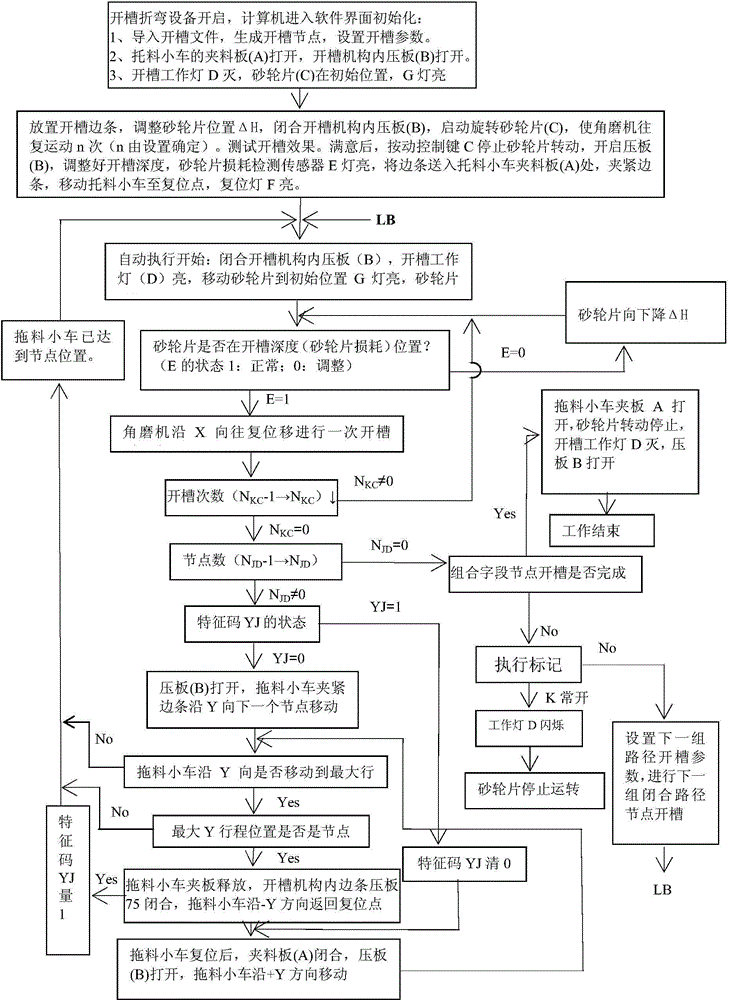

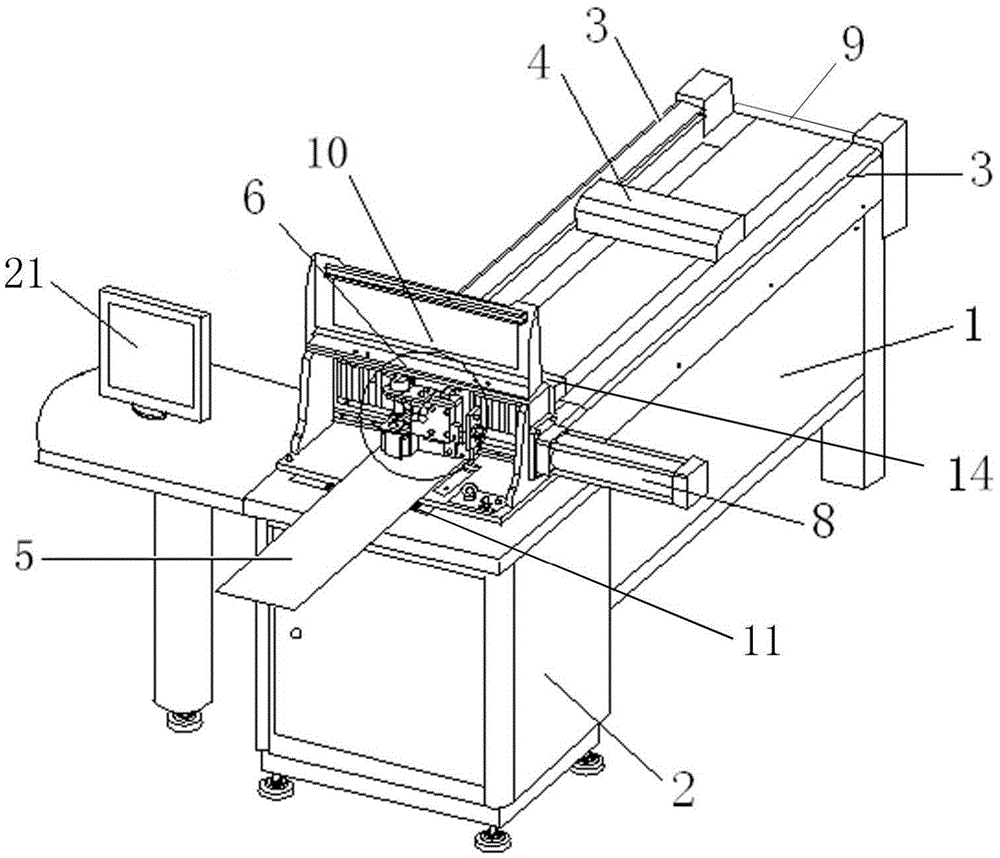

[0049] Such as figure 1 As shown, the present invention provides a full-automatic numerical control slotting bending machine for advertising font side strips, including a supporting platform 1, a dragging mechanism located on the supporting platform 1, a slotting mechanism 10 located at one end of the dragging mechanism, and a control device 2 etc;

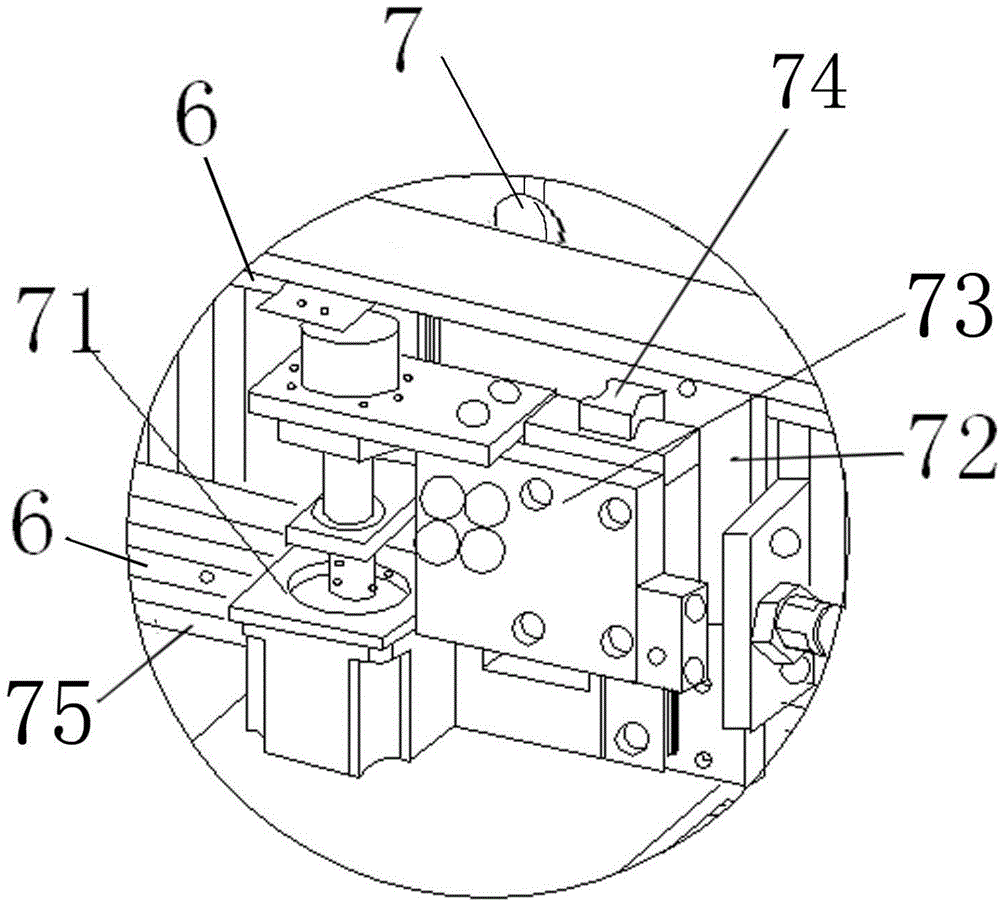

[0050] Such as figure 2 As shown, the slotting mechanism 10 is fixed on the support platform 1, and the slotting mechanism 10 includes a side bar pressing plate 75 on the bottom plate of the slotting mechanism 10 and a fourth power device that drives the side bar pressing plate 75 to rise and fall, and is arranged on Two parallel connecting plate assembly slide rails 6 inside the slotting mechanism 10, the connecting plate assembly 72 slidingly connected with the connecting plate assembly sliding rails 6, the first power unit 8 fixed on the outside of the slotting mechanism 10 and connected with the connecting plate assembly 72 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com