Exhaust emission control device with additive injector

a technology of emission control device and additive, which is applied in the direction of engine components, mechanical equipment, machines/engines, etc., can solve the problems of unstable mixing of urea aqueous solution with exhaust gas homogeneously, intense heat of exhaust gas, etc., to minimize the transmission of intense heat of exhaust emissions, facilitate machining of protruding parts, and minimize the adhesion of additiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

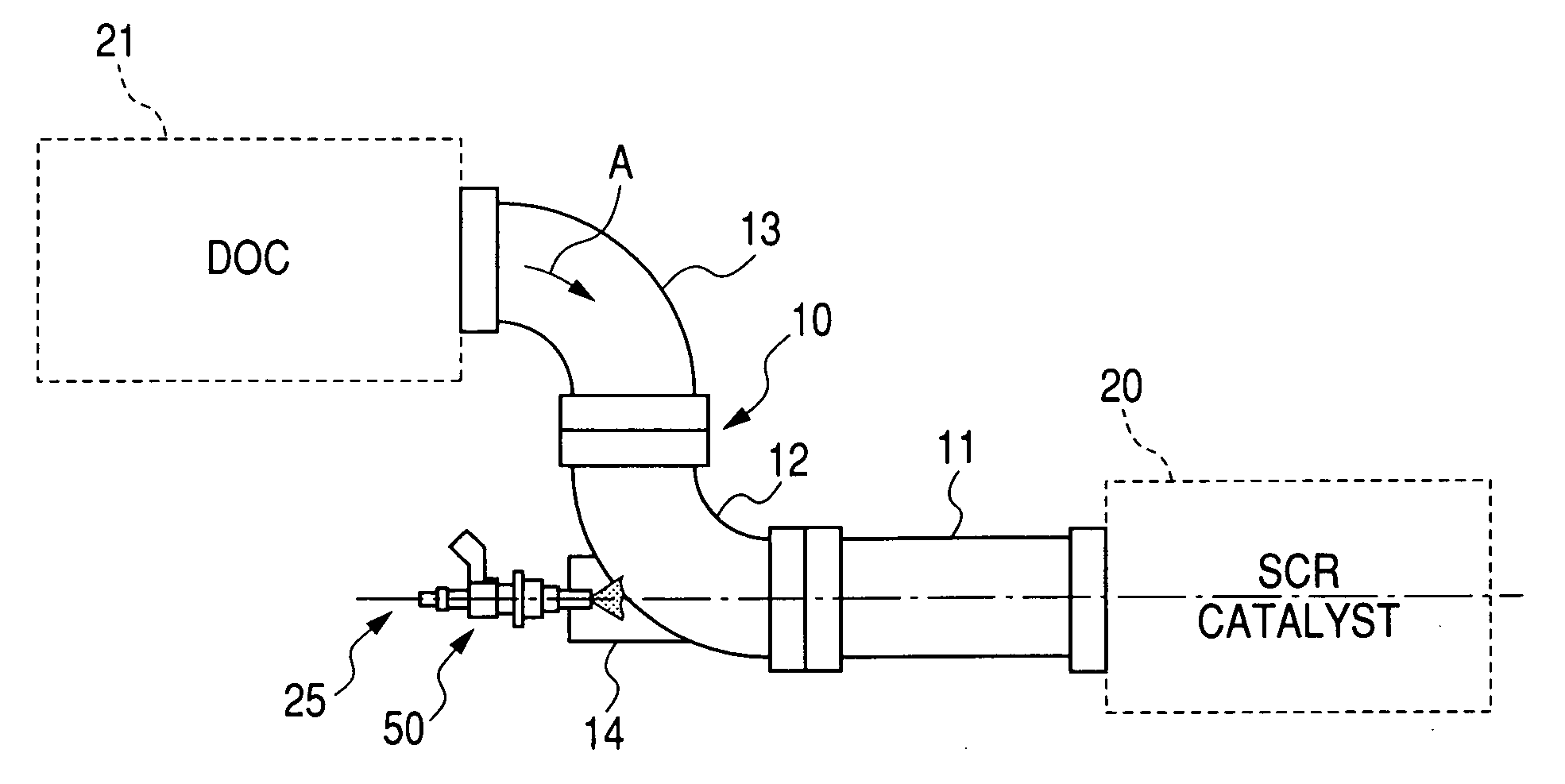

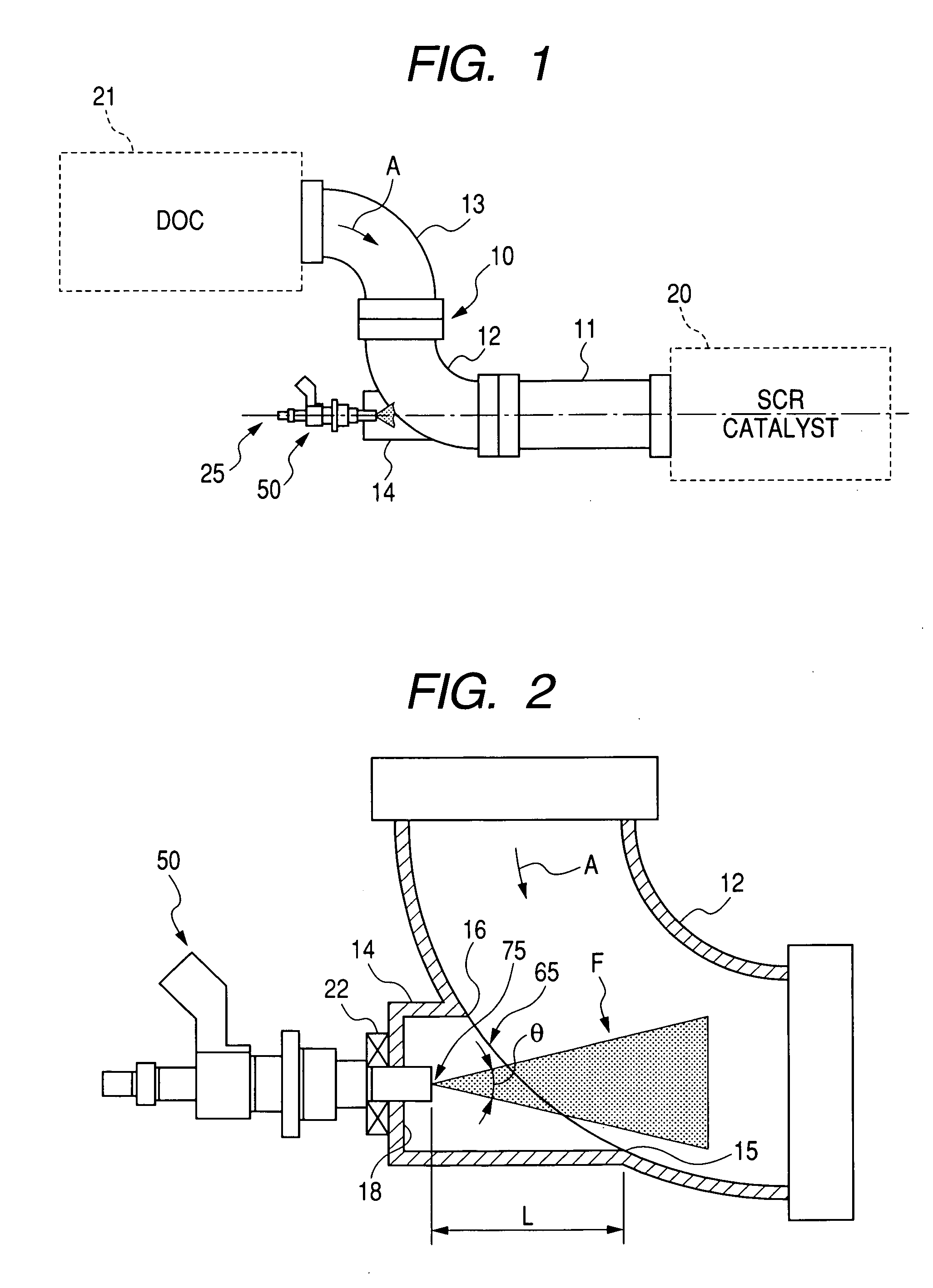

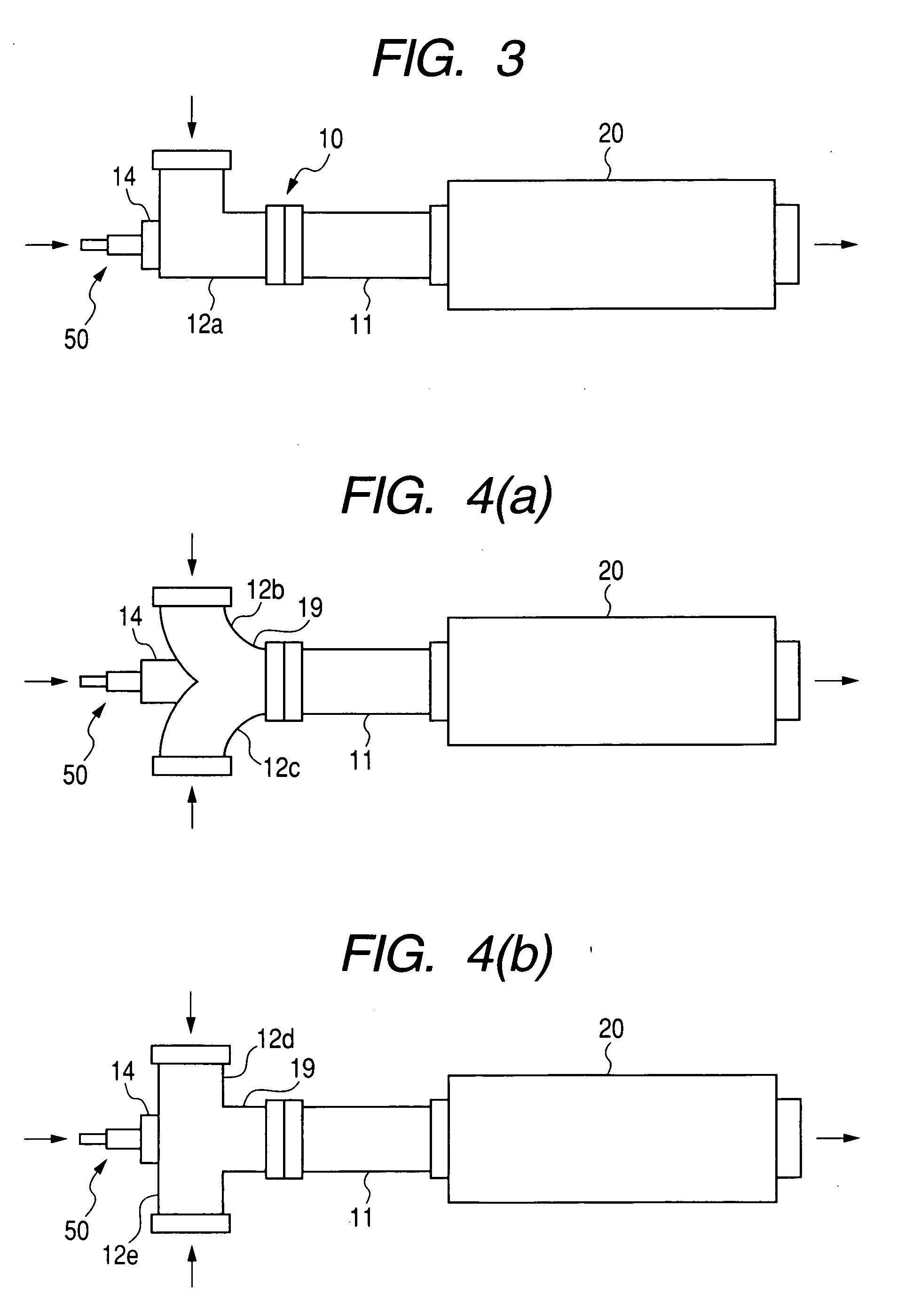

[0032]Referring to the drawings, particularly to FIG. 1, there is shown a urea SCR (Selectively Catalytic Reduction) system according to the invention which is engineered, like the one in FIG. 5, as an exhaust emission control device to convert NOx emissions contained in exhaust gas from an automotive diesel engine (not shown) into harmless products.

[0033]The urea SCR system includes a DOC (Diesel Oxidation Catalyst) 21, an exhaust pipe 10, and a SCR (Selectively Catalytic Reduction) catalyst 20, and a urea solution injection valve 50. The exhaust gas, as emitted from the diesel engine, flows through the exhaust pipe 10 in a direction A.

[0034]The urea solution injection valve 50 is installed in a portion the exhaust pipe 10 between the DOC 21 and the SCR catalyst 20. The urea solution injection valve 50 is controlled in operation by a controller (not shown) to inject or spray a urea aqueous solution as a reducing agent (also called reducer) to the exhaust gas flowing from the DOC 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com