Patents

Literature

30results about How to "Intense heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

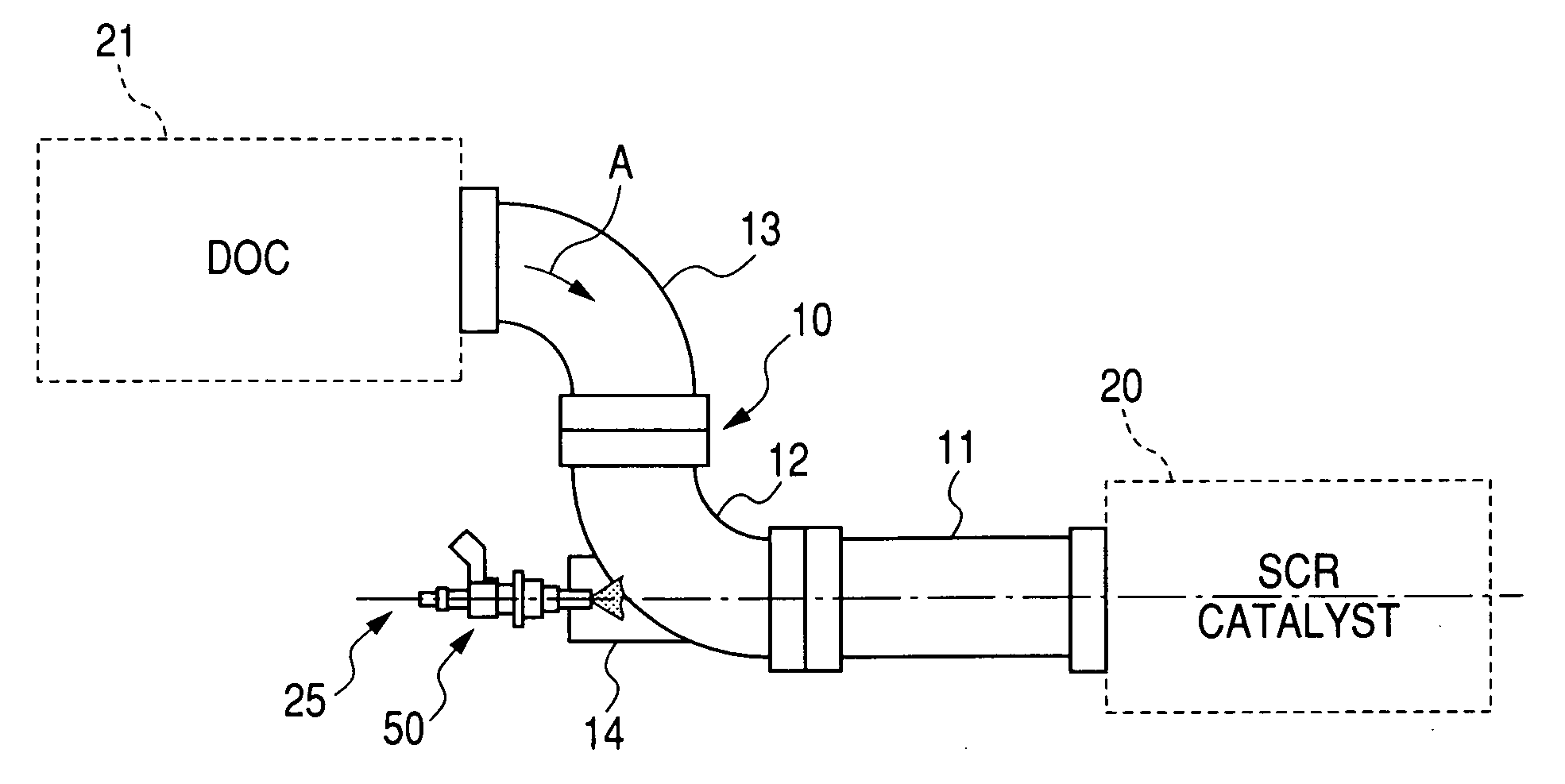

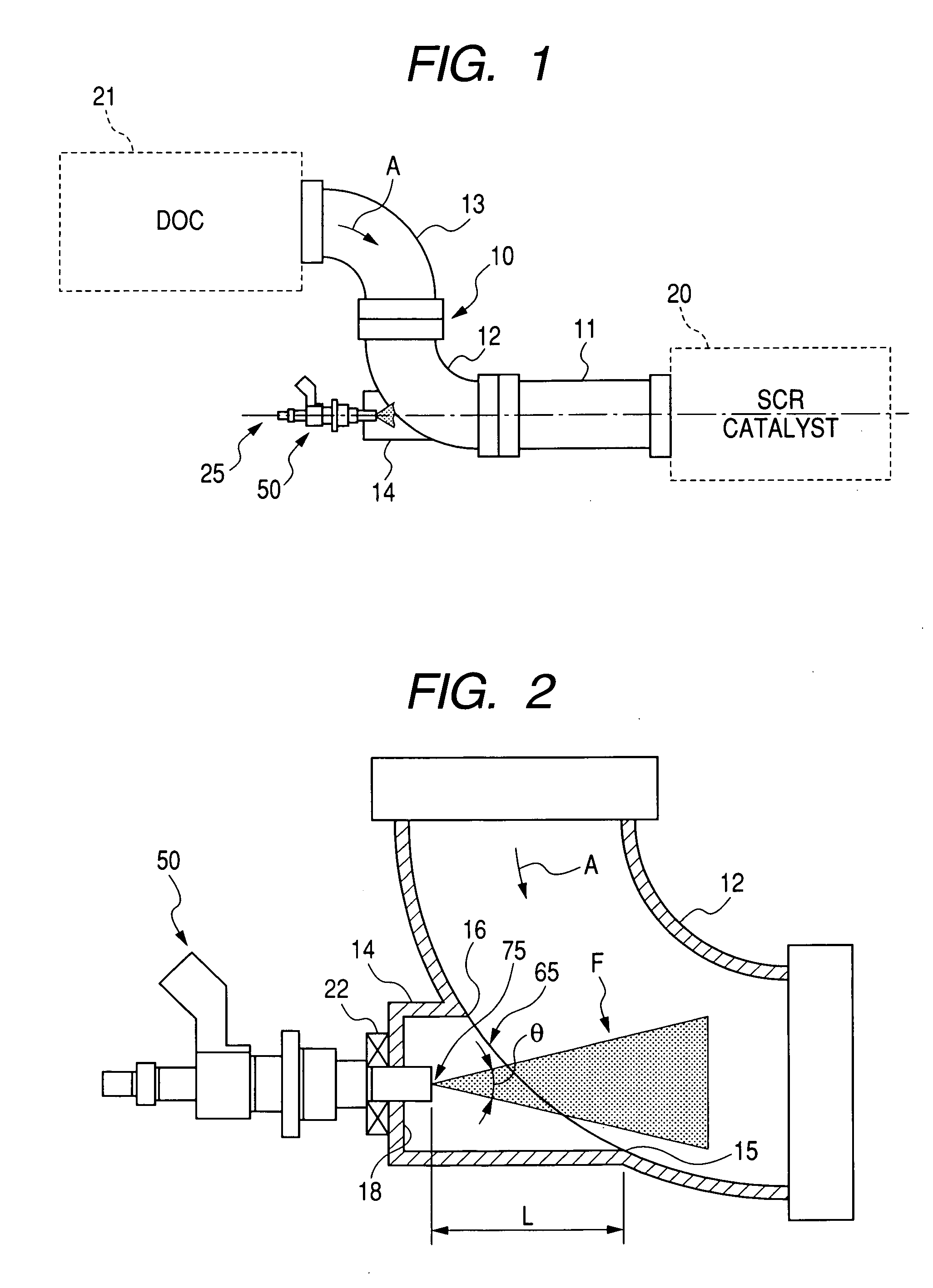

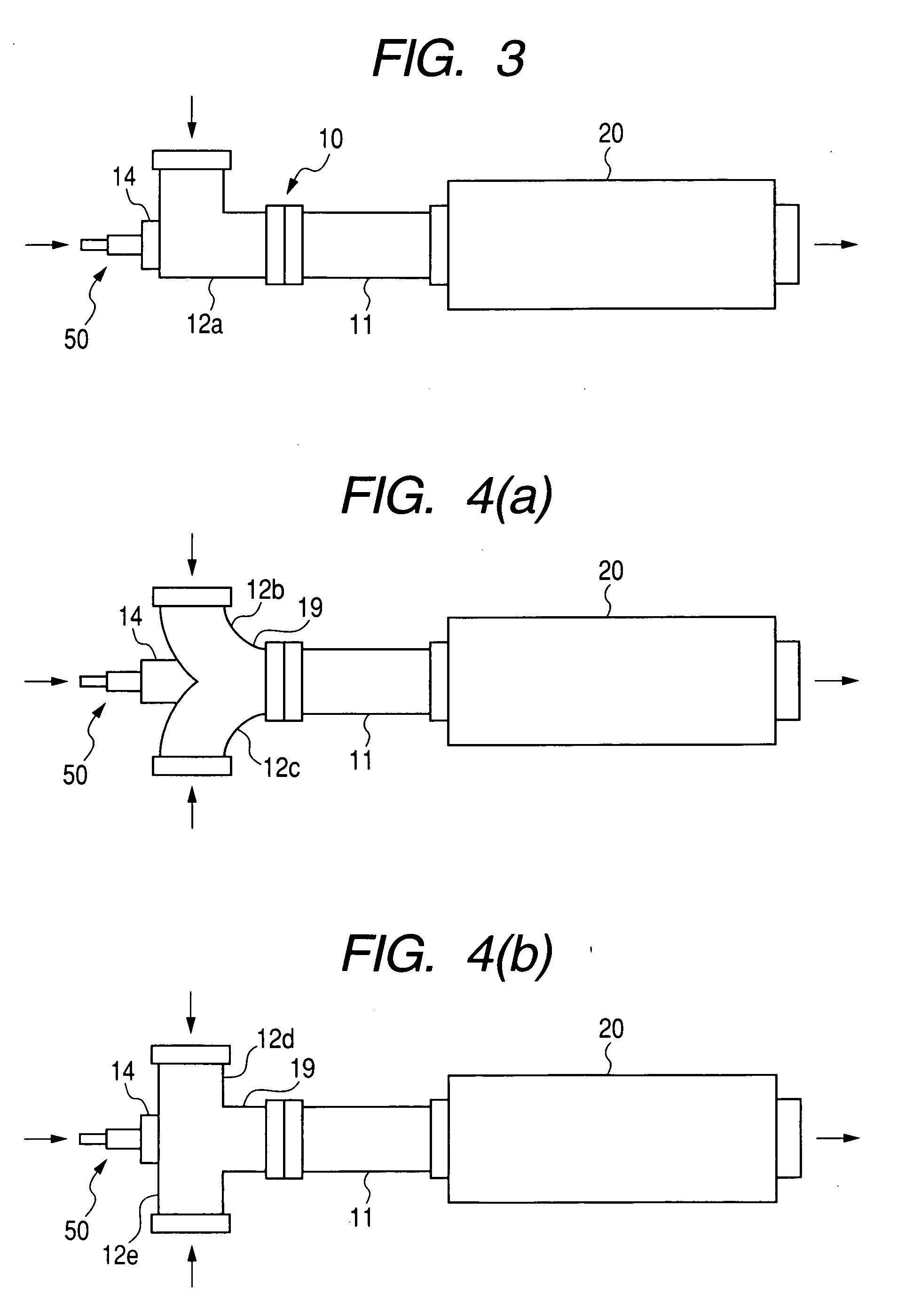

Exhaust emission control device with additive injector

InactiveUS20080155973A1Minimize transmissionMinimize adhesionInternal combustion piston enginesExhaust apparatusExhaust fumesAqueous solution

An exhaust emission control apparatus is provided which is equipped with an additive injector to inject additive such as a urea aqueous solution into an exhaust pipe through which exhaust emissions flow. The exhaust pipe includes a straight section and a bent section. A catalyst such as a SCR (Selective Catalytic Reduction) catalyst is disposed downstream of the straight section. A hollow protrusion is formed on an outer peripheral wall of the bent section substantially in parallel to a longitudinal center line of the straight section. The protrusion has an opening formed in one of opposed ends thereof which communicates with inside the bent section. The additive injector is designed to produce a cone-shaped spray of additive and installed on the other end of the protrusion to inject the cone-shaped spray of additive into the exhaust pipe without interfering with at least a downstream edge of the opening.

Owner:DENSO CORP

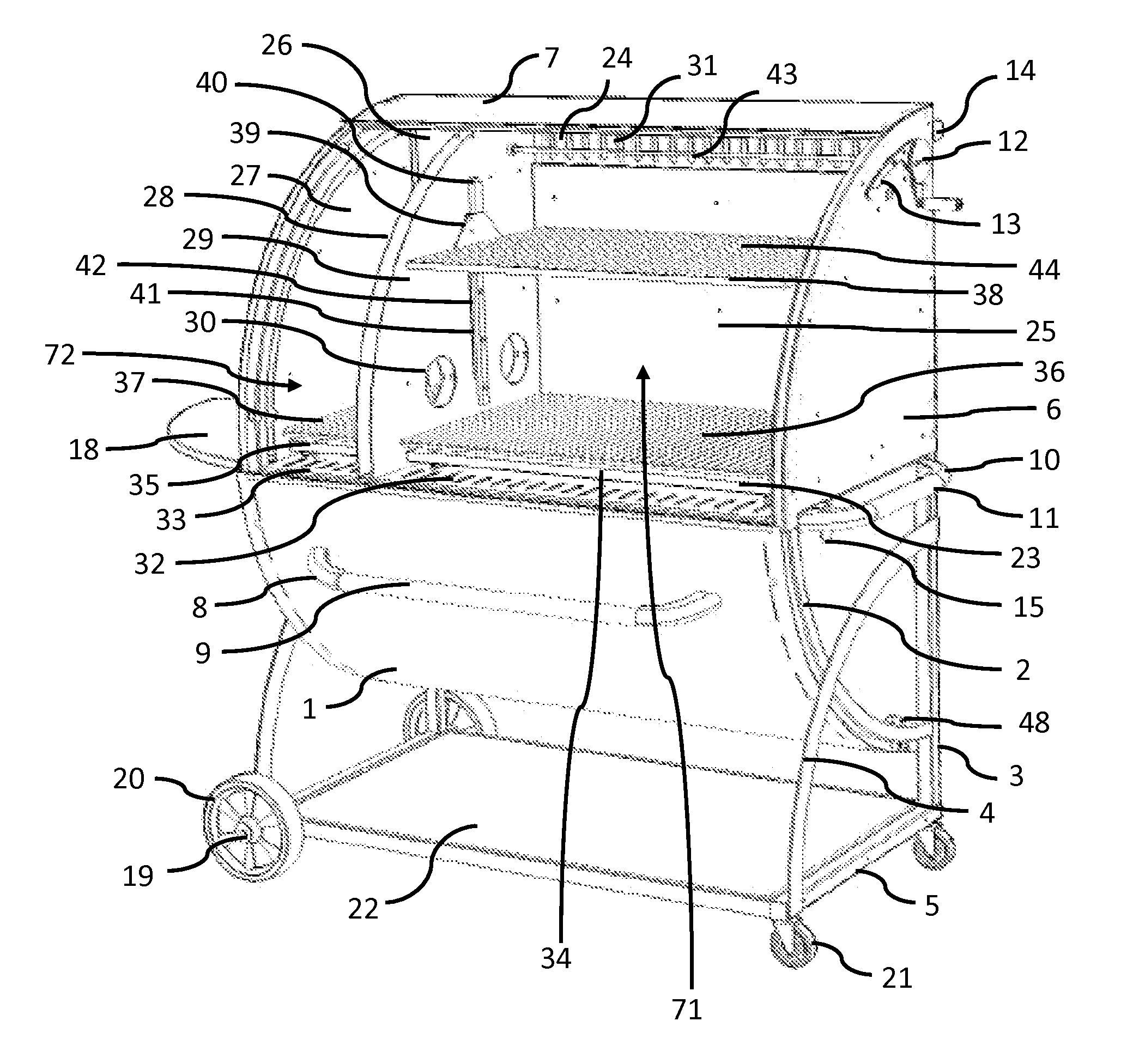

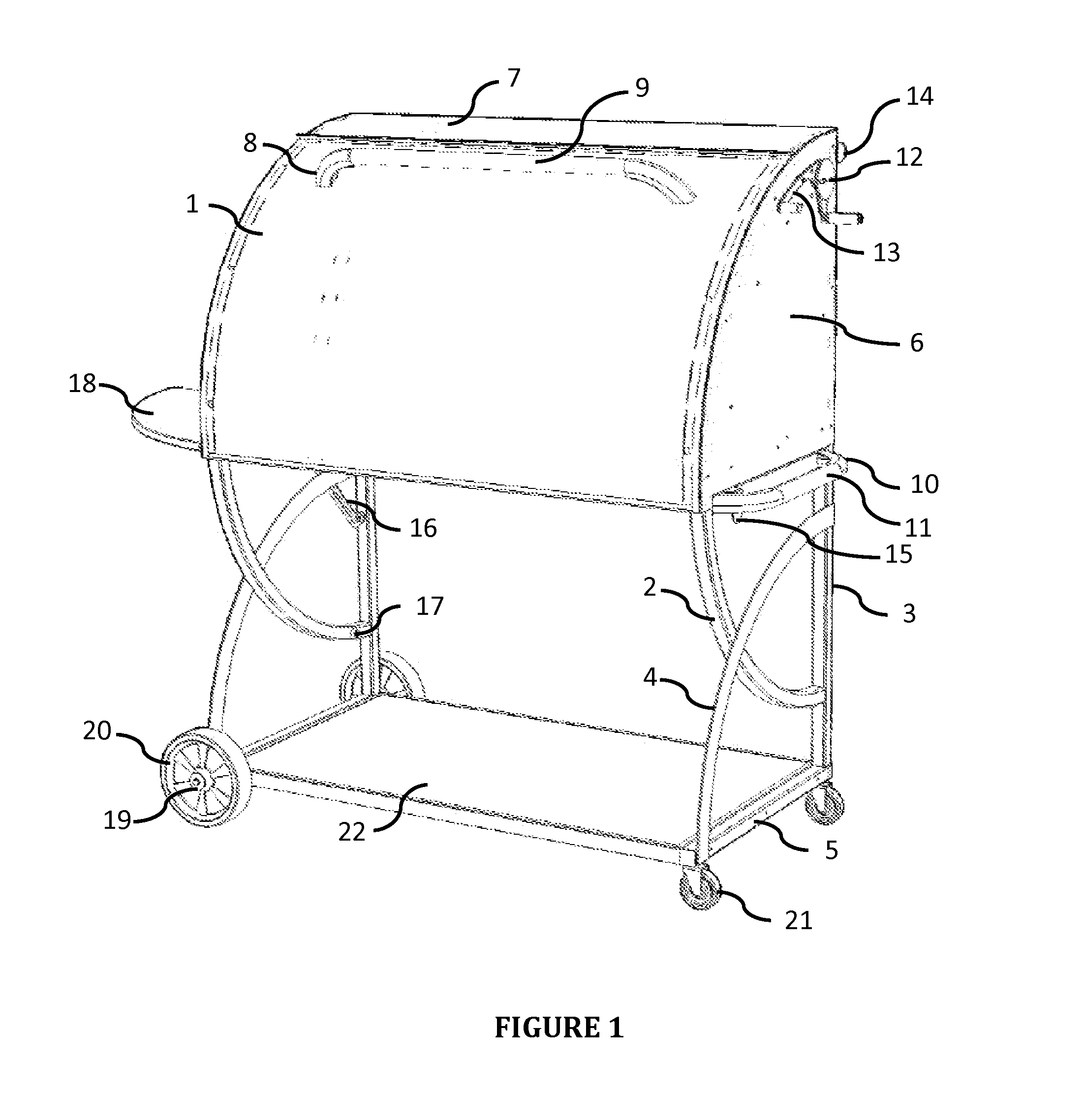

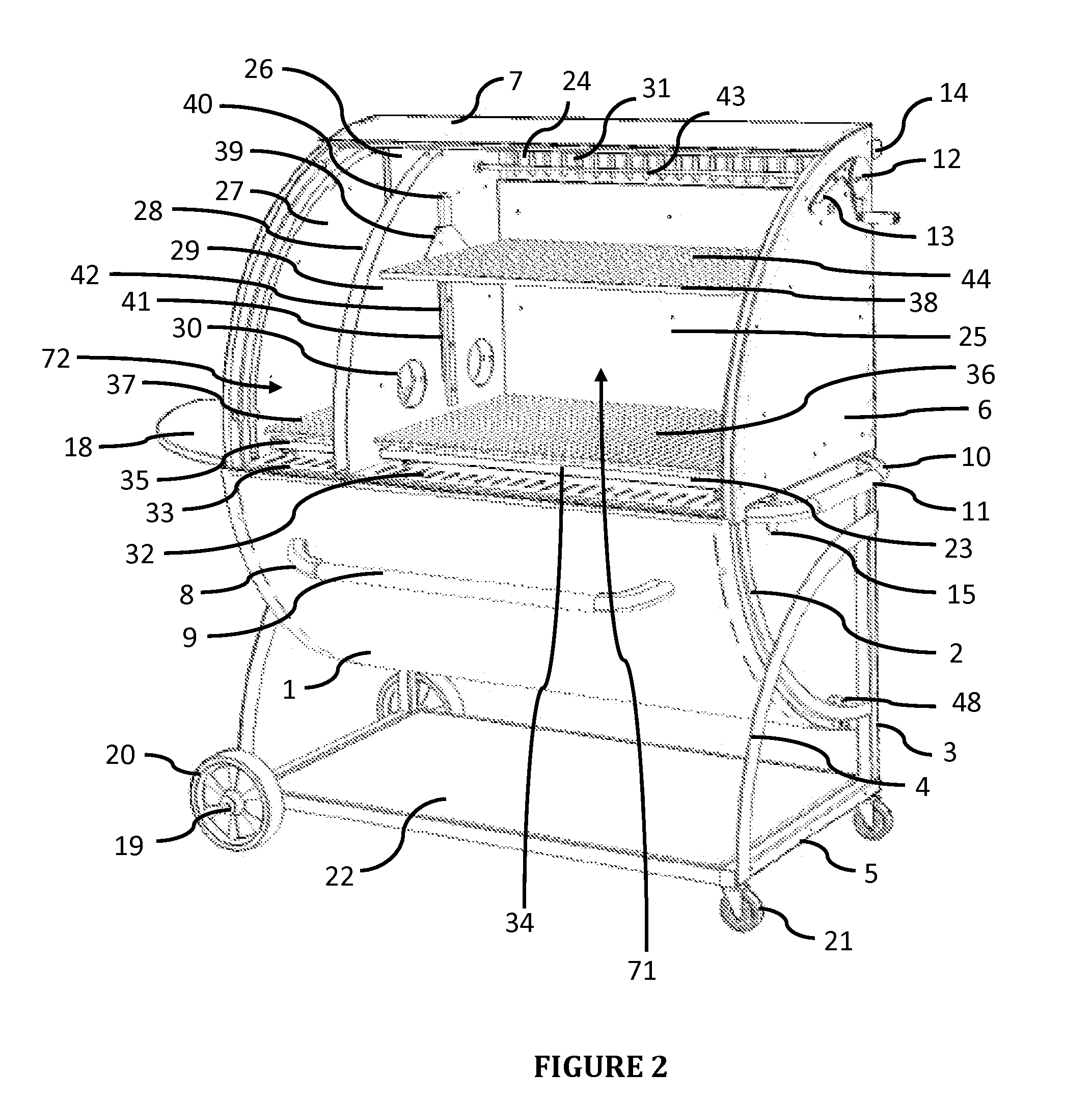

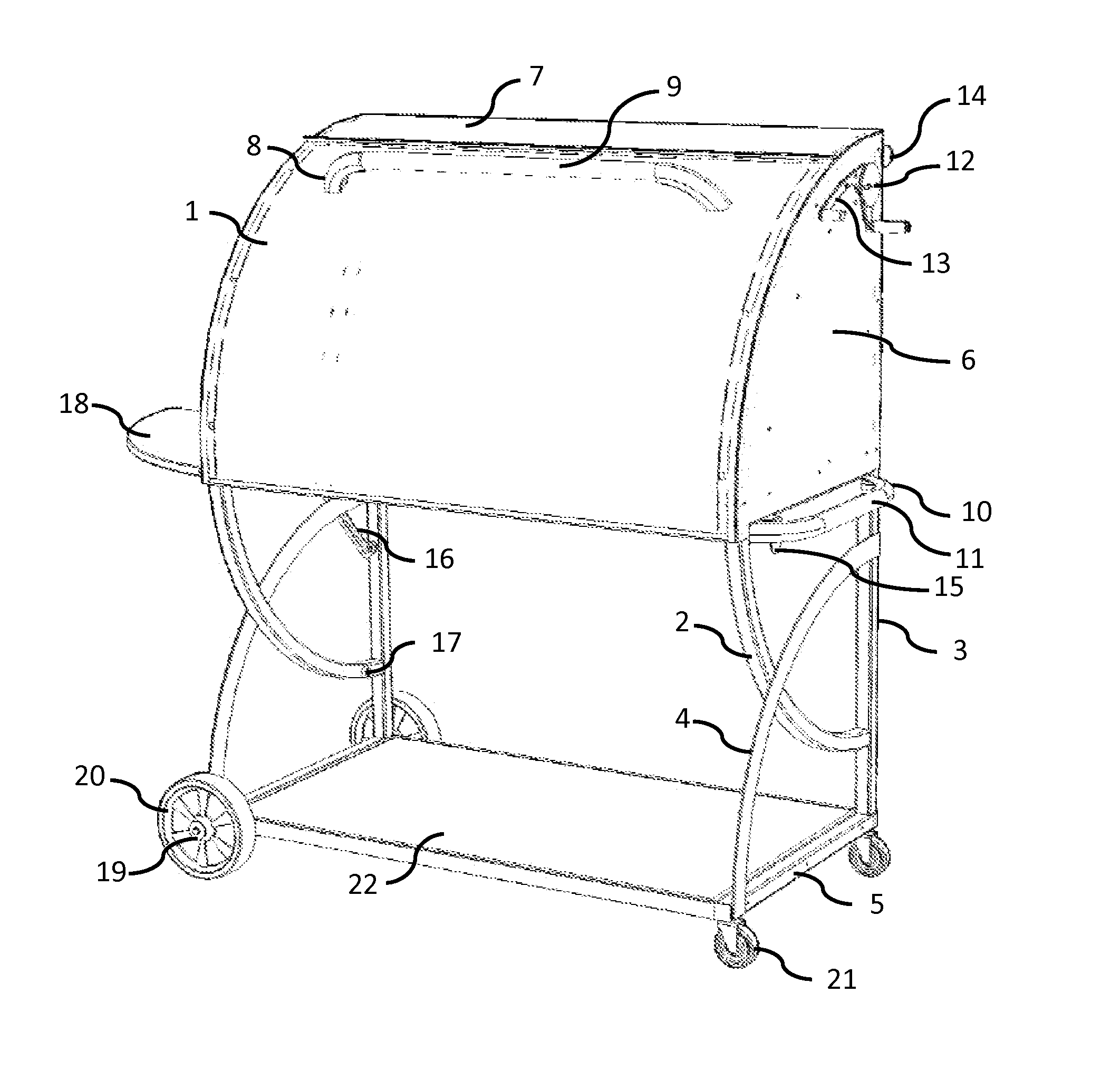

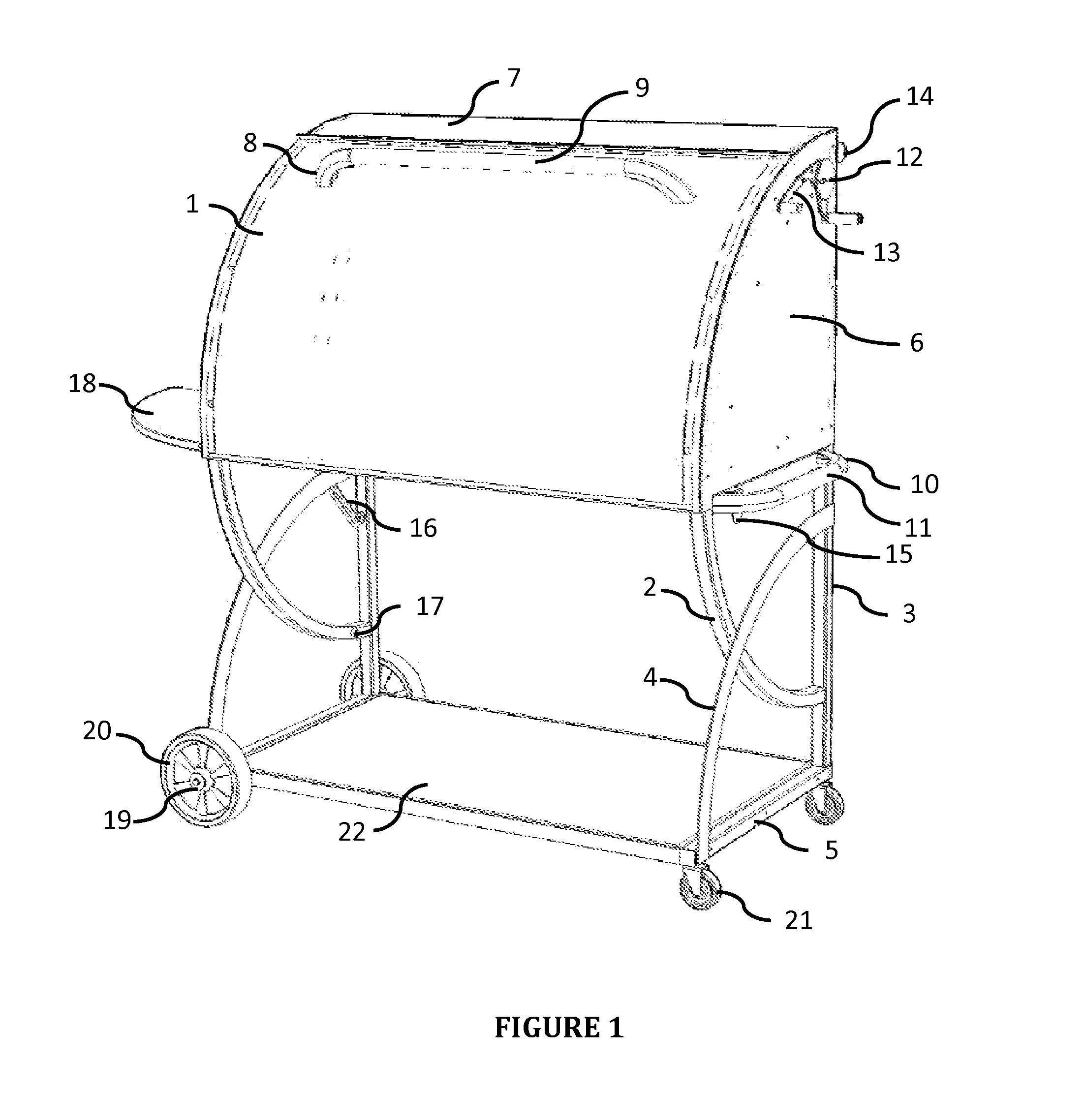

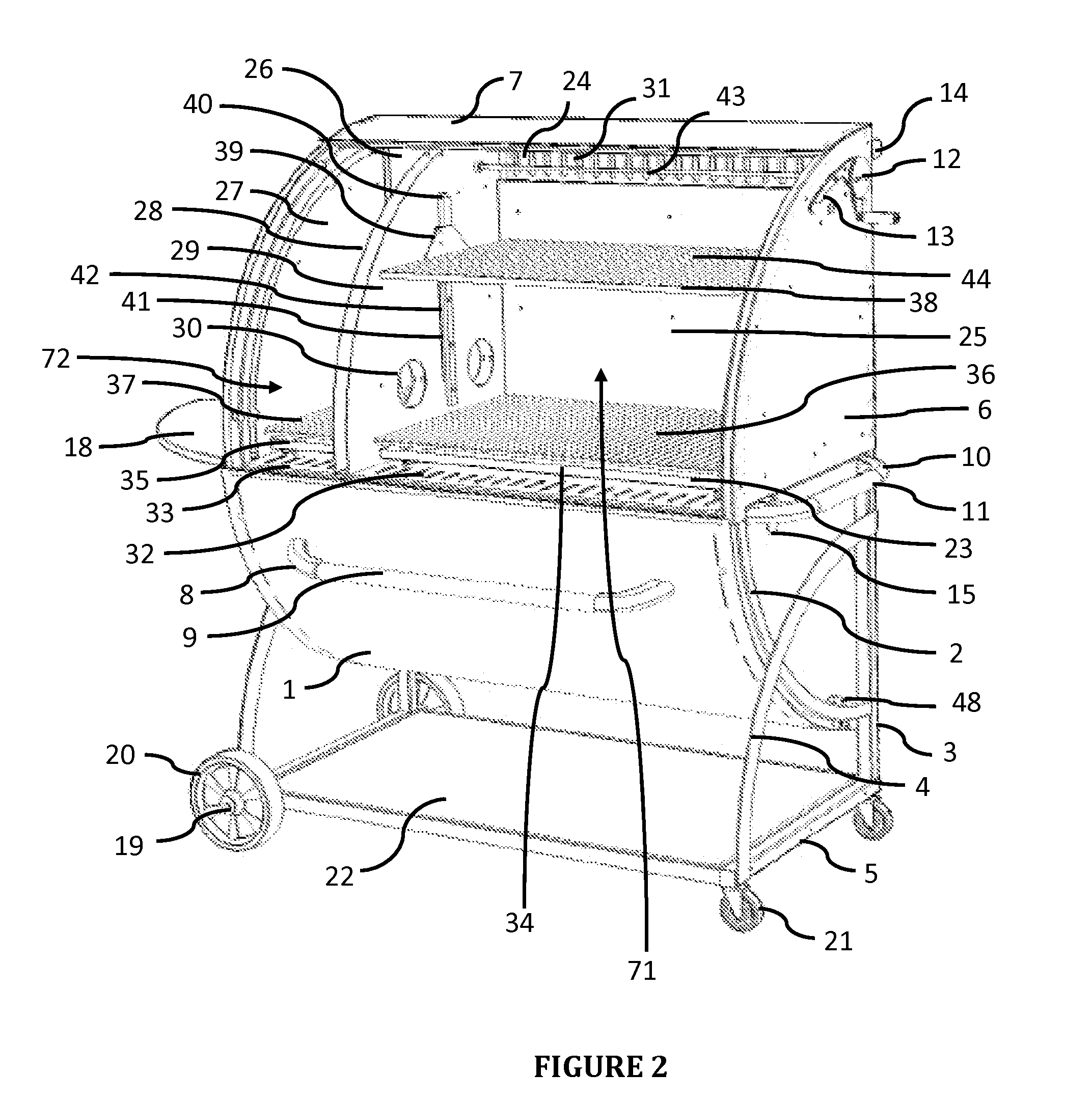

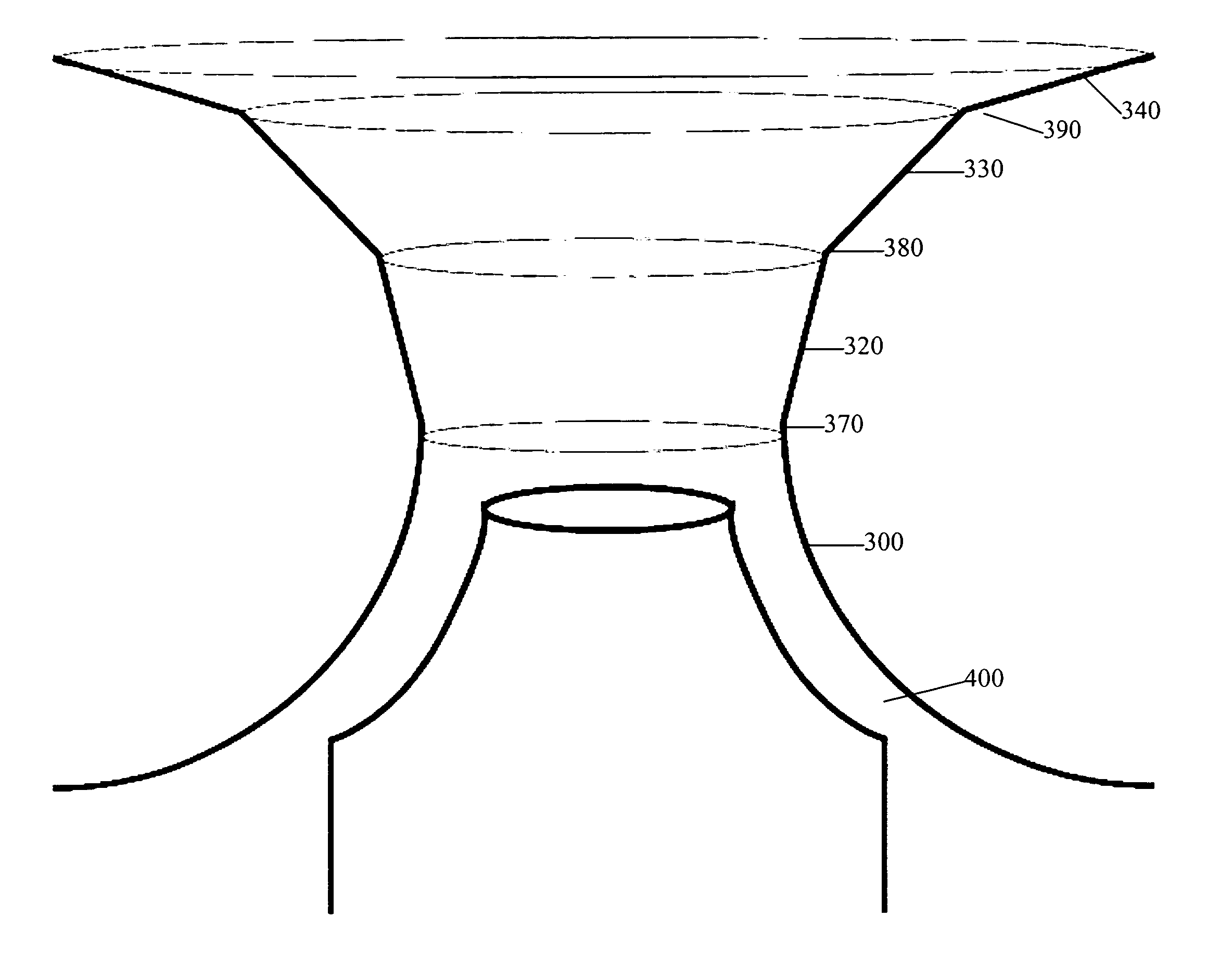

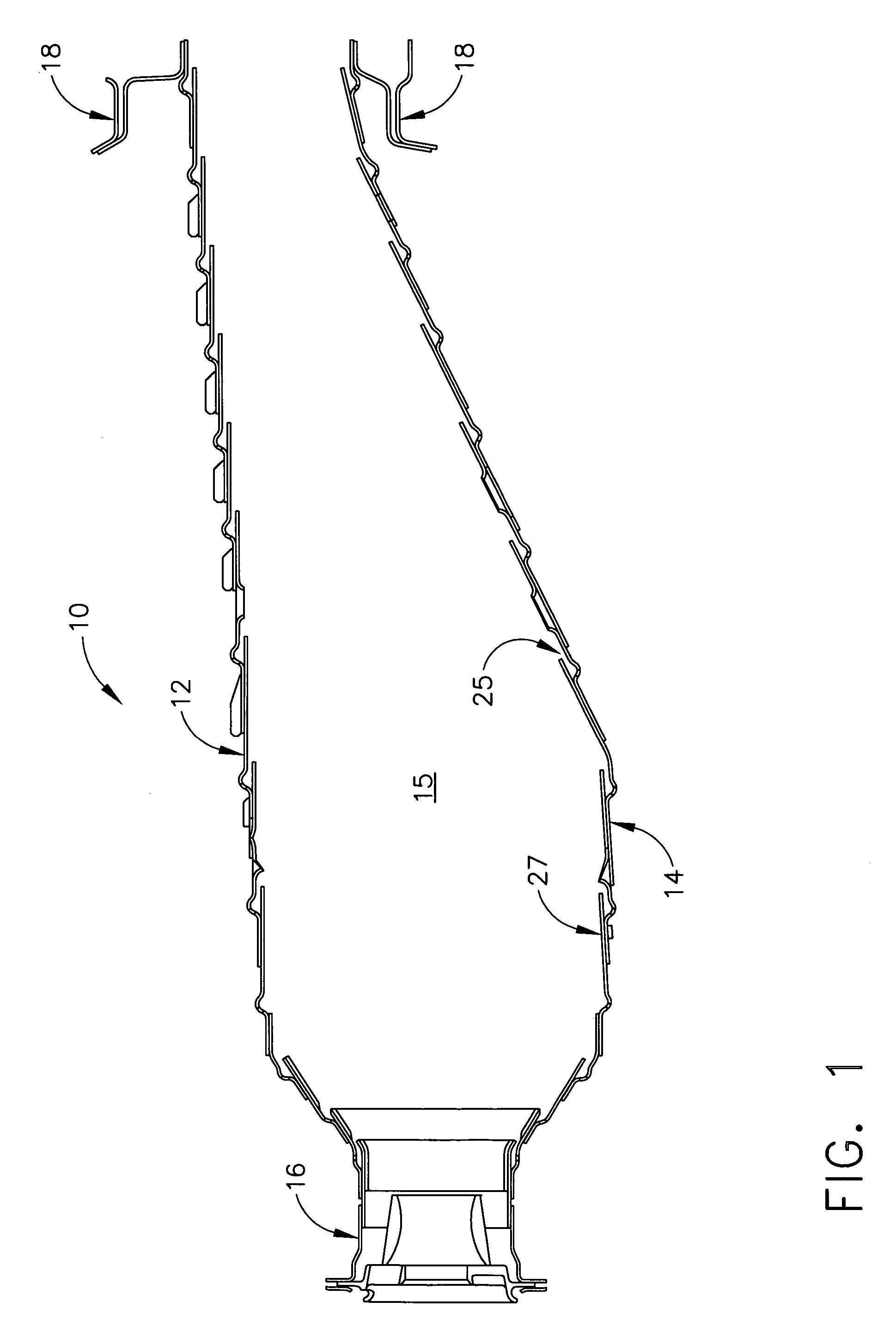

Cooking apparatus with downward opening lid

InactiveUS20120288596A1Easy to useEliminate needMilk preservationMeat/fish preservationTemperature controlEngineering

Provided is a cooking / grilling apparatus, primarily for outdoor use, providing smoking and / or direct or indirect heat cooking capability, and offering the user enhanced cooking flexibility, temperature control, safety and convenience of operation. The grill apparatus is unique in that it offers a downward opening lid that rotates, such as on rollers or a pivot mechanism, to a fully open position beneath the base plate of the cooking enclosure, and reverses to an upward rotation to re-close the cooking enclosure. Moreover, the grill apparatus offers a vertically adjustable cooking grate, controlled by a continuous loop cable, moving over a set of pulleys, thereby reliably controlling the height of the cooking grate when affixed to a crank on the outer surface of the grill, wherein movement of the grate can also be locked in place.

Owner:HOLDO BAGGOTT MAX ALEJANDRO

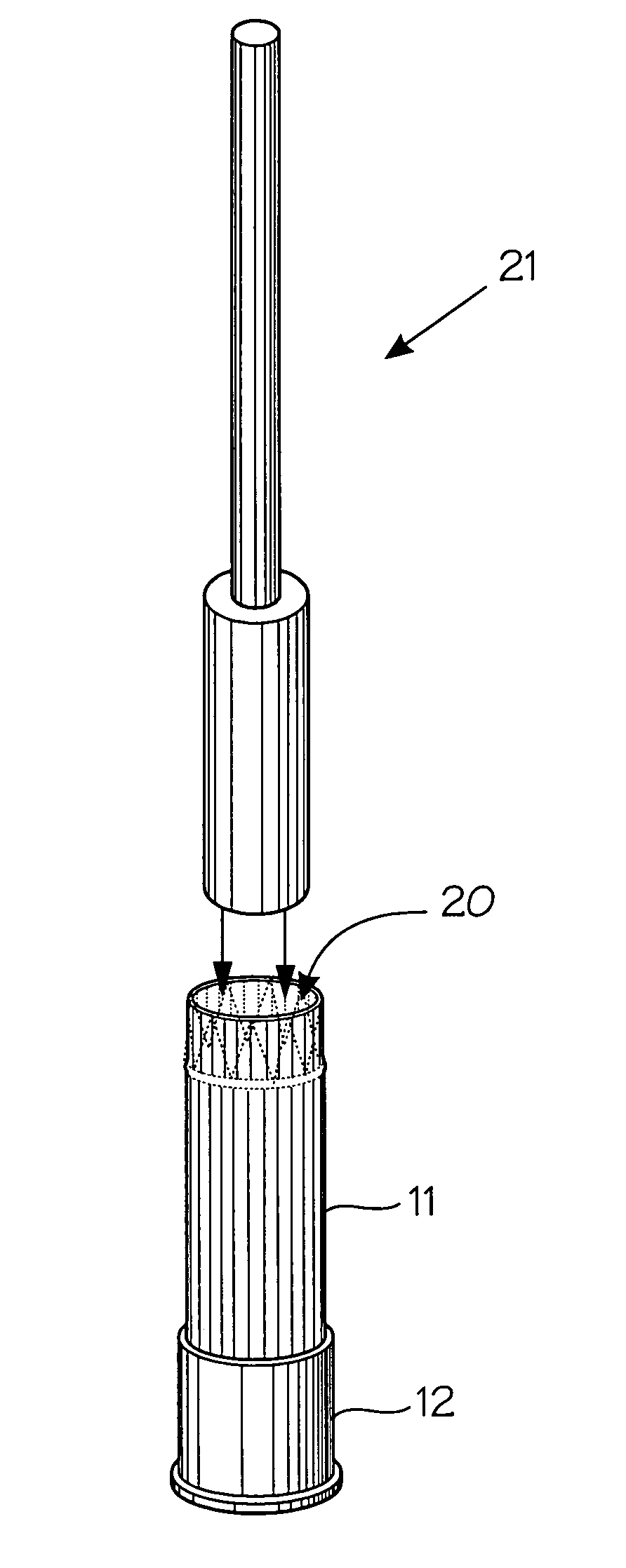

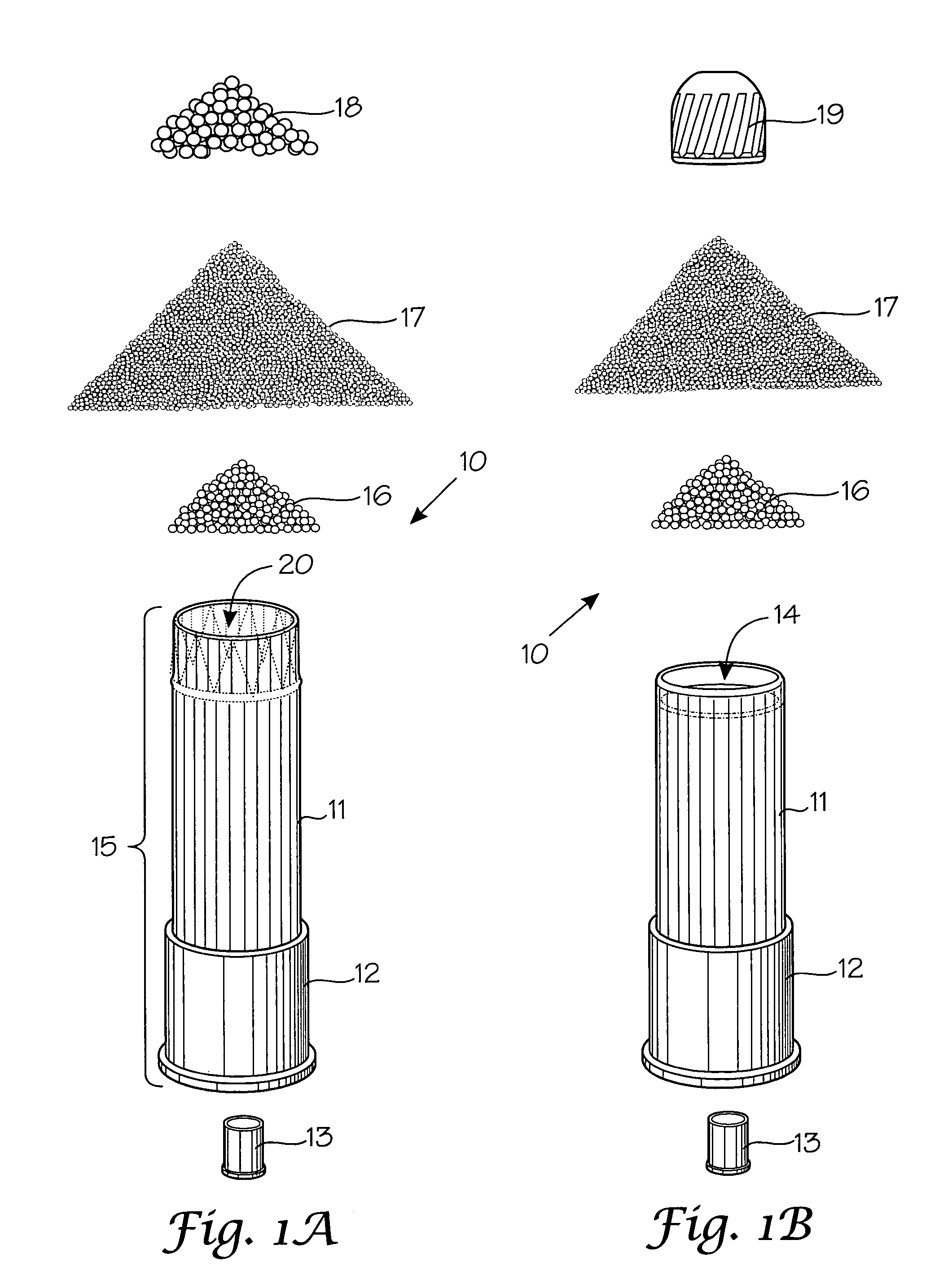

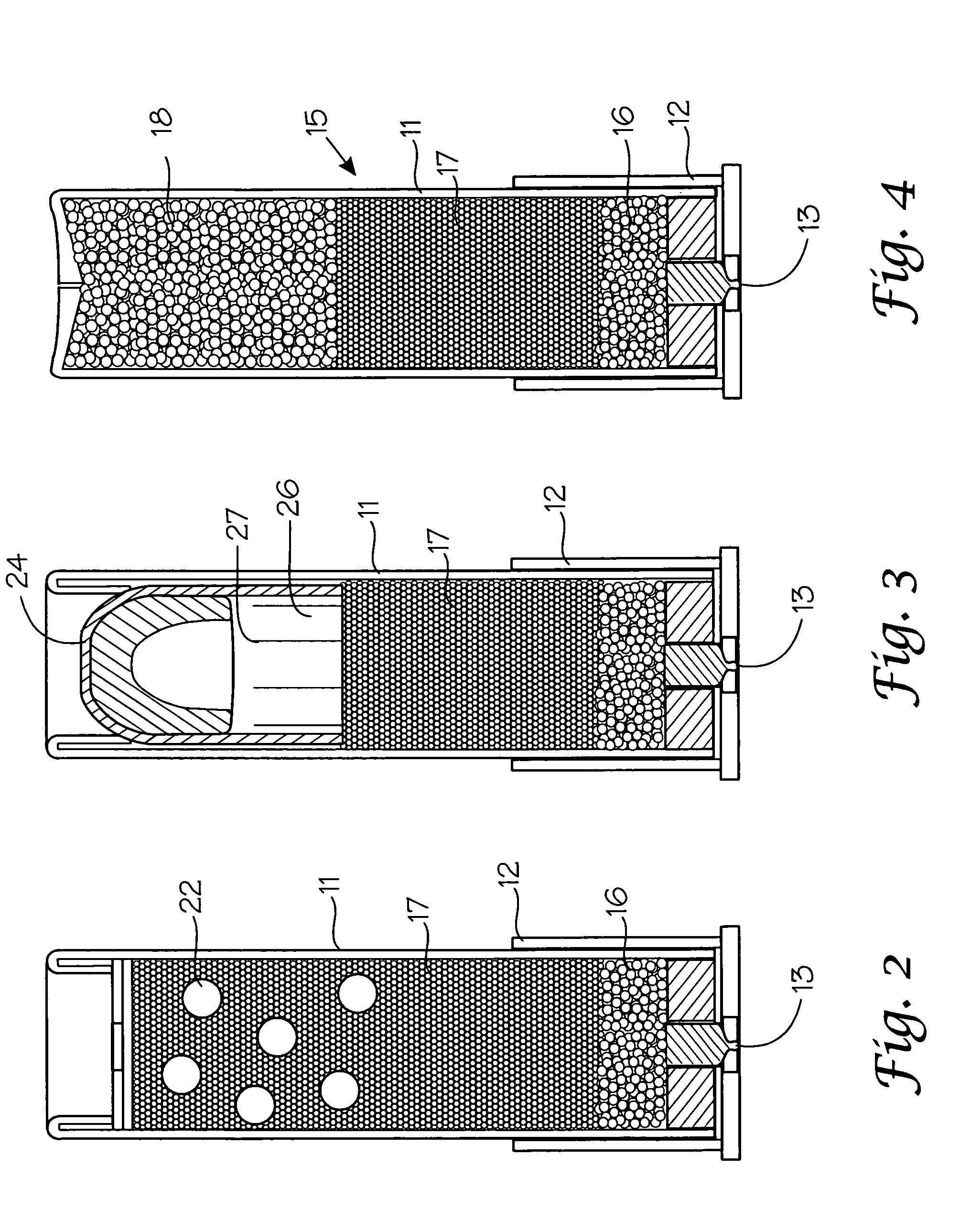

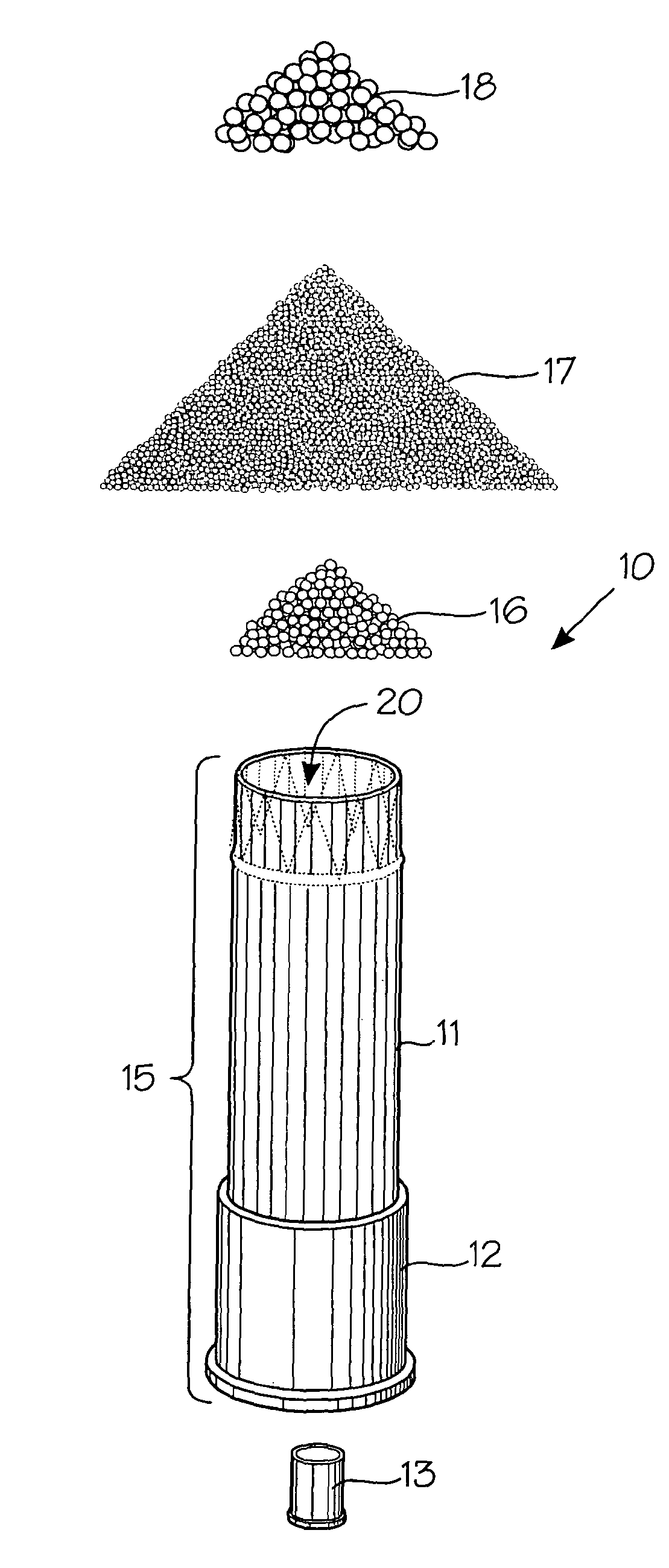

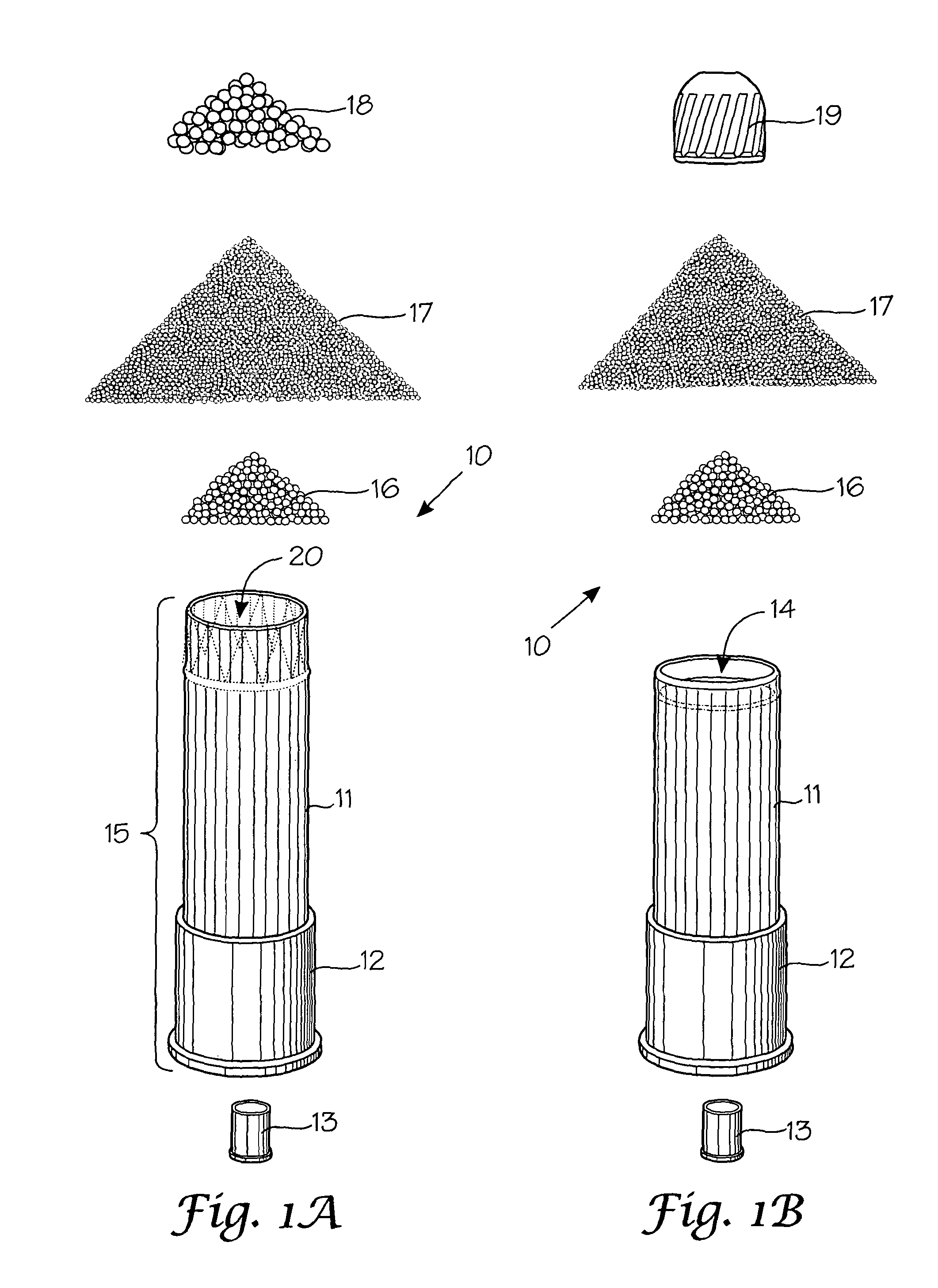

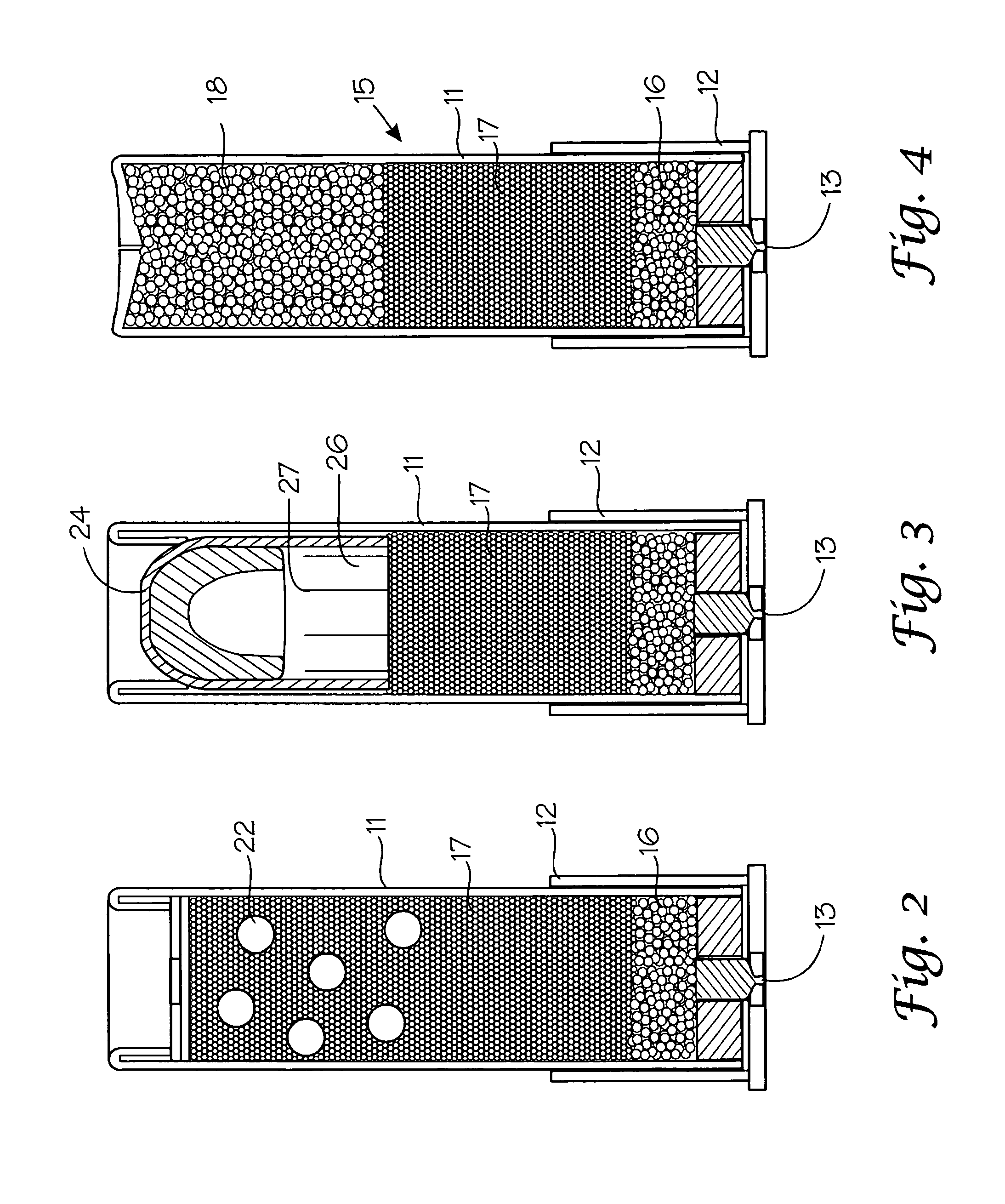

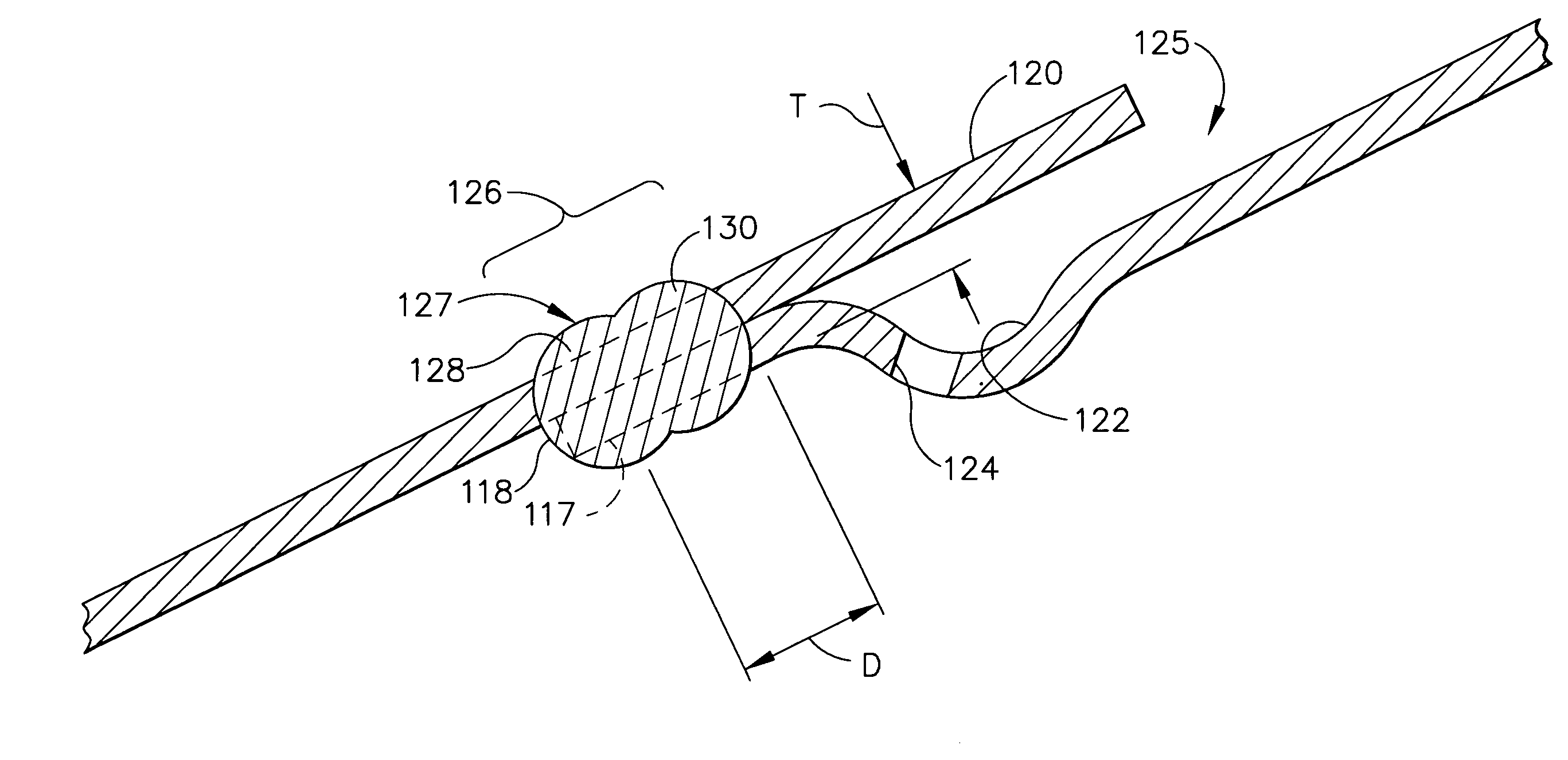

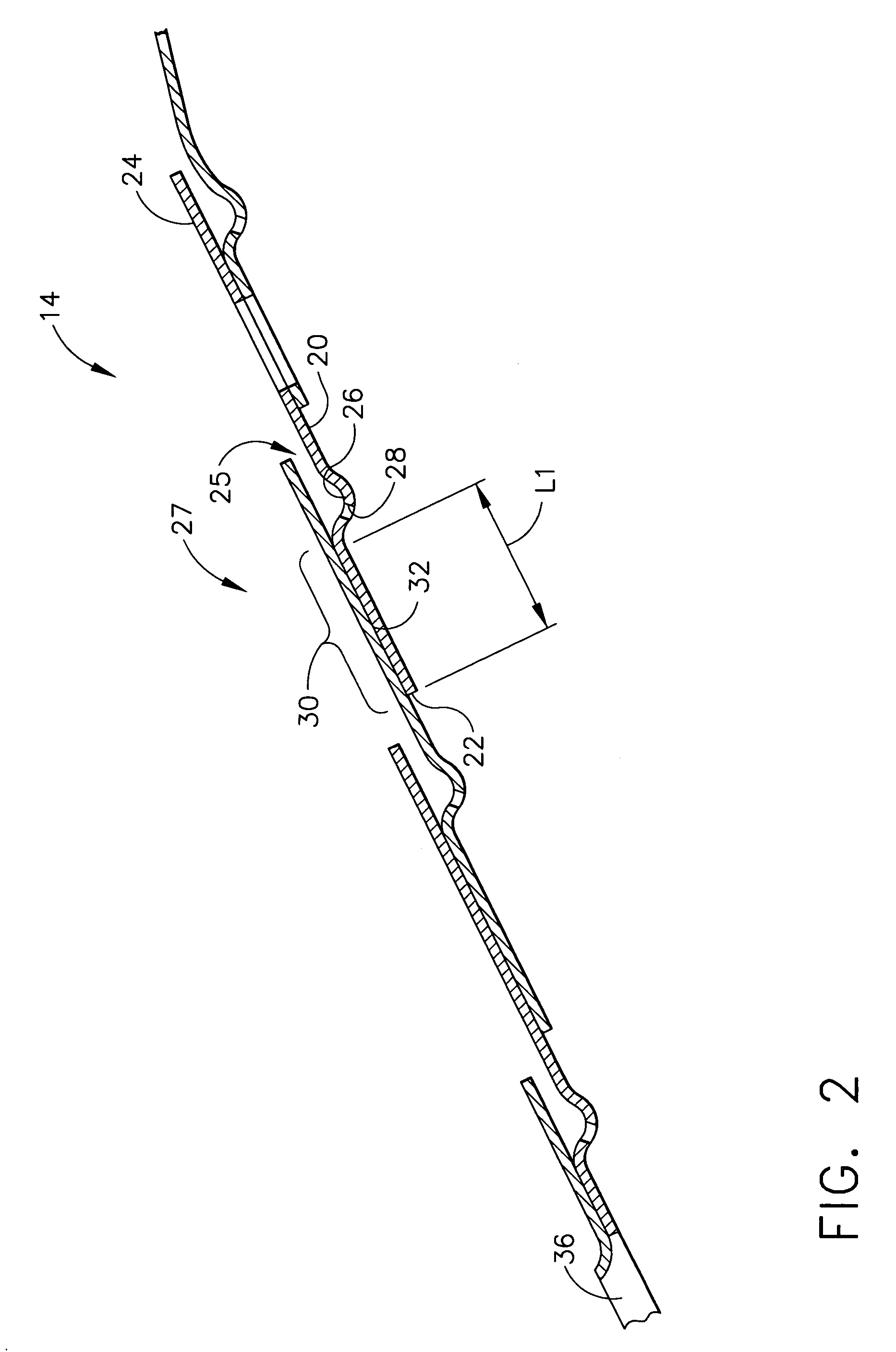

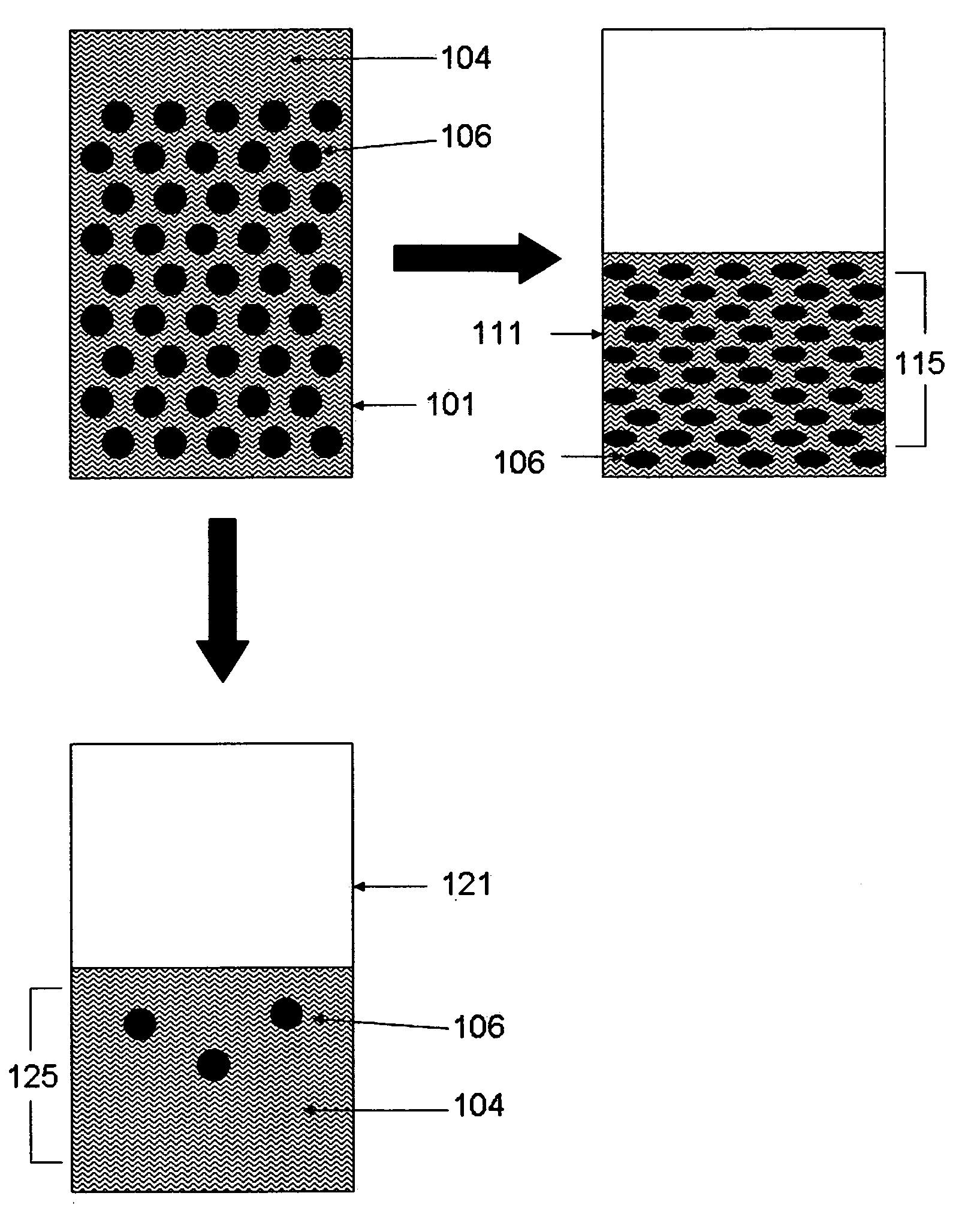

Method and apparatus for manufacturing wad-less ammunition

InactiveUS7814820B2Reduce distortionNot distort aerodynamic performanceShotgun ammunitionEngineeringSpherical form

Owner:POLYWAD

Wad-less cartridges and method of manufacturing the same

ActiveUS8276519B2Reduce distortionEasy to optimizeAmmunition projectilesShotgun ammunitionForming gasEngineering

This disclosure relates generally to cartridges for use in projectile-launching devices, such as ammunition cartridges, flare cartridges, and the like, including components of the cartridges, and methods for their manufacture. For example, the cartridges of this disclosure can be ammunition cartridges such as shotshell cartridges, which include an obturating medium which functions to seal the compressed but expanding hot gases and can be used without a pre -formed gas seal.

Owner:POLYWAD

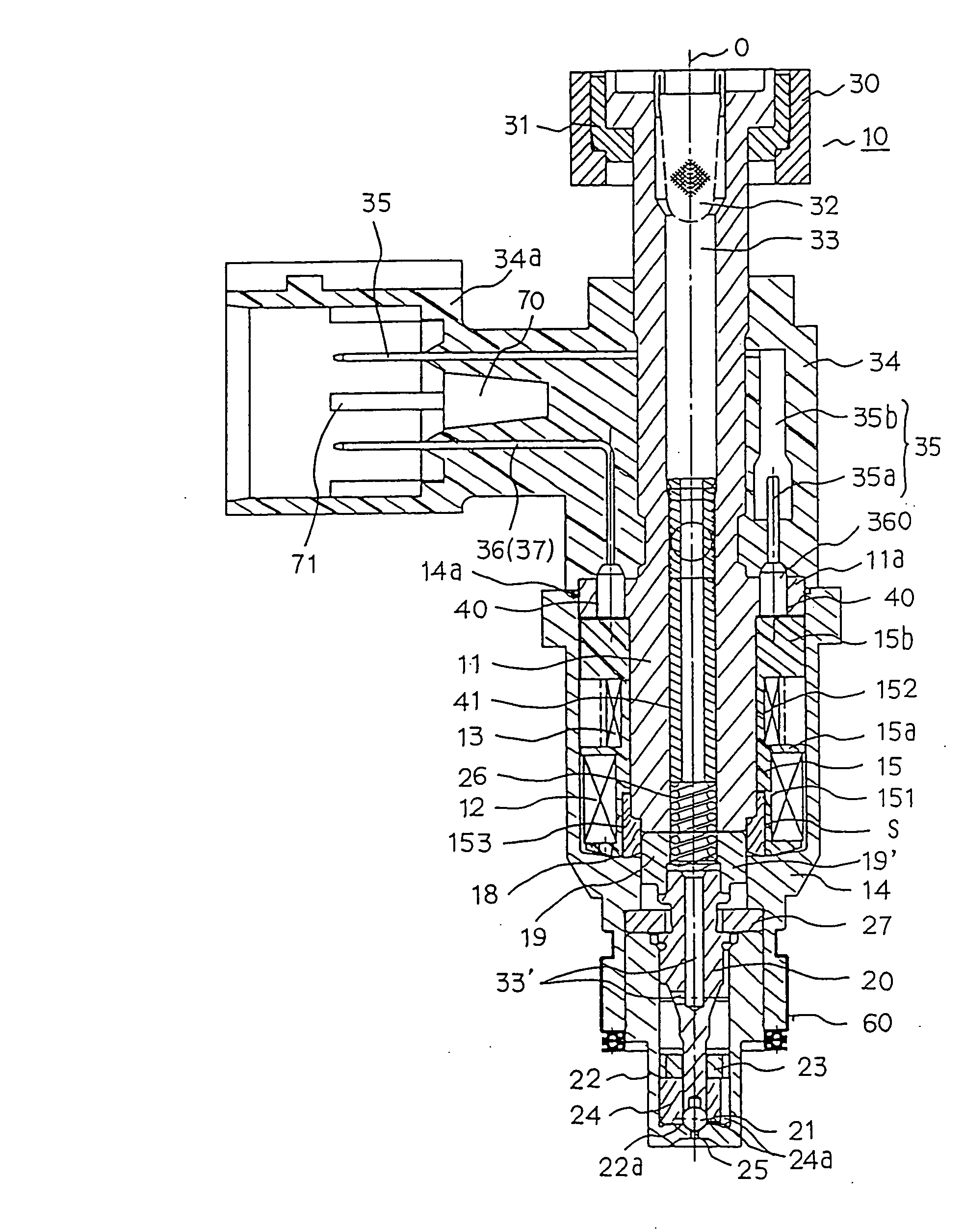

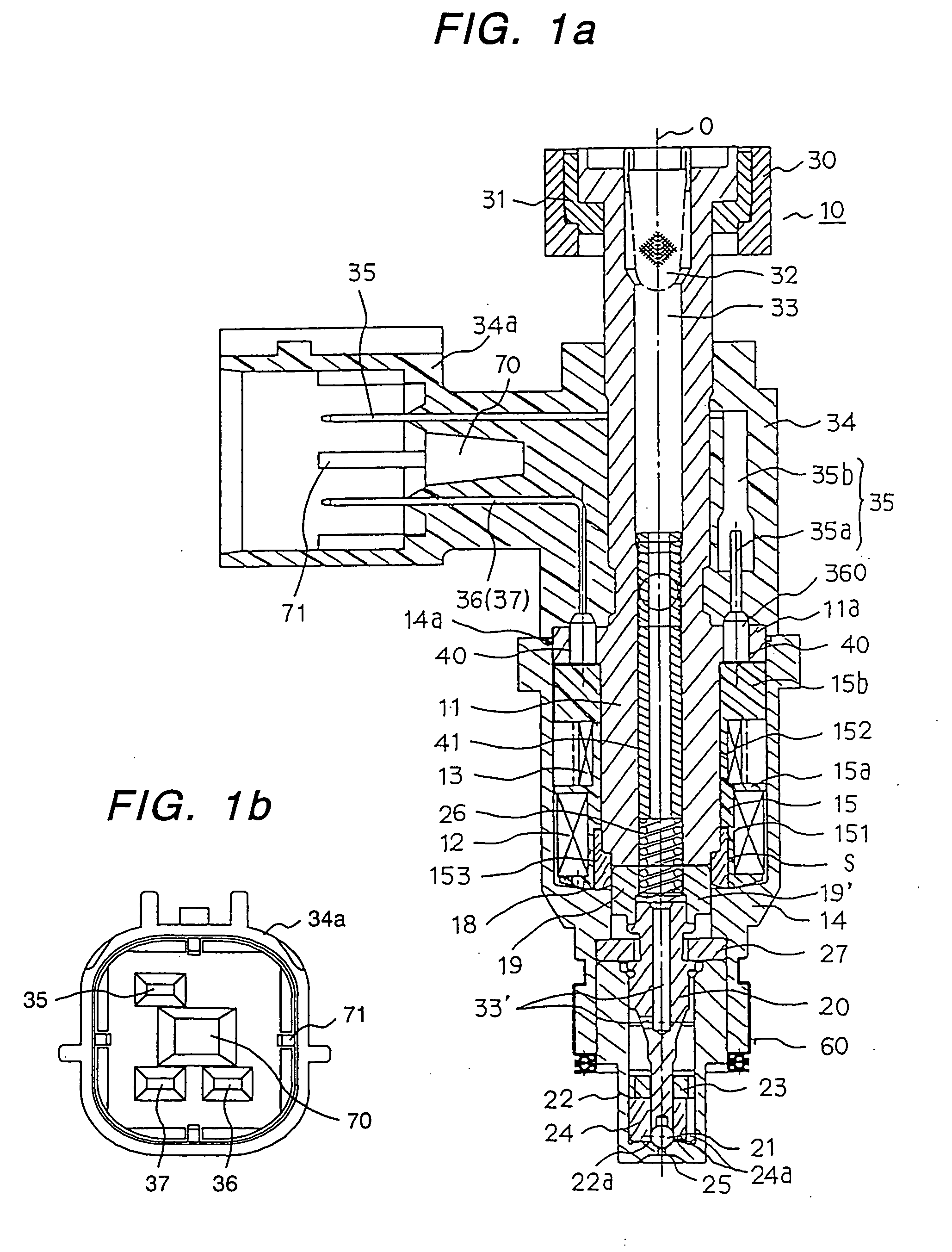

Electromagnetic fuel injector

InactiveUS20070007477A1Improve performanceCompact structureElectrical controlOperating means/releasing devices for valvesBobbinEngineering

In an electromagnetic fuel injector of an internal combustion engine, an electromagnetic coil for valve driving is to be wound on a bobbin, and the bobbin is constituted by a synthetic resin containing a filler having good heat conductivity. For example, the bobbin with the coil to be wound thereon is constituted by PPS containing iron oxide and / or alumina as a filler. Two types of electromagnetic coils different in characteristics are provided in the fuel injector. These coils are wound separately on one bobbin in an axial direction. Among them, one coil (hereinafter referred to as “first coil”) has a winding region near a movable unit with a valve element being the object of magnetic suction, and other-coil (hereinafter referred to as “second coil”) has a winding region away from the movable unit. The bobbin has a step difference of the outer diameter so that the bobbin outer diameter in the region with the second coil to be wound thereon is smaller than the bobbin outer diameter in the region with the first coil to be wound thereon, and the bobbin inner diameter has a step difference in that the bobbin inner diameter in the region with the first coil to be wound thereon is made large partially so as to secure an annular space to interpose a seal ring therein.

Owner:HITACHI LTD +1

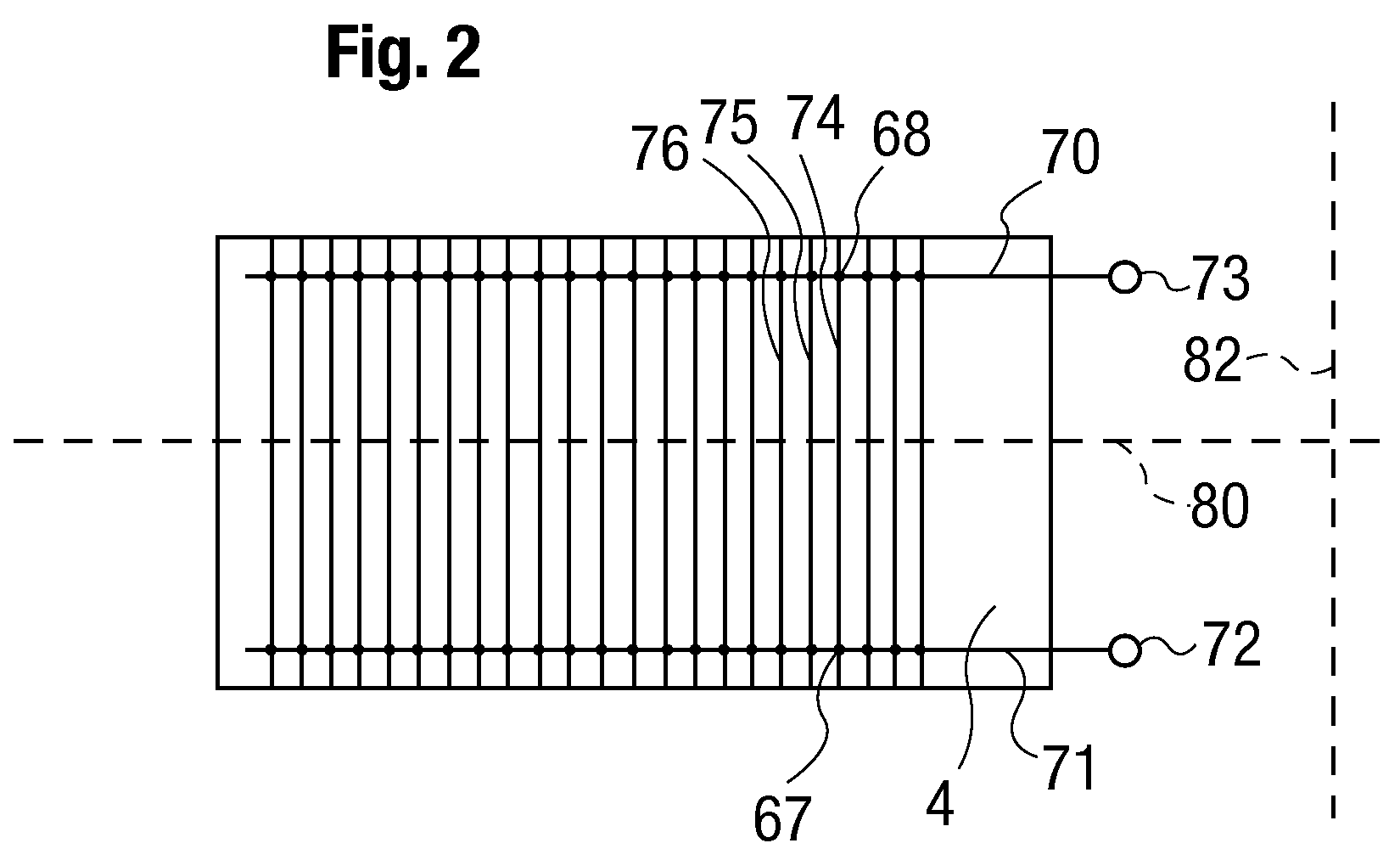

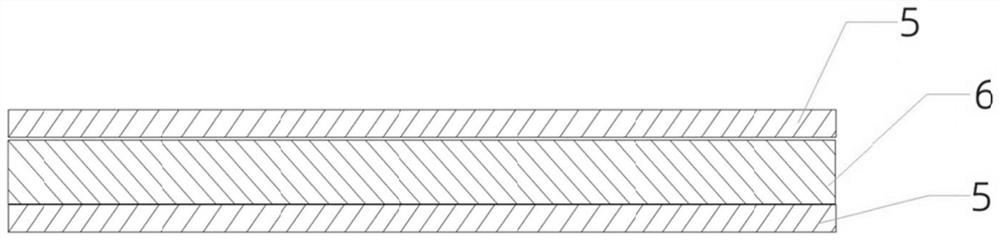

Patient bed for transporting and/or positioning a patient

InactiveUS7725967B2Low production costNo skin irritationOperating tablesDiagnosticsEmergency medicineStent

Owner:DRAGERWERK AG

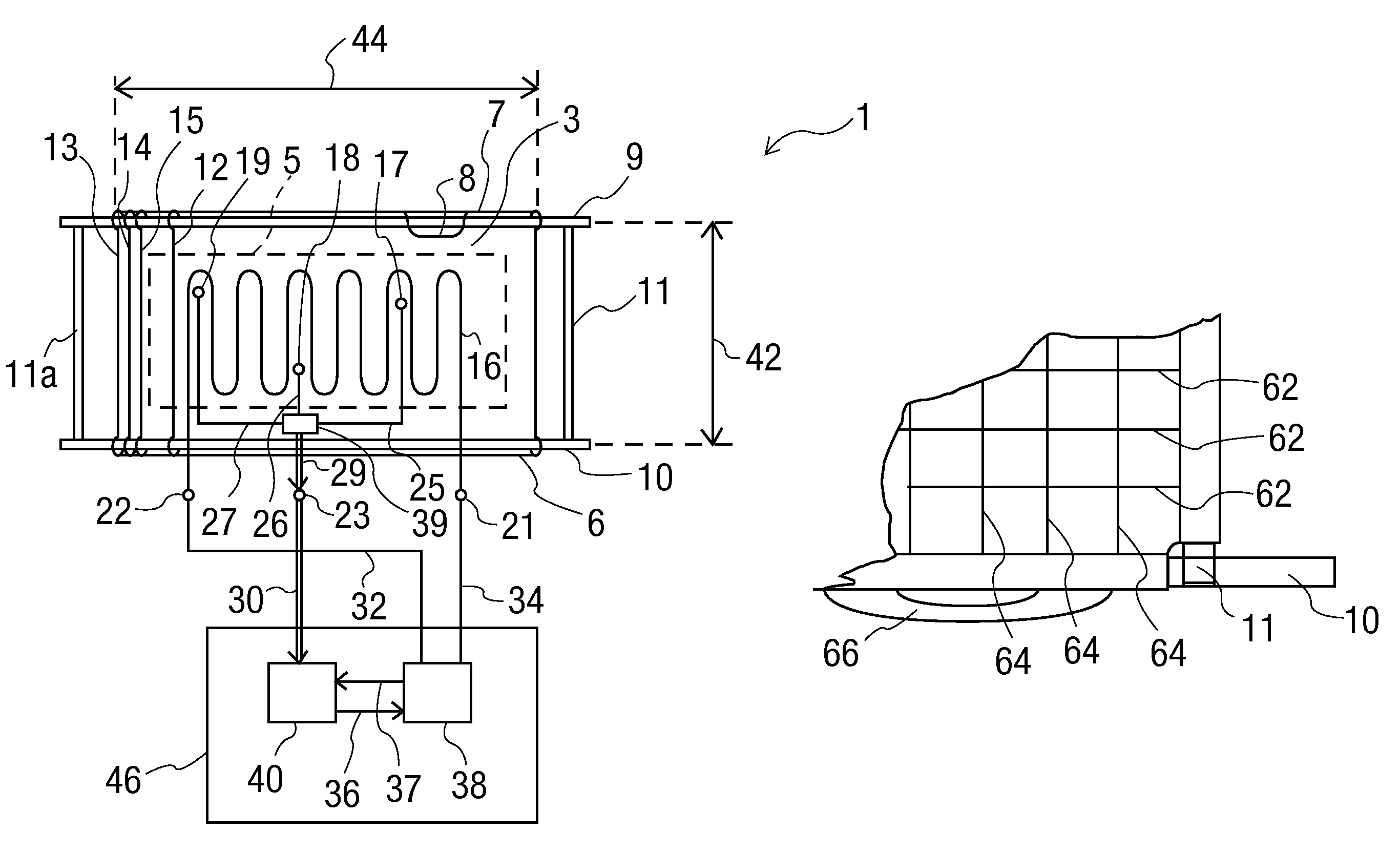

Patient bed for transporting and/or positioning a patient

InactiveUS20070251007A1Low production costNo skin irritationOperating tablesDiagnosticsEmergency medicineStent

A patient bed is provided for transporting and / or positioning a patient. The patient bed has a bed area provided for receiving a patient. The patient bed is flexible at least in the bed area in such a way that the patient bed can be rolled up around a part of the patient bed. The patient bed has at least one transport mount for acting on by a transporter, and the patient bed is designed to be transported via the at least one transport mount when loaded with a patient. The patient bed has a plurality of reinforcing fibers, which are flexible and tension-proof, wherein each of the reinforcing fibers passes through the bed area and is operatively connected to at least one of the at least one transport mount in such a way that a force acting on the bed area can be transmitted at least partially to the at least one transport mount.

Owner:DRAGERWERK AG

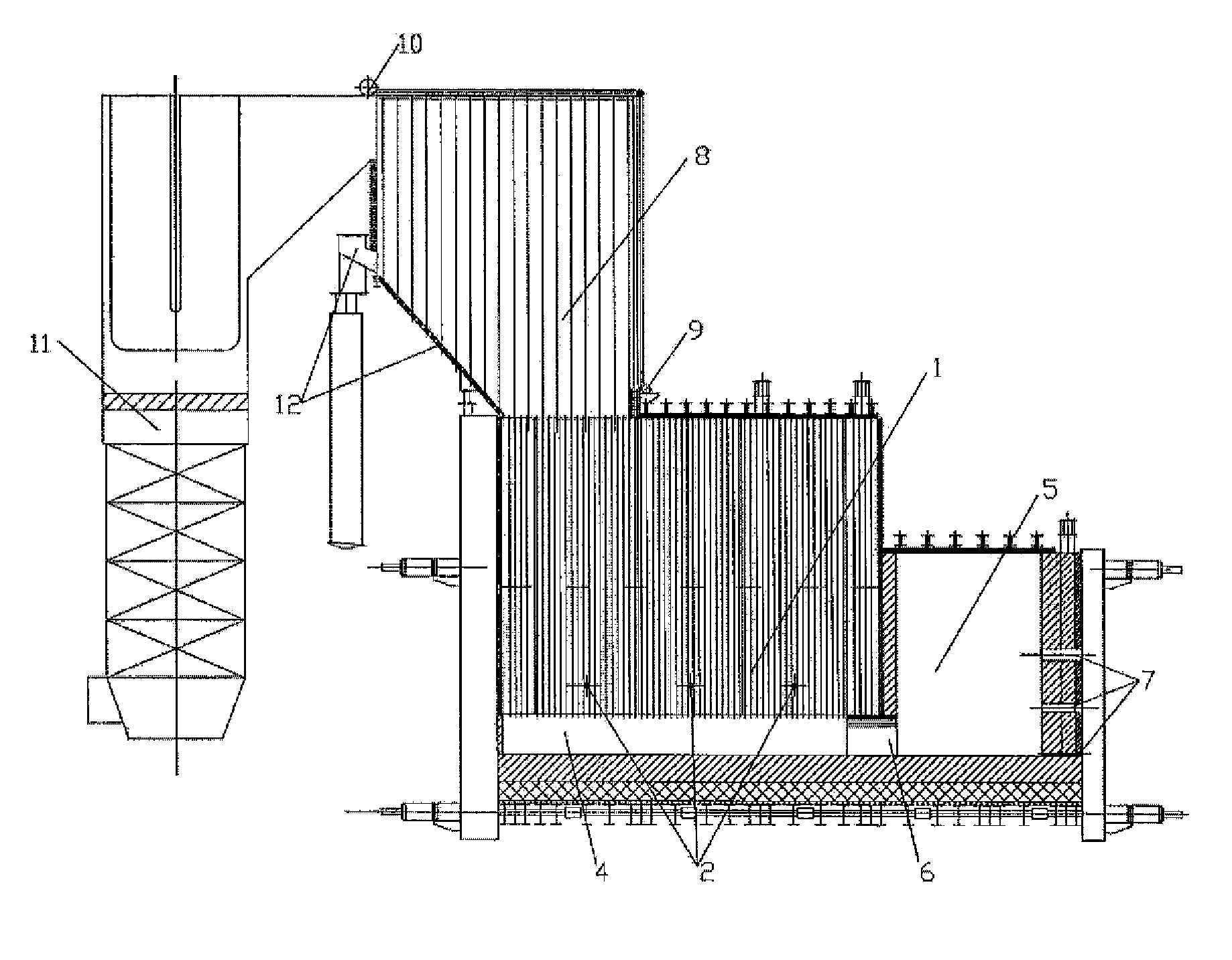

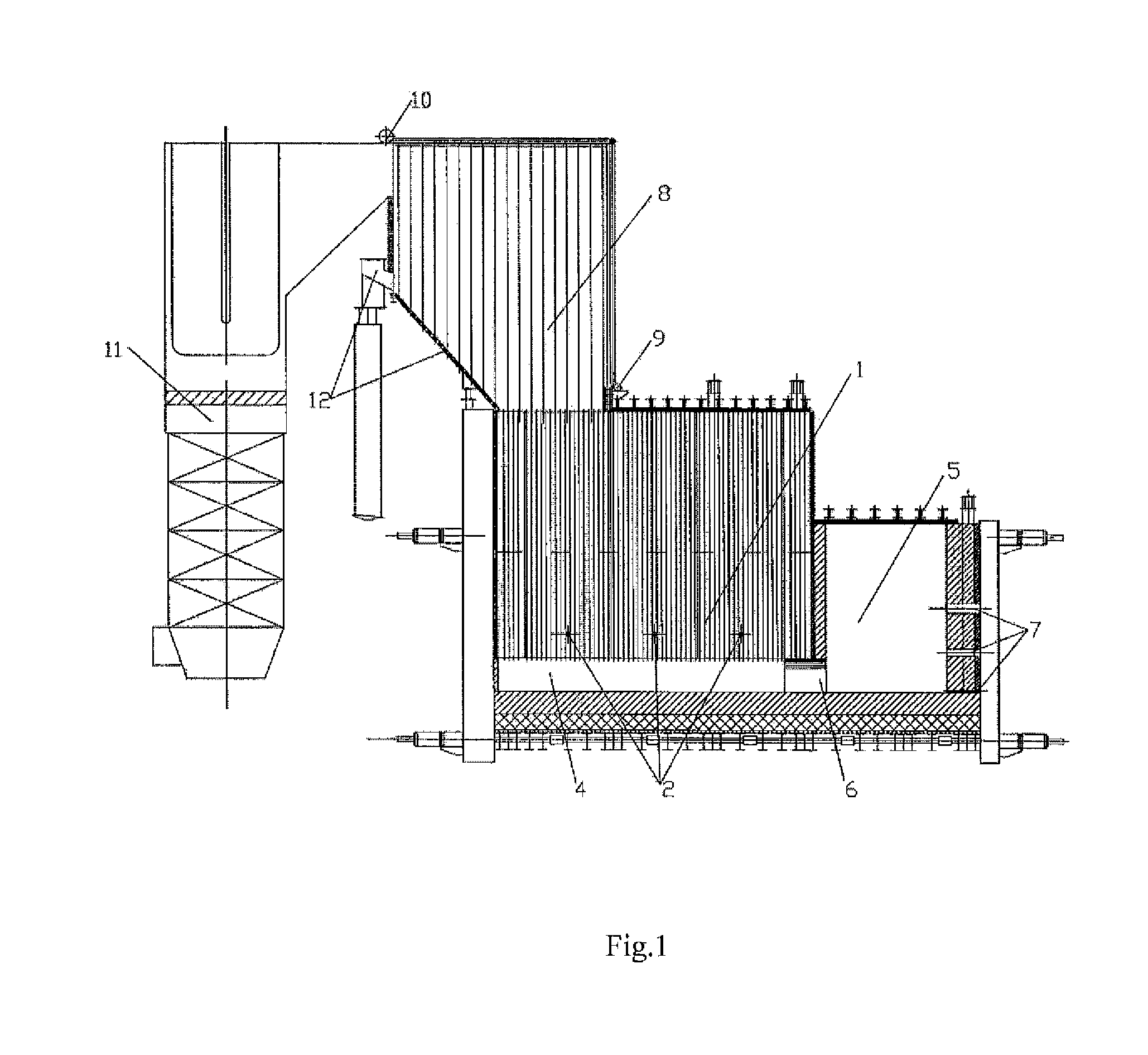

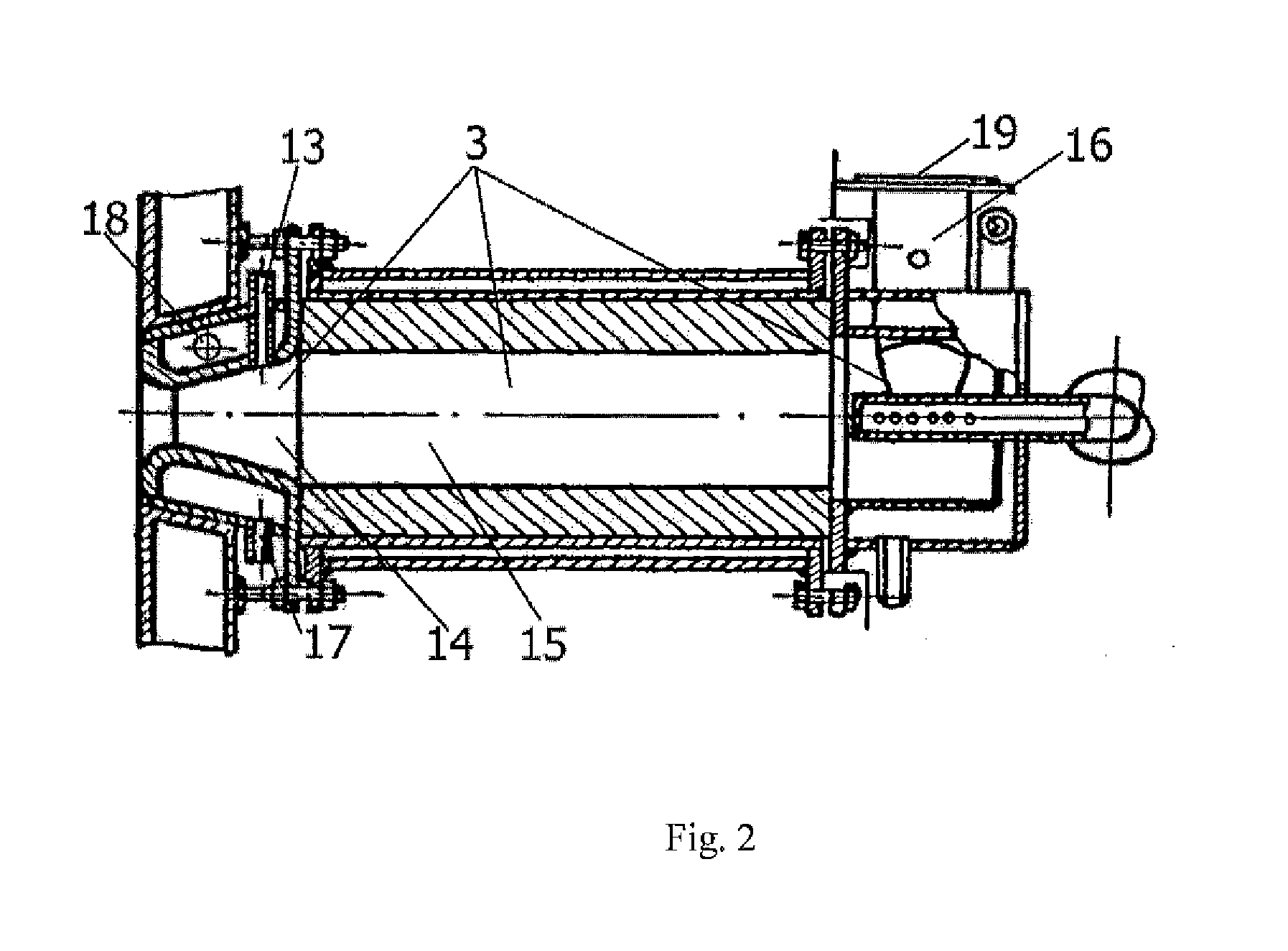

Glass melting method and molten glass layer bubbling glass melting furnace

InactiveUS20140318187A1Stable physical propertiesIncreased phase boundary areaCharging furnaceGlass furnace apparatusMelting tankGlass vessel

This invention relates to the continuous production of molten glass for further production of glassware and can be used for glass melting and obtaining glass semiproduct. The technical objective of this invention is to provide a method and a furnace for producing molten glass with stabilized physical properties due to an increased phase boundary area, higher temperature in the glass furnace bath and intensified mixing as well as due to a higher output of the glass furnace. Molten glass layer bubbling glass melting method comprising melting the glass layer in the first chamber of the furnace to the working level, further uninterrupted loading of large and small charge portions into the molten glass layer with simultaneous intense bubbling of the molten glass layer with high-temperature combustion products aiming at the formation of the maximum possible charge / molten glass phase boundary area and achieving a molten glass temperature of at least 1500° C., which conditions intensify the melting, silicate formation, vitrification and homogenizing processes, delivery of the chemically and thermally homogeneous molten glass produced by bubbling to the degassing and cooling section located under the bubbled molten glass layer, with an intense release from the molten glass layer of process gases that pass through the bubbled layer to the space above the layer where the process gases undergo primary cleaning and cooling, and the degassed molten glass is delivered to the further output section.

Owner:FEDERALNOE GOSUDARSTVENNOE AVTONOMNOE OBRAZOVATELNOE UCHREZHDENIE VYSSHEGO PROFESSIONALNOGO OBRAZOVANIJA NATSIONALNYJ ISSLEDOVATELSKIJ TEKHNOLOGICHESKIJ UNIVT MISIS

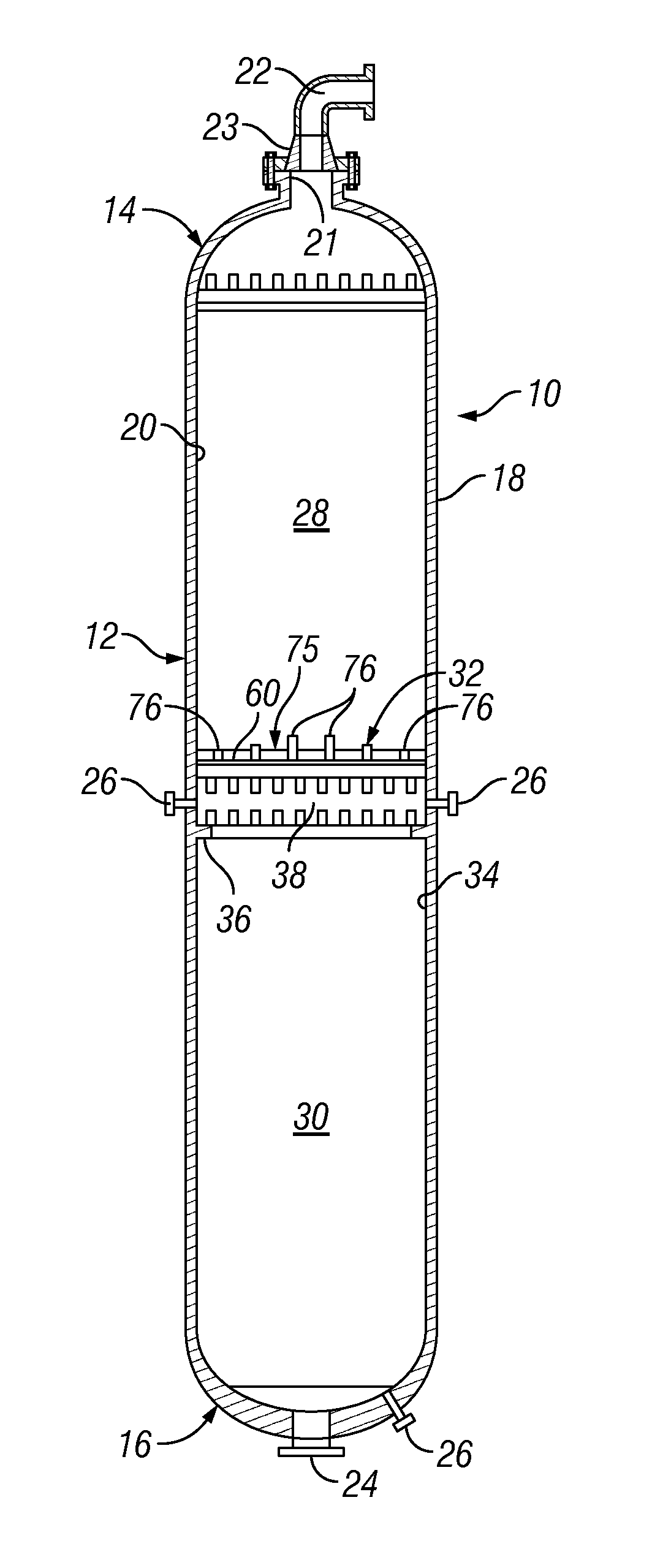

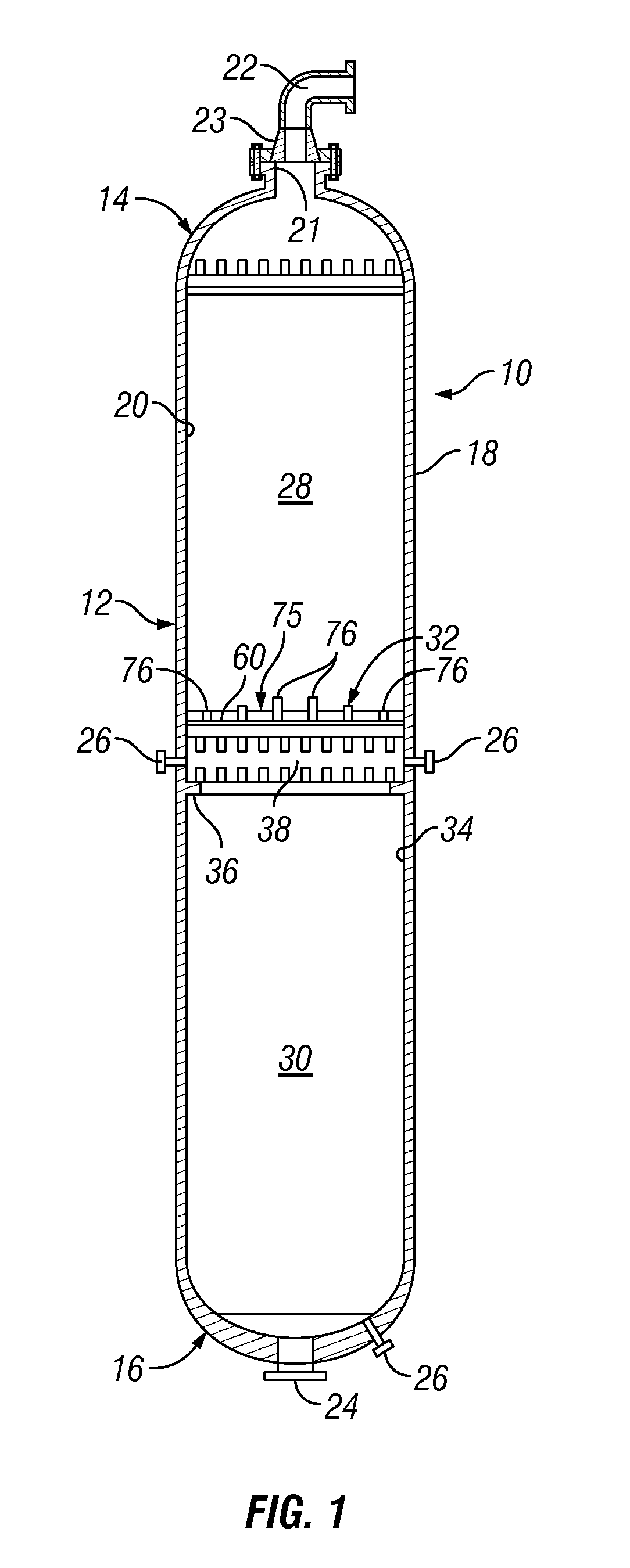

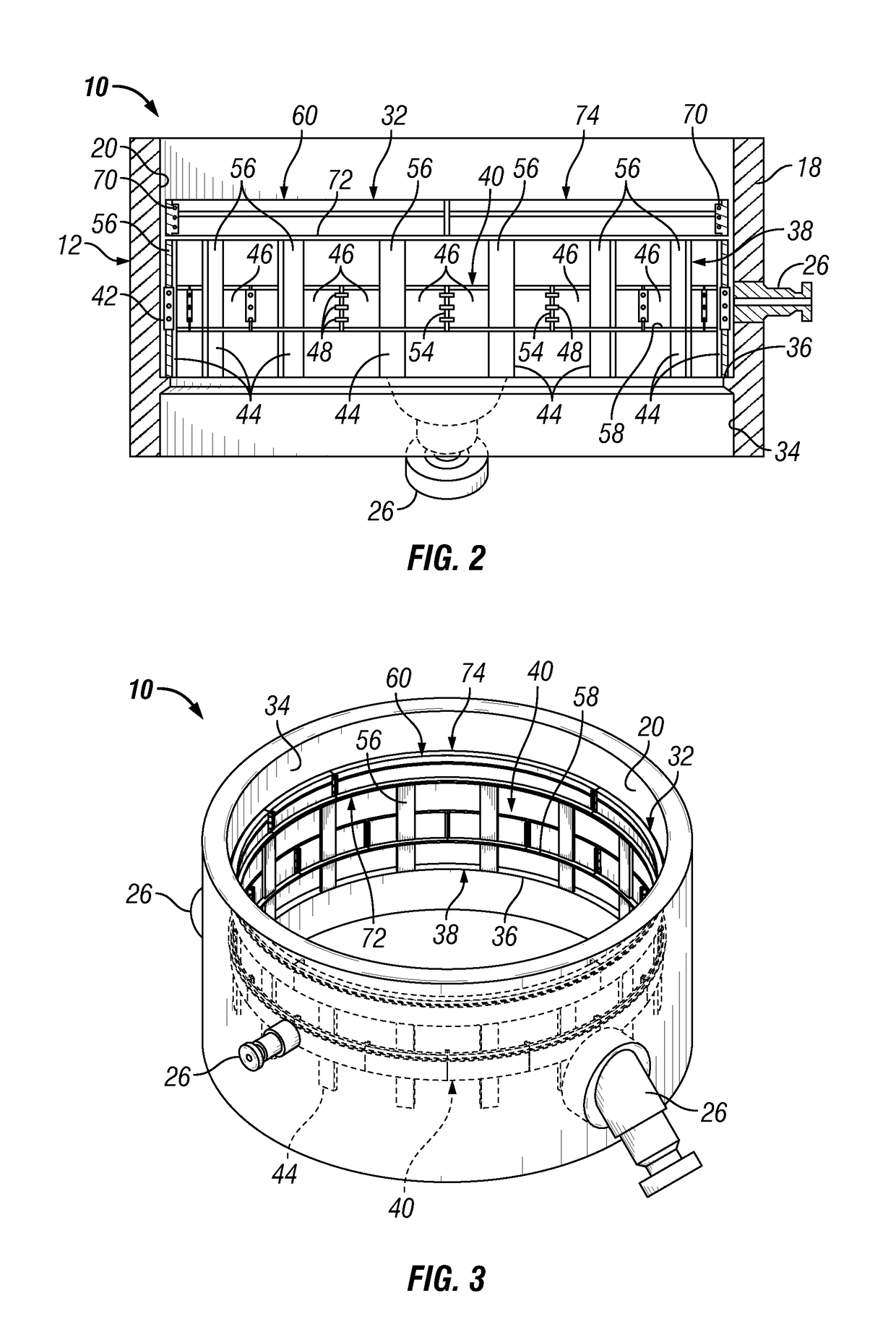

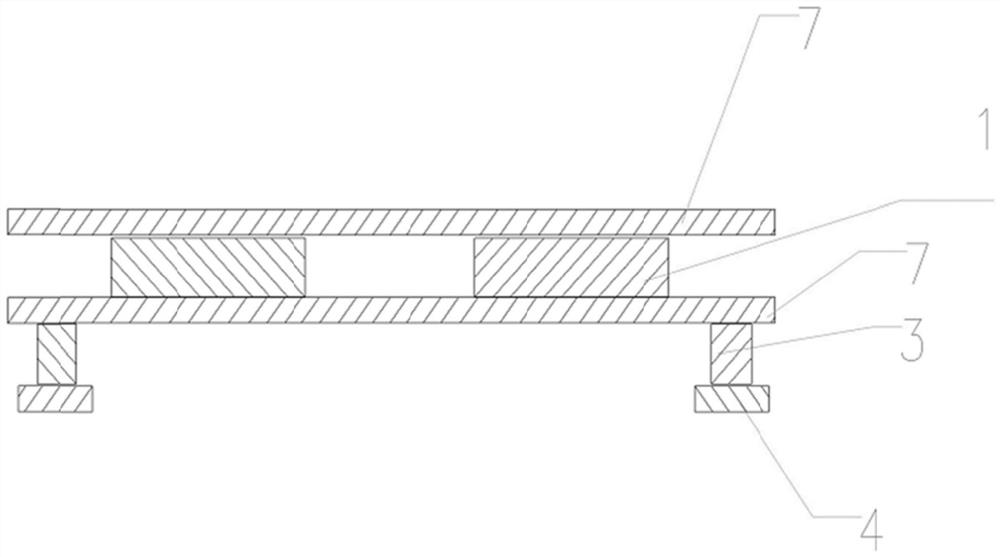

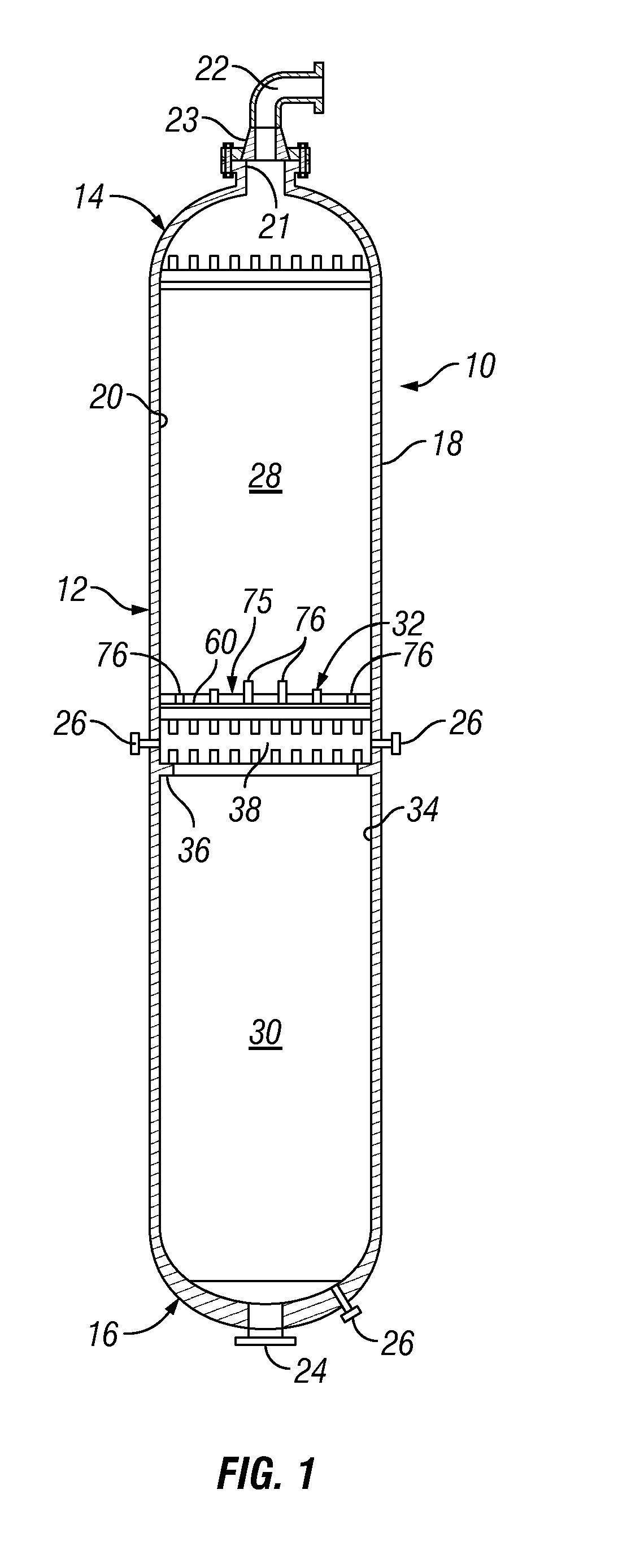

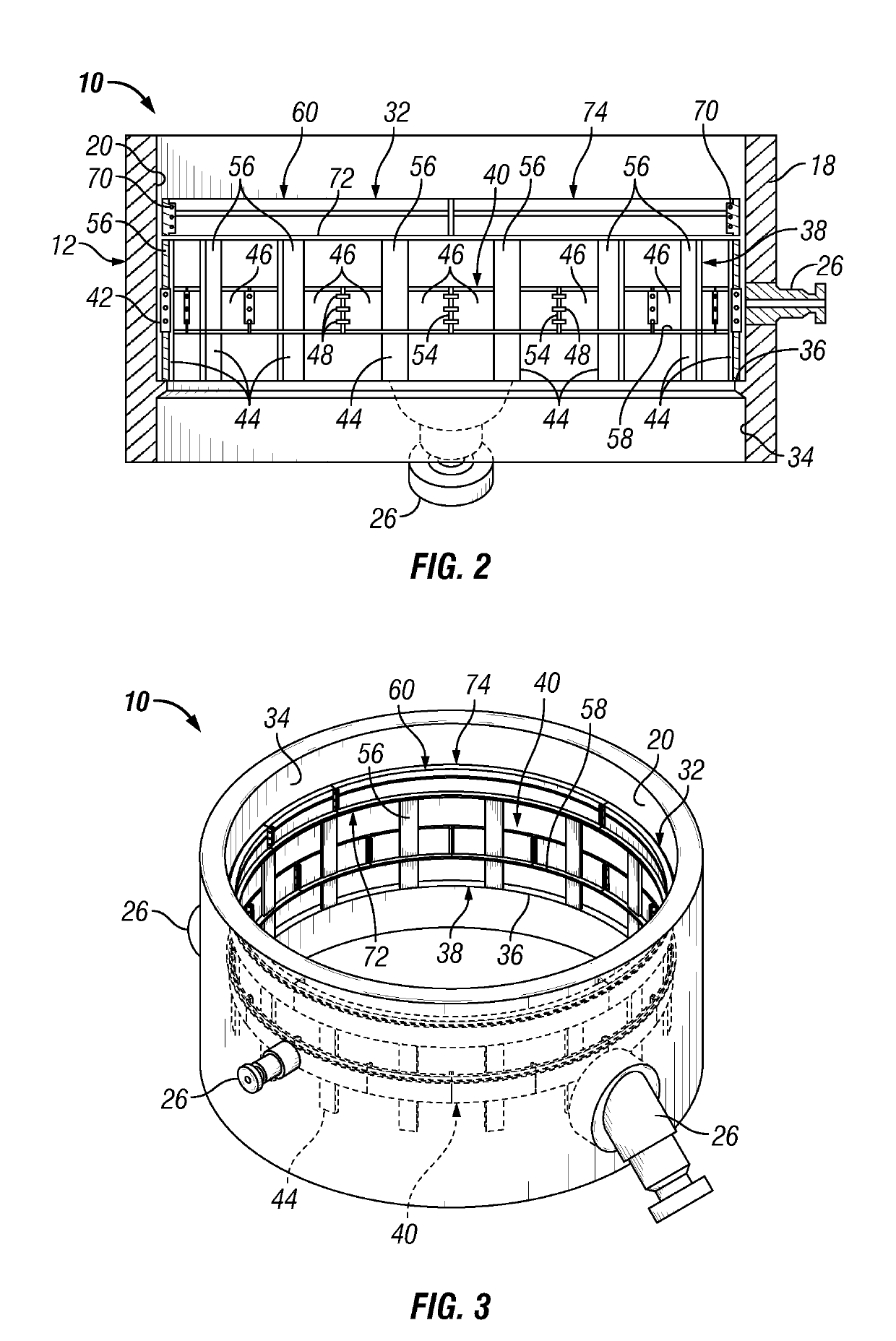

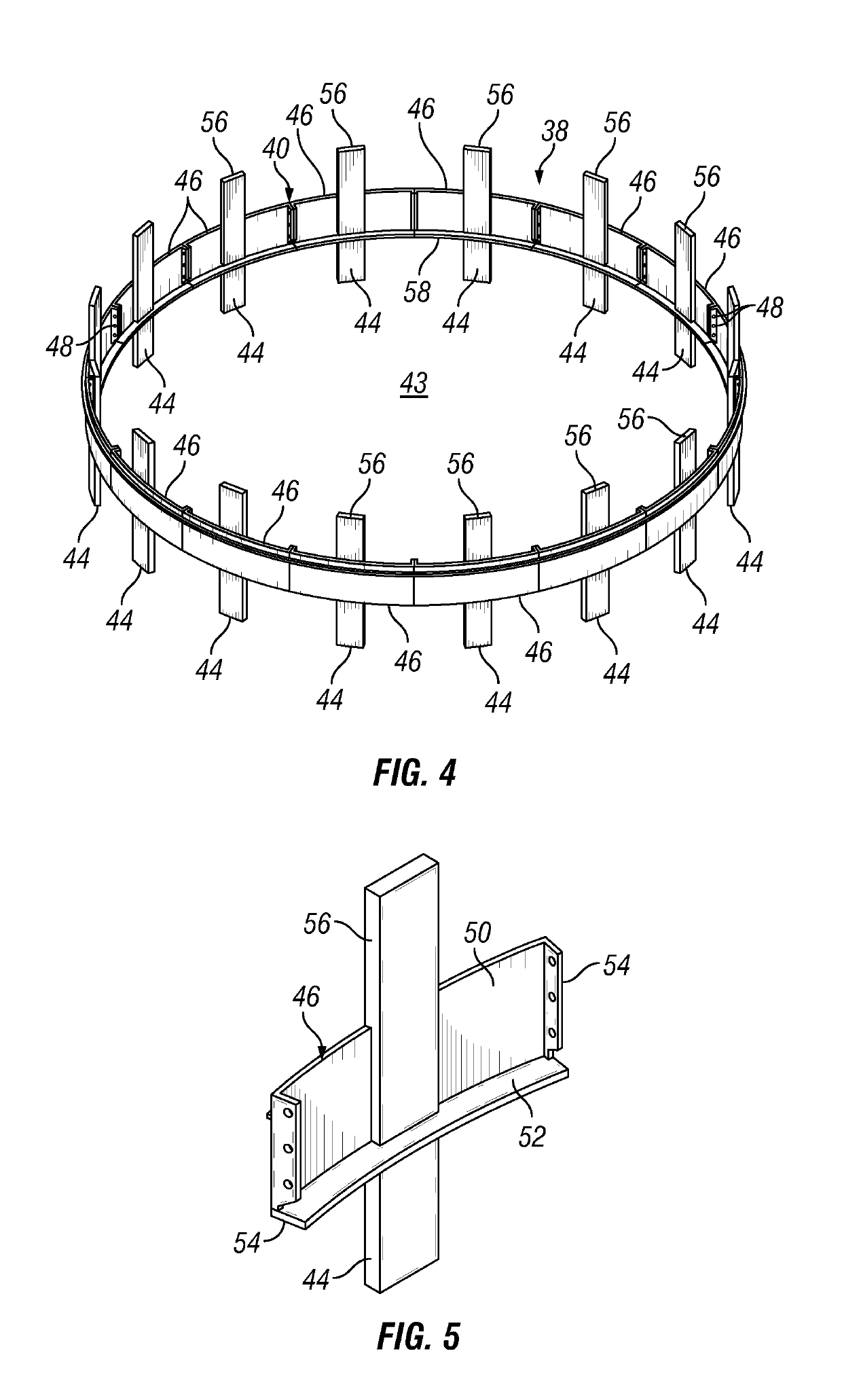

Tray support insers for chemical reactor vessels and methods of use

ActiveUS20170173547A1Heavy weightIntense heatMachine supportsHydrocarbon oil crackingEngineeringChemical reactor

Owner:SHELL USA INC

Cooking apparatus with downward opening lid

InactiveUS8936017B2Easy to useEliminate needDomestic stoves or rangesSolid materialTemperature controlEngineering

Provided is a cooking / grilling apparatus, primarily for outdoor use, providing smoking and / or direct or indirect heat cooking capability, and offering the user enhanced cooking flexibility, temperature control, safety and convenience of operation. The grill apparatus is unique in that it offers a downward opening lid that rotates, such as on rollers or a pivot mechanism, to a fully open position beneath the base plate of the cooking enclosure, and reverses to an upward rotation to re-close the cooking enclosure. Moreover, the grill apparatus offers a vertically adjustable cooking grate, controlled by a continuous loop cable, moving over a set of pulleys, thereby reliably controlling the height of the cooking grate when affixed to a crank on the outer surface of the grill, wherein movement of the grate can also be locked in place.

Owner:HOLDO BAGGOTT MAX ALEJANDRO

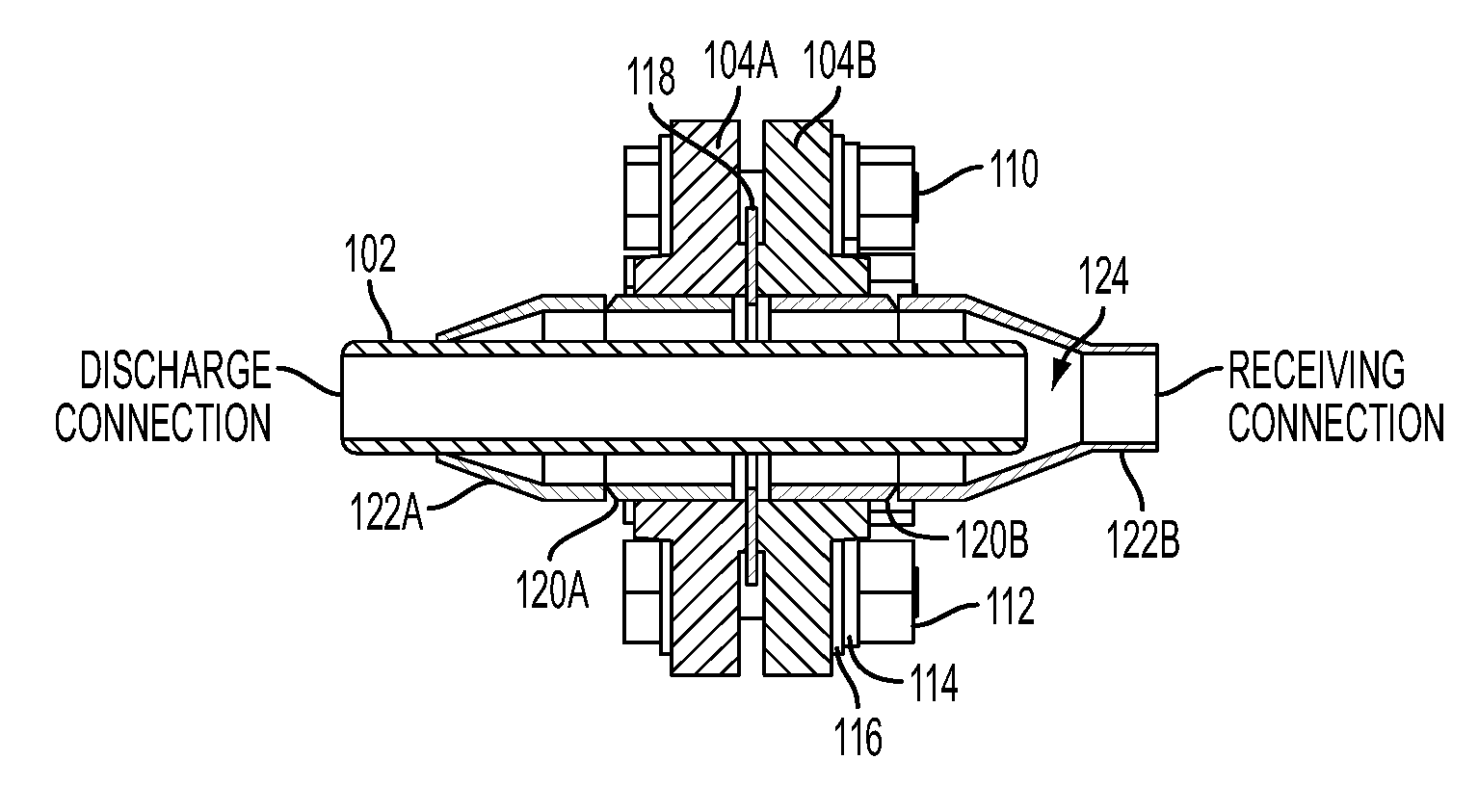

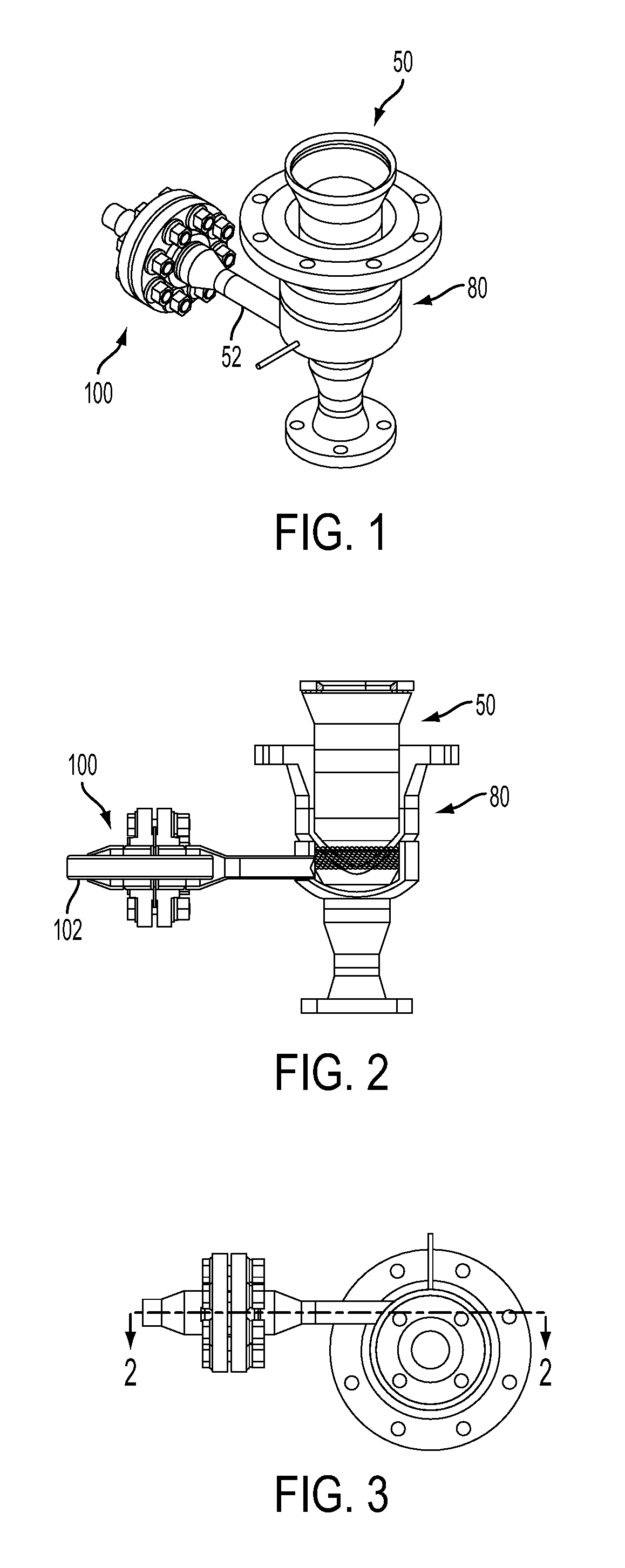

Joint with heat-shielding element

InactiveUS20120280496A1Enhanced convective heat transferGreat surface exposureSleeve/socket jointsFlanged jointsHeat sensitiveReducer

A joint for connecting pipe sections is provided in which a portion of the joint includes a first pipe section, a first reducer fitting section, a first flange attached to the first pipe section and having holes for receiving fasteners, and a fluid conduit (such as a pipe sleeve) positioned inside at least a portion of the first pipe section and the first reducer fitting, wherein the fluid conduit forms an annular space defined by the outside surface of the fluid conduit wall and the inner walls of the first pipe section and the first reducer fitting. The annular space separates the heat-sensitive flange, a flange gasket, and the flange fasteners from high-temperature fluids flowing in the fluid conduit, thereby allowing for the use of lower rated and less expensive components than would otherwise be required in a direct heat contacting arrangement.

Owner:BLUESCAPE CLEAN FUELS LLC

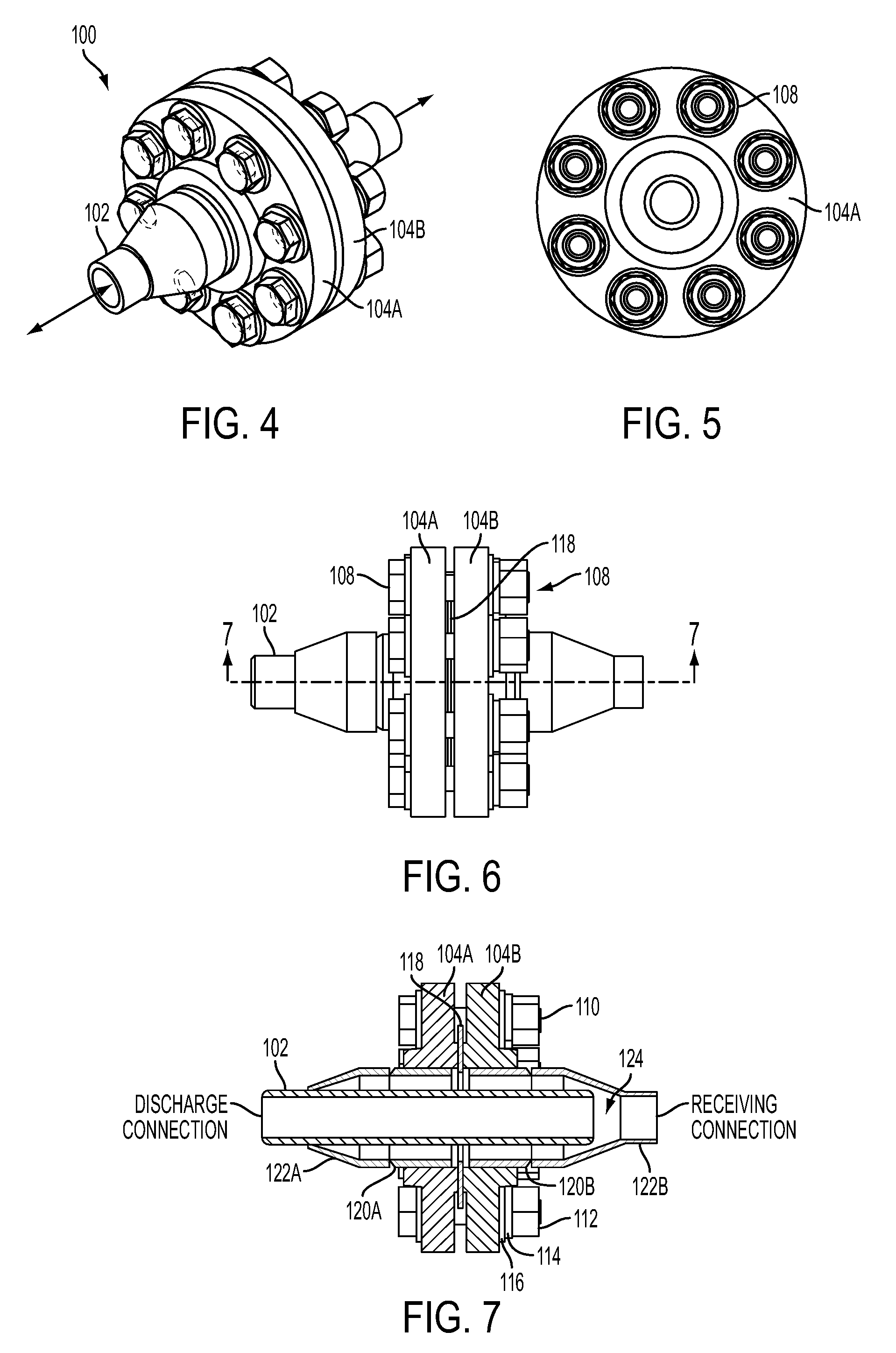

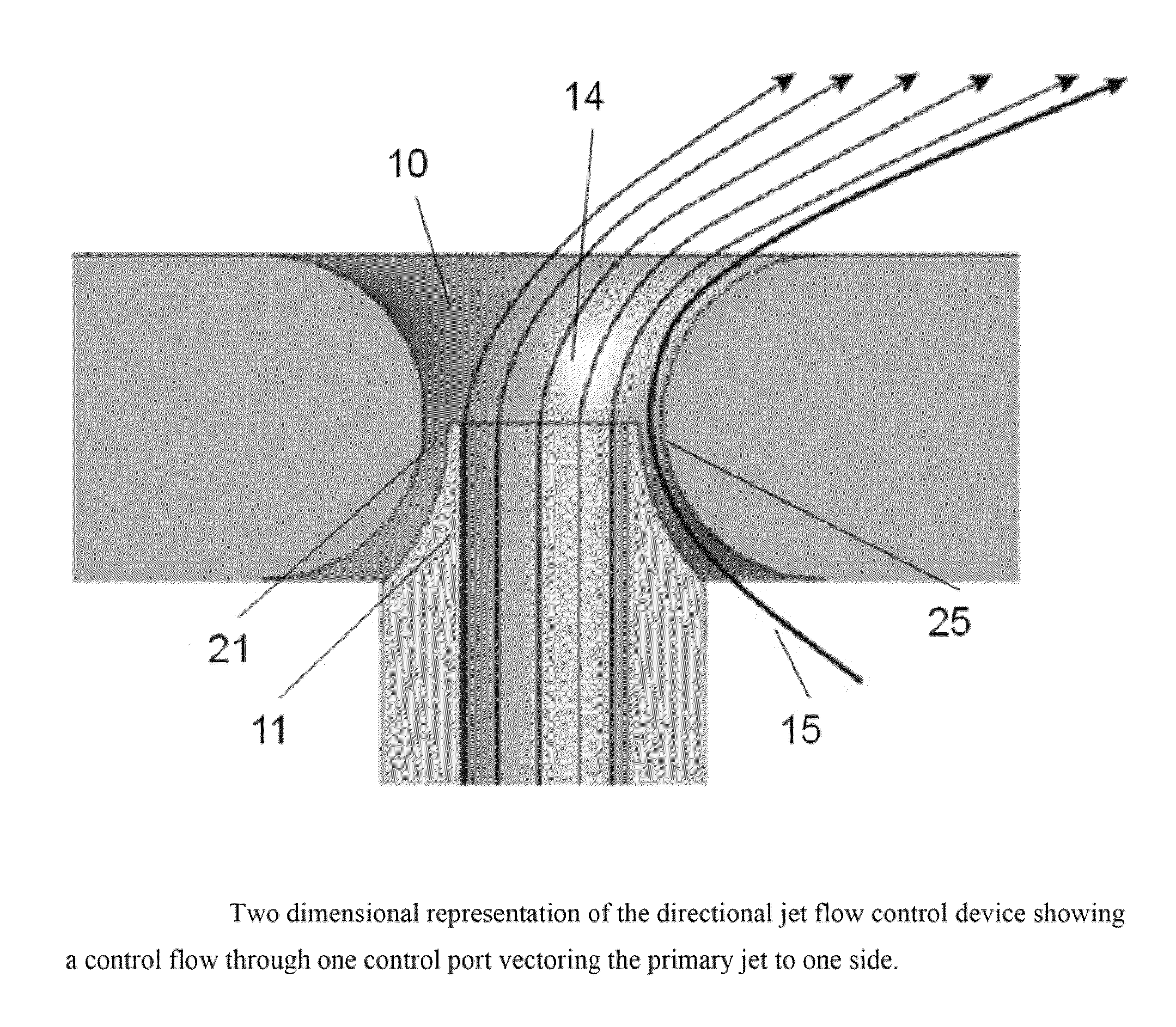

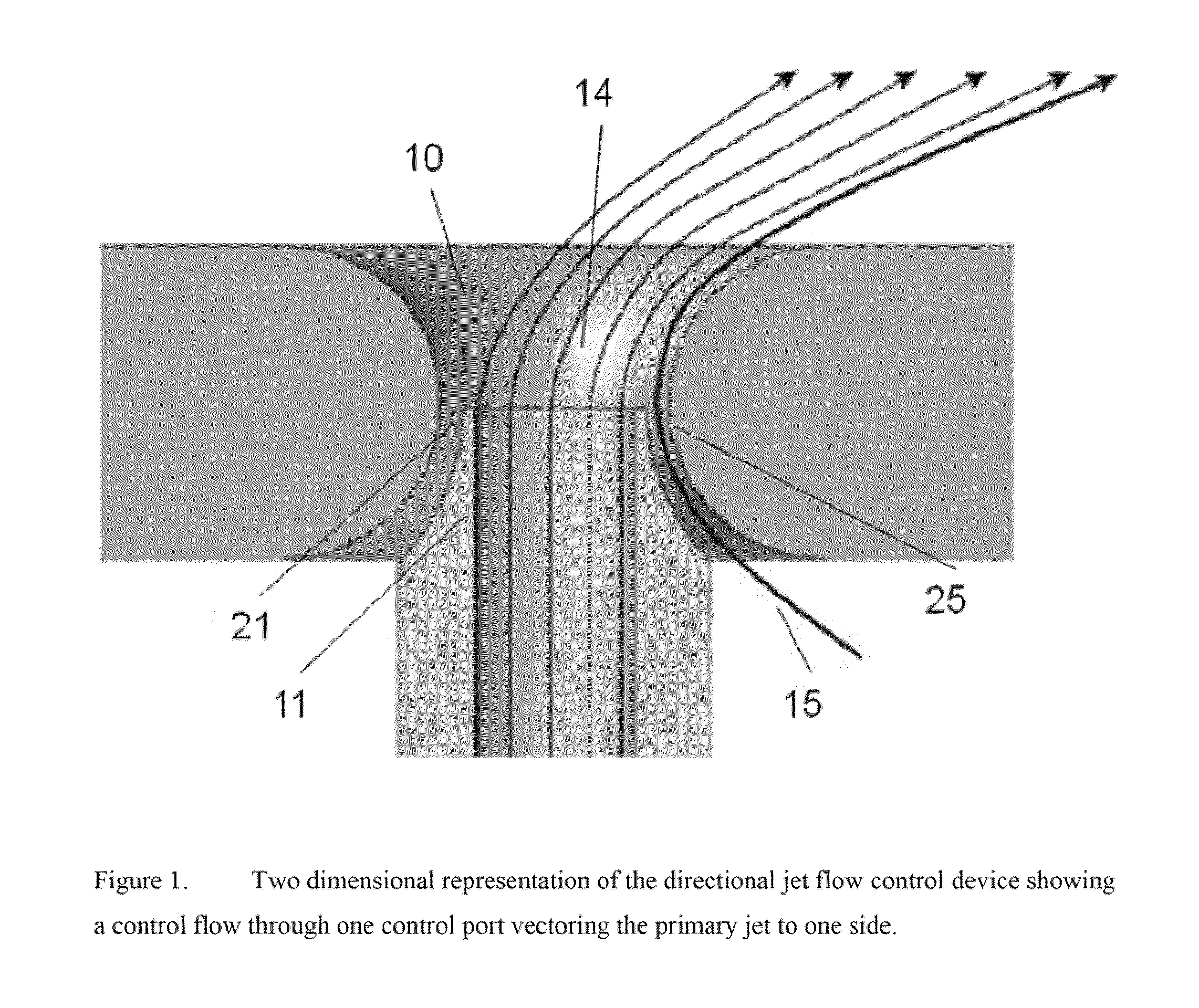

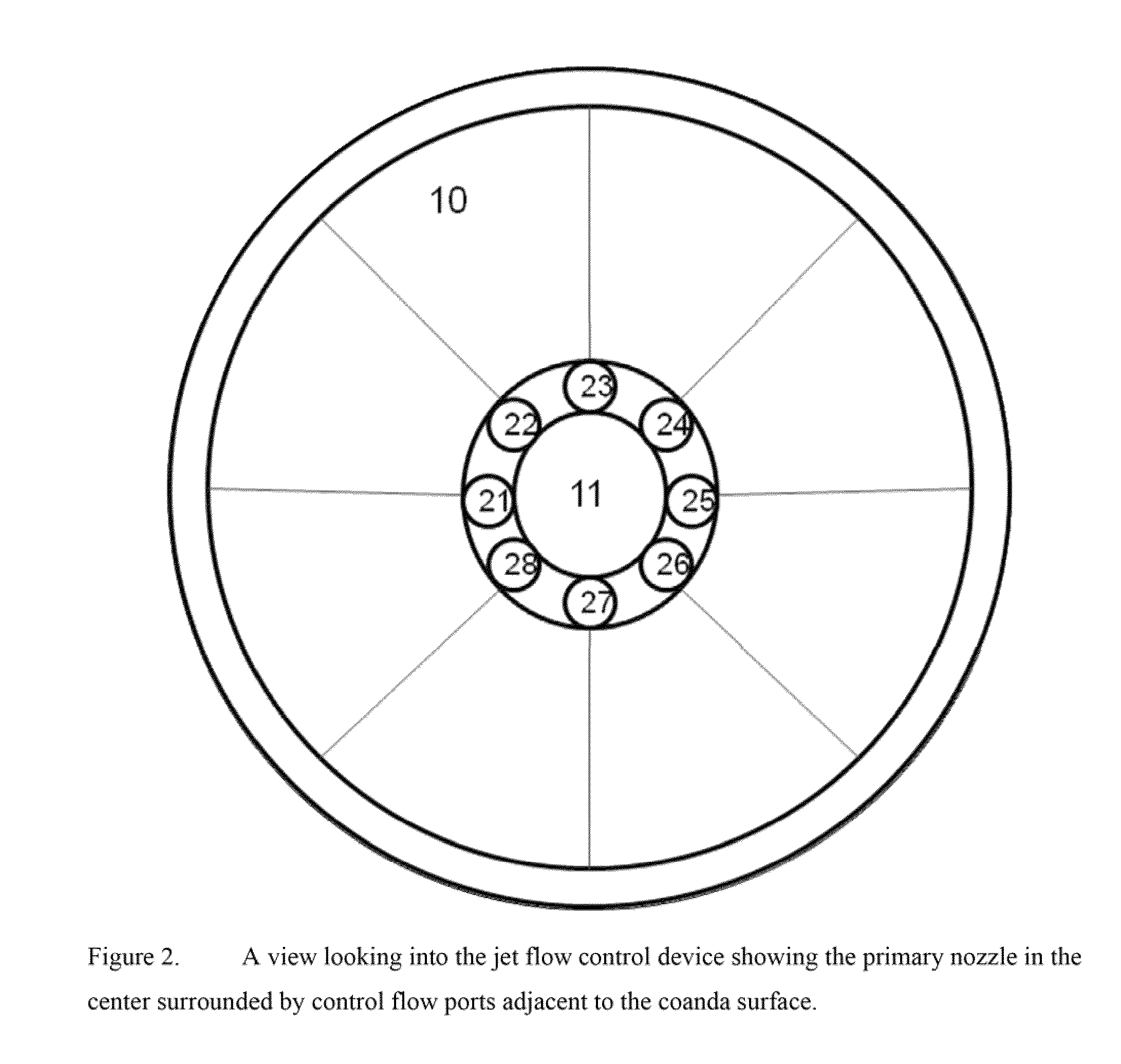

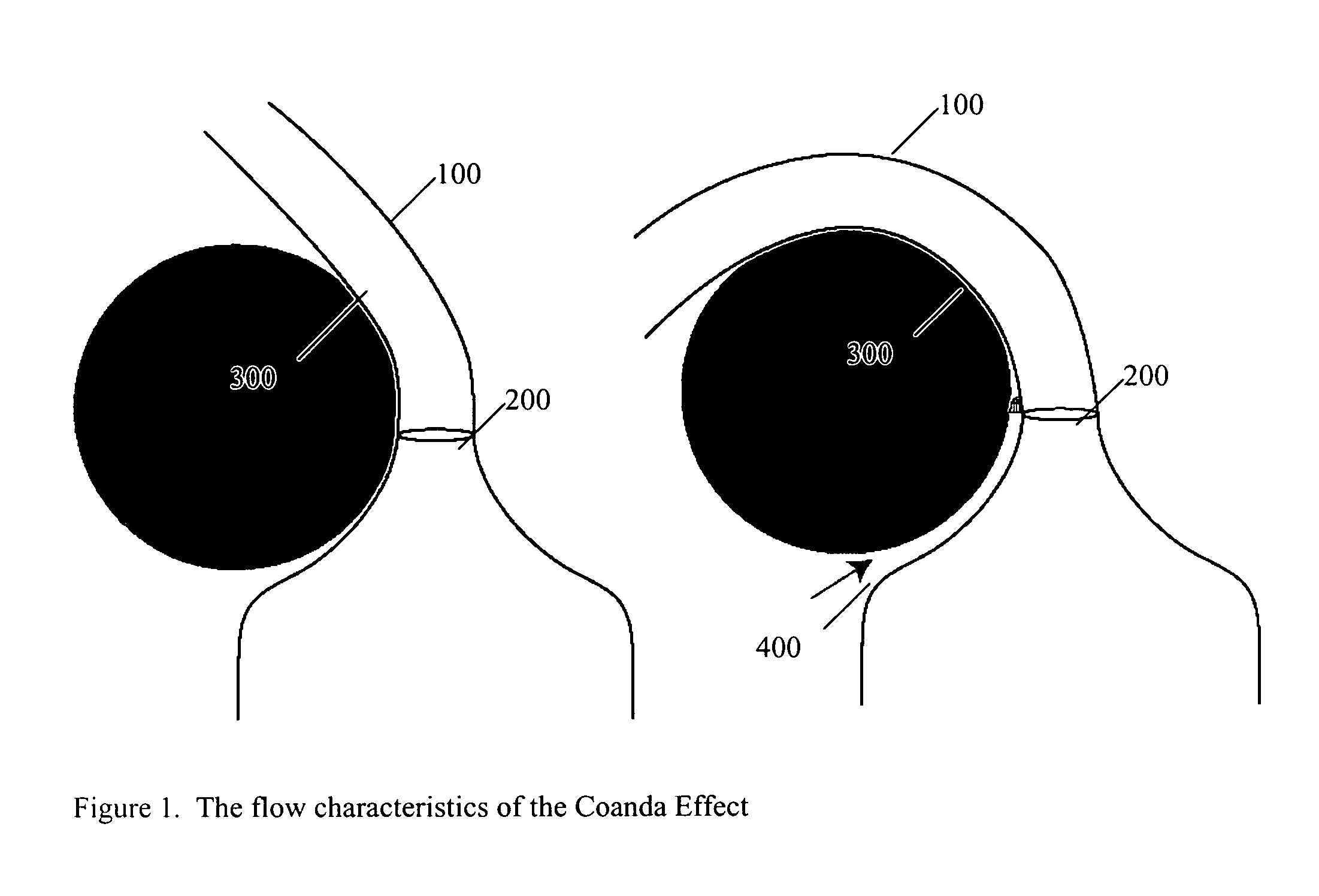

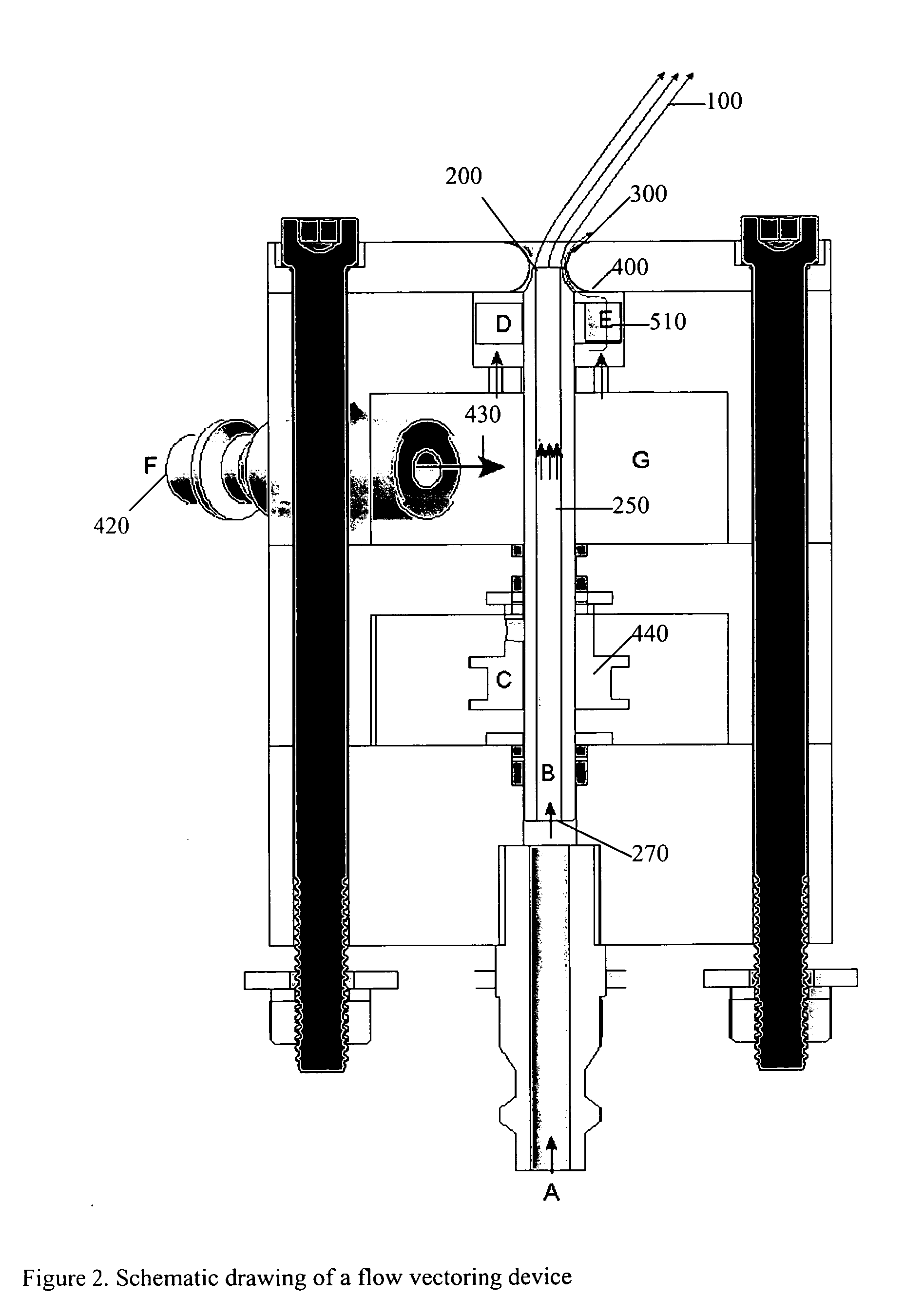

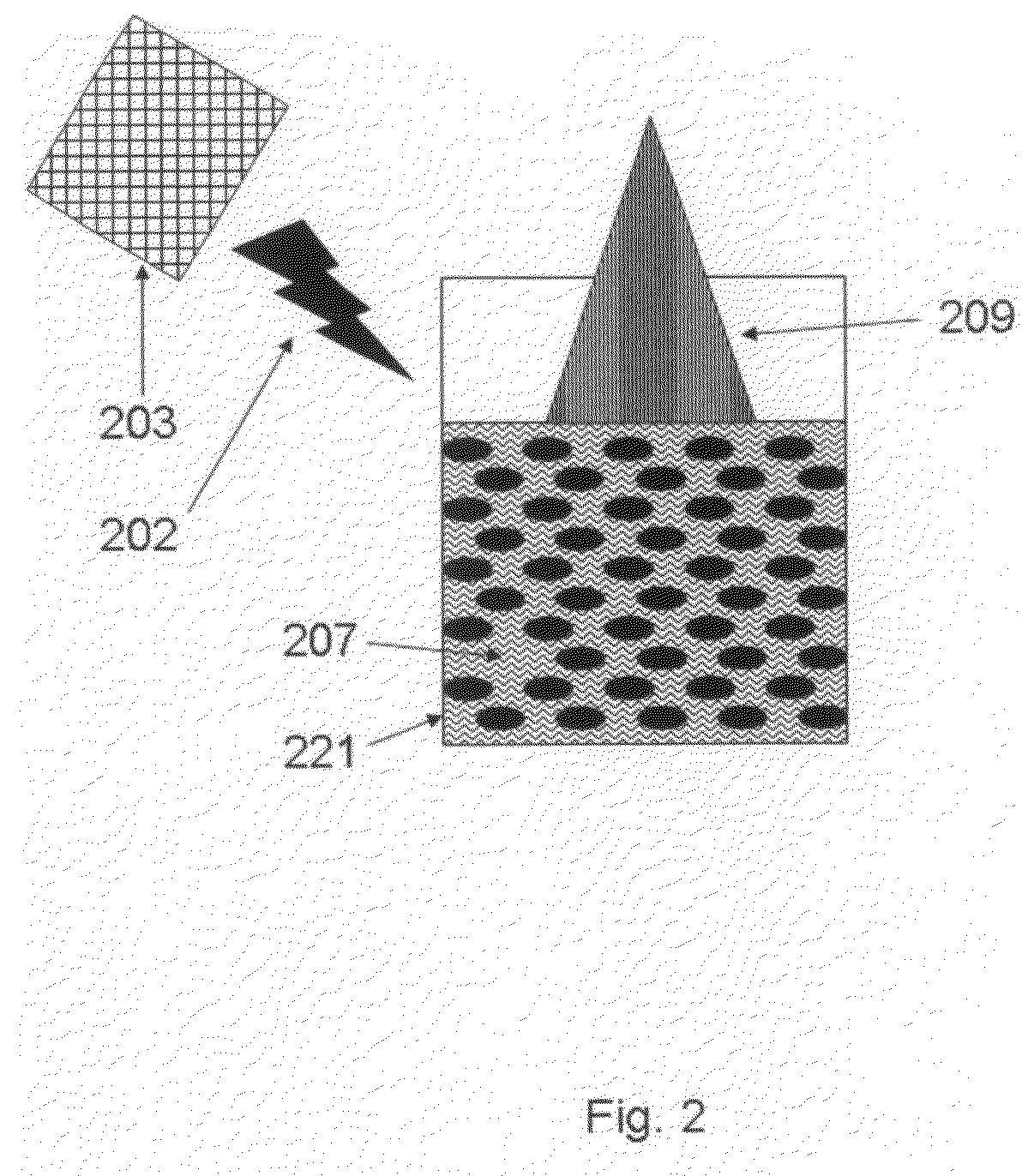

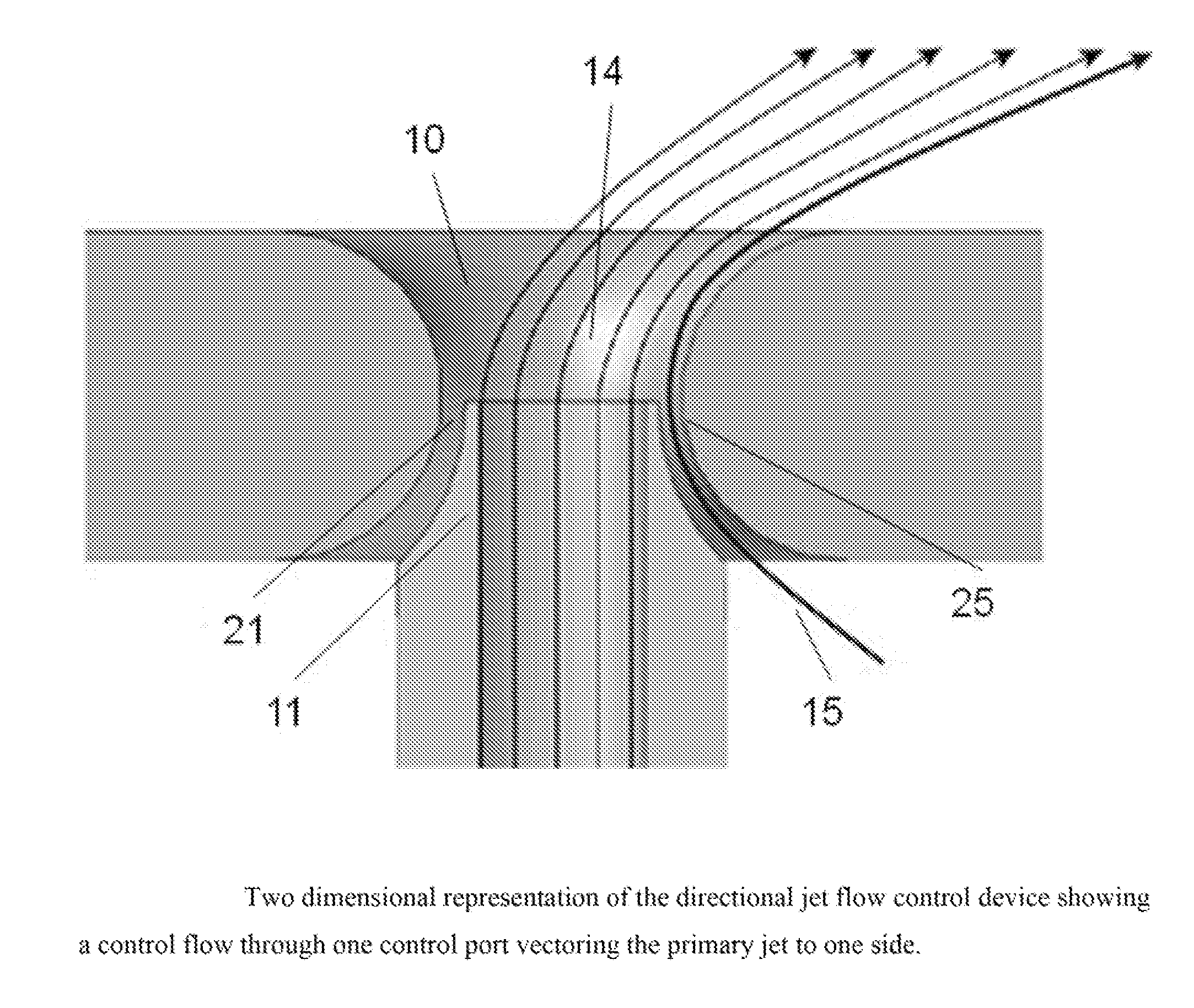

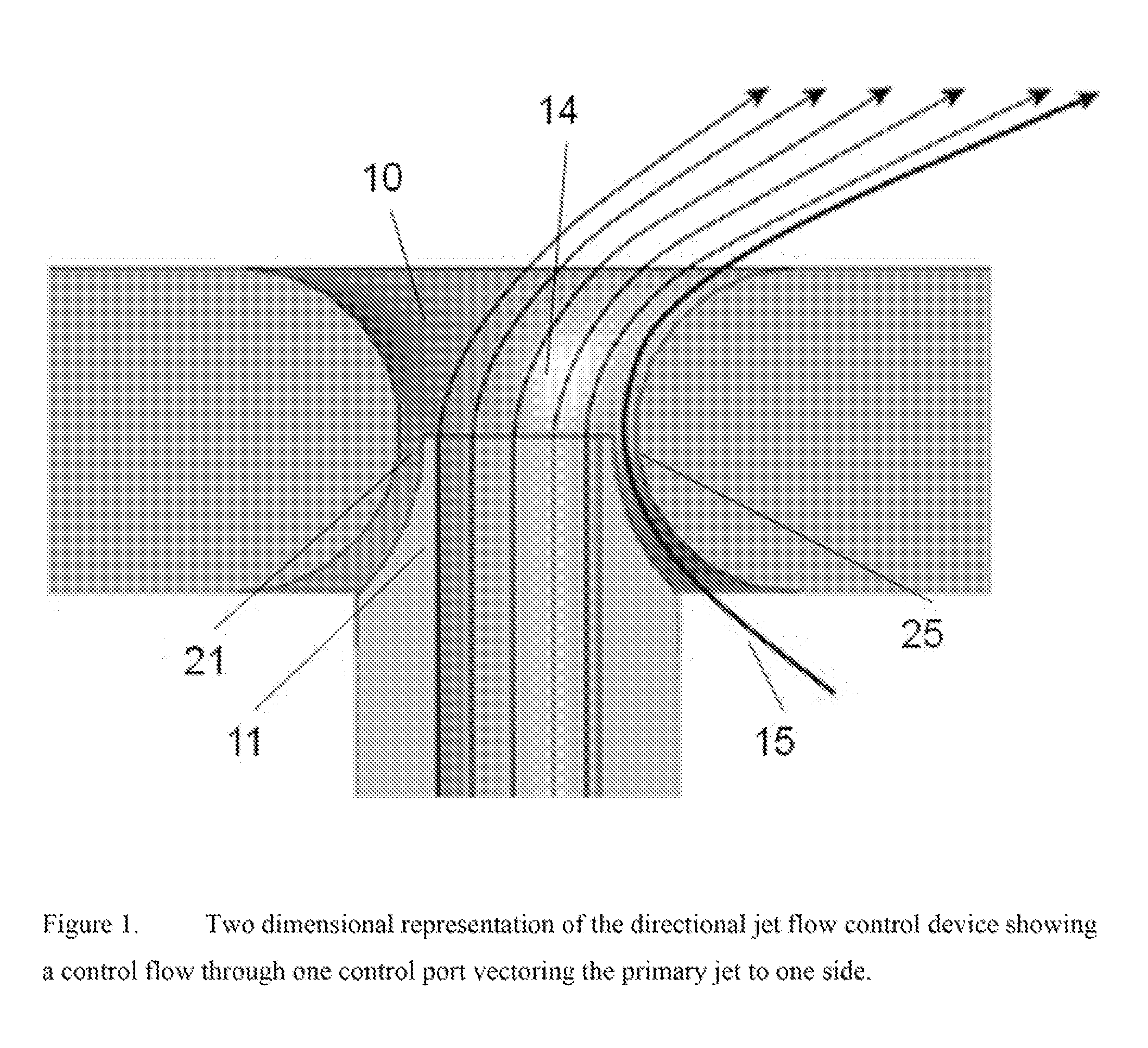

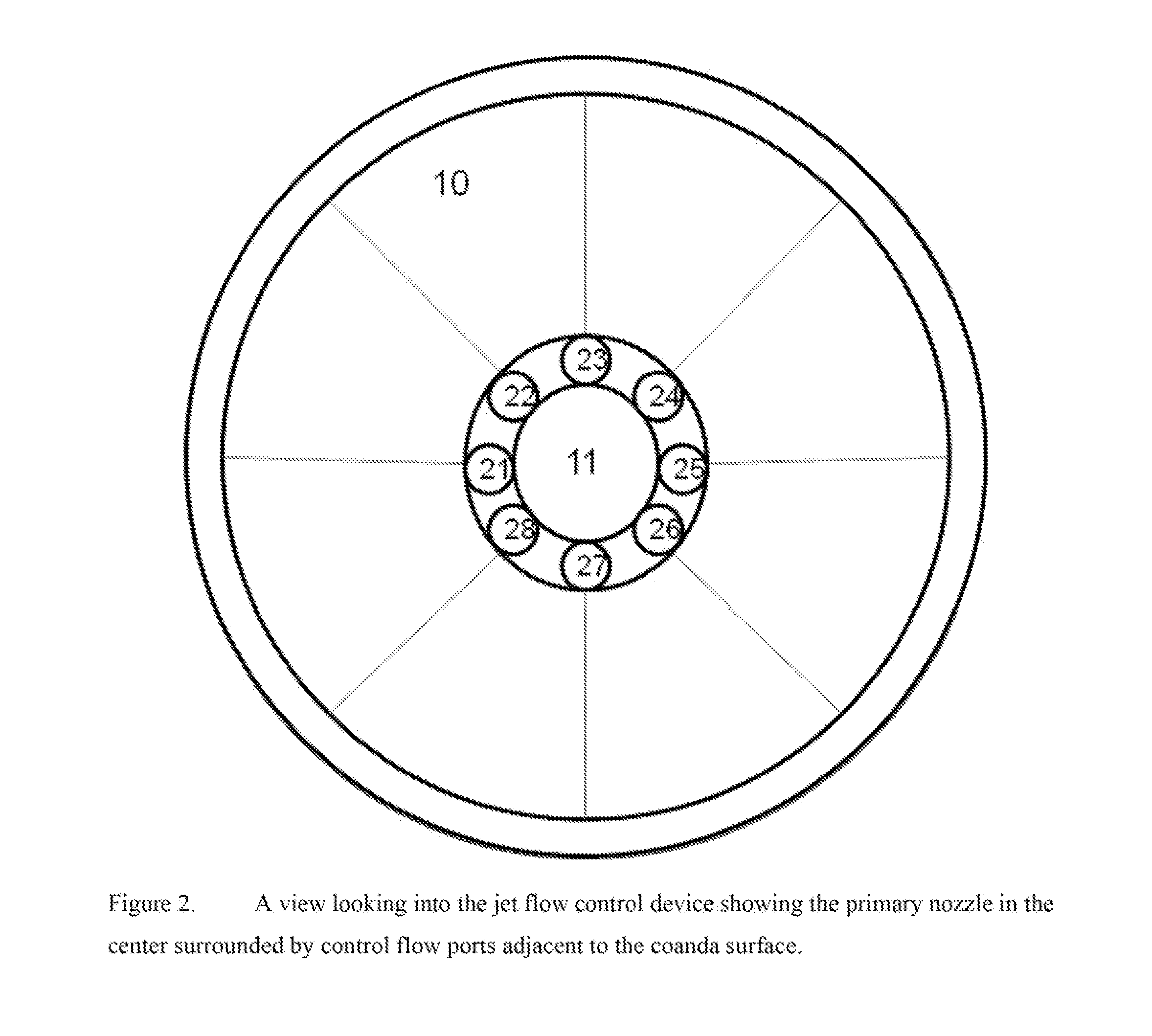

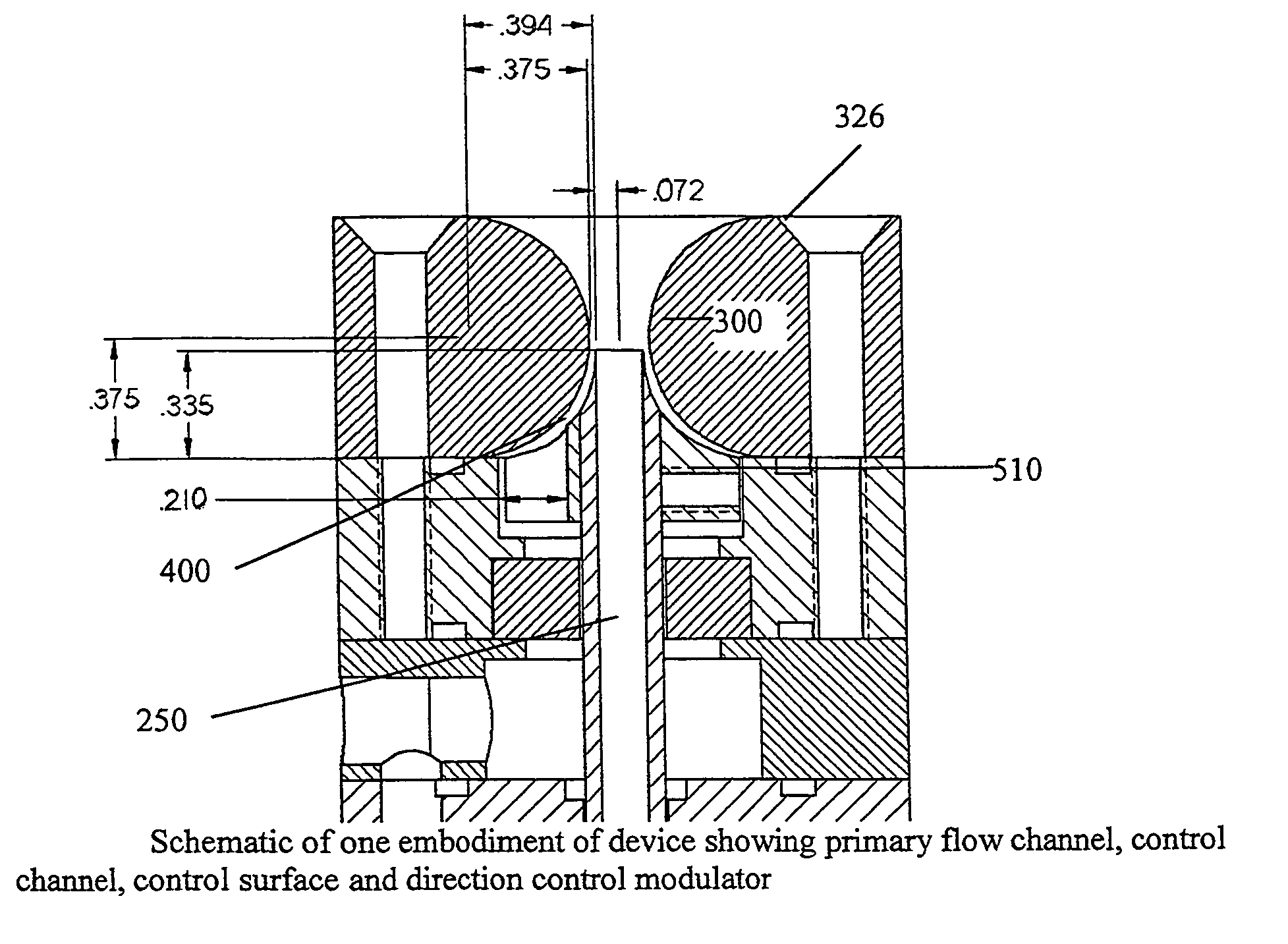

Directional jet flow control

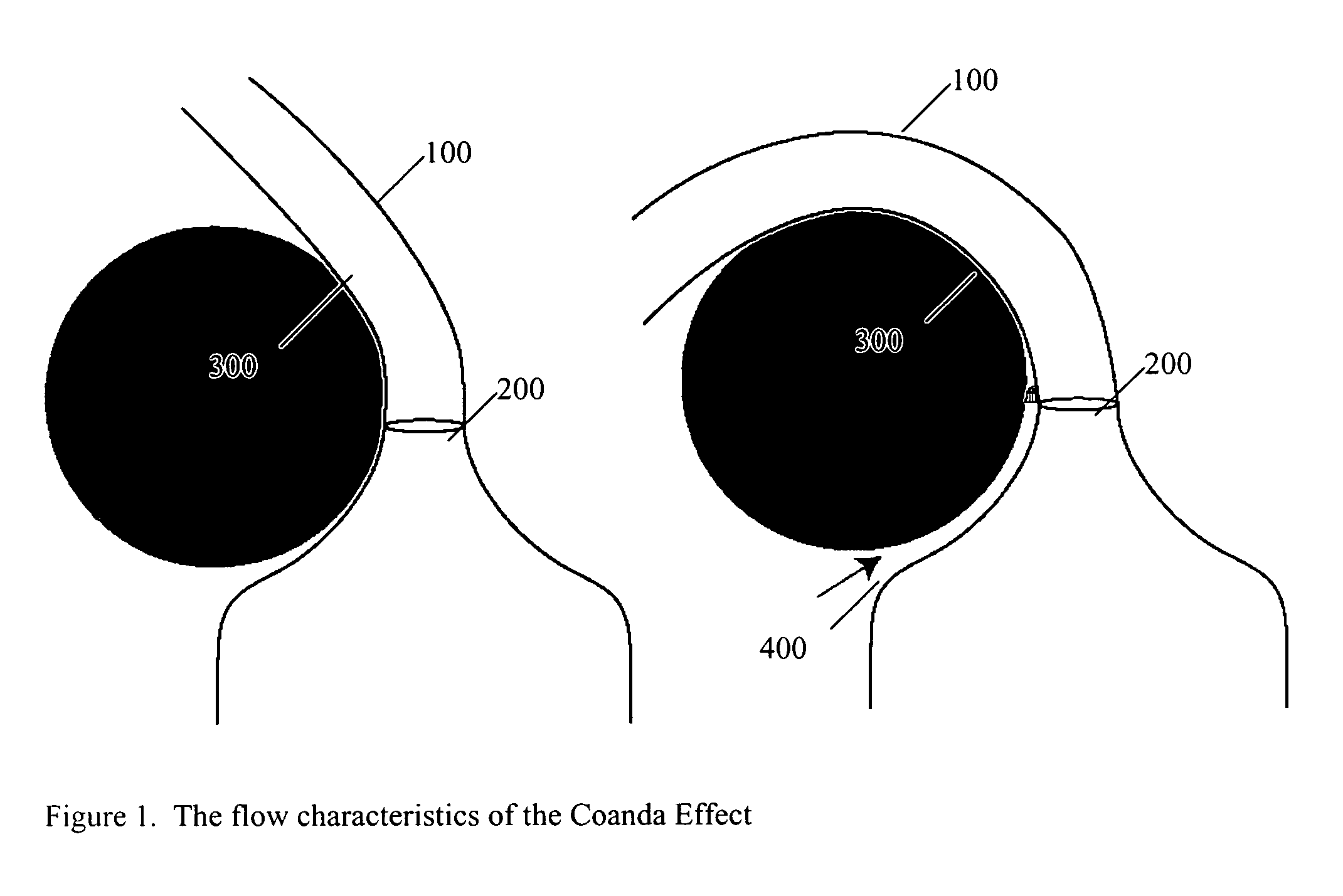

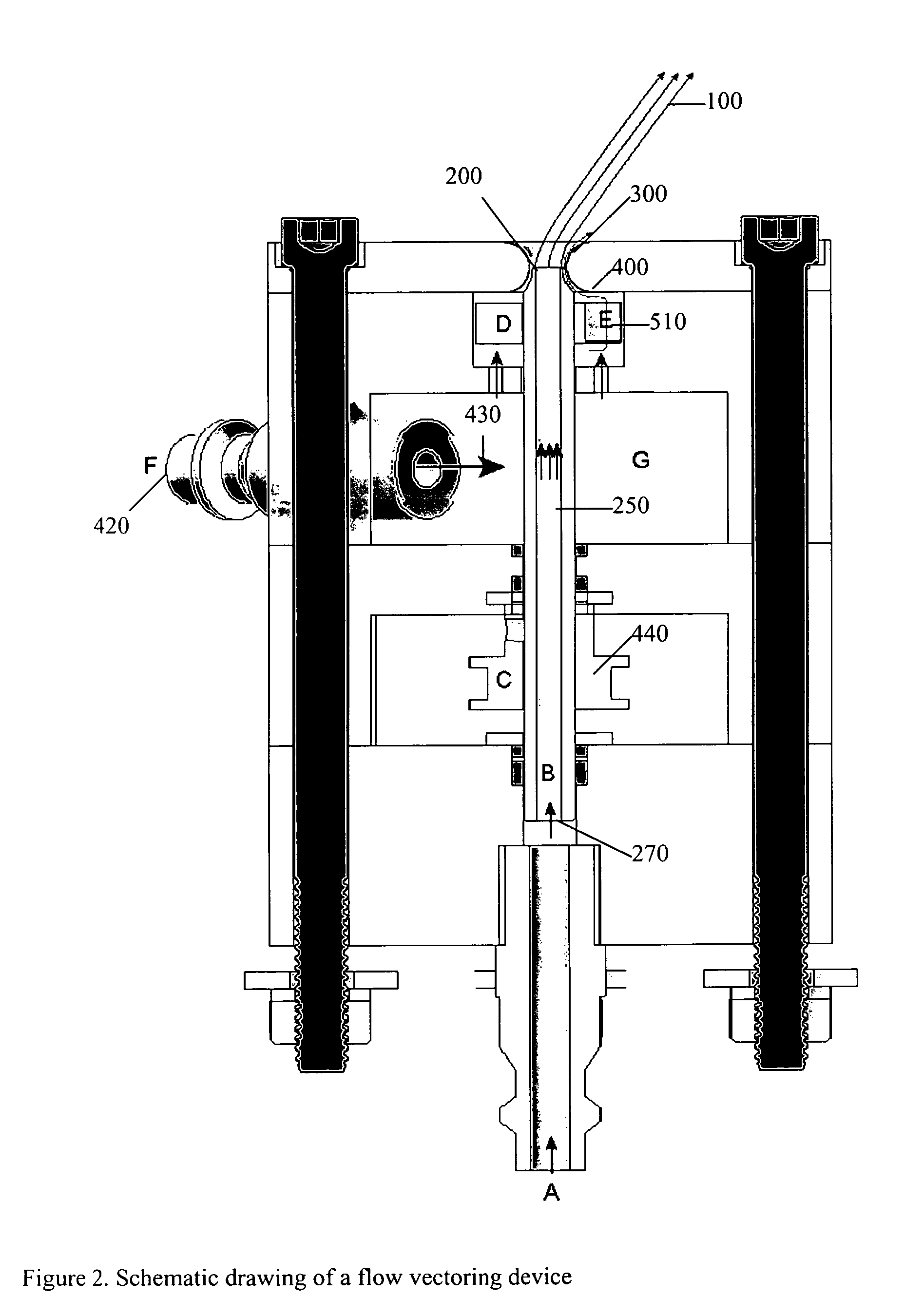

InactiveUS8297529B2Enhanced Coanda effectHigh frequencyMolten spray coatingSpray nozzlesControl flowJet flow

A device is disclosed that uses a flow-control methodology to control sprays at very high precision and frequency. The device is based on an enhanced Coanda effect. The control flow is selectively applied to the region in which we desire the jet to vector and control the profile (width) of the jet. The control flow is introduced through multiple control flow ports surrounding the primary nozzle and adjacent to the Coanda surface. By selectively opening and closing different control flow ports the motion and profile of the jet can be controlled.

Owner:UTAH STATE UNIVERSITY

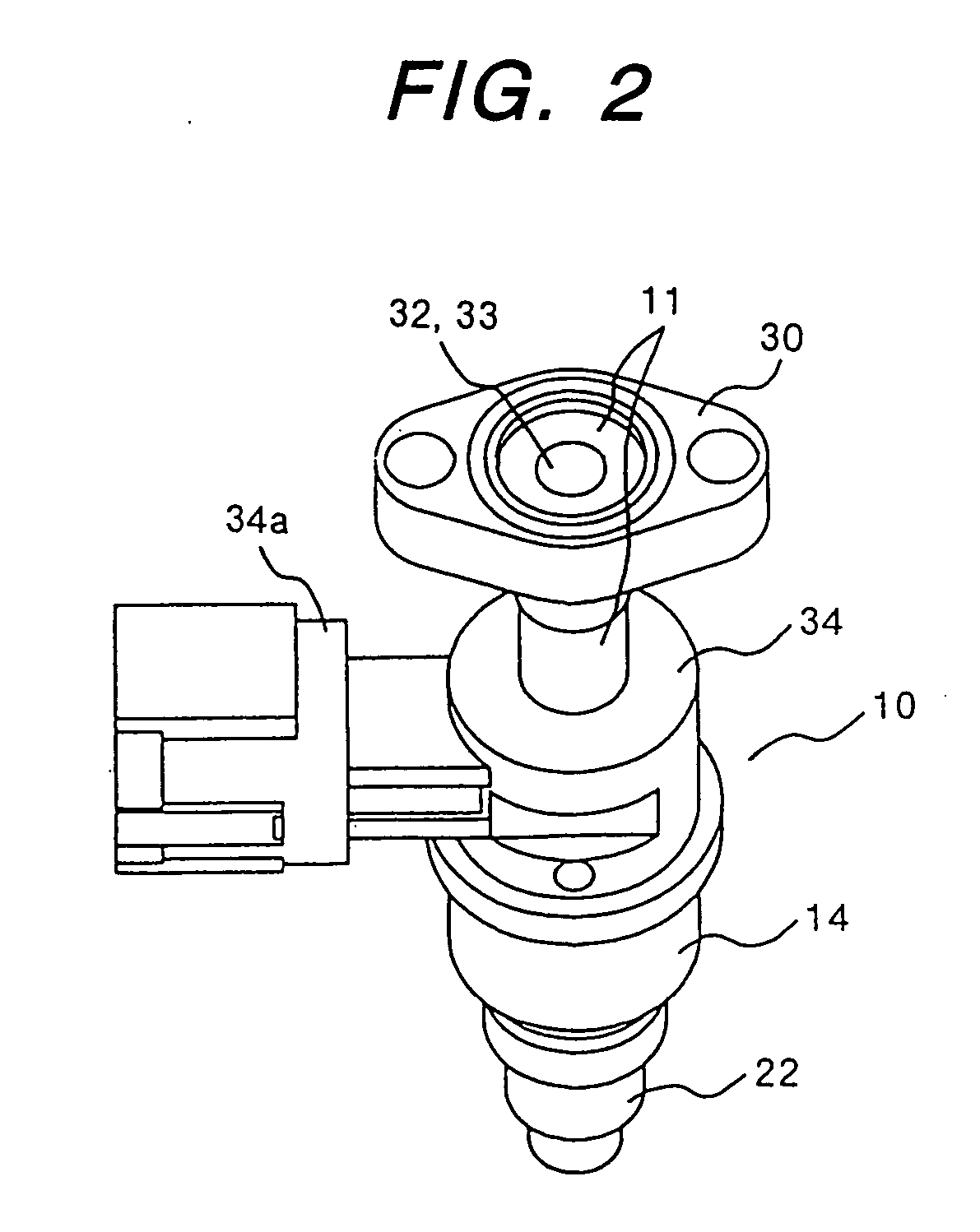

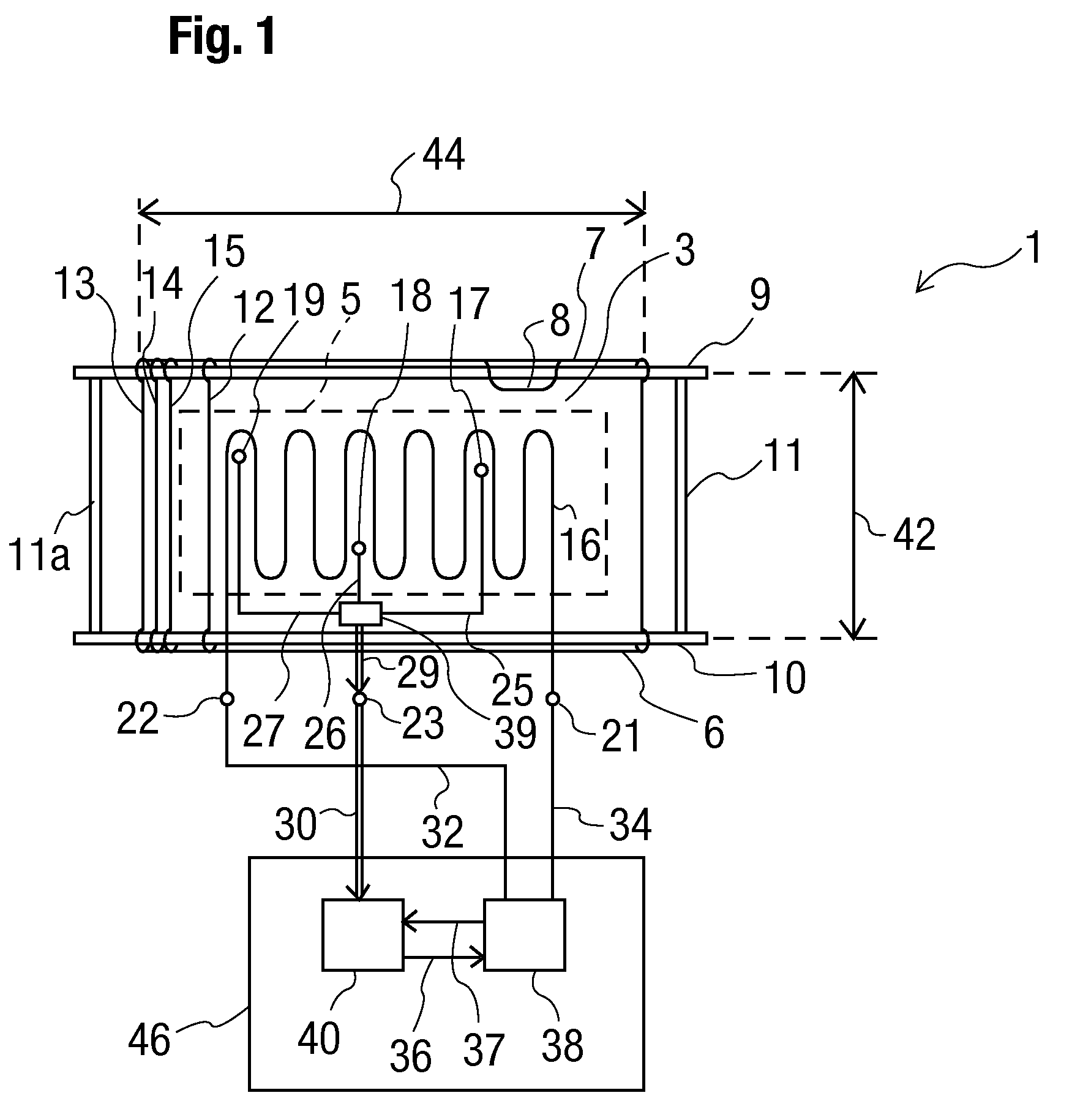

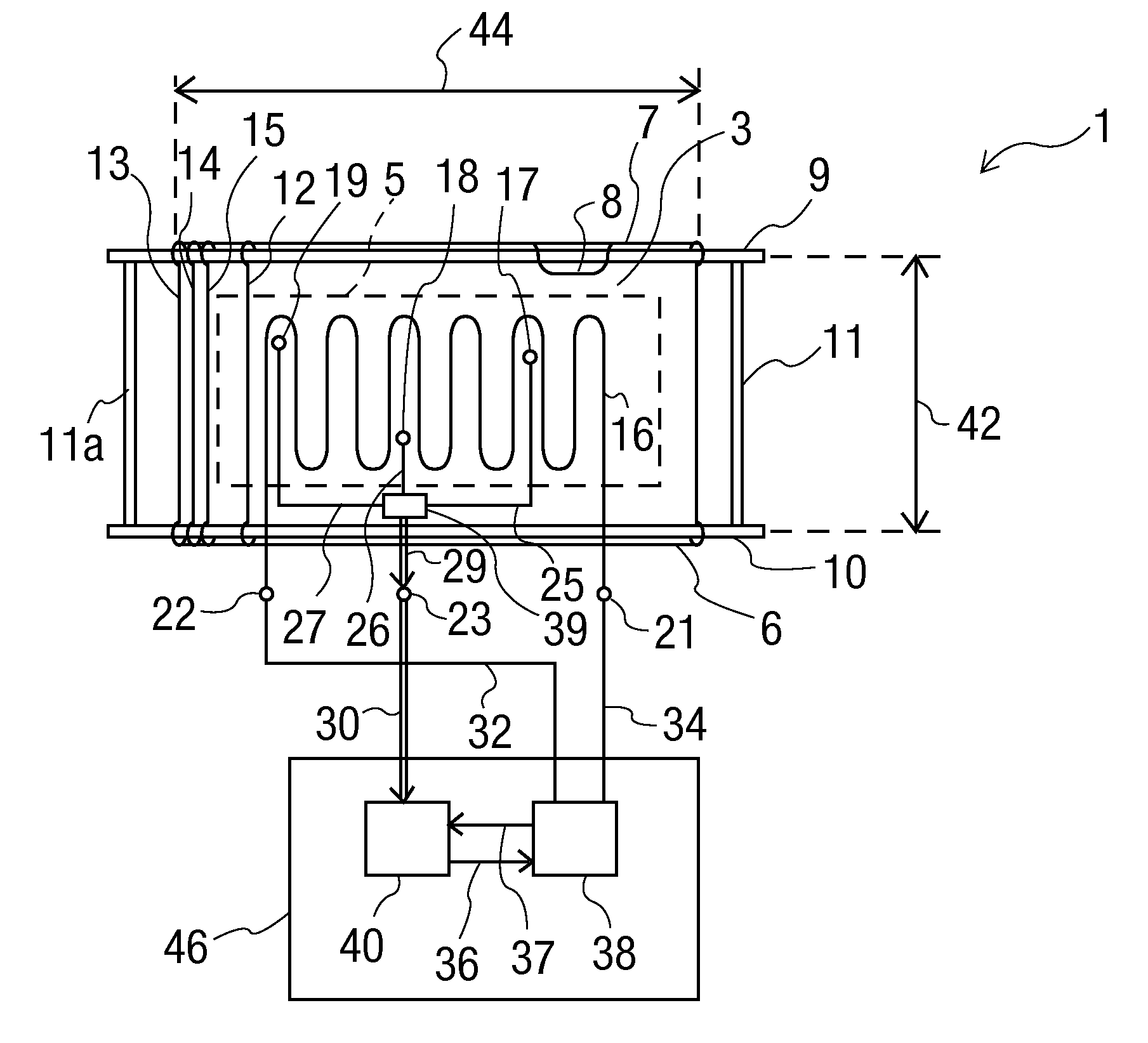

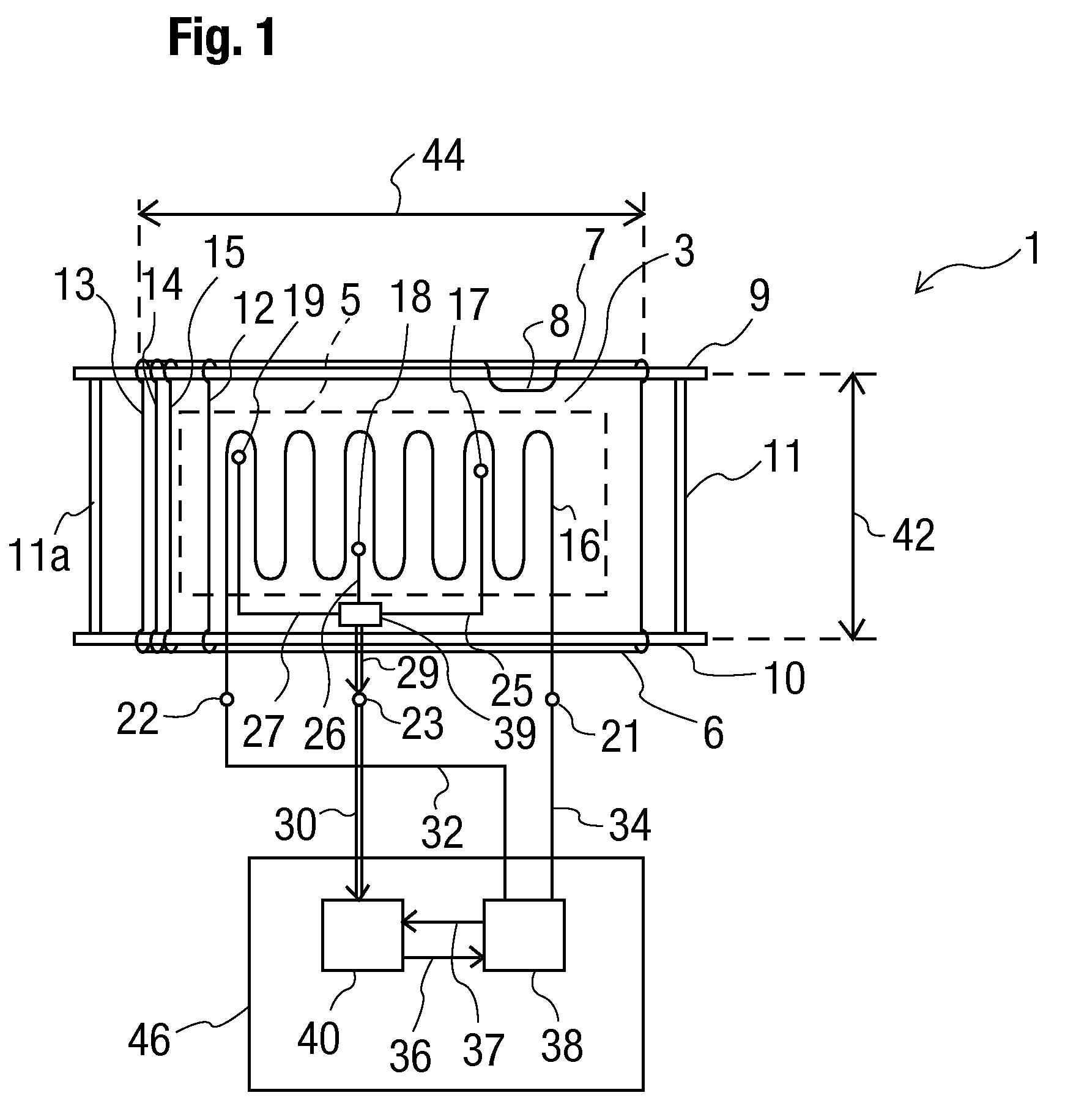

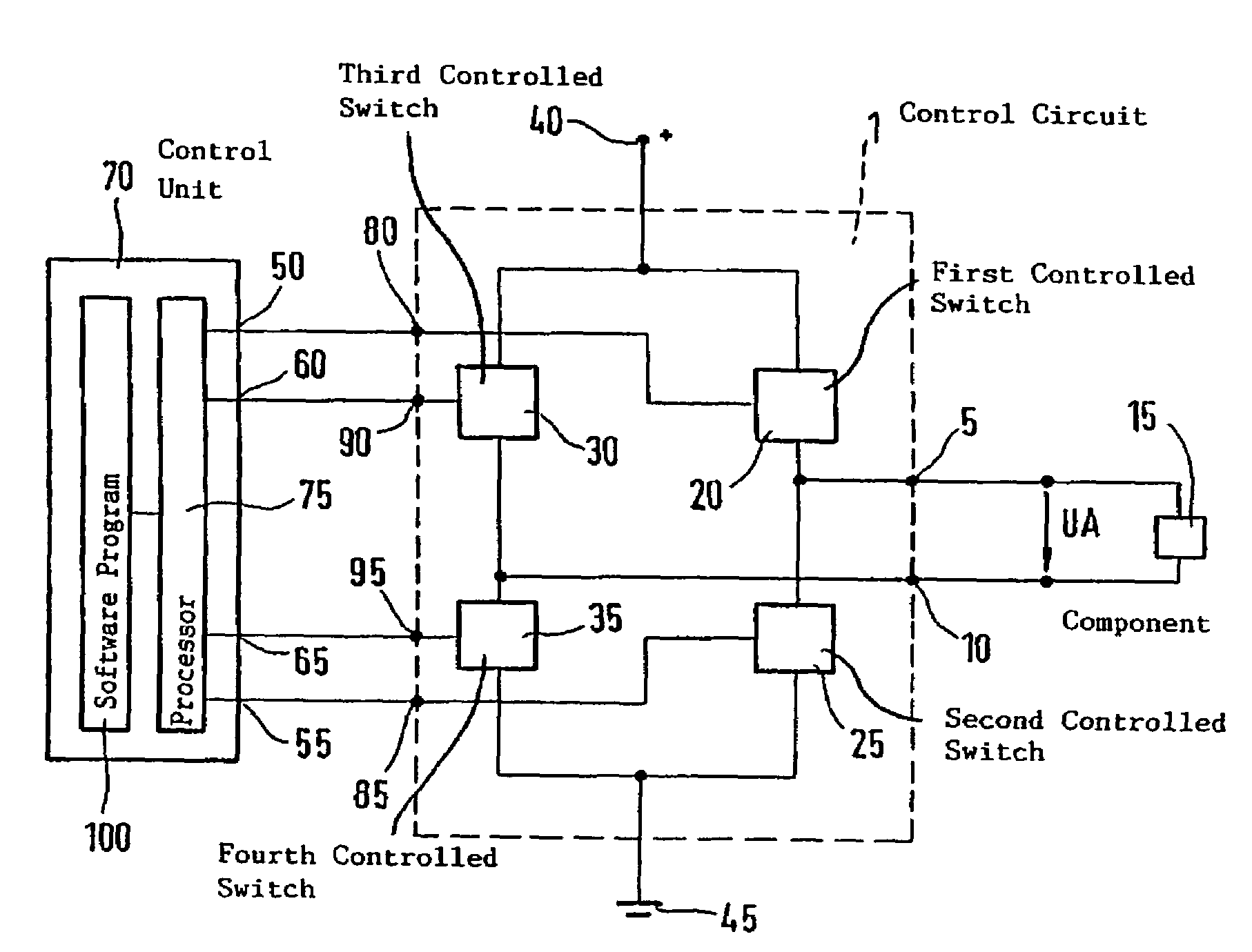

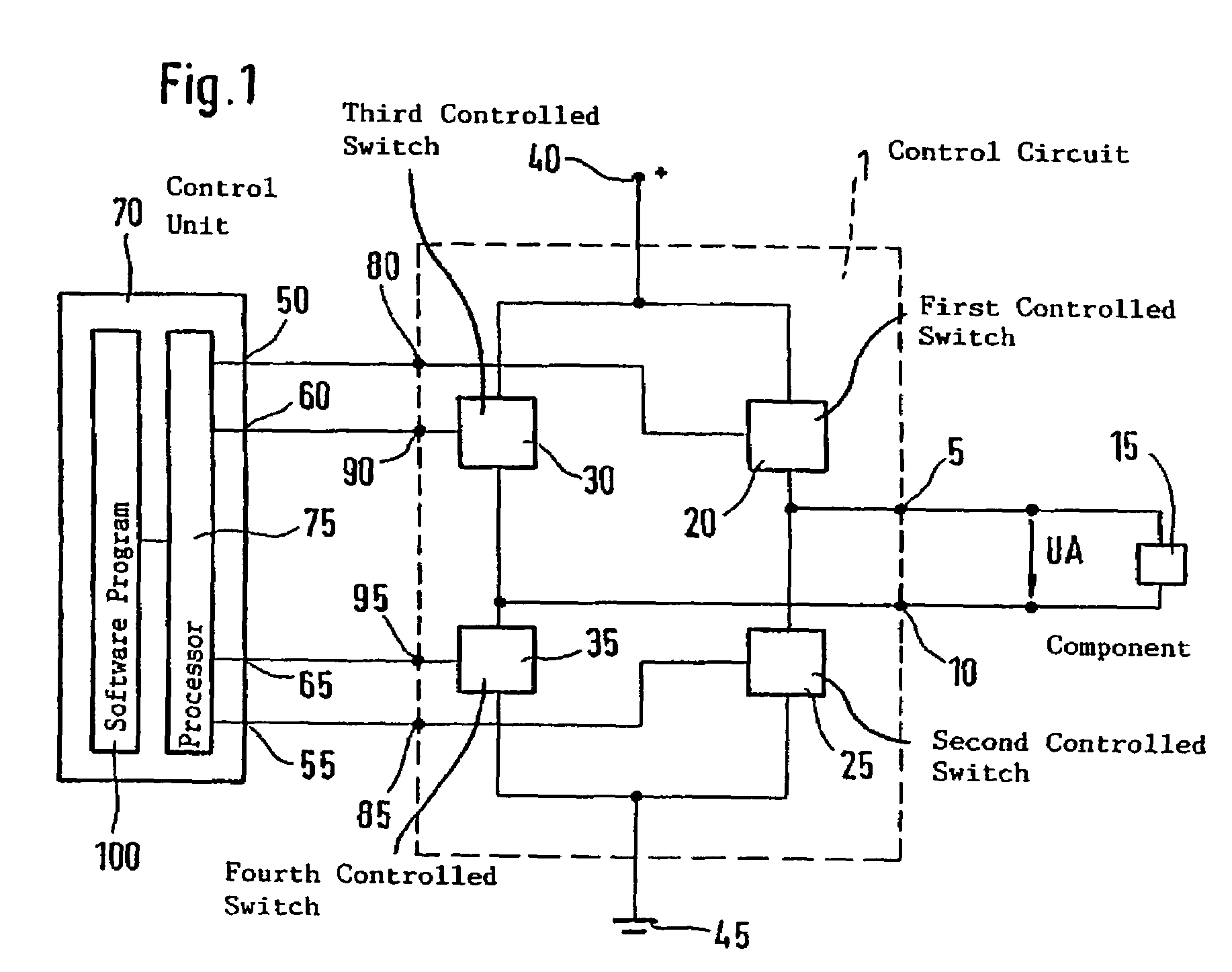

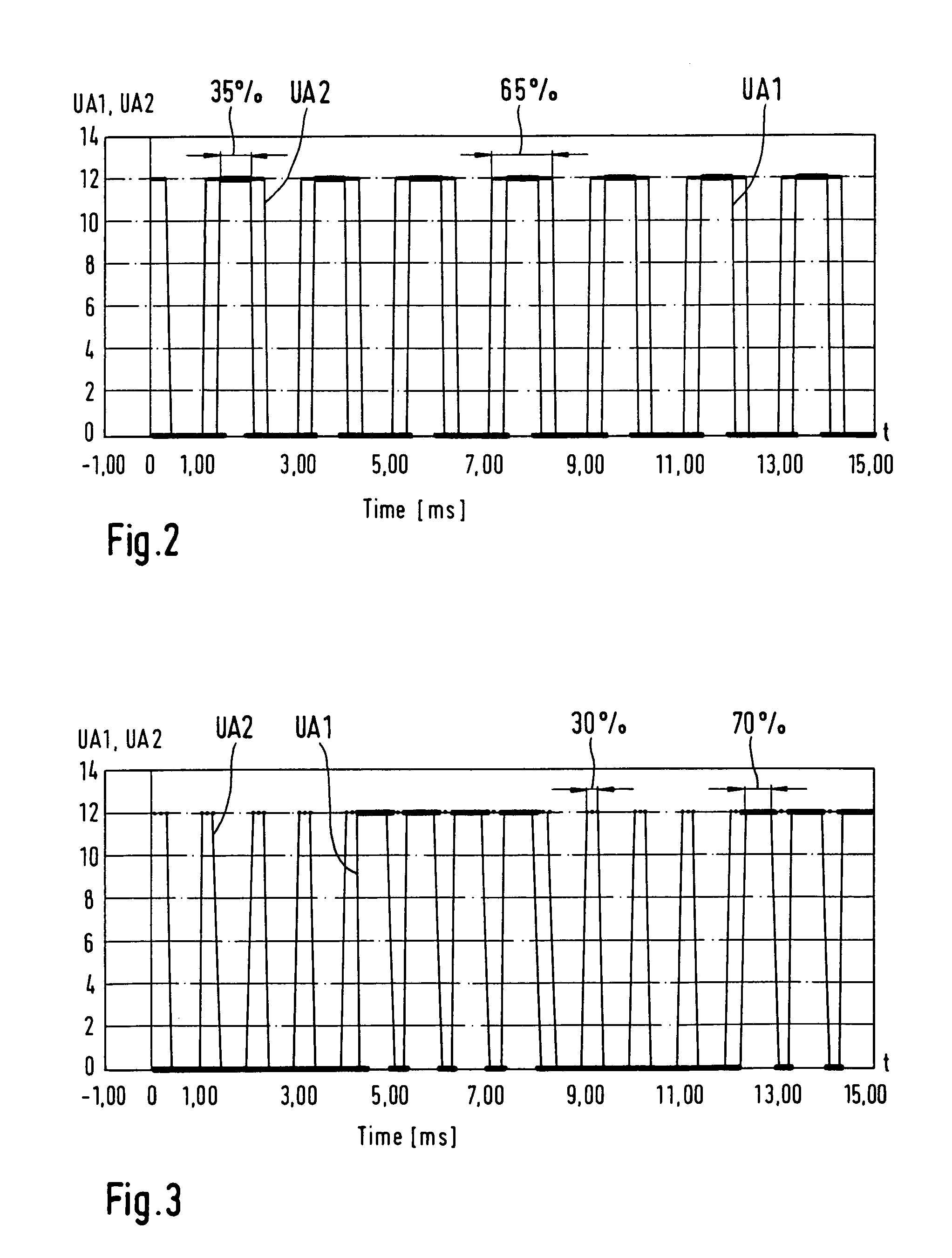

Method and control unit for driving a control circuit

InactiveUS7397150B2Avoid destructionImprove heat distributionField or armature current controlSwitch power arrangementsEngineeringControl circuit

A method and a control unit for driving a control circuit (1) are suggested which make possible an improved distribution of the generated power loss. A component (15), especially of a motor vehicle, is driven via at least two outputs (5, 10) of the control circuit (1). Each output (5, 10) is connected pairwise to one of several potentials (40, 45) via controllable switch means (20, 25; 30, 35) and a drive voltage (UA) is formed for the component (15) from a difference between the potentials at the two outputs (5, 10). A pregiven clocked course of the drive voltage (UA) is adjusted by switching more than one of the controllable switch devices (20, 25; 30, 35).

Owner:ROBERT BOSCH GMBH

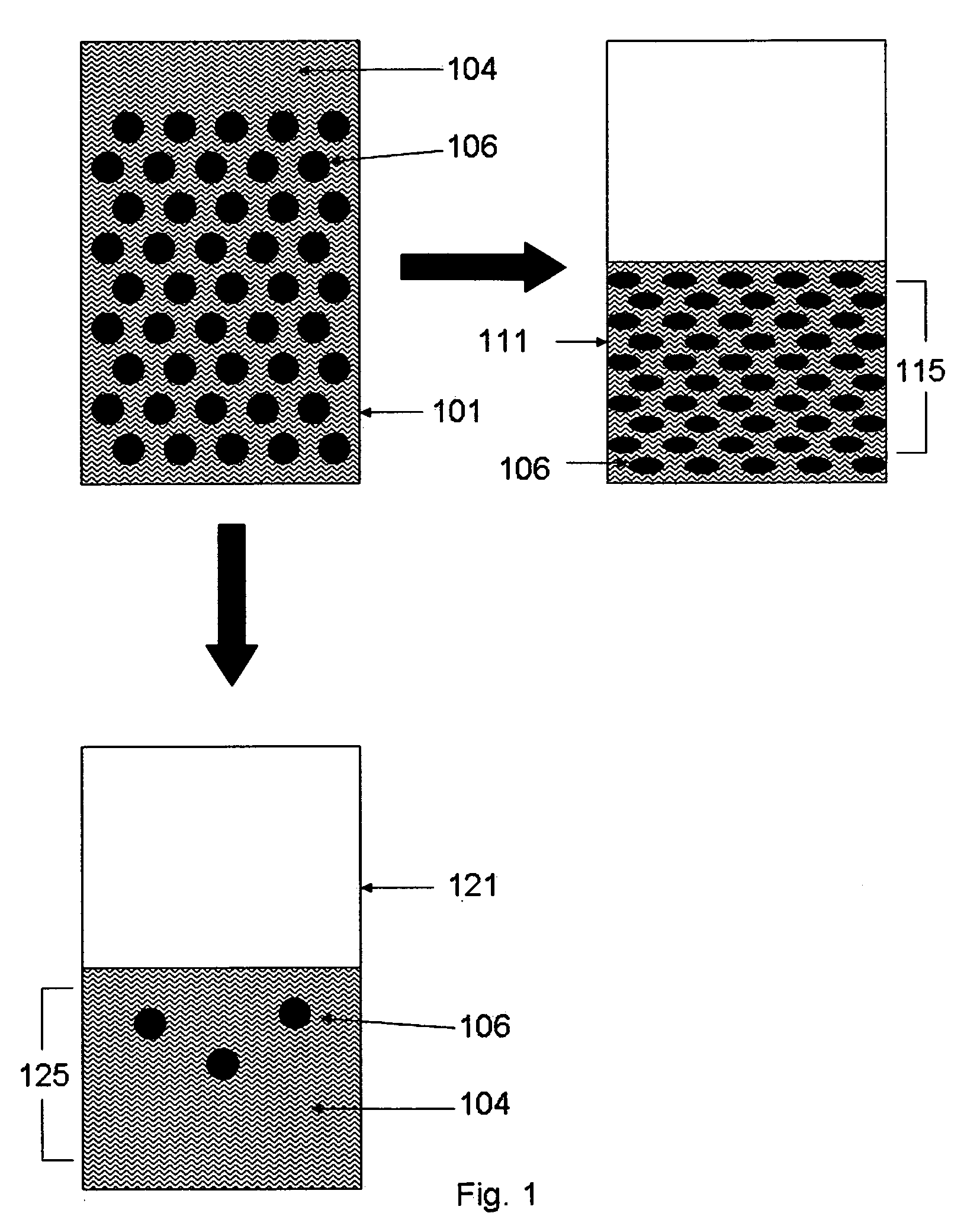

High-speed jet control

InactiveUS20070158468A1Improve flame spray processesReduce the temperatureLiquid surface applicatorsMolten spray coatingControl flowCircular disc

A device is disclosed that uses a flow-control methodology to control sprays at very high precision and frequency. The device is based on an enhanced Coanda effect. The control flow is selectively applied to the region in which we desire the jet to vector and control the profile (width) of the jet. In one embodiment, the control flow is applied at the desired circumferential location by the action of a rotting disk with a flow passage of a size that spreads the jet the desired amount. The size of this flow passage may be controlled by using two overlapping disks with large holes in each. By rotating one disk relative to the other, the size of the resultant passage can be modified.

Owner:UTAH STATE UNIVERSITY

Combustor linear and method for making thereof

A combustor liner is provided having first and second annular bands which define an overlapping circumferential joint area, wherein a weld is disposed in the joint area encompassing substantially all of the axial length of the joint area. A method for producing such a combustor liner is also provided.

Owner:GENERAL ELECTRIC CO

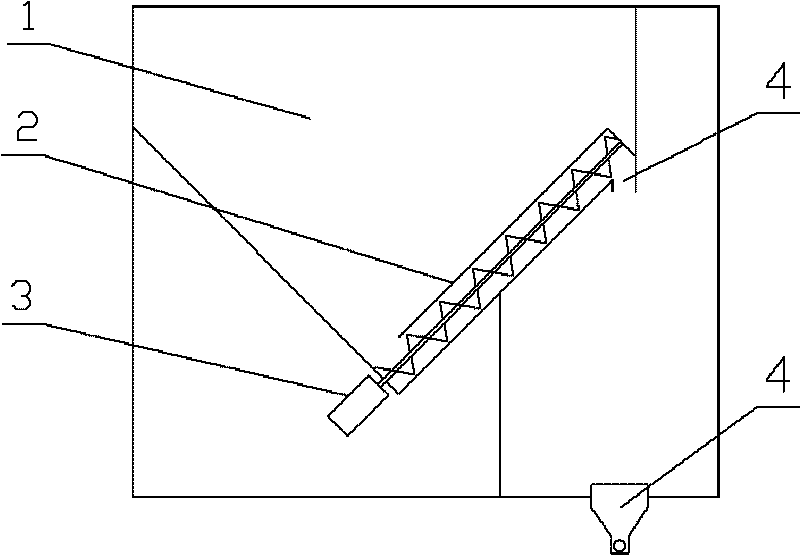

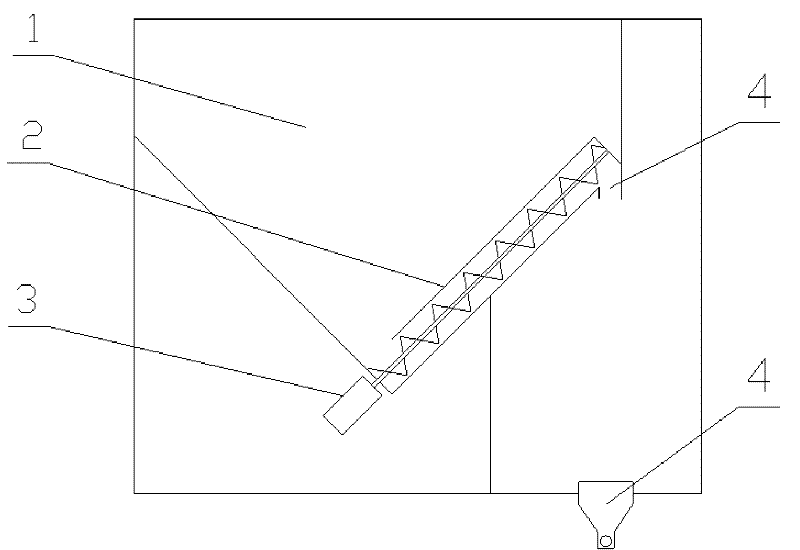

Closed fireplace with intake air distribution system

InactiveCN101701720AGuaranteed widthGuaranteed to fall intoDomestic stoves or rangesLighting and heating apparatusSocial benefitsCombustion chamber

The invention discloses a closed fireplace with an intake air distribution system, comprising a heath, a combustion conveyor and a hot air system. The heath is internally provided with a ventilation pipeline and a combustion chamber; the bottom of the combustion chamber is provided with a fireplace box in long groove structure; the length direction of the fireplace box is identical with the width direction of the fireplace; the bottom of the fireplace box is provided with a heating rod both sides of which are provided with air inlets; and the box wall of the fireplace box is provided with a plurality of secondary air inlets. The invention effectively solves the problems of fuel integration, low combustion efficiency and great environmental pollution existing in the traditional fireplace using wood grains as fuel, also solves the problems of flame integration, unobvious heat feeling and poor viewing effect existing in the traditional fireplace, has great fireplace flame width, strong heat feeling, good viewing effect, high heat efficiency, little environmental pollution and notable economic benefits and social benefits.

Owner:朱宏锋 +1

Preparation method for green tea wine and application of green tea wine

ActiveCN104962445AIncrease the content of active pharmaceutical ingredientsGuaranteed qualityAlcoholic beverage preparationFood preparationYeastAdditive ingredient

The invention discloses a preparation method for green tea wine. The preparation method comprises the following steps of S1, taking fresh tea leaves for airing, then performing enzyme deactivation, controlling the temperature of enzyme deactivation to be 290 to 310 DEG C, performing smothered enzyme deactivation for 2 to 4 minutes, then thoroughly frying the tea leaves for 3 to 5 minutes, and kneading and frying the tea leaves to obtain green tea; S2, performing temperature rise and heating on the green tea, mixing the heated green tea with sorghum for wetting and steaming materials; S3, adding distiller's yeast and yeast into first grain raw materials obtained in the S2 for fermenting large dregs; S4, adding rice hulls into the fermented large dregs, and then performing distillation and solid-liquid separation to obtain large dreg wine and second grains, wherein the large dreg wine is the green tea wine. According to the green tea wine prepared according to the scheme, the wine yield is higher, effective ingredients are retained to the maximum extent, the mouthfeel and the quality of the green tea wine are effectively improved, and the problems that the green tea medicated wine is mostly prepared by soaking, and the pharmacological function of the green tea wine is limited due to the fact that green tea medicated wine difficultly simultaneously guarantees the wine yield and effective ingredients are solved.

Owner:周然

Desalination with production of brine fuel

InactiveUS20090188866A1Intense heatWater cleaningWater/sewage treatment by irradiationSeawaterSaline water

The present invention involves a water-based vessel for the production of desalinated water and concentrated brine. The former is usable for drinking water in areas that lack sufficient potable water, while the latter may be used as fuel in electricity production. The invention additionally includes capabilities of providing electricity, food, and lodging in response to emergency conditions.

Owner:BLUMENTHAL BENJAMIN ELIAS

Directional jet flow control

A device is disclosed that uses a flow-control methodology to control sprays at very high precision and frequency. The device is based on an enhanced Coanda effect. The control flow is selectively applied to the region in which we desire the jet to vector and control the profile (width) of the jet. The control flow is introduced through multiple control flow ports surrounding the primary nozzle and adjacent to the Coanda surface. By selectively opening and closing different control flow ports the motion and profile of the jet can be controlled.

Owner:UTAH STATE UNIVERSITY

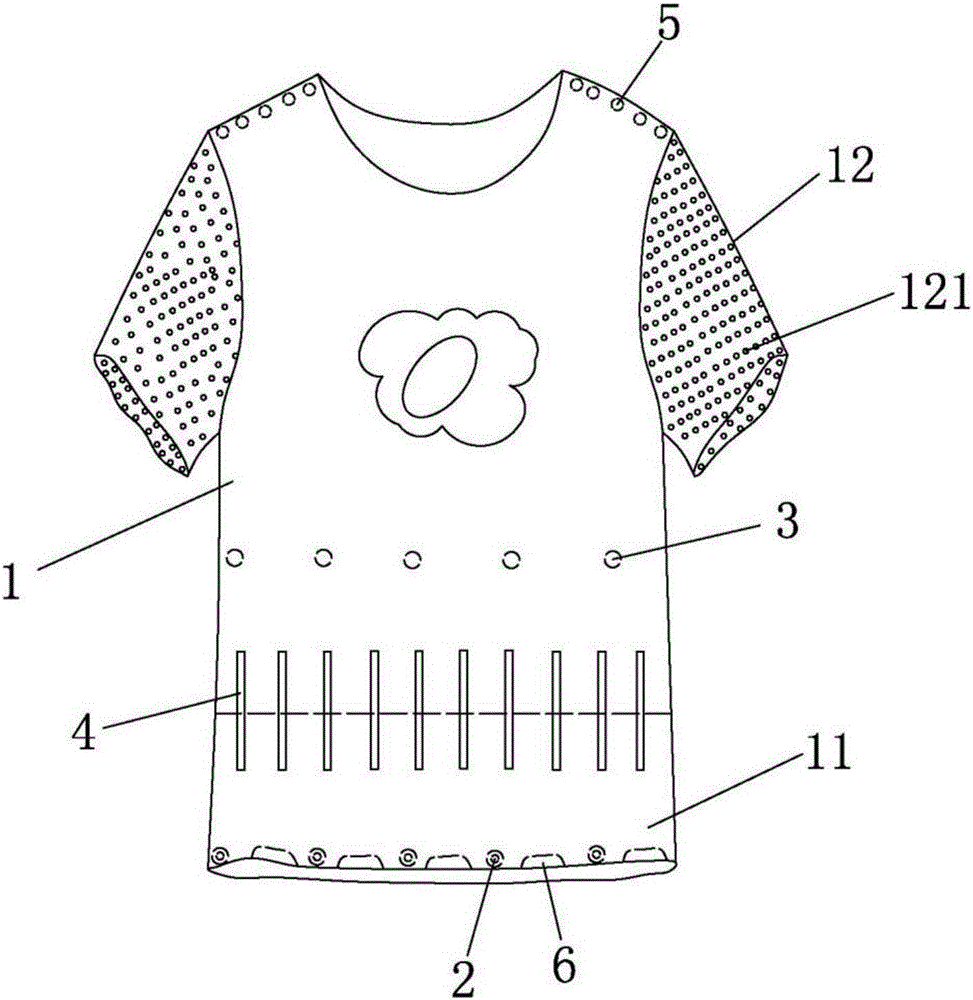

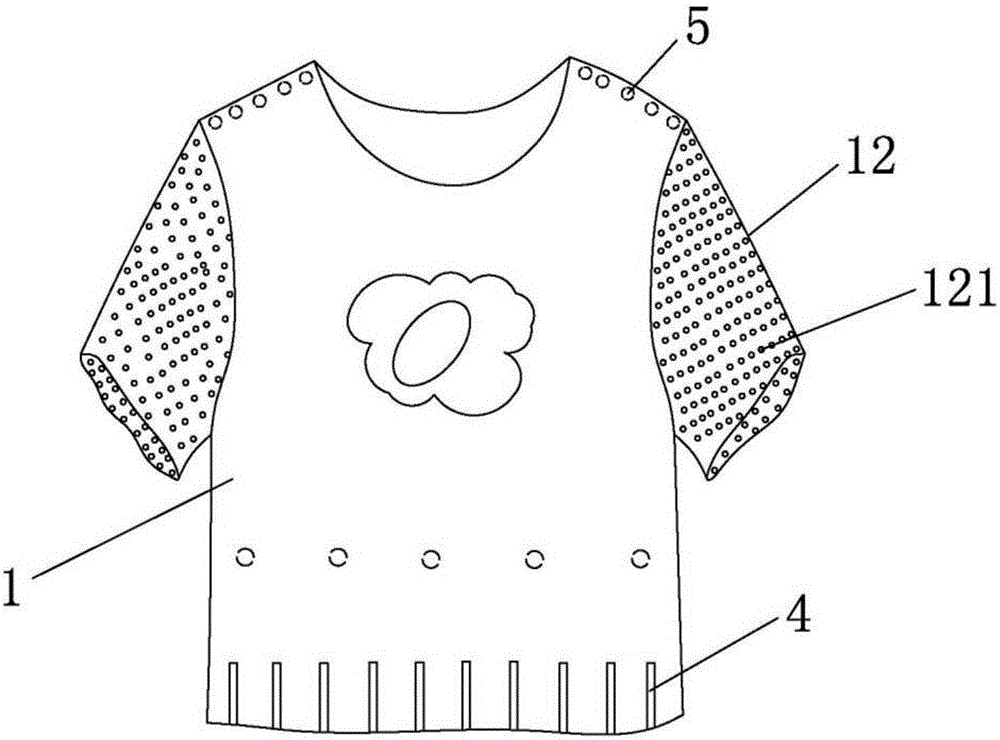

T-shirt with comprehensive function

The invention discloses a T-shirt with comprehensive function. The T-shirt is weaved from Coolmax fibers and cotton fibers and is made through antibacterial treatment. The T-shirt is provided with a strip-shaped medicinal material layer corresponding to the spinal column of the human body. The medicinal material layer coats the back part of the T-shirt through textile glue and comprises sinalbin, tourmalinite powder and vanillyl butyl ether. The front or / and the back of the T-shirt is provided with a fluorescent layer made from a fluorescent fabric. The lower edge of the T-shirt forms a turnover part, which can be turned inward the T-shirt and be fixed inside the T-shirt to form a double-layer fabric. The double-layer fabric can cover the navel of the human body. The insides of the shoulders of the T-shirt are provided with massage projections, which are filled with round cobbles. The T-shirt comprises short sleeve parts, which are uniformly provided with meshes, the diameter of each mesh being 1-2 mm. The T-shirt is excellent in breathability and massage curative effect and provides good visual impact when worn by people. Moreover, the T-shirt can prevent people from catching cold during afternoon nap.

Owner:MEISHENG CULTURE INNOVATION HLDG

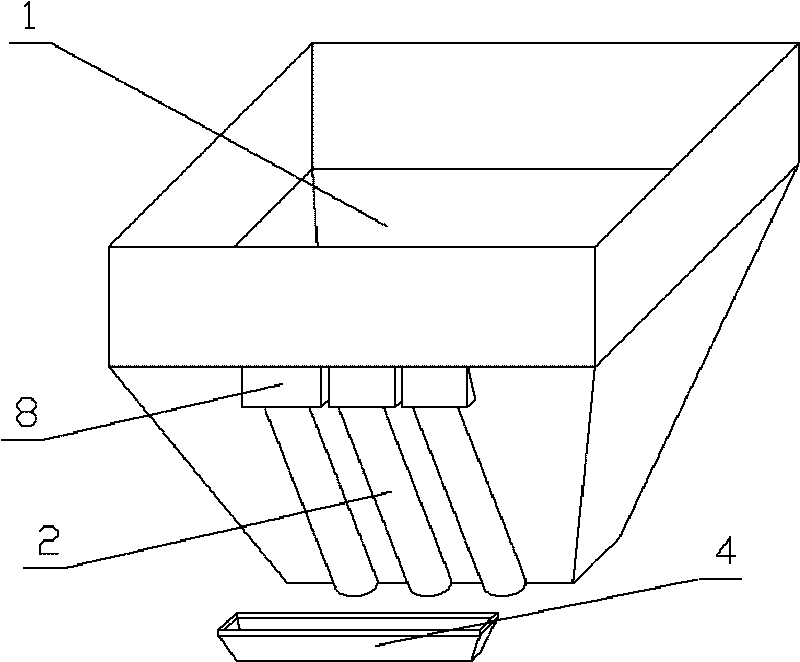

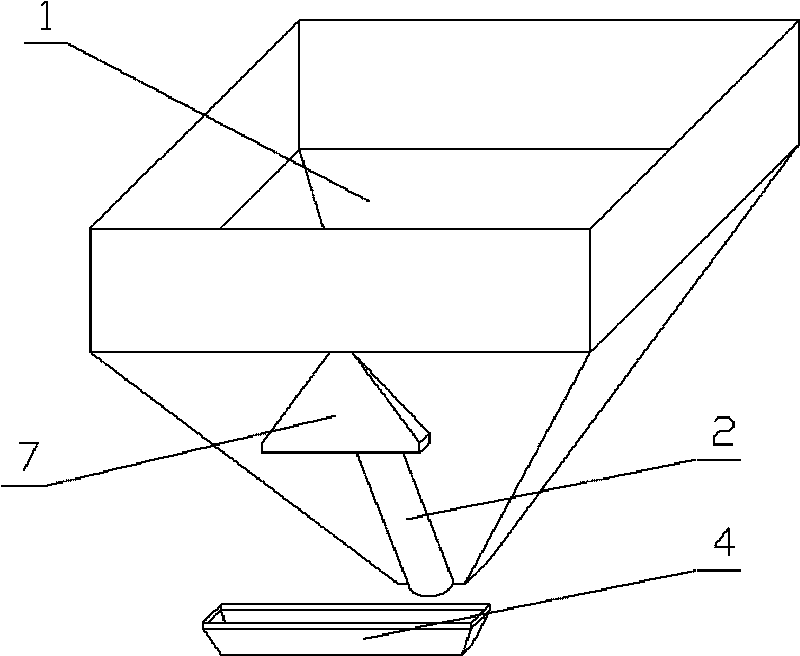

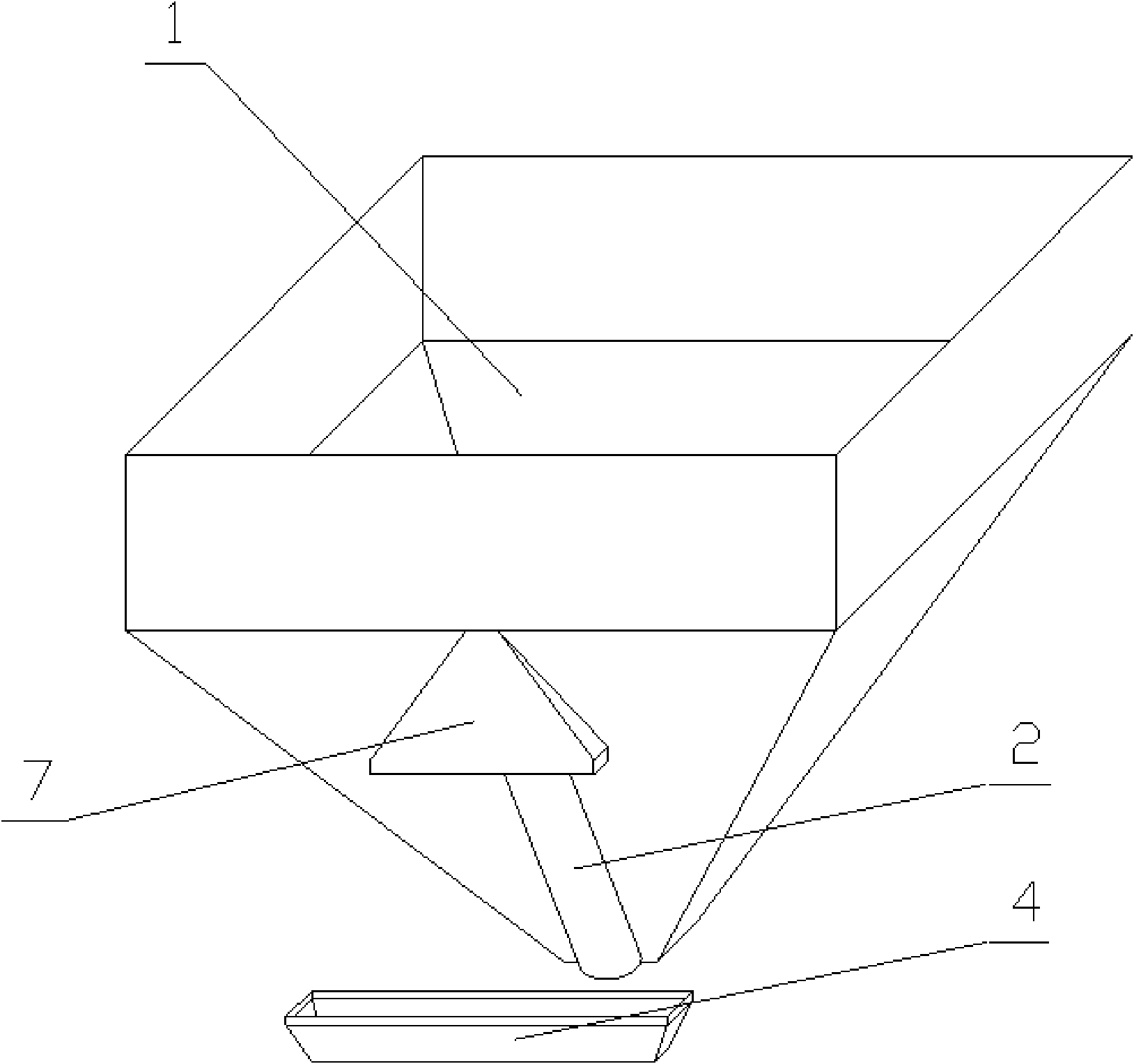

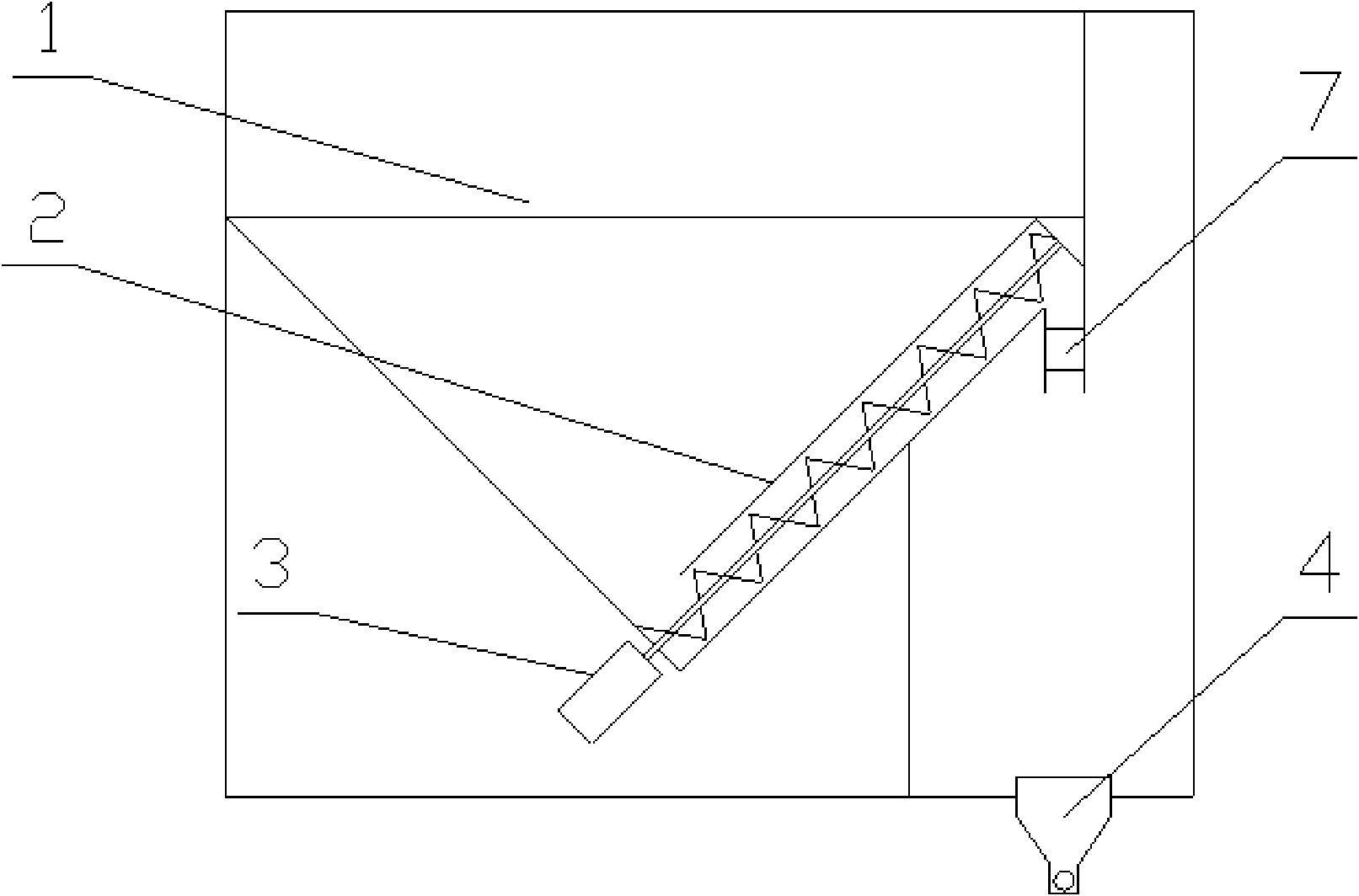

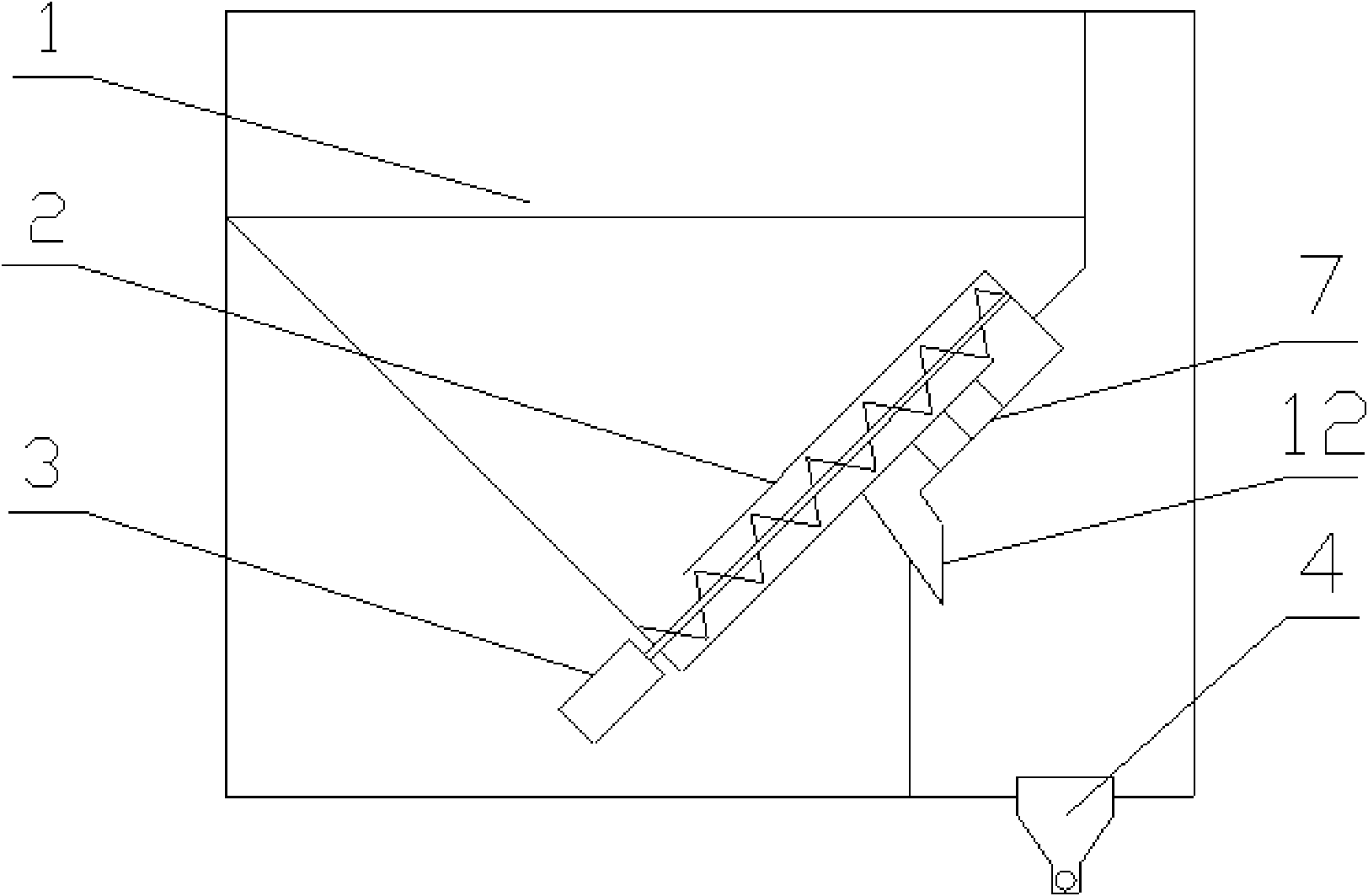

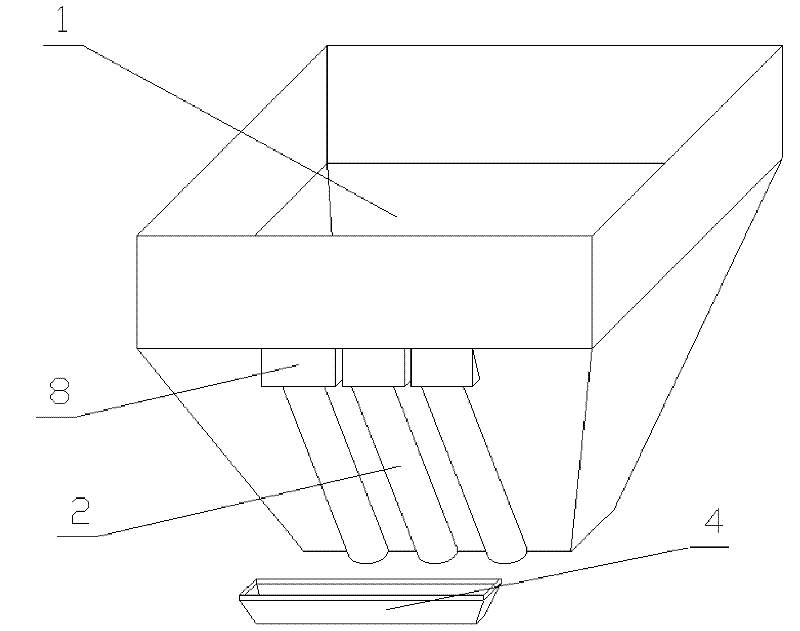

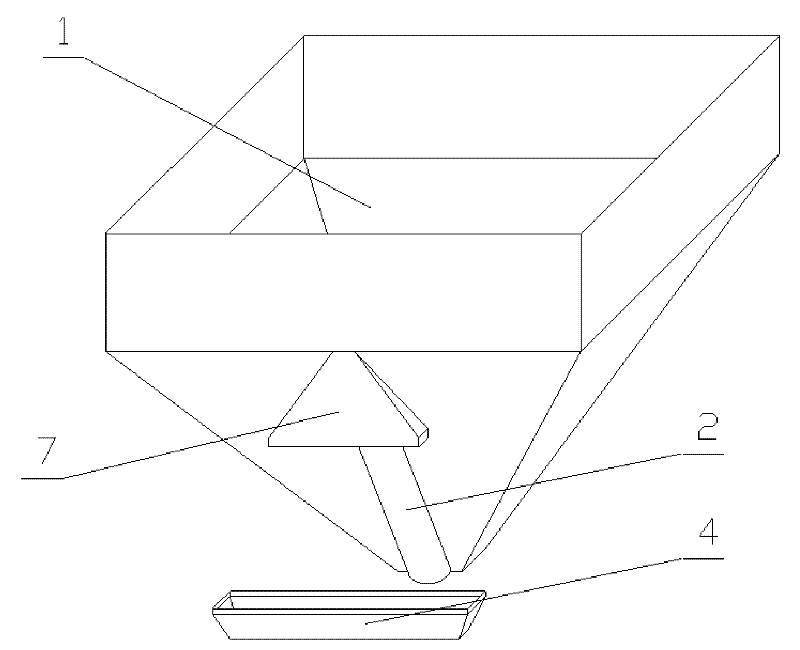

Wide-flame close type fireplace

InactiveCN101699168BIntense heatIncrease heatDomestic stoves or rangesLighting and heating apparatusSocial benefitsCombustion chamber

The invention discloses a wide-flame close type fireplace, which comprises a hearth, a fuel conveying device and a hot air system, wherein a ventilation pipe and a combustion chamber are arranged in the hearth; the bottom of the combustion chamber is provided with a furnace box having a long-groove structure; the length direction of the furnace box and the width direction of the fireplace are consistent; a material distribution device is arranged on a hearth rear wall above the furnace box; the material distribution device comprises a material distribution chamber, a feed inlet and a discharge hole; the feed inlet connected with the fuel conveying device is arranged on the upper end of the material distribution chamber; the strip discharge hole is arranged on the lower end of the materialdistribution chamber; and the length direction of the discharge hole is consistent with the length direction of the furnace box. The wide-flame close type fireplace solves the problems of narrow flame, poor warm sense, poor aesthetic effect and low heat efficiency of the traditional fireplace and has wide flame, strong warm sense, excellent aesthetic effect, high heat efficiency, little harmful gas discharge and obvious economic and social benefits.

Owner:朱宏锋 +1

Composition and method for protecting labile active components during high temperature drying

InactiveUS20110091406A1Reduce and eliminate risk of damageIntense heatBiocideCosmetic preparationsPersonal careDecomposition

A composition and method for protecting personal care components, advantageously labile active personal care components, from decomposition during high temperature drying, employing water-soluble hydrolyzed polysaccharide encapsulants. Also disclosed is an additive for a personal care composition comprising a personal care component that is at least partially encapsulated within a hydrolyzed polysaccharide encapsulant. Also disclosed is a method for protecting a composition containing labile biologically active particles which comprises encapsulating at least a portion of the biologically active particles within hydrolyzed polysaccharide particles, thereby protecting said portion of said biologically active particles.

Owner:GRUBER JAMES V +1

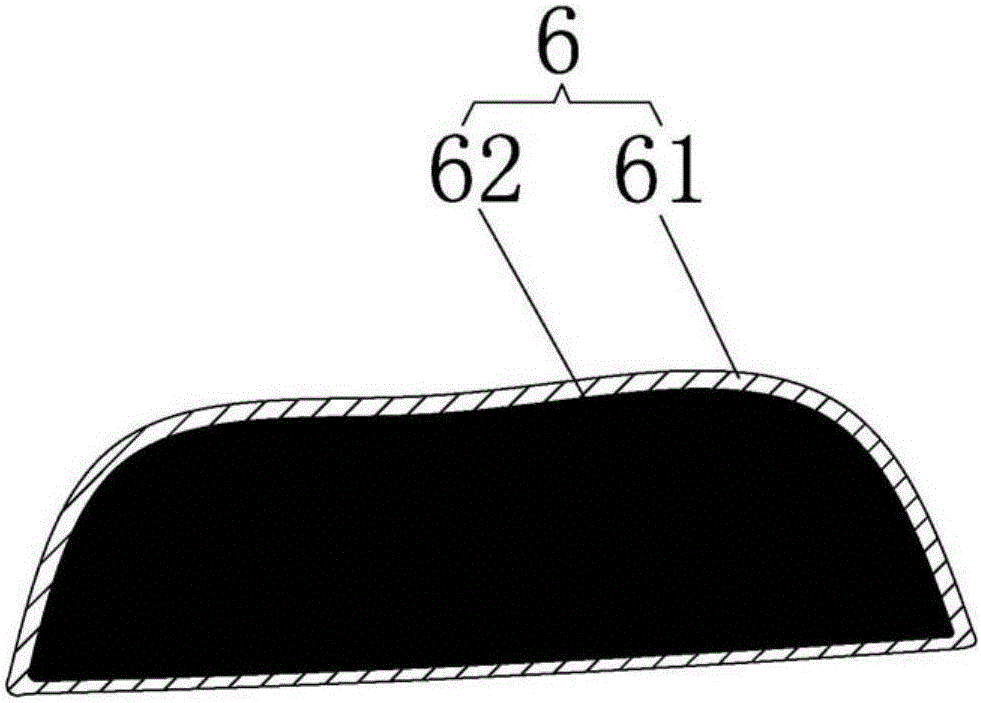

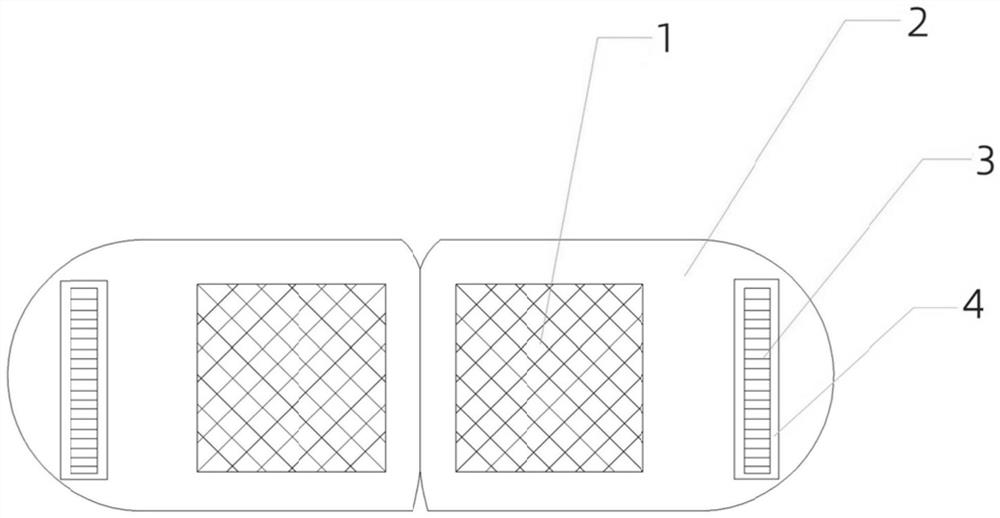

Traditional Chinese medicine steam eyeshade for relieving asthenopia

PendingCN114569327APromote absorptionRelieve fatigueSenses disorderEye-masksThermodynamicsMuscular asthenopia

The invention aims to provide a traditional Chinese medicine steam eyeshade for relieving asthenopia, which comprises an eyeshade body, and a traditional Chinese medicine heating bag is arranged in the eyeshade body; the traditional Chinese medicine heating bag is filled with a heating inner material; the heating inner material comprises the following components in parts by mass: 1-100 parts of a heating material, 1-20 parts of a heat sensitizer and 1-20 parts of traditional Chinese medicine essential oil microcapsule powder. According to the invention, eye fatigue can be relieved for a long time, so that the problem that in the prior art, the eye is wetted and relieved by steam generated by heating water, but the effect of relieving eye fatigue is poor is solved.

Owner:珠海横琴澳叶健康科技有限公司

Tray support inserts for chemical reactor vessels and methods of use

ActiveUS10293321B2Heavy weightIntense heatMachine supportsHydrocarbon oil crackingChemical reactorEngineering

Owner:SHELL USA INC

A kind of preparation method and application of green tea wine

ActiveCN104962445BIncrease the content of active pharmaceutical ingredientsGuaranteed qualityAlcoholic beverage preparationFood scienceBiotechnologyYield (wine)

The invention discloses a preparation method for green tea wine. The preparation method comprises the following steps of S1, taking fresh tea leaves for airing, then performing enzyme deactivation, controlling the temperature of enzyme deactivation to be 290 to 310 DEG C, performing smothered enzyme deactivation for 2 to 4 minutes, then thoroughly frying the tea leaves for 3 to 5 minutes, and kneading and frying the tea leaves to obtain green tea; S2, performing temperature rise and heating on the green tea, mixing the heated green tea with sorghum for wetting and steaming materials; S3, adding distiller's yeast and yeast into first grain raw materials obtained in the S2 for fermenting large dregs; S4, adding rice hulls into the fermented large dregs, and then performing distillation and solid-liquid separation to obtain large dreg wine and second grains, wherein the large dreg wine is the green tea wine. According to the green tea wine prepared according to the scheme, the wine yield is higher, effective ingredients are retained to the maximum extent, the mouthfeel and the quality of the green tea wine are effectively improved, and the problems that the green tea medicated wine is mostly prepared by soaking, and the pharmacological function of the green tea wine is limited due to the fact that green tea medicated wine difficultly simultaneously guarantees the wine yield and effective ingredients are solved.

Owner:周然

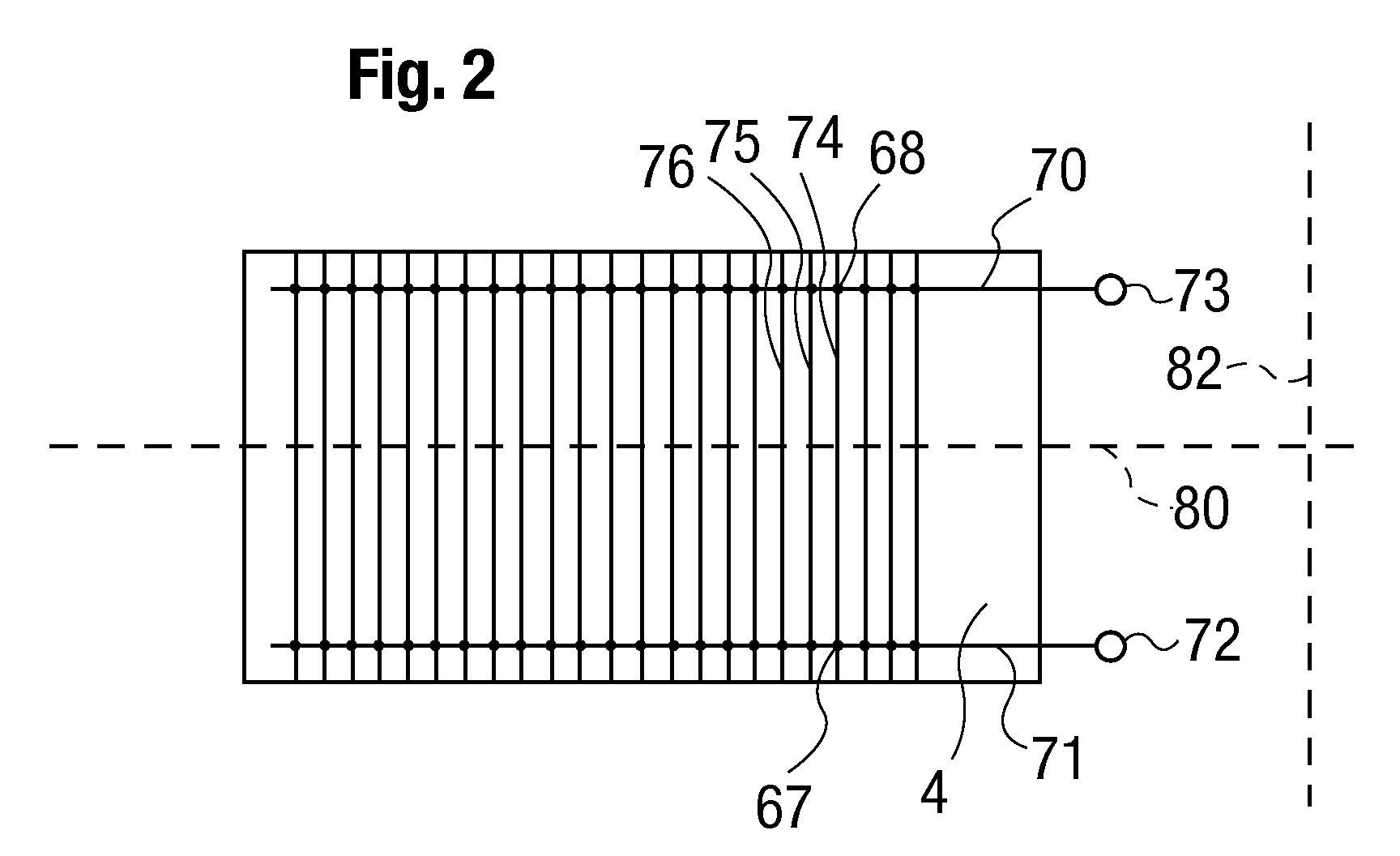

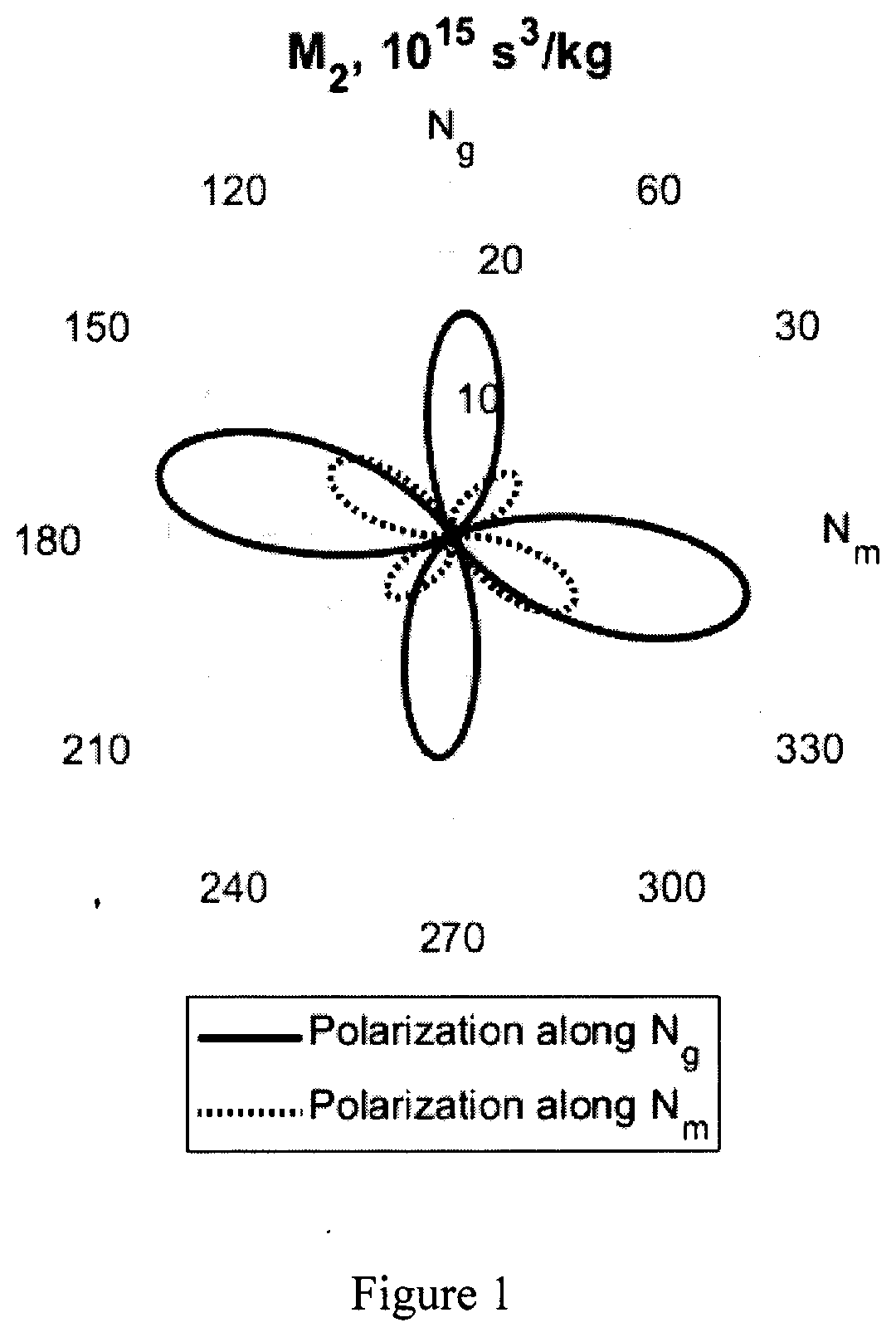

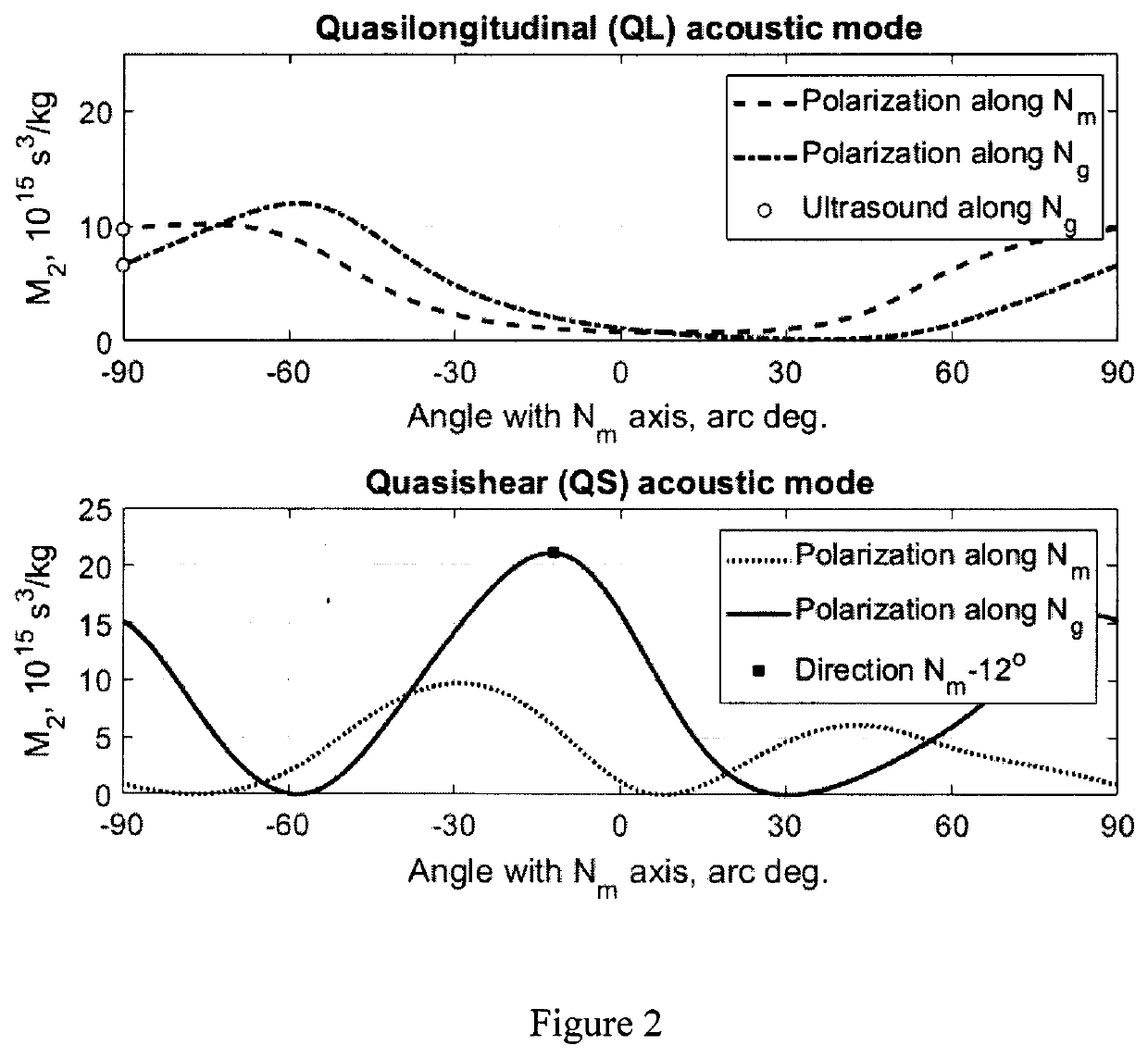

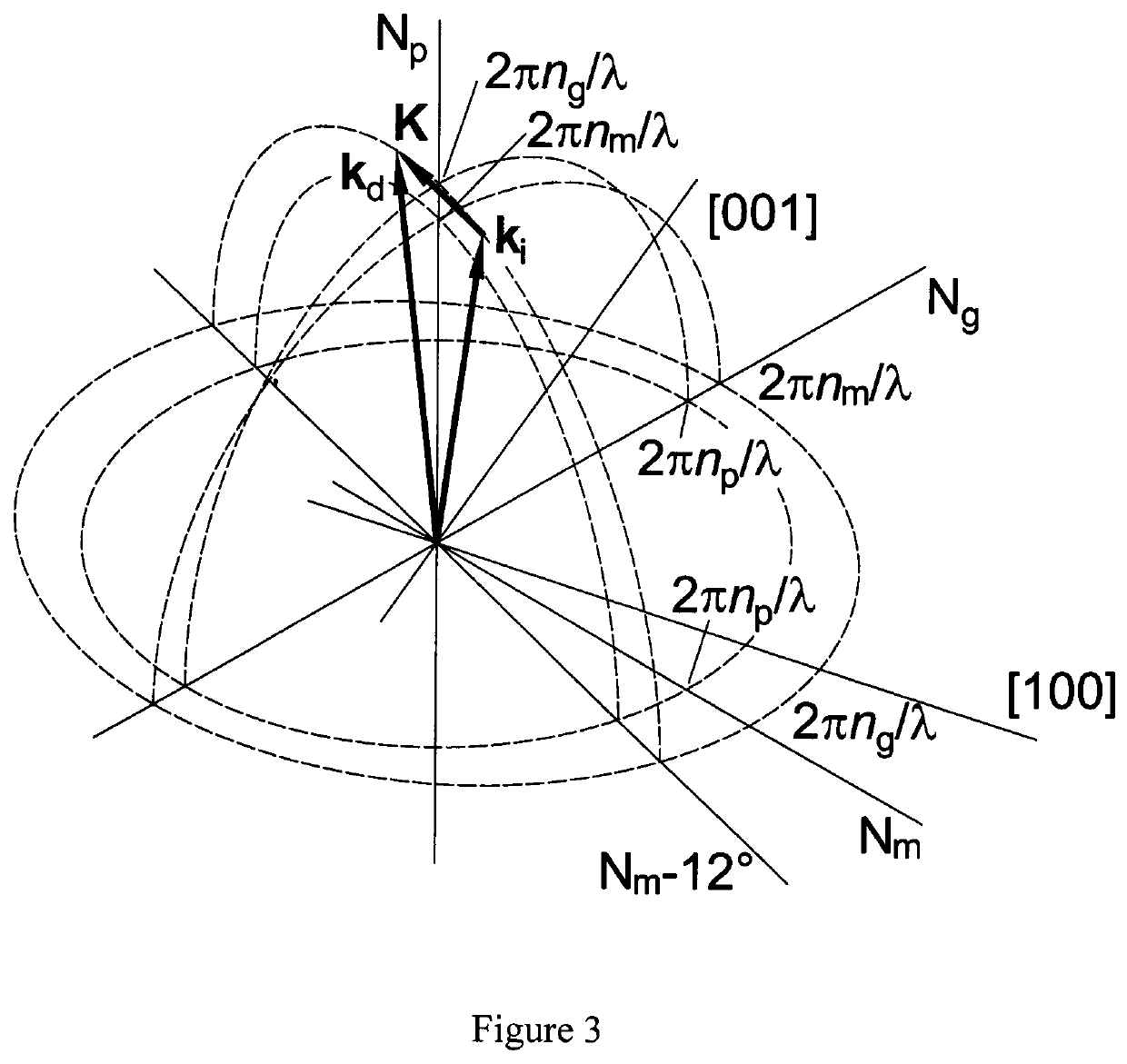

Method and Device for Laser Radiation Modulation

PendingUS20210391682A1Increase the areaReduce HF electric power densityLaser detailsNon-linear opticsOptical radiationLaser technology

The proposed method and device relate to acousto-optics and laser technology and can be attributed, in particular, to acousto-optical (AO) laser resonator Q-switches, AO devices for extra-cavity control of single-mode (collimated) and multimode (uncollimated) monochromatic and non-monochromatic laser radiation, i.e, AO modulators, AO frequency shifters, and dispersion delay lines for visible and middle IR wavelengths (0.4-5.5 μm). The object of the method and device is providing a geometry of AO interaction in laser resonator Q-switches so that to optimize the preset parameters of the Q-switch in accordance with the system requirements to the laser operation mode depending on the intended use of the laser, more specifically, lower control RF power and capability of operation without additional efficiency loss with multimode or uncollimated laser radiation.

Owner:NATIONAL RESEARCH TECHNOLOGICAL UNIVERSITY

Closed fireplace with intake air distribution system

InactiveCN101701720BGuaranteed widthGuaranteed to fall intoDomestic stoves or rangesLighting and heating apparatusSocial benefitsCombustion chamber

The invention discloses a closed fireplace with an intake air distribution system, comprising a heath, a combustion conveyor and a hot air system. The heath is internally provided with a ventilation pipeline and a combustion chamber; the bottom of the combustion chamber is provided with a fireplace box in long groove structure; the length direction of the fireplace box is identical with the widthdirection of the fireplace; the bottom of the fireplace box is provided with a heating rod both sides of which are provided with air inlets; and the box wall of the fireplace box is provided with a plurality of secondary air inlets. The invention effectively solves the problems of fuel integration, low combustion efficiency and great environmental pollution existing in the traditional fireplace using wood grains as fuel, also solves the problems of flame integration, unobvious heat feeling and poor viewing effect existing in the traditional fireplace, has great fireplace flame width, strong heat feeling, good viewing effect, high heat efficiency, little environmental pollution and notable economic benefits and social benefits.

Owner:朱宏锋 +1

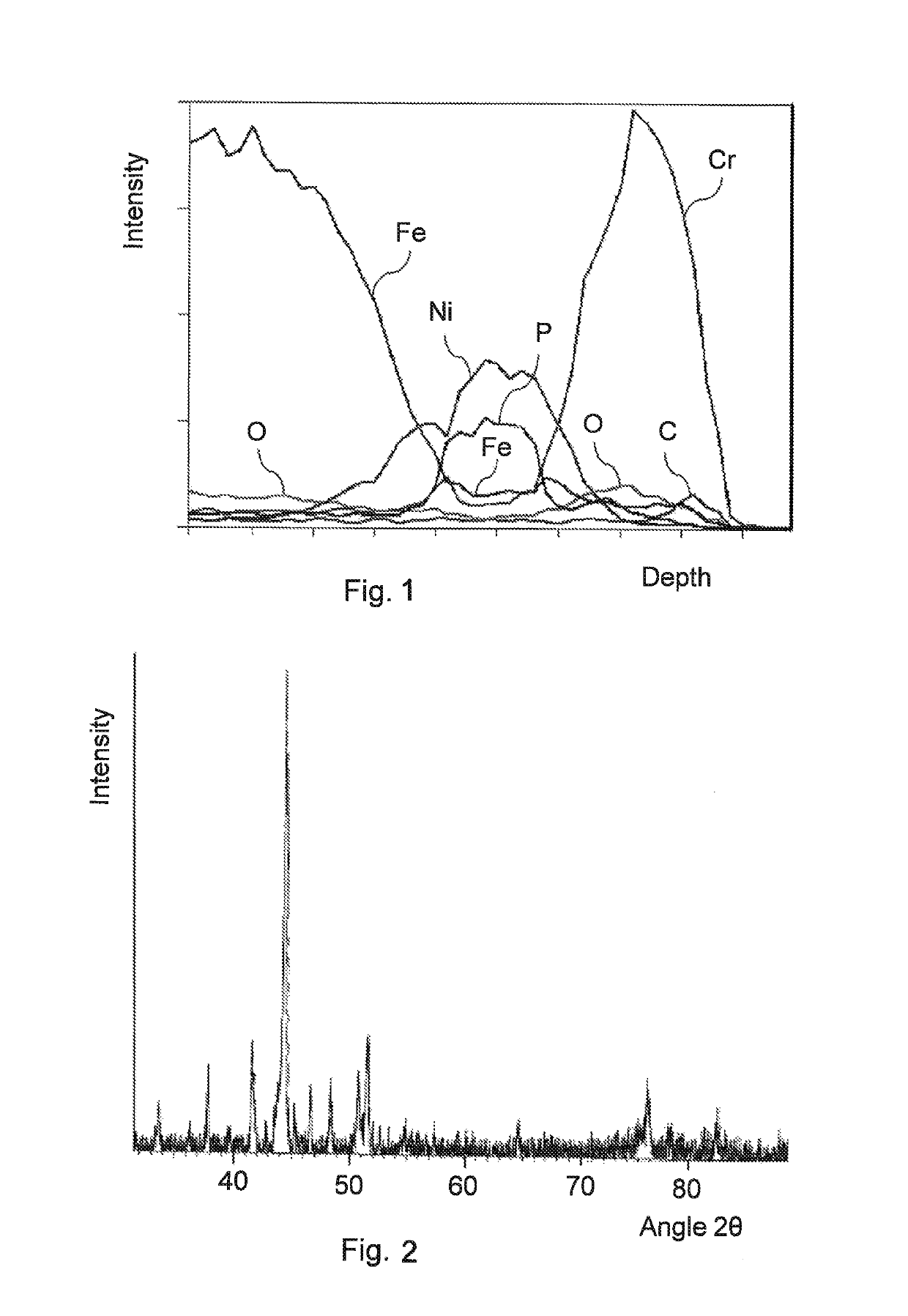

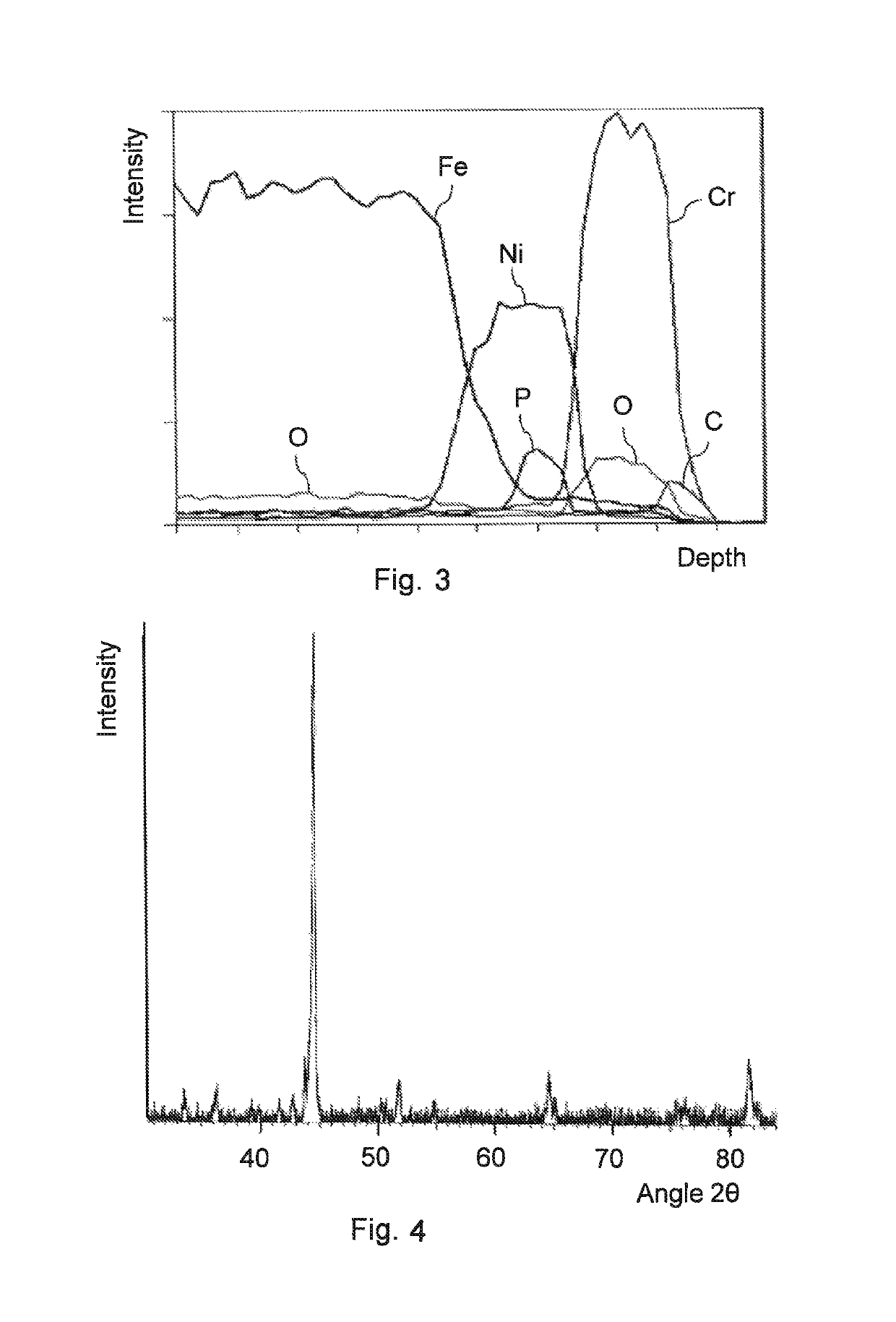

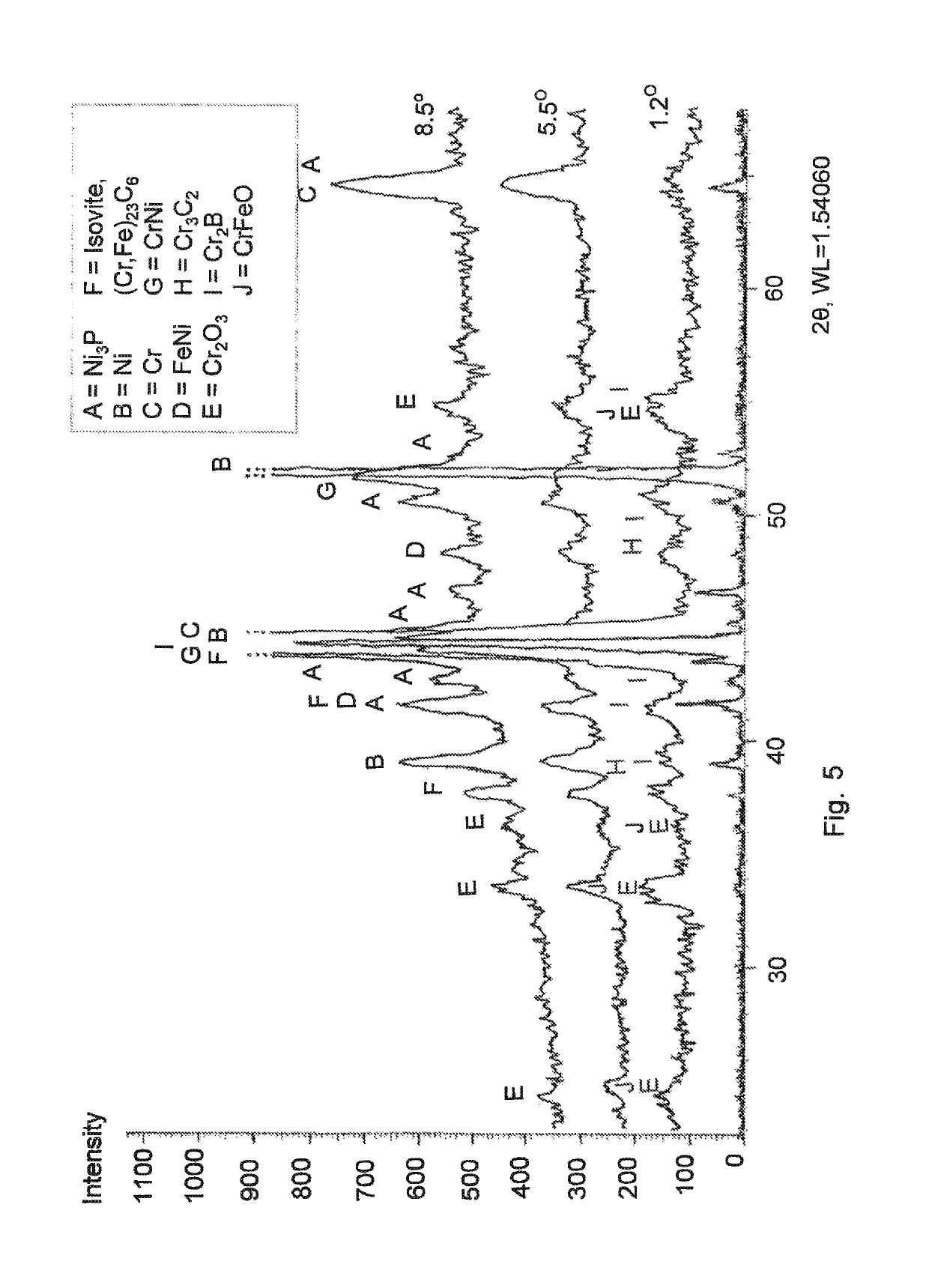

Method for producing a chromium coating and a coated object

ActiveUS10443143B2Improve adhesionIntense heatVacuum evaporation coatingSputtering coatingMetal alloyCarbide

To produce a trivalent chromium based coating on an object, a layer of nickel phosphorus alloy is deposited on the object, an intermediate layer of another metal or metal alloy or ceramic is deposited on the NiP layer, and a chromium layer is deposited from a trivalent chromium bath on the intermediate layer. The coated object is subjected to one or more heat treatments to harden the coating and to produce multiphase layers including at least one layer containing crystalline Ni and crystalline Ni3P and at least one layer containing crystalline Cr. The intermediate layer can consist of copper, molybdenum, a metal alloy or a non-metallic solid, such as an oxide, nitride or carbide of a metal.

Owner:SAVROC

High-speed jet control

InactiveUS7757966B2Enhanced Coanda effectHigh frequencyLiquid surface applicatorsMolten spray coatingControl flowEngineering

Owner:UTAH STATE UNIVERSITY

Short sleeve

InactiveCN106400478AStrong ability to inhibit bacteriaImprove disease resistanceBiocideInorganic boron active ingredientsFiberSpinal column

The invention discloses a short sleeve. The short sleeve is made through weaving Coolmax fibers and cotton fibers and carrying out antibiosis treatment. The short sleeve reserves the high perspiration capability of the Coolmax fibers, and the antibiosis treatment makes the short sleeve have extremely strong bacterium inhibition capability. The short sleeve corresponding to the human body spinal column is provided with a long and narrow medicinal material layer, the back of the short sleeve is coated with the medicinal material layer through a textile adhesive, and the medicinal material layer comprises sinalbin, tourmalinite powder and vanillyl butyl ether; and the above three medicinal materials commonly act on the spinal column to improve local blood circulation and increase metabolism. The front side or / and the back side of the short sleeve is / are provided with a fluorescent layer, and the fluorescent layer is made of a fluorescent fabric. The fluorescent fabric has the advantages of avoiding of dropping of a fluorescent material, caused by multi-time washing, protection f the integrity of a fluorescence pattern, and good safety.

Owner:MEISHENG CULTURE INNOVATION HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com