Wide-flame close type fireplace

A closed, fireplace technology, applied in the direction of household stoves/stoves, lighting and heating equipment, solid heating fuels, etc., can solve the problems of low thermal efficiency, poor viewing effect, narrow flame, etc. Narrow, thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

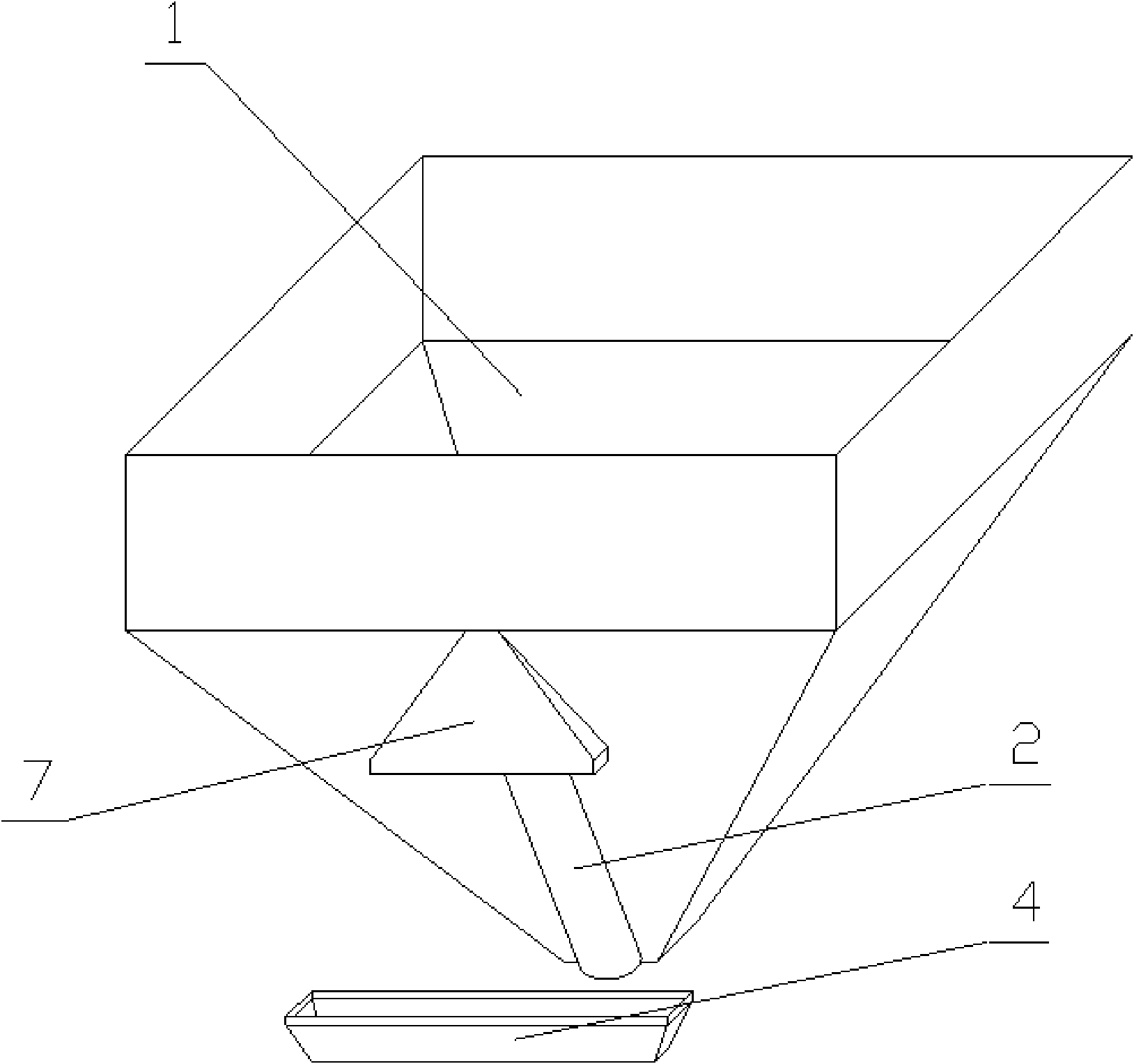

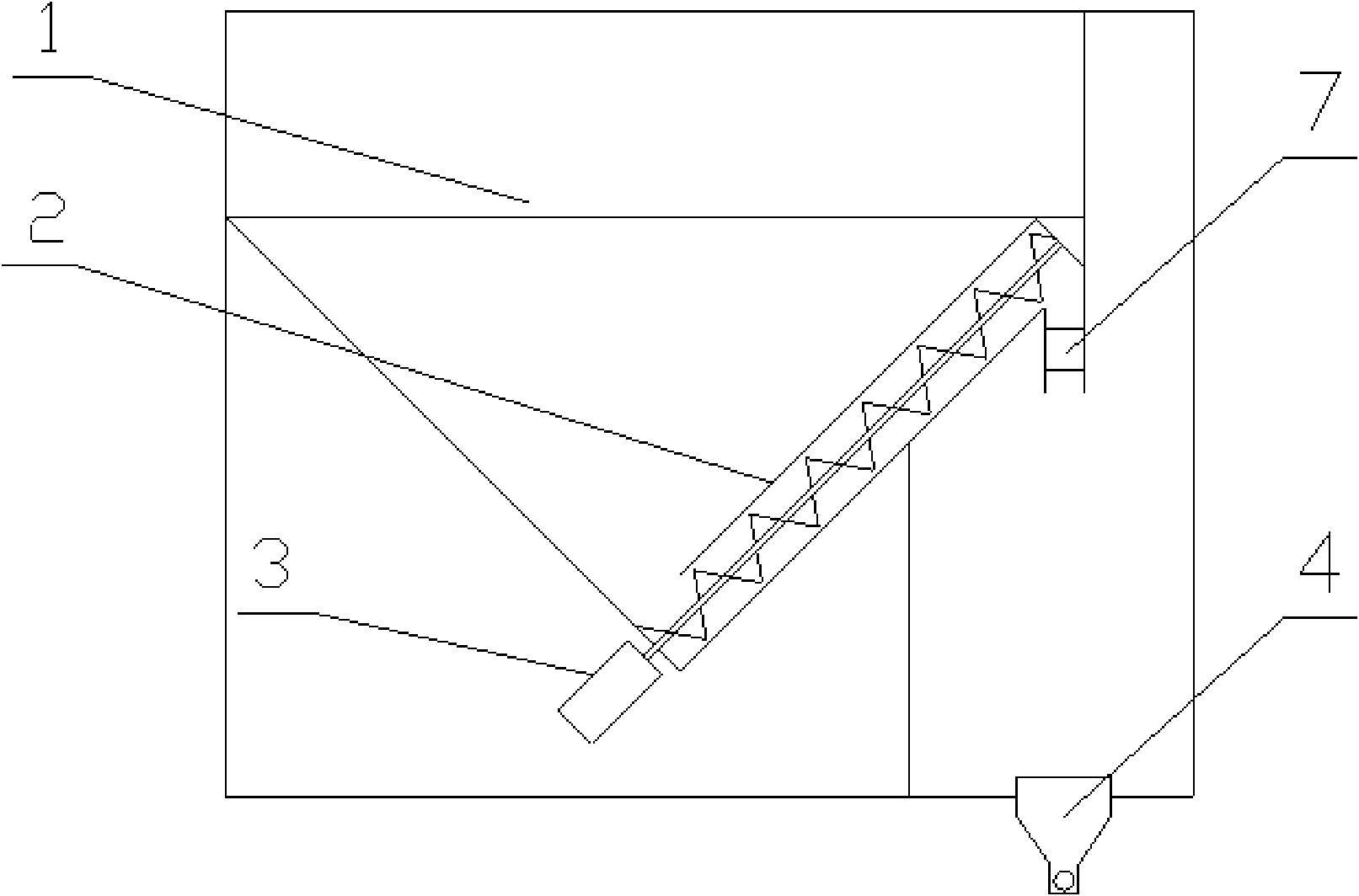

[0026] in such as figure 1 figure 2 In the shown embodiment 1, a wide flame closed fireplace includes a furnace, an air inlet and outlet system, and a hot air system. A ventilation duct and a combustion chamber (not shown in the figure) are arranged in the furnace, and a hopper is provided on the rear side of the furnace. 1 and the fuel conveying device 2, the front wall of the hopper 1 is the rear wall of the furnace, the fuel conveying device is an auger device driven by the motor 3, and is arranged on the bottom slope of the fireplace hopper, and the bottom of the combustion chamber is provided with a furnace box 4, The furnace box is a long groove structure, the bottom is provided with a heating rod 5, the two sides of the heating rod are provided with air inlets 6, the length of the furnace box is 60% of the width of the furnace, and the length direction of the furnace box is consistent with the width direction of the fireplace , the rear wall of the hearth above the fu...

Embodiment 2

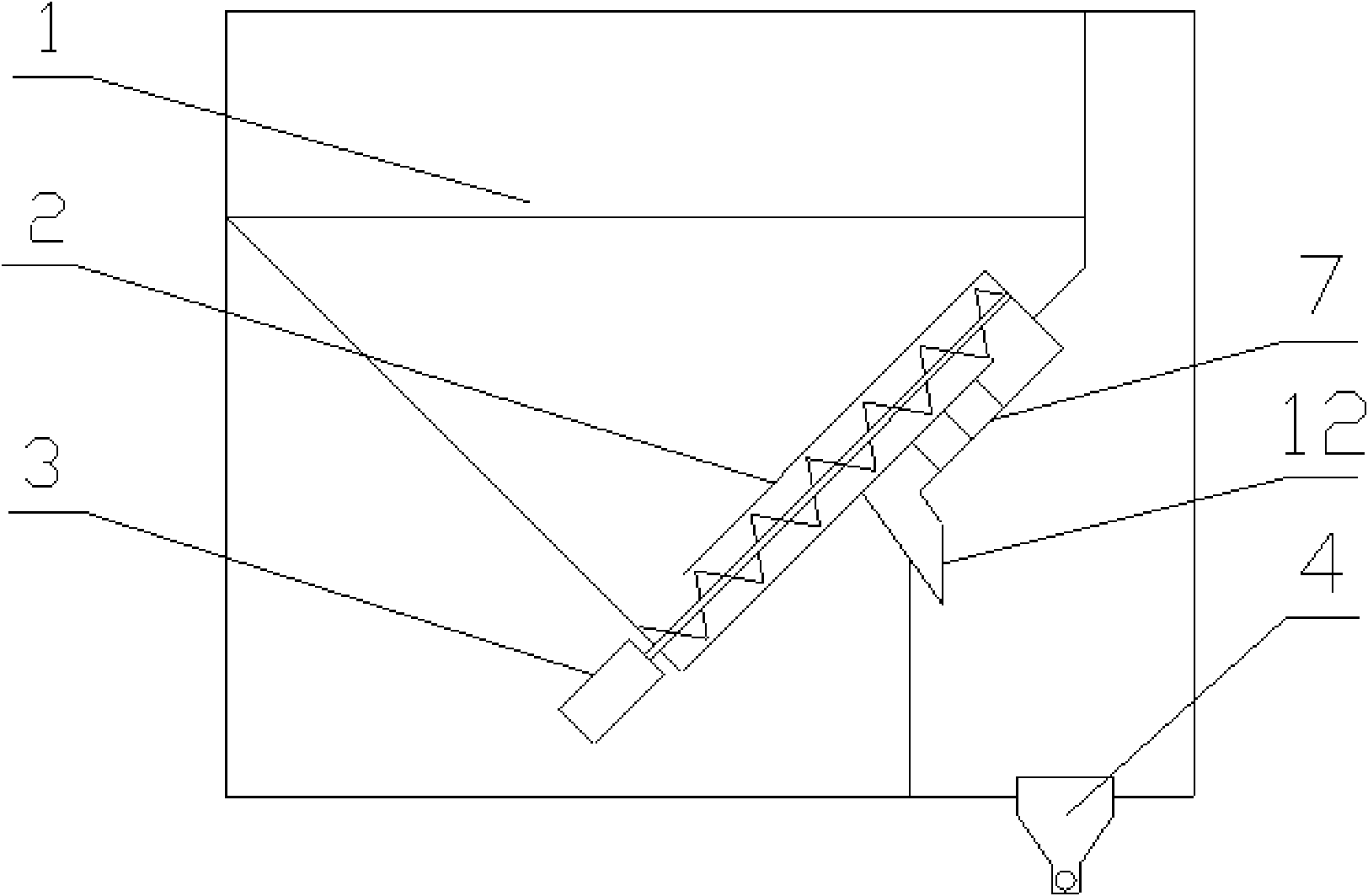

[0028] in such as image 3 In the shown embodiment 2, the length of the furnace box is 70% of the width of the furnace, the material distribution device is arranged obliquely, the feed inlet is arranged on the top side of the material distribution chamber, and the distribution rods in the material distribution chamber are arranged in layers and misplaced. , the distribution density of the distribution rods near the edges on both sides is greater than that of the distribution rods in the middle (see Figure 7 ), the material distribution chamber is close to the rear wall of the furnace, the discharge port of the material distribution device is connected with a guide device 12, and the outlet of the guide device is located at the side top of the furnace box, and the rest are the same as in embodiment 1.

Embodiment 3

[0030] in such as Figure 4 In the shown embodiment 3, the length of the furnace box is 50% of the width of the hearth, the distribution device is arranged obliquely, and is in a state perpendicular to the furnace wall, and the distribution cavity is an equal thickness structure, which is independently arranged (see Figure 8 ), the discharge port of the material distribution device is located above the side of the furnace box, the bottom of the furnace box is provided with a heating rod, the two sides of the heating rod are provided with air inlets, and the side wall of the furnace box near the rear wall of the furnace is provided with a number of air inlets hole 13 (see Figure 9 ), all the other are identical with embodiment 1.

[0031] The hearth, furnace door, air inlet and outlet system, hot air system and fuel delivery device of the wide-flame closed fireplace are basically consistent with the existing technology, and the working principle and working process of its co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com