Mechanical excavation method for hard-rock tunnel with medium-short length

A tunneling and mechanical technology, applied in tunnels, earth-moving drilling, mining equipment, etc., can solve problems such as restriction of driving efficiency and high energy consumption, and achieve the effect of improving economy and excavation efficiency and reducing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, the mechanical excavation method for medium and short length hard rock tunnels proposed by the present invention is adopted. The specific construction method is as follows:

[0028] (1) Mechanically excavate the road cutting at the entrance of the hole and take preliminary protection and drainage measures.

[0029] (2) Do a good job of opening support or pre-support structure.

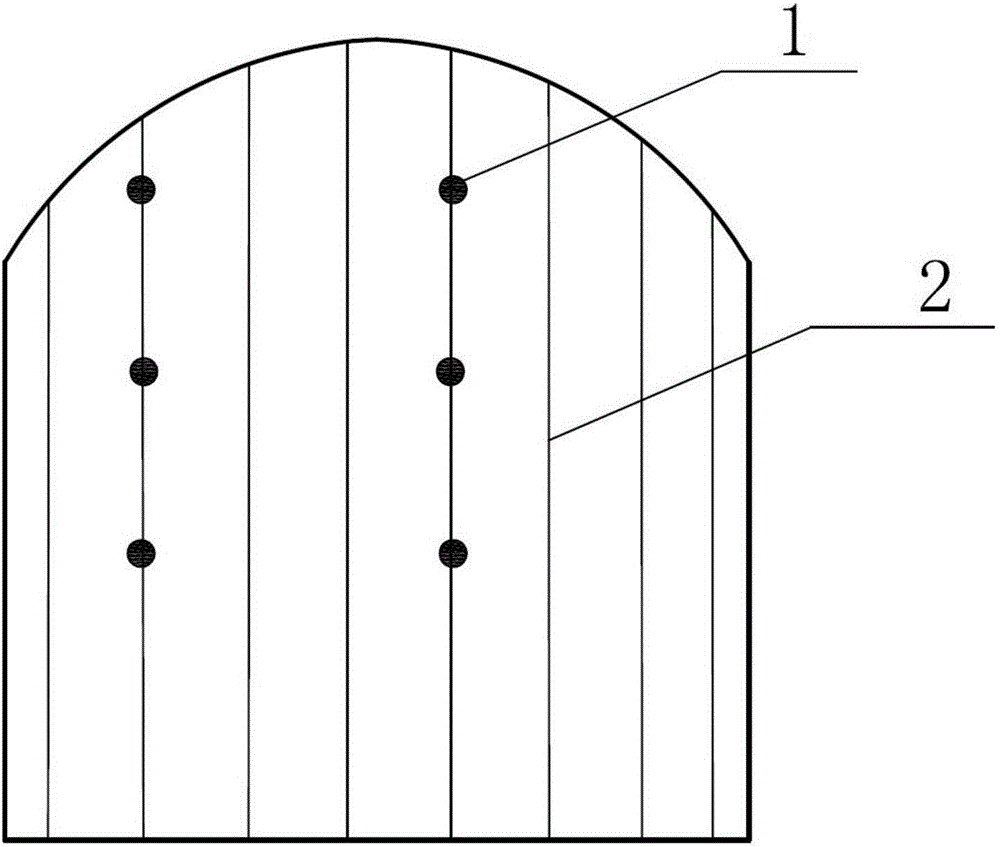

[0030] (3) Use a rock saw (rock saw blade specification φ2200mm) to cut a vertical groove with a depth of 50 cm every 60 cm on the face of the tunnel starting from one side of the tunnel contour, as shown in figure 1 shown. The width of each vertical groove is 1 cm.

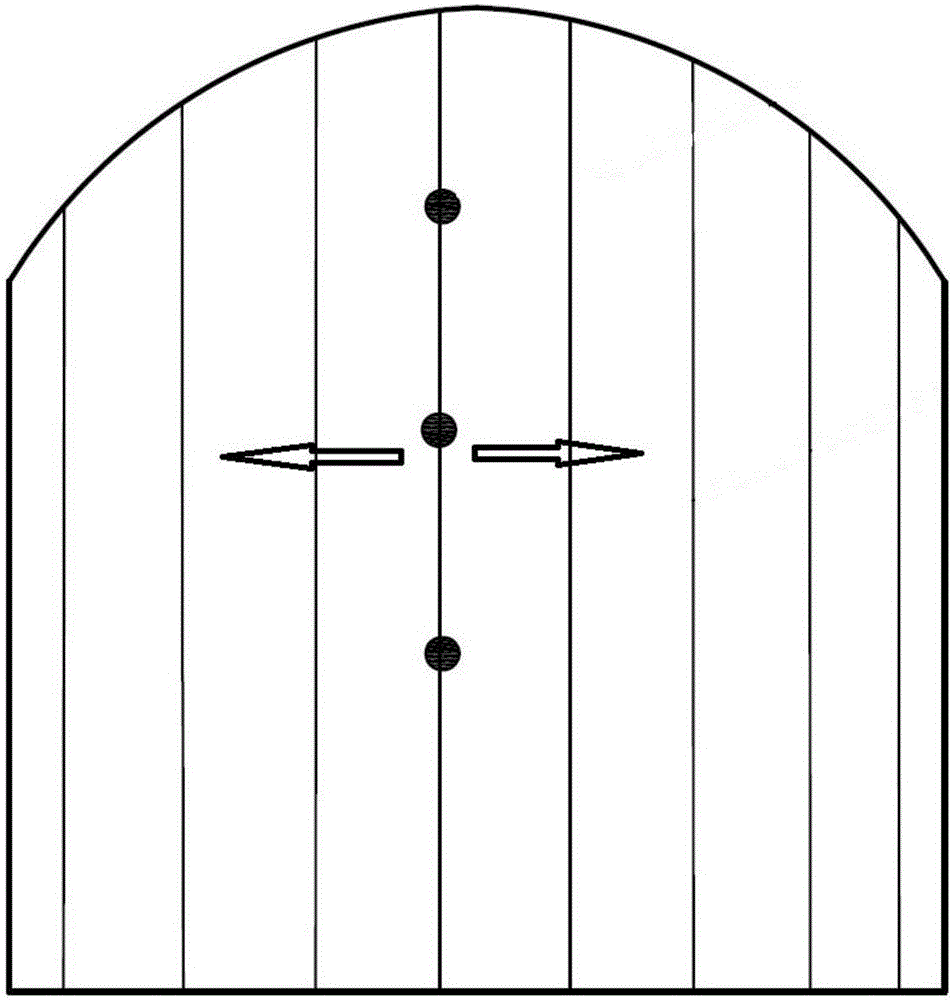

[0031](4) Mark a fracturing point 1 every 120cm in the vertical groove 2 in the tunnel. The crushing equipment starts to crush the rock mass from the middle of the face. The drill rod of the hydraulic breaker is pushed against the fracturing point 1, and the diameter of the drill rod should be greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com