Closing structure for flat tube of condenser of automobile air-conditioner

A technology for automotive air conditioners and flat tubes, which is applied to evaporators/condensers, refrigerators, tubular components, etc. It can solve problems such as poor appearance, difficulty in insertion and positioning, and inability to ensure no change, so as to ensure welding reliability, The effect of improving appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

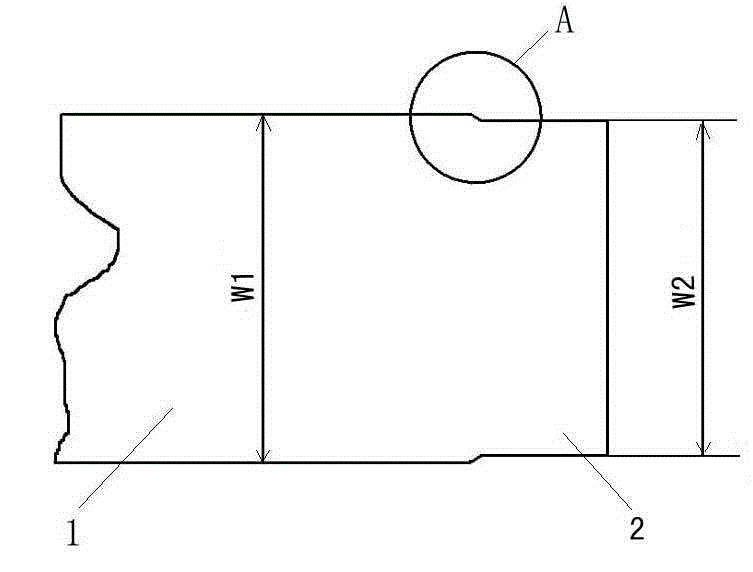

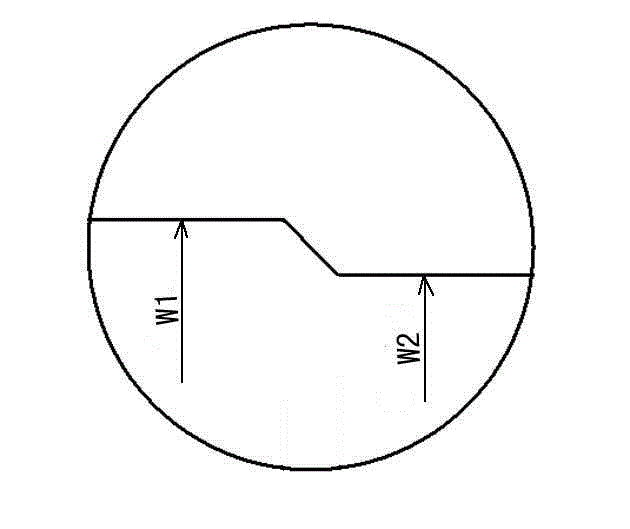

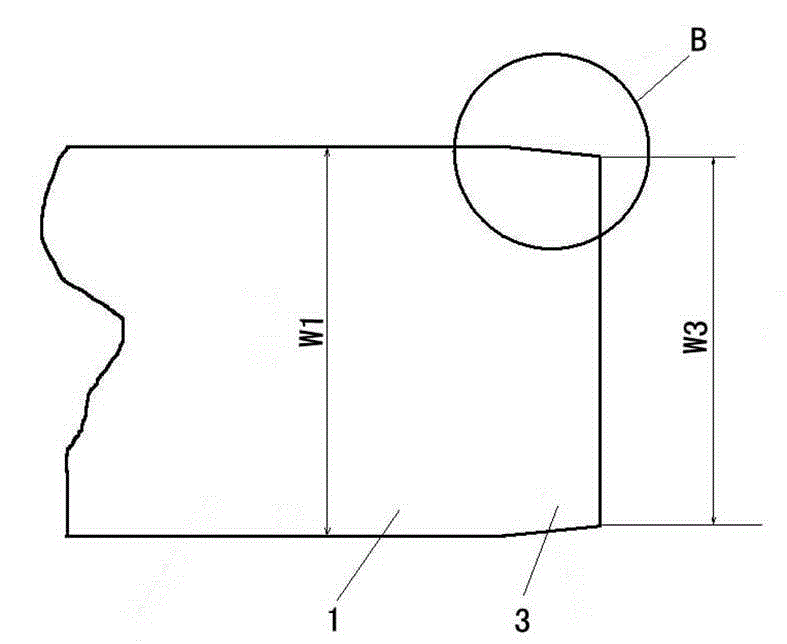

[0011] attached figure 1 It is a structural schematic diagram of the step inserted into the end of the flat tube in the prior art, with figure 2 to attach figure 1 The enlarged schematic diagram of the insertion step in , in the figure, 1 is the body of the flat tube, and 2 is the end of the flat tube. As can be seen from the figure, in order to facilitate assembly and positioning, an insertion step is designed at both ends of the flat tube. The so-called insertion step refers to reducing the width of both ends of the flat tube to a certain size (usually called the closing), so that the two ends of the tube body The portion width dimension becomes smaller to form a step. A flat tube assembly hole (usually called a flat tube groove or a flat tube hole) is provided on the header, and the size and shape of the hole match the closed section of the flat tube. In this embodiment, the nominal width W1 of the flat tube is 16 mm, and the nominal width W2 of the mouth of the flat tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com