A vapor-liquid separator

A technology of vapor-liquid separator and outlet connection, which is applied in refrigeration and liquefaction, lighting and heating equipment, refrigeration components, etc. It can solve problems such as roughness of the press-fitting part, difficulty in press-fitting of the copper outlet connection, and poor product consistency. The effect of welding fit distance stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solution of the present invention, further detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

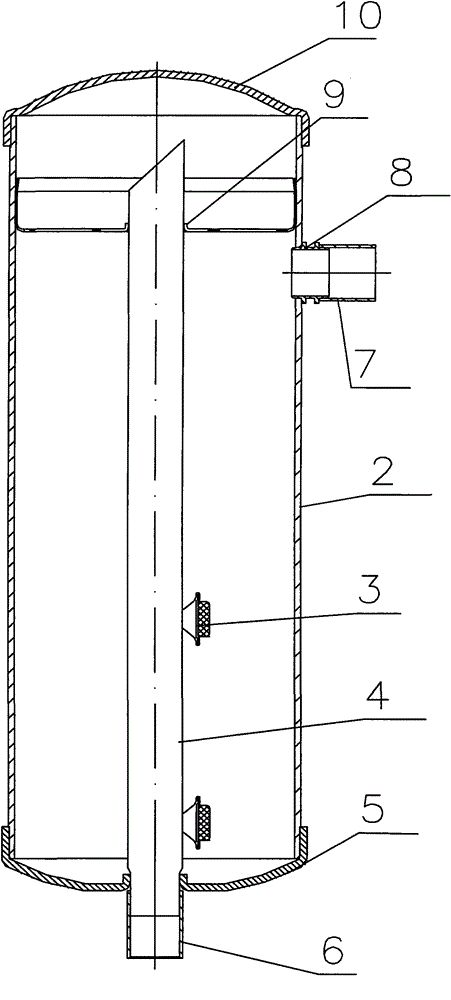

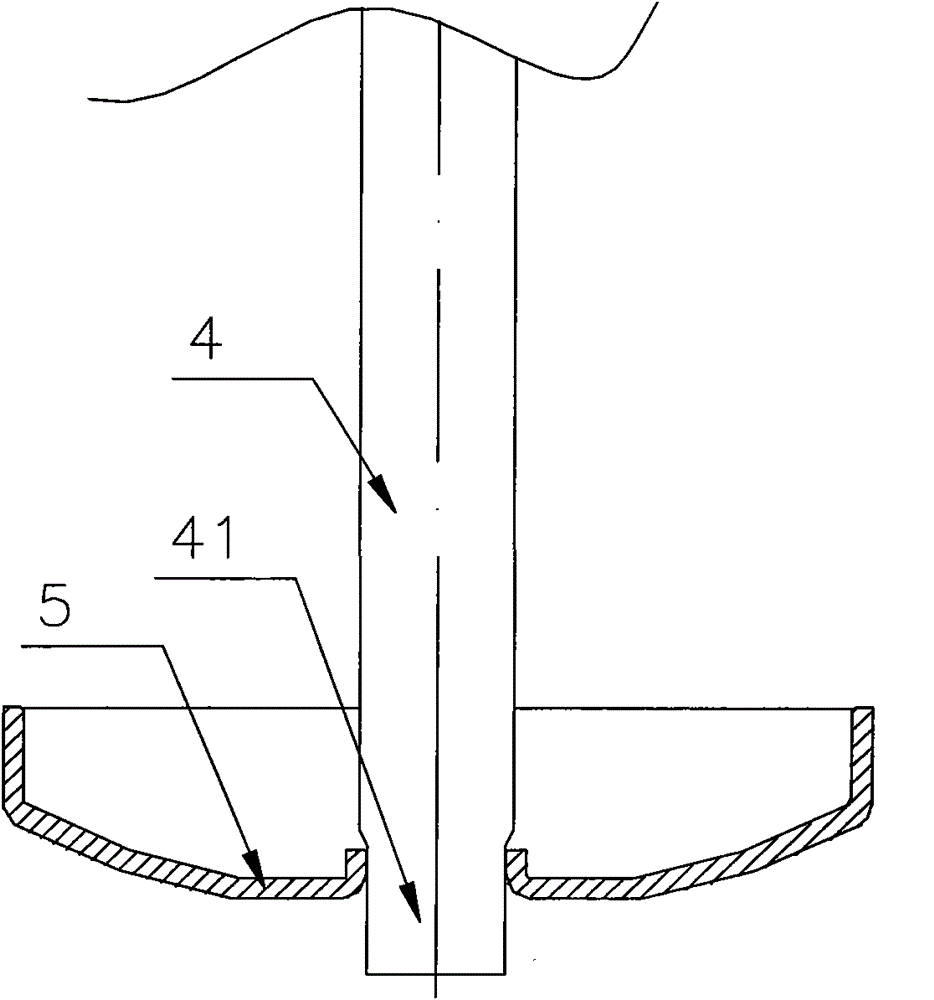

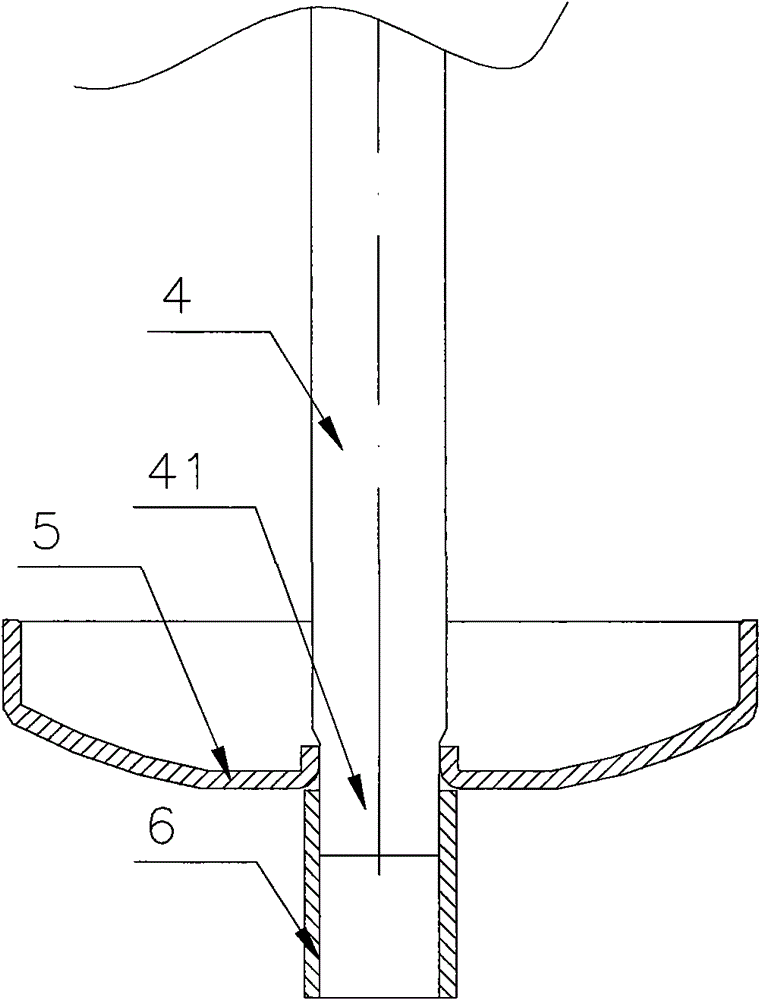

[0025] Figure 4 It is a structural schematic diagram of an embodiment of the vapor-liquid separator of the present invention, Figure 5 for Figure 4 The schematic diagram of the lower end cover of the gas-liquid separator and the iron pipe after pressing, Image 6 for Figure 4 Schematic diagram of the outlet connecting pipe of the gas-liquid separator after being press-fitted with the lower end cover and the iron pipe. As shown in the figure, the gas-liquid separator includes a cylinder body 2, an upper end cover 10 at the upper end of the cylinder body 2, and a lower end cover 15 at the lower end of the cylinder body 2. An iron bushing 8 is also fixed on the simplified body 2, and the lower end cover 15 is provided with a The out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com