Ultra wide band millimeter wave vertical interconnection structure based on HTCC

An interconnection structure and millimeter wave technology, applied in the field of radio frequency interconnection, can solve problems such as discontinuity of radio frequency signal transmission, and achieve the effects of good consistency, high reliability and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

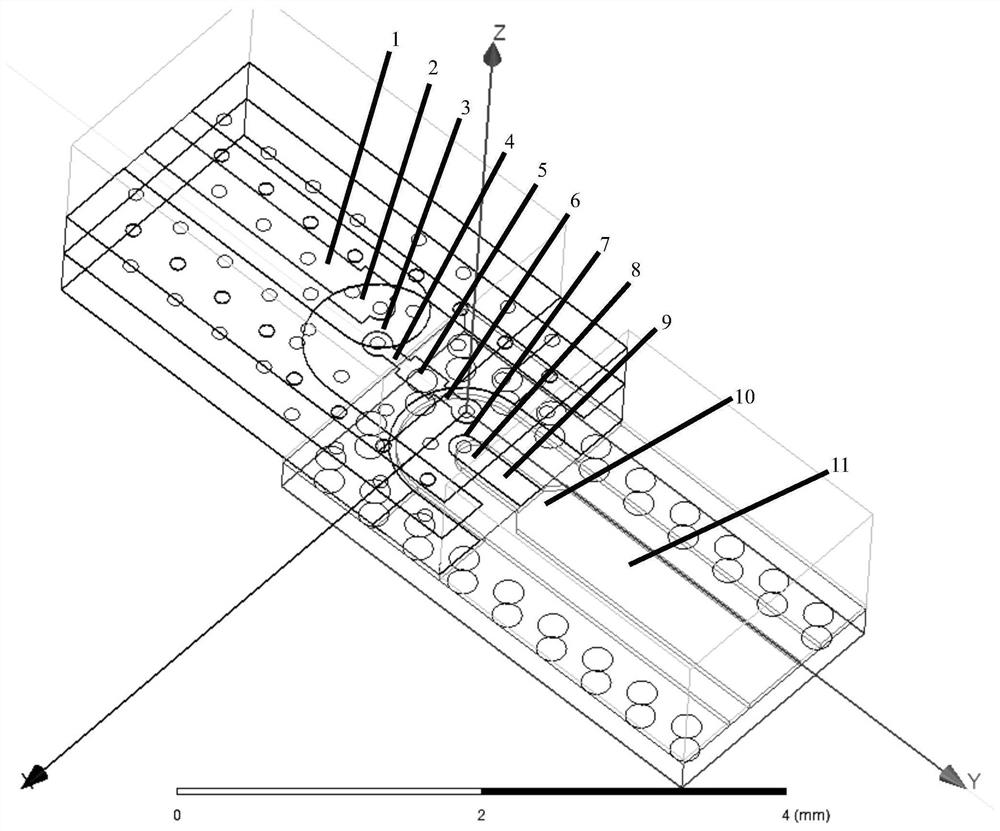

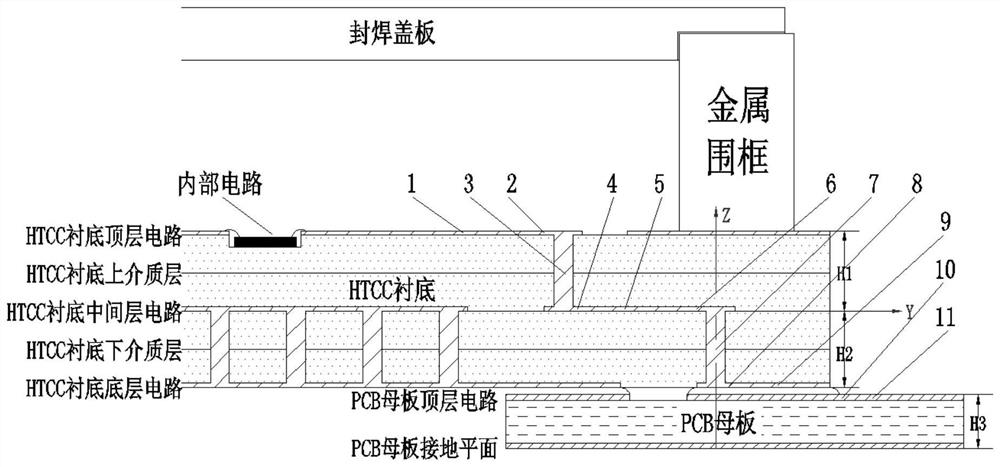

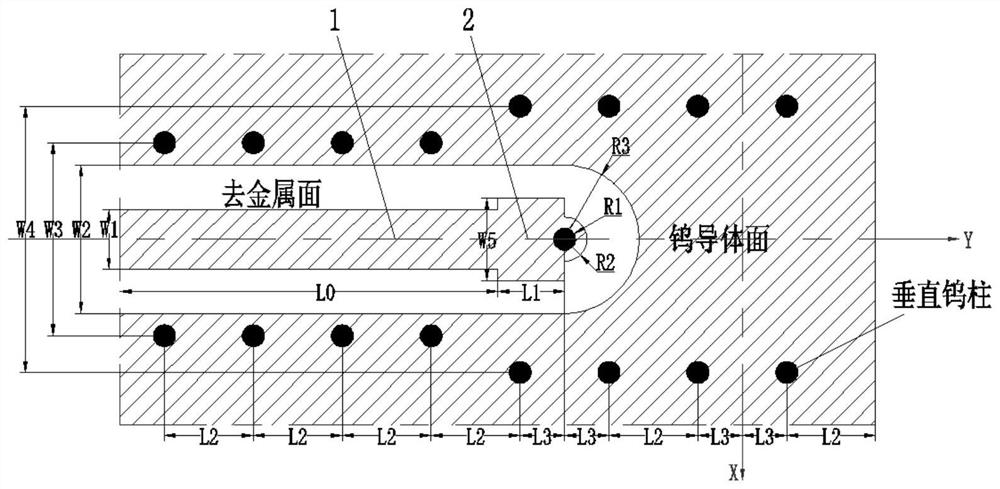

[0041] An HTCC-based ultra-wideband millimeter-wave vertical interconnection structure disclosed by the present invention, such as figure 1 as shown, figure 1 The sectional view of the middle YOZ plane is as follows figure 2 as shown, figure 2 HTCC substrate top layer circuit pattern such as image 3 as shown, figure 2 The pattern of the dielectric layer on the medium HTCC substrate is as follows Figure 4 as shown, figure 2 The circuit pattern of the middle layer of the HTCC substrate is as follows: Figure 5 as shown, figure 2 The pattern of the dielectric layer under the medium HTCC substrate is as follows Figure 6 as shown, figure 2 The underlying circuit pattern of the HTCC substrate is as follows: Figure 7 as shown, figure 2 The top layer circuit pattern of the middle PCB mother board is as follows: Figure 8 shown. The present invention achieves vertical interconnection by rationally designing the pattern of each tungsten conductor layer in the HTCC...

Embodiment 2

[0063] Such as figure 2 As shown, the present invention provides a packaging structure, including the HTCC-based ultra-wideband millimeter-wave vertical interconnection structure of Embodiment 1, a sealing cover plate and a metal enclosure, and the HTCC-based ultra-wideband millimeter-wave vertical interconnection structure is installed on the package The welding cover plate and the metal enclosure, and the sealing welding cover plate is covered in the metal enclosure.

[0064]In this embodiment, the packaging structure provided by the present invention adopts the HTCC-based ultra-wideband millimeter-wave vertical interconnection structure of Embodiment 1, which has excellent electrical characteristics such as ultra-high operating frequency, ultra-wide operating frequency band, and ultra-low insertion loss. At the same time, the interconnect structure is easy to process, has high reliability, good consistency, and strong derivability, which is very suitable for mass productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com