Chip ferrite product electro-plating pre-treatment method

A technology for electroplating pretreatment and ferrite, which is applied in the field of electroplating pretreatment of chip ferrite products, and can solve the problems of uneven products, decreased welding performance of products with coating thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

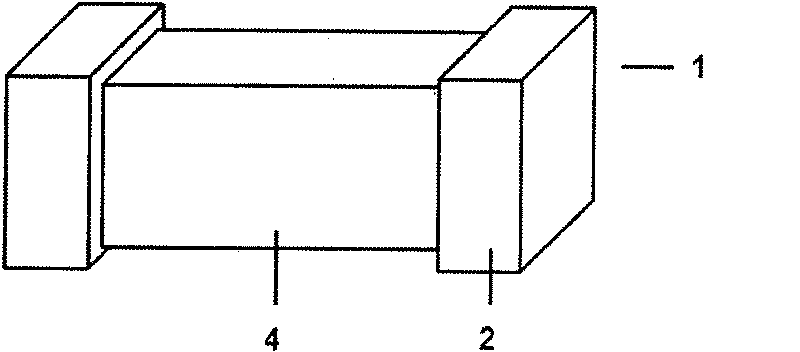

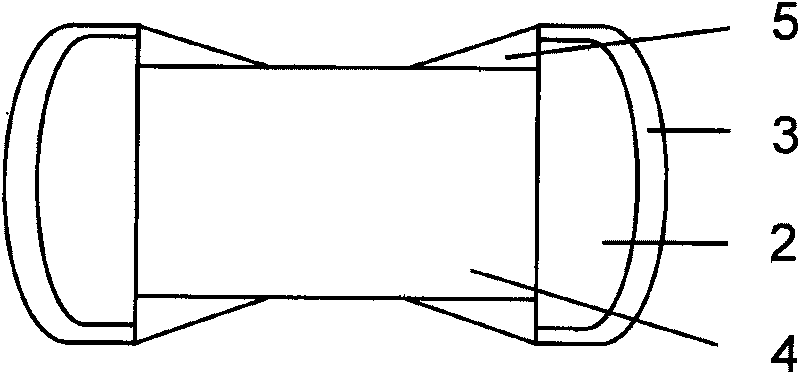

Image

Examples

Embodiment 1

[0024] Embodiment 1: the electroplating pretreatment method of ferrite product, comprises the following steps:

[0025] 1. Dissolve the iron dispersant OA-01 (produced by Shanghai Maike Import and Export Co., Ltd.) in propyl acetate, and prepare four kinds of iron dispersant OA-01 with contents of 1‰, 2‰, 3‰, 5‰ of OA-01 solution.

[0026] 2. Place ferrite semi-finished products in glass cups containing four kinds of OA-01 solutions respectively. The volume ratio of ferrite semi-finished products and OA-01 solutions is 1:2.

[0027] 3. Put the four kinds of OA-01 solution glasses in the water of ultrasonic cleaning equipment with a water temperature of 55°C, the water level is 2 / 3 of the glass height, and the vibration time is 10 minutes.

[0028] 4. Take out the processed ferrite semi-finished product, wash it with 80°C pure water for 5 times, and complete the electroplating pretreatment process of the ferrite product.

[0029] Electroplate the above four ferrite semi-finis...

Embodiment 2

[0033] Embodiment 2: the electroplating pretreatment method of ferrite product, comprises the following steps:

[0034] 1. Dissolve iron dispersant OA-01 (manufactured by Shanghai Maike Import & Export Co., Ltd.) in propyl acetate to prepare OA-01 solution with a content of 3‰.

[0035] 2. Soak the ferrite semi-finished product in a glass cup filled with OA-01 solution for 10 hours. The volume ratio of ferrite semi-finished product to OA-01 solution is 1:2.

[0036] 3. Take out the processed ferrite semi-finished product, wash it with 80°C pure water for 5 times, and complete the electroplating pretreatment process of the ferrite product.

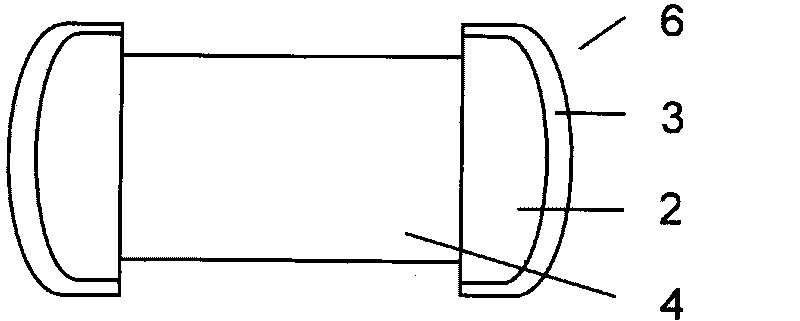

[0037] Electroplating the ferrite semi-finished product after the pre-plating treatment above: use barrel plating to electroplate a nickel layer and a tin layer on the outside of the silver terminal to obtain the following: image 3 The ferrite inductor finished product 6 shown in the figure, the magnet surface of the finished ferrite indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com