Deep and narrow gap submerged arc welding device with melon petal welding track self-recognition and welding method

A narrow-gap, self-identifying technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problem of insufficient technical adaptability, failure to remove manual teaching procedures, failure to achieve independent planning and intelligent welding path control issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

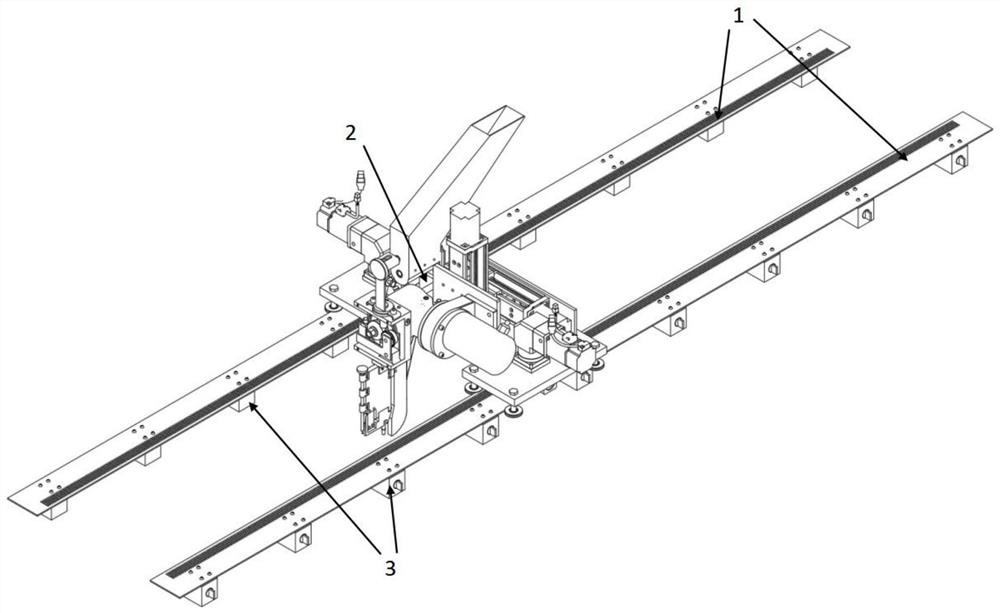

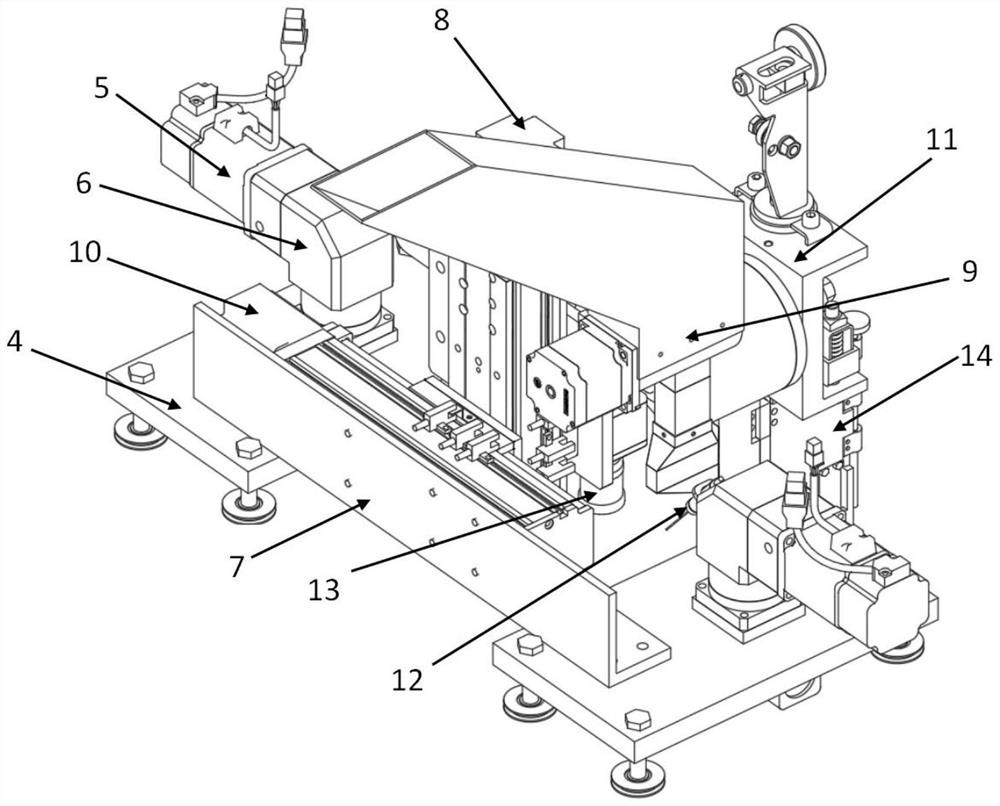

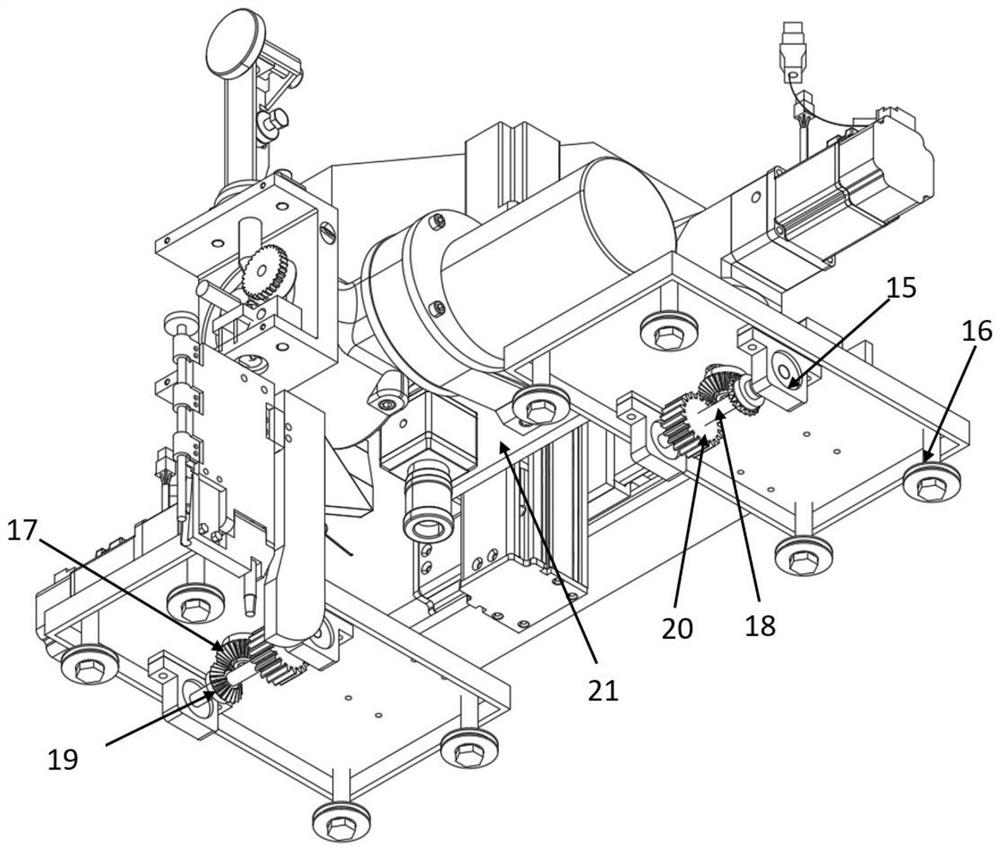

[0060] see Figure 1 to Figure 3 As shown, the present invention provides a deep narrow gap submerged arc welding device for self-identification of melon petal welding trajectory, including a flexible track, a laser vision sensor and a device walking body 2; The flexible guide rails 1 arranged in parallel on both sides, each flexible guide rail 1 is fixed with a switch magnet seat 3 for absorbing the parts to be welded; An integrated guide mechanism, an automatic flux delivery mechanism 9 positioned above the deep and narrow gap to be welded, a deep and narrow gap welding torch 14, an automatic wire feeding mechanism 11 fixedly connected above the deep and narrow gap welding torch 14, the deep and narrow gap The welding torch 14 is fixedly connected to the side of the automatic flux delivery mechanism 9, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com