Gear rack center distance adjusting mechanism

A technology of adjusting mechanism, gear and rack, applied in the direction of belt/chain/gear, mechanical equipment, transmission parts, etc., can solve the problems of inaccurate positioning, long transmission distance, difficult to guarantee the quality of processed workpieces, etc., and achieve accurate positioning accuracy , easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

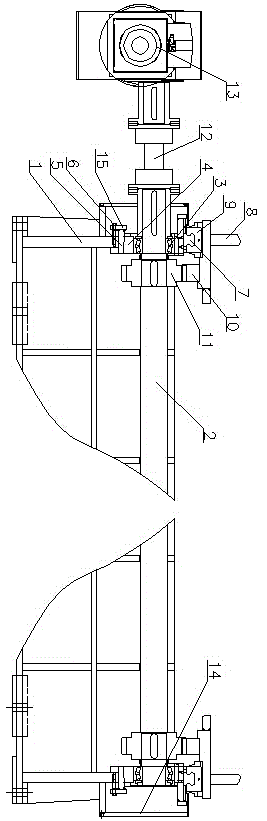

[0014] A rack and pinion center distance adjustment mechanism, including a frame 1 installed on the base, a synchronous shaft 2 is installed on the width direction of the frame 1, and the two ends of the synchronous shaft 2 are installed on both sides of the frame 1 through bearings 3 In the bearing seat, an upper wedge 4 is provided under the bearing seat, and a lower wedge 5 matching with the upper wedge 4 is provided at the lower end of the upper wedge 4, and an adjusting screw 6 is connected to the outer end of the lower wedge 5 , the upper end of both sides of the frame 1 is provided with a linear guide rail 7, and the linear guide rail 7 is provided with a slider 9 installed on the lower end of the knife rest 8, and racks 10 are installed on both sides of the lower end surface of the knife rest 8, and the synchronous rotating shaft 2 There are two synchronous gears 11 on the upper sleeve, and the two synchronous gears 11 are respectively meshed with the rack 10, and one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com