A processing method for electric steering gear rack

A technology of electric steering and processing method is applied in the field of auto parts processing technology to achieve the effects of improving efficiency, reducing cutting stress and improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

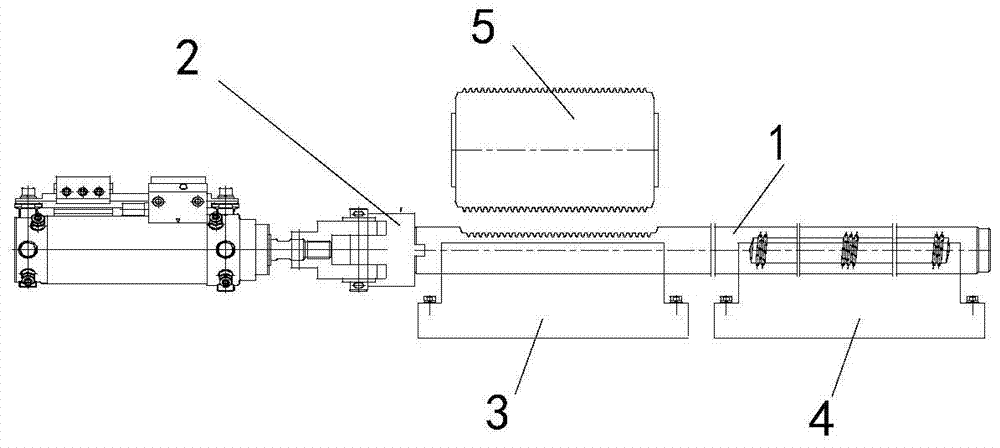

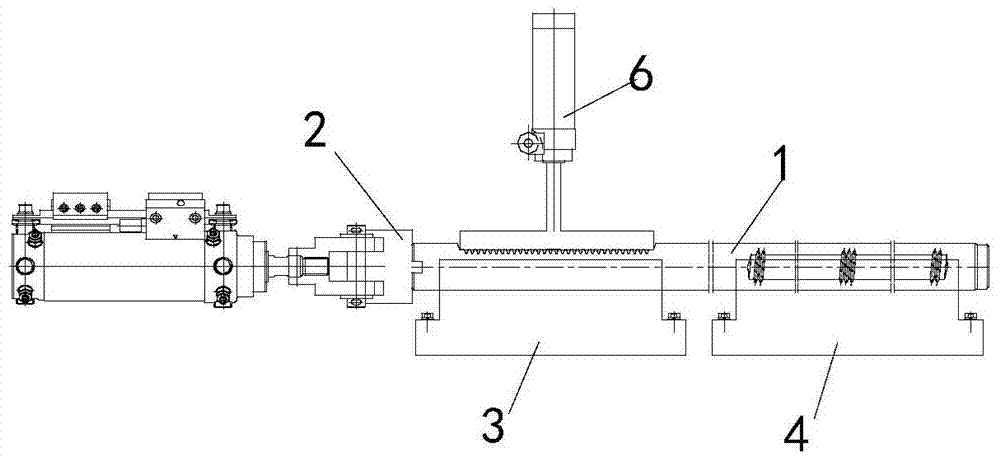

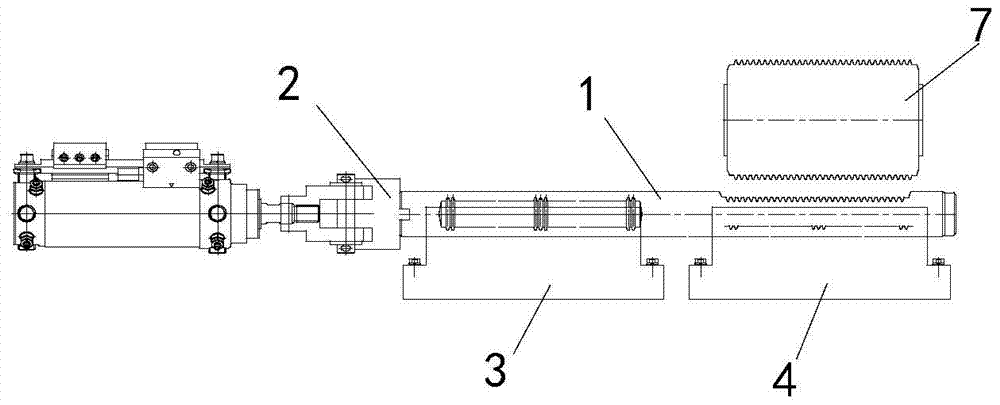

[0021] Cooperate see Figure 1 to Figure 4 , the processing method of the electric steering gear rack of the present invention is that the driving teeth and the driven teeth at the two ends of the rack are roughly milled first, and a good margin and deformation are reserved for combined grinding; ℃ tempering, then placed in a box furnace for 560 ℃ stress relief tempering, heat preservation for 4 hours, then air cooling, multi-point automatic alignment to ensure straightness of 0.05, natural aging for 4 days, so that the internal stress of raw materials and chip stress Release to prepare for combined grinding; then clamp the rack after natural aging for 4 days on a combined grinding machine; carry out combined grinding of active teeth and driven teeth to meet the stated requirements.

[0022] The specific practice of combination grinding Figure 1 to Figure 4 described as follows:

[0023] First clamp the rack 1 with the servo rotating end face positioning fixture 2, and use th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com