A kind of multi-blade T-shaped tool and its processing method

A processing method and cutting tool technology, which is applied to metal processing equipment, milling cutters, manufacturing tools, etc., can solve the problems of melting chips, chip breaking, and poor chip removal, so as to reduce the phenomenon of tool breaking, prevent chip sticking, reduce Effect of small chip volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

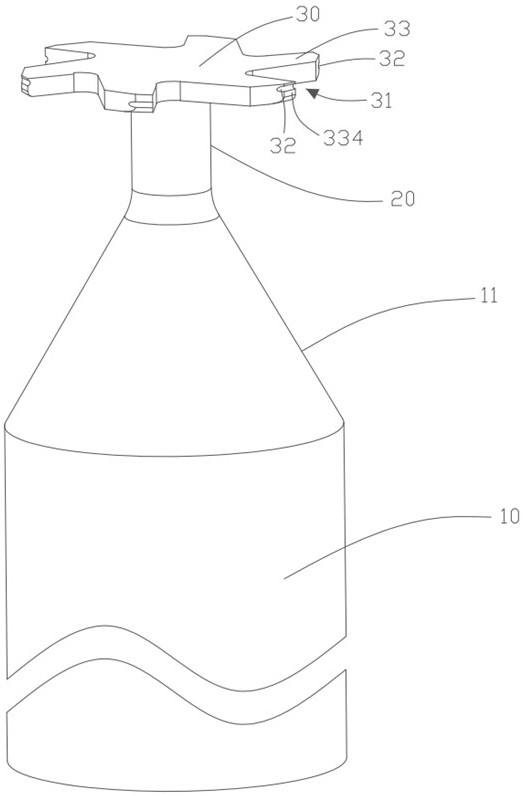

[0035] On the one hand, please refer to the attached Figure 1-5 , The invention provides a multi-edged T-shaped cutter.

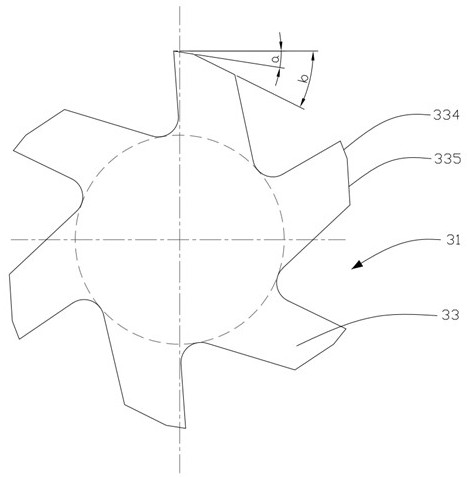

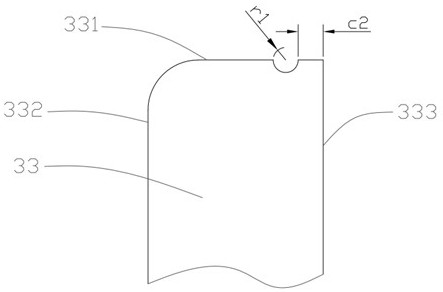

[0036] The multi-edged T-shaped cutter includes: a cutter bar 10 , a neck 20 connected with the cutter bar 10 , and a cutting head 30 connected with the neck 20 . The material of the cutter bar 10 , the neck 20 and the cutting head 30 are all cemented carbide, and the neck 20 and the cutting head 30 are T-shaped. The cutting head 30 is formed with: an even number of cutting edges 33 evenly distributed, and a chip removal groove 31 between the two cutting edges 33 for chip removal. An even number of cutting edges 33 form a spiral shape. The cutting edge 33 includes a peripheral edge 331. The peripheral edge 331 includes a first relief surface 334 and a second relief surface 335. A chip breaker 32 is opened on the first relief surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com