Positioning fixture for turning inner hole in casting

A technology for positioning fixtures and inner holes, which is applied in the field of mechanical processing, can solve the problems of scrapped workpieces, failure of inner hole turning, and difficult positioning of inner holes to be turned, and achieve the effect of reducing scrap rate and improving concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the content of the present invention easier to be understood clearly, the following further describes the present invention in detail based on specific embodiments in conjunction with the accompanying drawings.

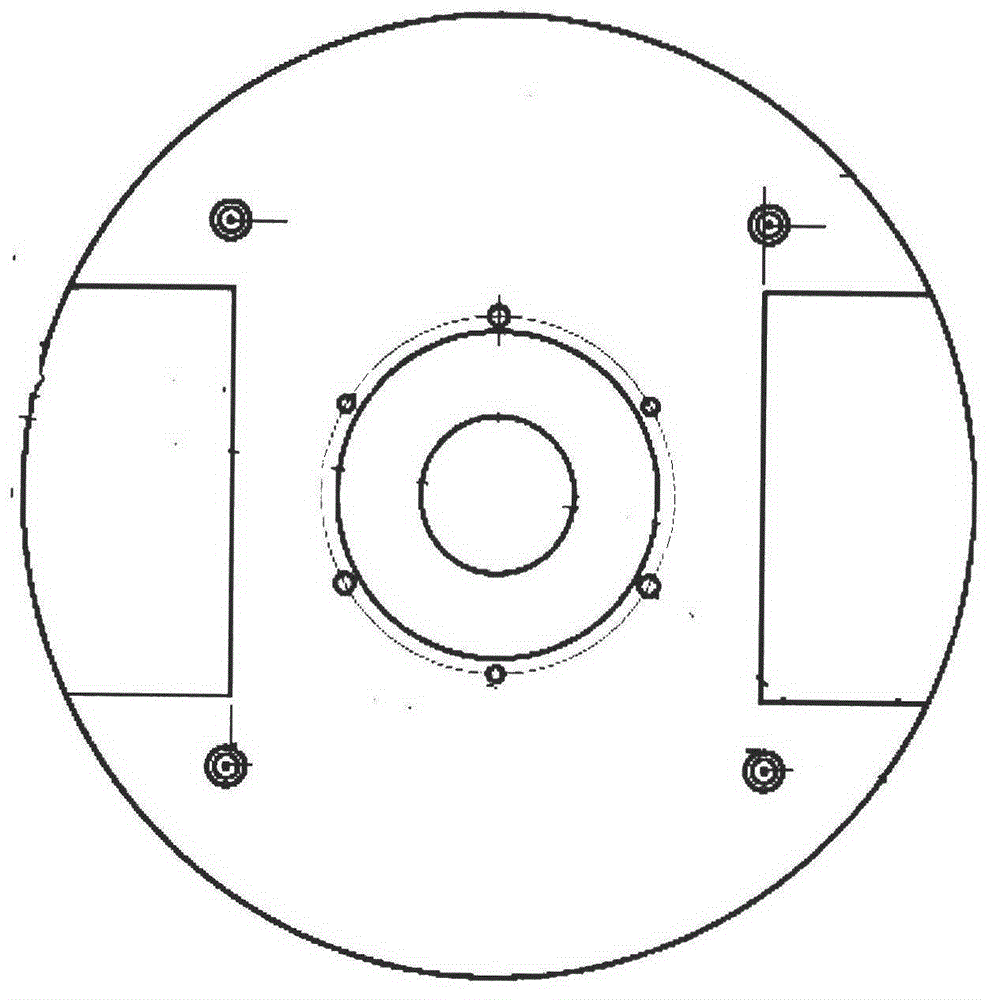

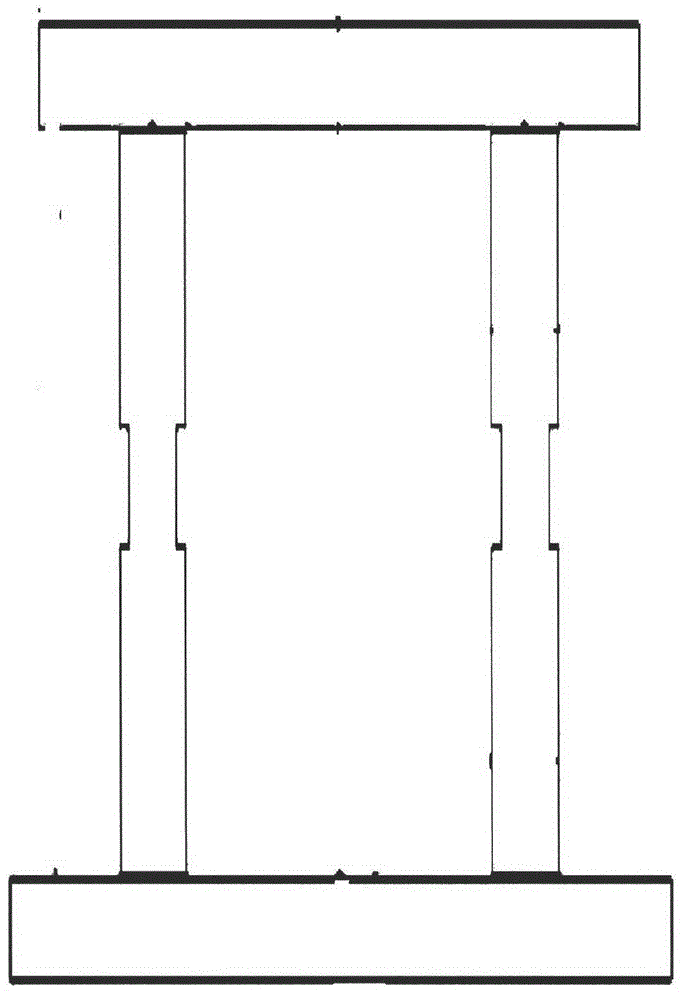

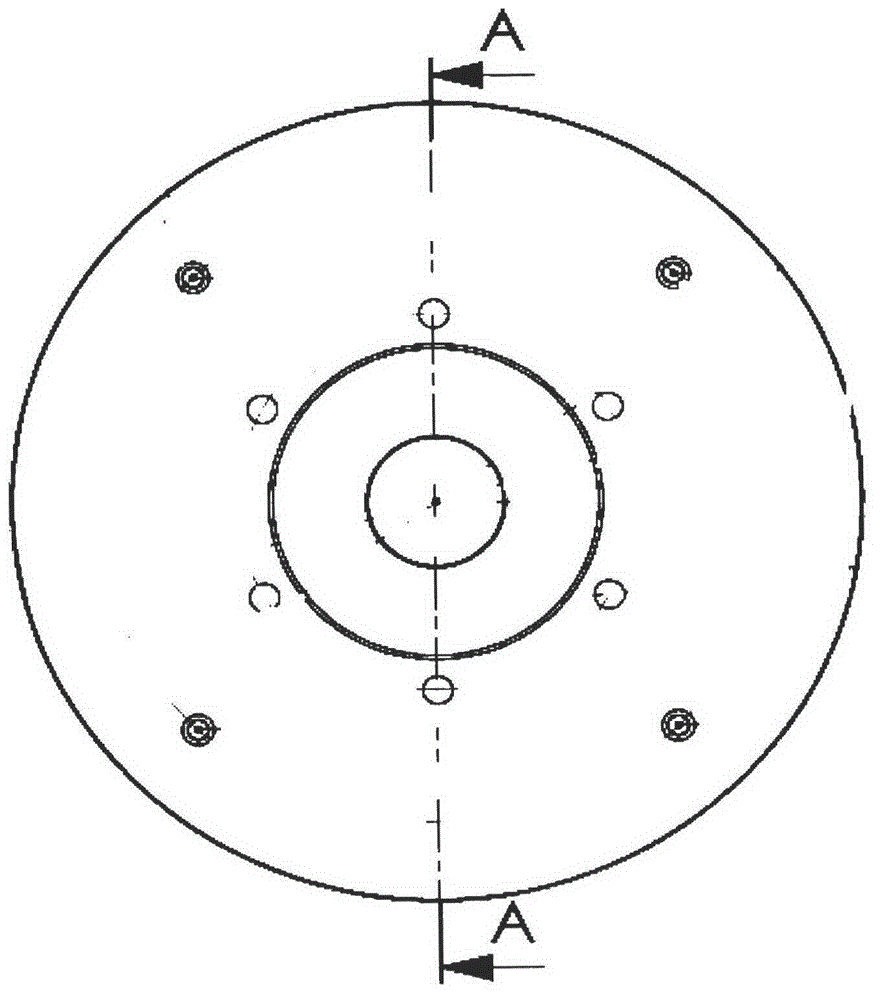

[0024] See Figure 1-Figure 5 , A positioning fixture for casting inner hole turning, a pair of flanges are arranged in parallel, and the pair of flanges are fixedly connected by 4 pins 3; the center of the first flange 1 is provided with a first pass Hole 101, the center of the second flange plate 2 is provided with a second through hole 201, the first and second through holes are coaxial, and the aperture of the second through hole 201 is larger than the aperture of the first through hole 101; The flange 1 is provided with a first set of pin holes 103, and the holes of the first set of pin holes 103 are evenly distributed on a circumference centered on the center of the first flange; the second flange 2 is provided with a second Group pin holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com