outboard carburetor

A carburetor and carburetor technology, applied in carburetor, machine/engine, mechanical equipment, etc., can solve the problems of increased emission of pollutants, unstable idling, and high cost, and achieve the reduction of pollutant emissions and throttle Fast response and less pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with specific embodiments.

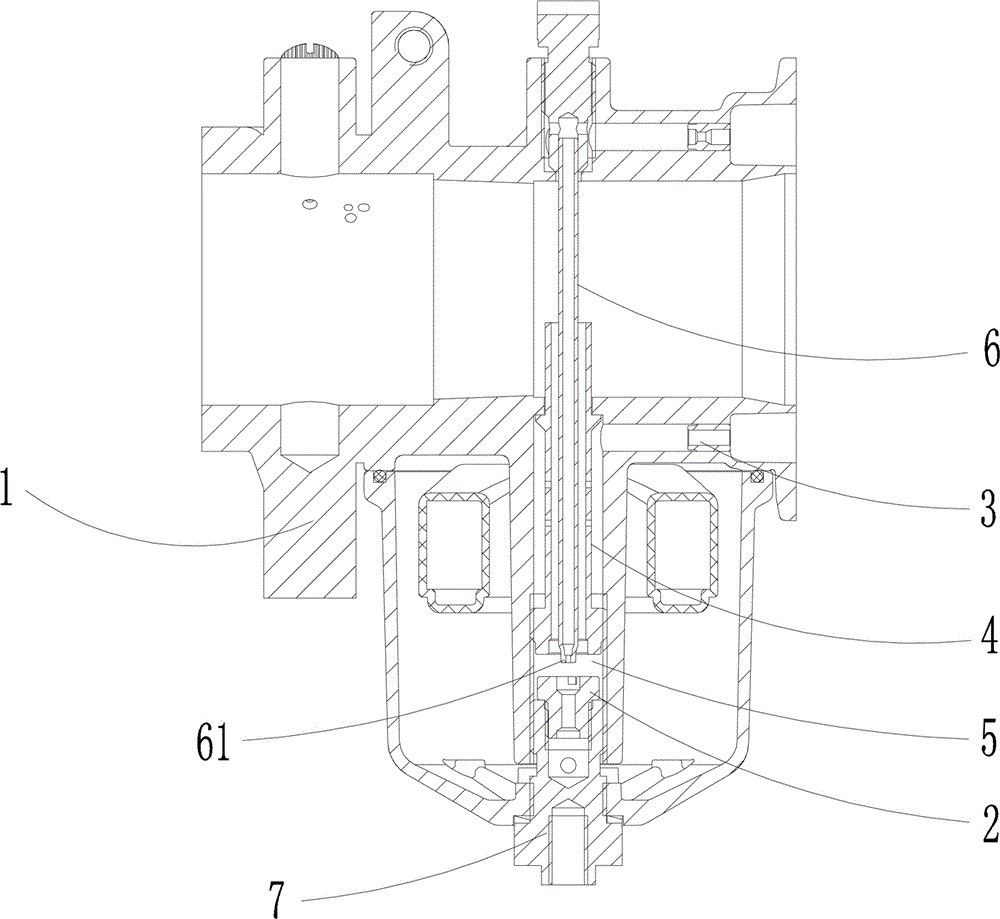

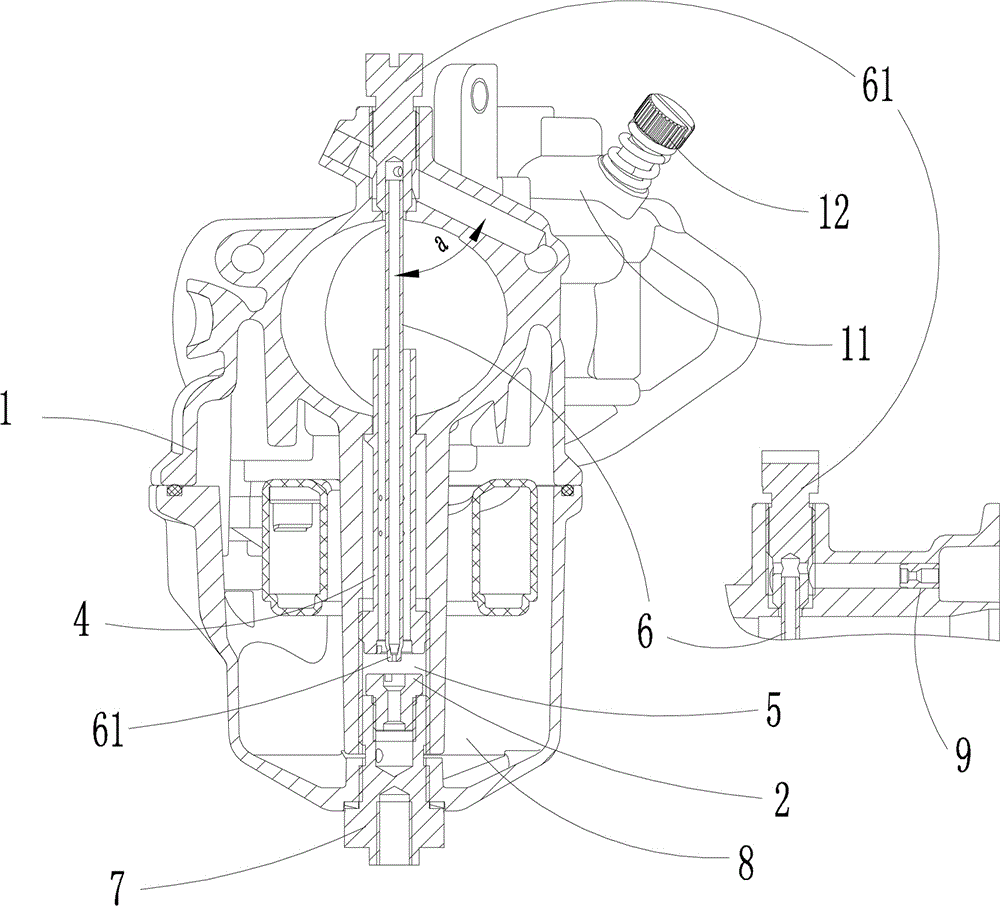

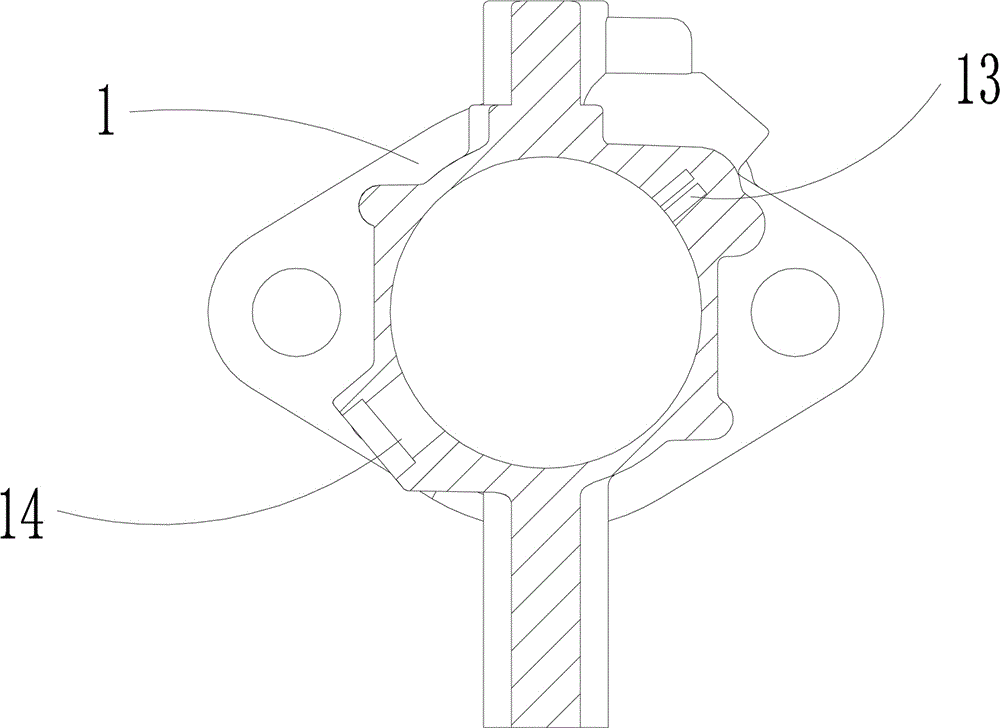

[0021] see figure 1 and figure 2 As shown, it is a structural schematic diagram of the oil circuit system of the original outboard carburetor, including the carburetor body 1, and the original main oil circuit system and the idle speed oiler channel on the body 1 are combined in one It is mainly composed of the main measuring hole 2, the main air hole 3, the foam tube 4 and the oil channel 5, etc., and a copper tube 6 is installed in the foam tube 4, and the lower end of the copper tube 6 is an idle speed measuring hole 61 constitutes the idle oiler channel. In the original main oil circuit and idle oiler system structure, the fuel in the float chamber 8 passes through the side hole of the connecting bolt 7 and the main measuring hole 2 installed on the connecting bolt to the foam tube 4 and The lower part of the idle speed metering hole 61 is divided into two branches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com