Split overlength shaft sleeve and bearing ring inner bore processing auxiliary device and processing method

An auxiliary device and bearing ring technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of low precision of parts, large matching clearance, inability to ensure the coaxiality of the rotating shaft, etc., to reduce the circular runout , to ensure the effect of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

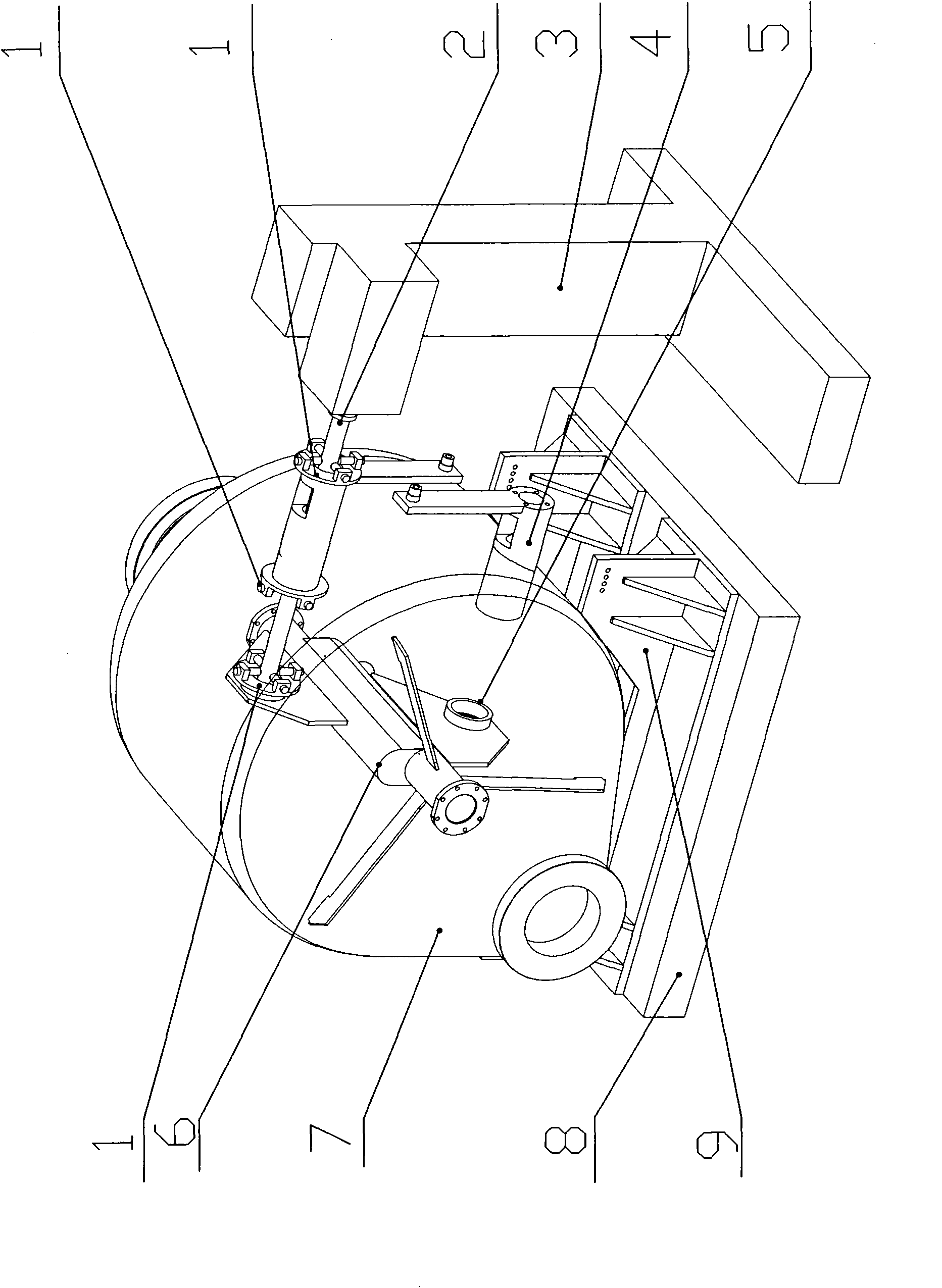

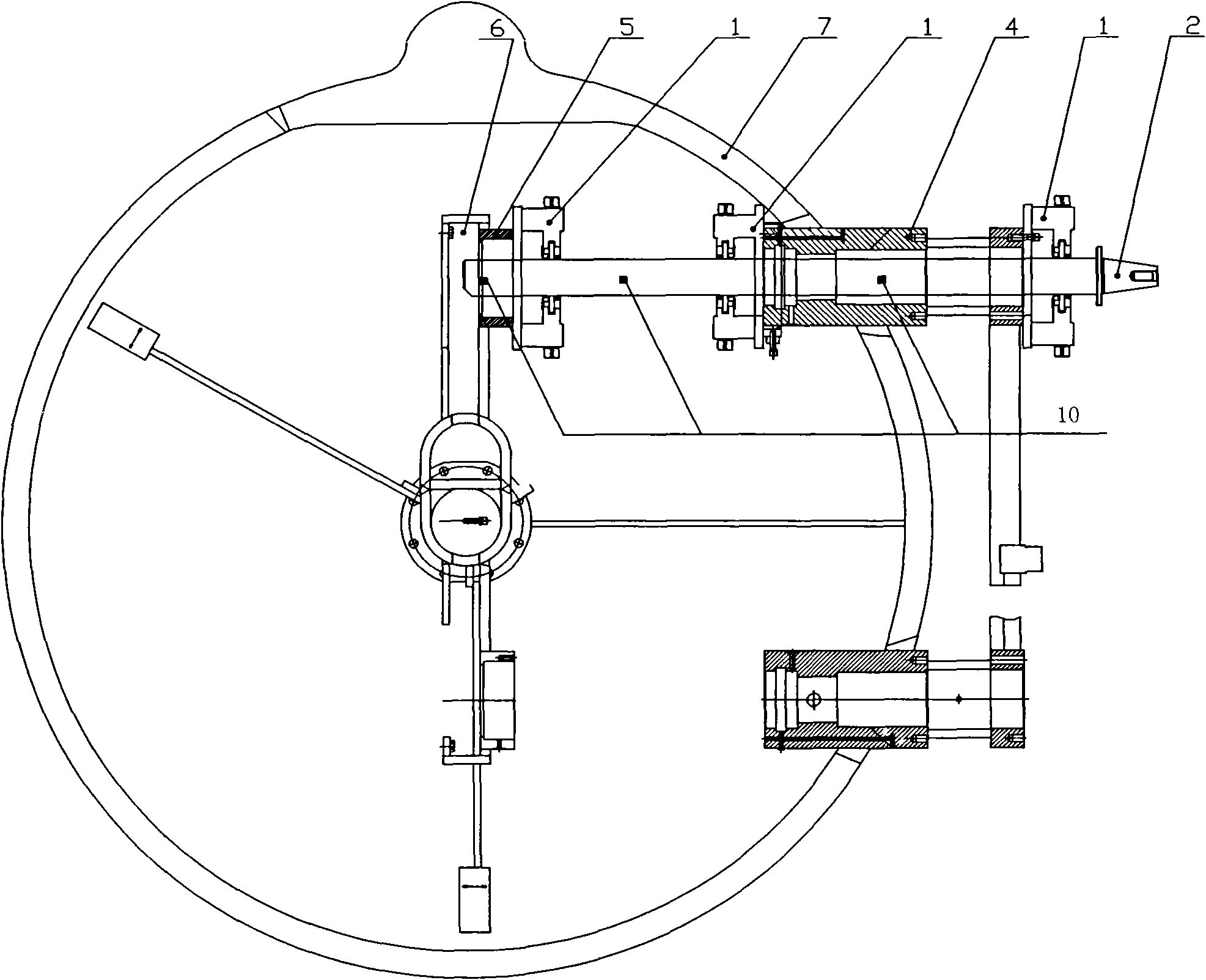

[0023] Split super long shaft sleeve and bearing ring inner hole processing auxiliary device, its composition includes: V-shaped support 9, the V-shaped support 9 is connected to the gray lock housing 7, and the gray lock housing is connected to the inner The swing rod shield 6, the inner swing rod shield is connected to the bearing ring 5, the shaft sleeve 4 is connected to the gray lock housing, the shaft sleeve and the bearing ring are on the same axis, The inner and outer end faces of the shaft sleeve and the end face of the bearing ring are respectively fixed by bolts to the auxiliary support device 1, and the extended tool bar 2 passes through the described auxiliary support device and finally connects with the floor type CNC milling and boring machine 3 The main shaft is connected, and the elongated tool bar has a group of boring tool installation square grooves 10, and a boring tool is installed in the boring tool installation square grooves.

[0024] The split-type su...

Embodiment 2

[0026] figure 1 , figure 2 It is a structural schematic diagram and a cross-sectional view of the shaft sleeve 4 and the bearing ring 5 processed on the gray lock. The size of the numerically controlled rotary table 8 used for loading gray locks is 3000mm×3000mmm. The gray lock has a diameter of about 2700mm and a length of about 4700mm, on which there is a shaft sleeve 4 with a length of 780mm and a bearing ring 5 with a distance of 1700mm from the end face of the shaft sleeve. The shaft sleeve 4 and the bearing ring 5 are welded on the gray lock housing 7 and the inner swing rod shield 6, and the inner holes to be processed are all left with a machining allowance of 5 mm. In order to ensure the smooth rotation of the inner swing rod shaft passing through the shaft sleeve 4 and the bearing ring 5, there is a high coaxiality requirement between the shaft sleeve 4 and the bearing ring 5 in the same group, and the shaft sleeve 4 and the bearing ring 5 with different axes The...

Embodiment 3

[0029] The method for processing the split super-long shaft sleeve and the inner hole of the bearing ring by using the above-mentioned split super-long shaft sleeve and bearing ring inner hole processing auxiliary device includes the following steps:

[0030] (1) Install the inner swing rod shield 6 inside the gray lock housing 7, and weld the shaft sleeve 4 and bearing ring 5 with the machining allowance in the inner hole to the gray lock housing 7 and the inner swing rod shield 6 respectively In addition, after the installation of other parts, the gray lock is subjected to stress-relieving overall heat treatment;

[0031] (2) After the heat treatment is completed, use the V-shaped support 9 to install the gray lock on the CNC rotary table 8;

[0032] (3) Fasten the auxiliary support device 1 to the inner end face, the outer end face of the shaft sleeve 4 and the end face of the bearing ring 5 by bolts;

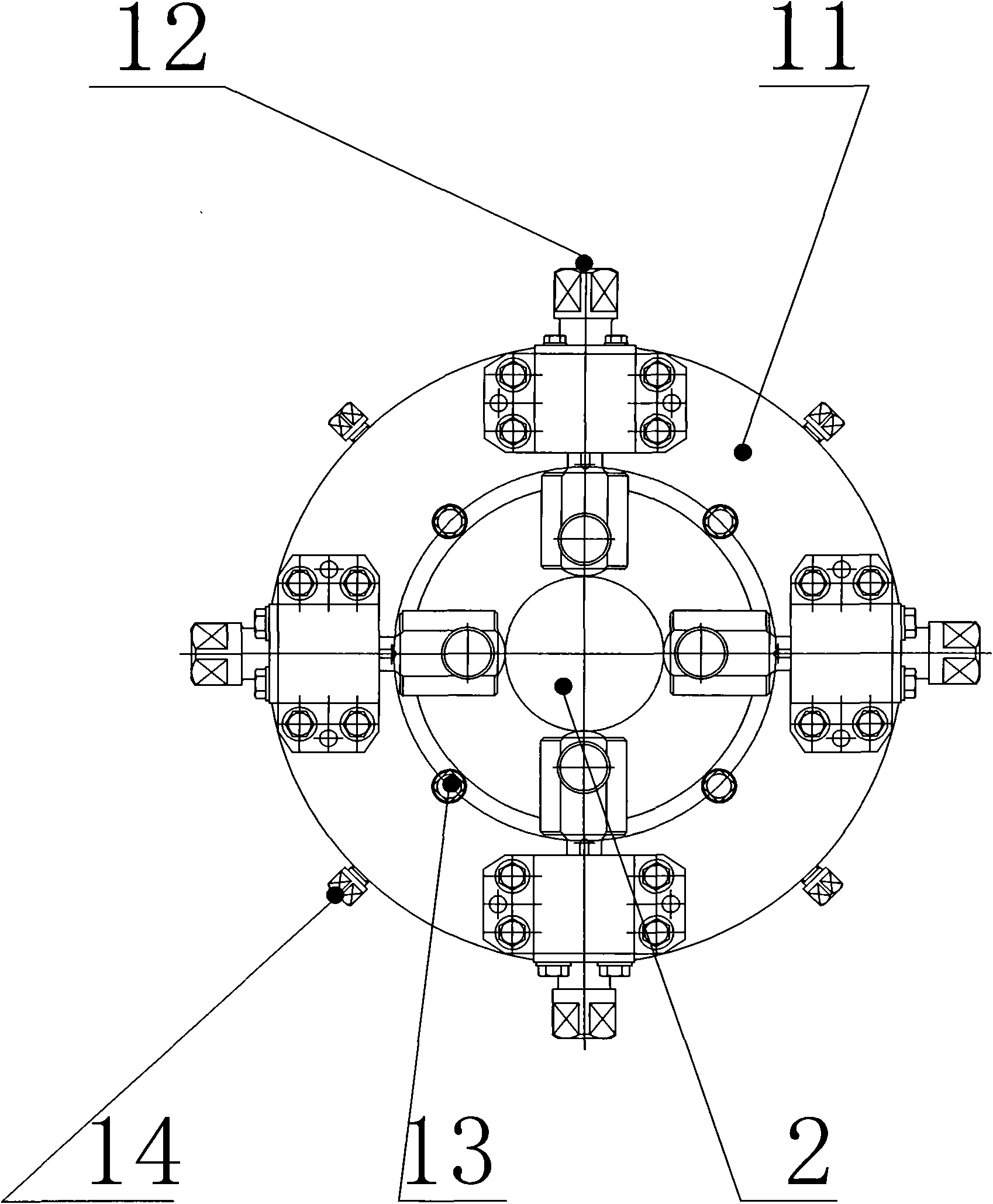

[0033] (4) Roughly adjust the adjustable fastening bearing tip 12 of e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com