Crossed hole processing method

A processing method, the technology of cross holes, applied in the field of processing of cross holes, can solve the problems of the distance difference between the center of the large hole and the center of the small hole, the tool is easy to shift, etc., and achieve the effect of saving manufacturing cost and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

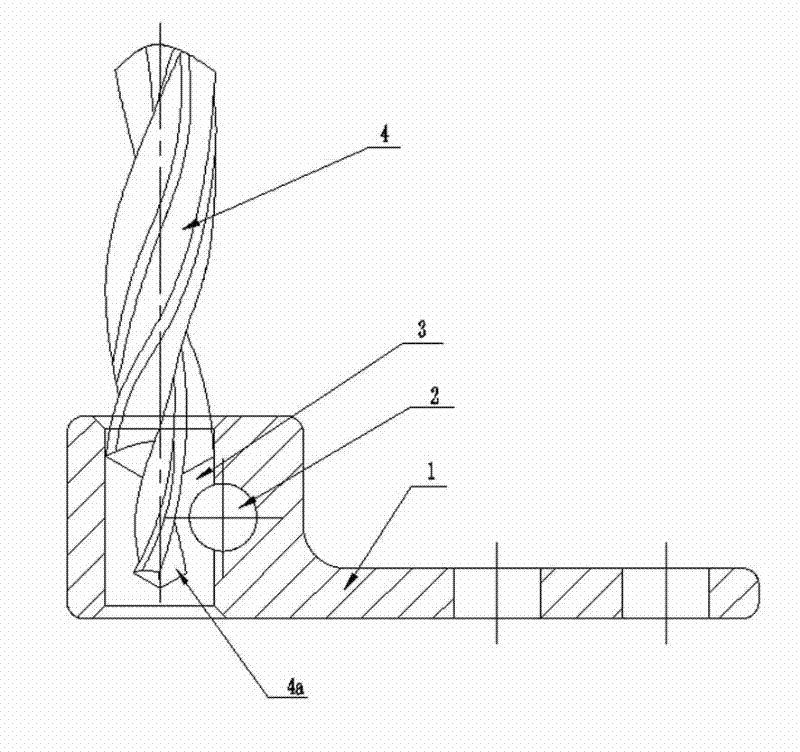

[0008] Such as figure 1 As shown, taking the part 1 to be processed as an example, the present invention is described as follows: first process the small hole 2, pre-position with the small hole 2, when processing the large hole 3, use a step drill 4, the radius of the step drill minor diameter 4a is smaller than the small hole 2 The outer generatrix to the center distance of the large hole 3, when the large diameter of the step drill 4 cuts in, the step drill minor diameter 4a has passed the small hole 2, thereby ensuring the center distance of the two intersecting holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com