Ground assembly and installation method for air box and ash discharge pipes of chain grate

A technology of ash unloading pipe and grate machine, which is applied in the direction of furnace components, processing discharged materials, furnaces, etc., and can solve problems such as uneven ash unloading valves and chute pipes, inaccurate control of angle and height, left and right asymmetry, etc. , to achieve the effect of improving installation efficiency and construction quality, improving construction efficiency and ensuring installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further illustrated below by specific examples.

[0016] Such as figure 1 , figure 2 Shown, a kind of chain grate blower bellows ash unloading pipe ground assembly method, comprises

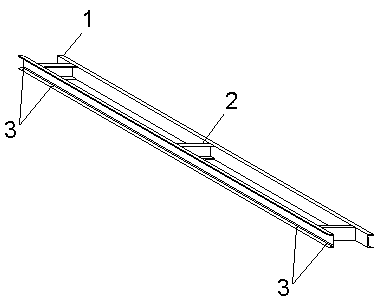

[0017] Step 1. According to the design size of the ash discharge pipe 6 flange, use channel steel to make the spreader 1 and open the bolt hole 3 on the spreader 1; the position of the bolt hole 3 should be consistent with the design size of the ash discharge pipe 6 flange screw hole;

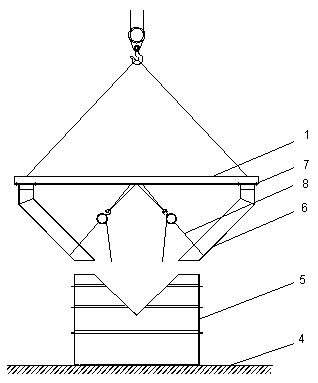

[0018] Step 2. Set up a horizontal work platform or find a concrete floor 4, flush down the big mouth of the bellows body 5 and place it upside down on the platform 4, and level it with a spirit level and backing plate;

[0019] Step 3. Connect the flanges of two horizontally placed ash discharge pipes 6 to the spreader 1 with bolts 7 on the ground, hang two chains 8 on the middle beam 2 of the spreader 1, and connect the 6 pairs of ash discharge pipes The interface is locked ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com