Tapping tooling of automobile engine support

An automobile engine and tooling technology, which is applied in the directions of support, thread trimmer, positioning device, etc., can solve the problems of inconvenient operation and difficulty in ensuring the center distance of three threaded holes, and achieve the effect of easy operation, easy implementation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

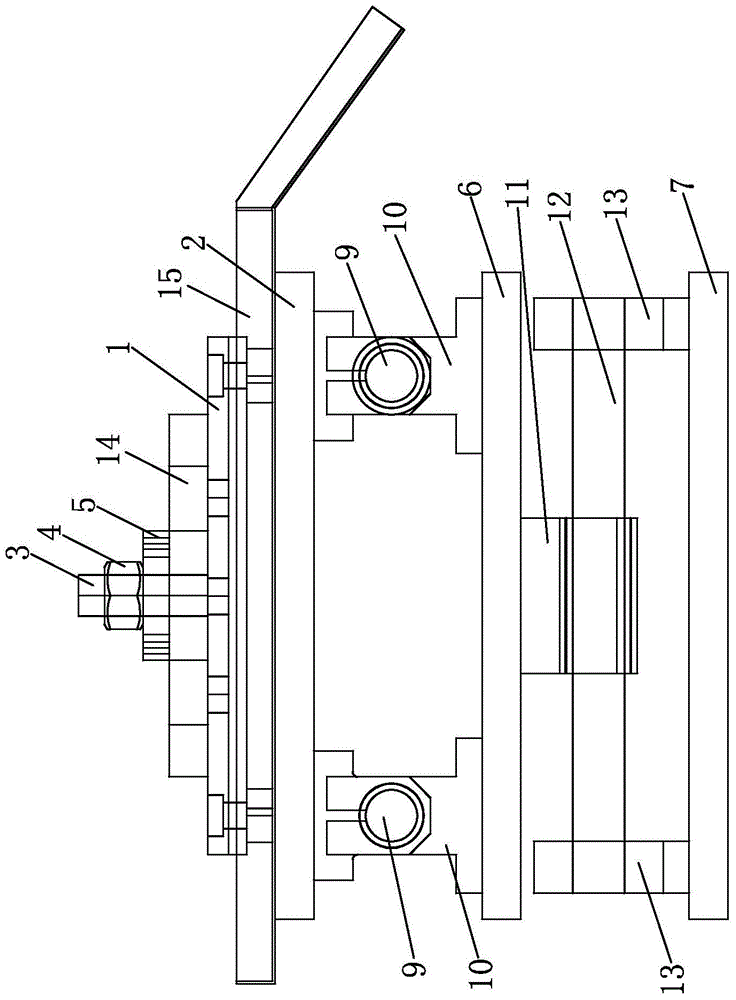

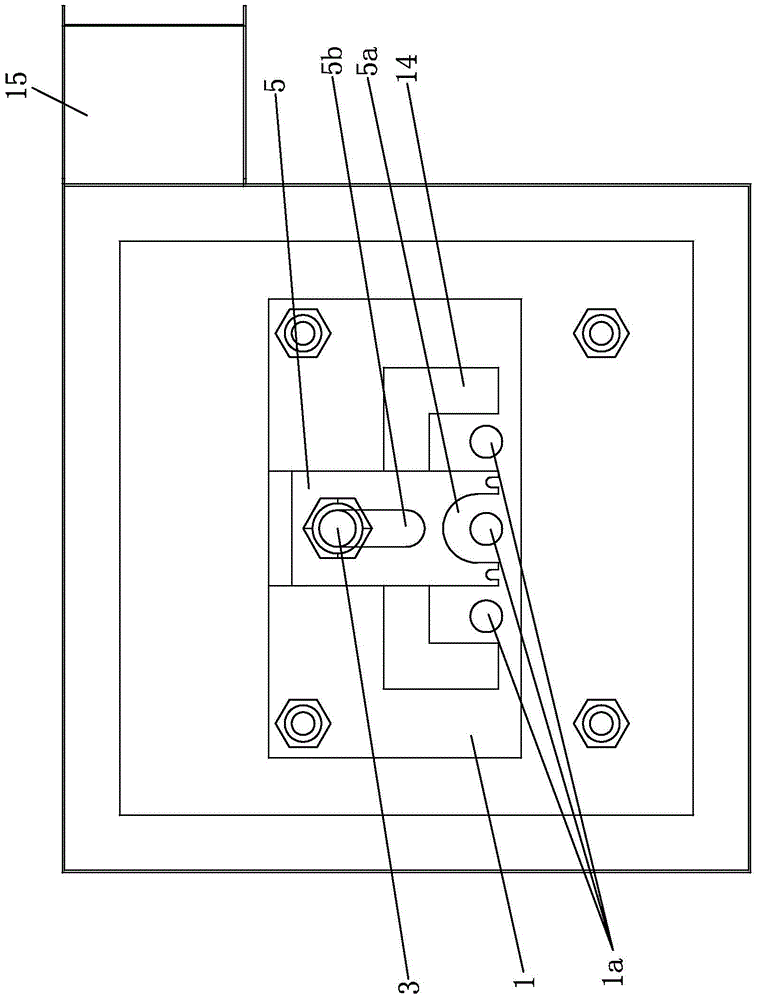

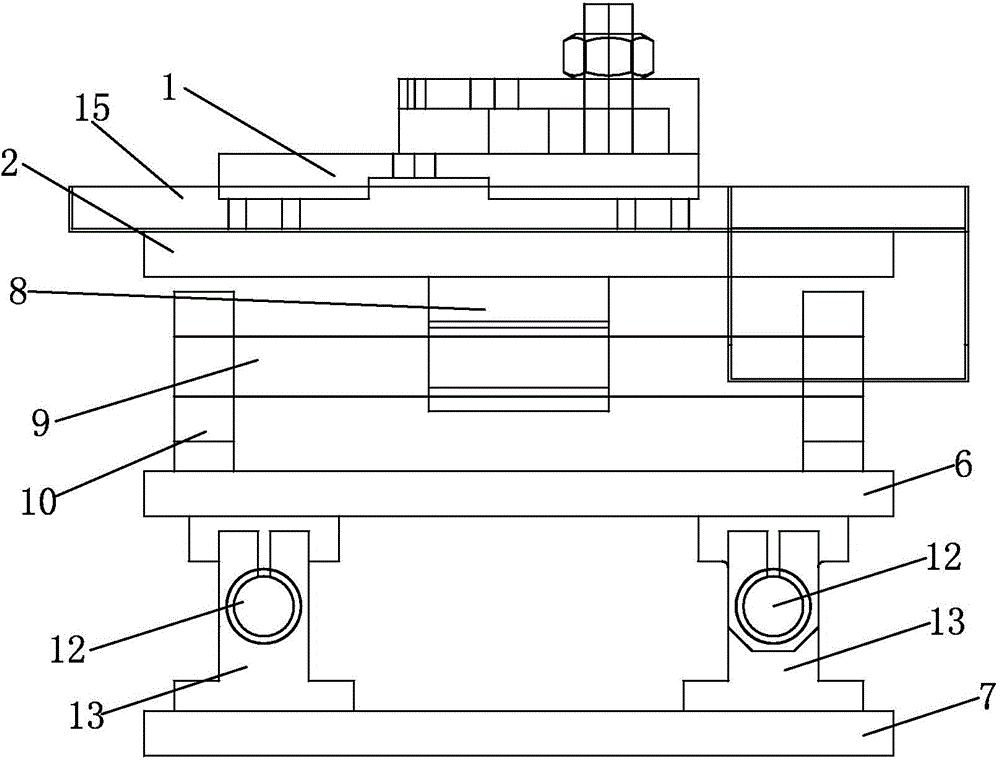

[0022] like figure 1 , 2 And shown in 3, a kind of automobile engine bracket tapping tool, mainly by horizontal support plate 1, workbench 2, screw rod 3, nut 4, pressure plate 5, slide table 6, horizontal bottom plate 7, the first moving assembly, the second moving assembly Components, limiting plate 14 and liquid receiving tray 15 etc. constitute. Wherein, the bottom surface of the horizontal support plate 1 is fixed to the top surface of the workbench 2 by four uprights, and the workbench 2 is a horizontal plate structure. The horizontal support plate 1 is vertically provided with three side-by-side tap relief holes 1a, and a limiting plate 14 is fixed on the top surface of the workbench 2. The limiting plate 14 is a U-shaped structure with an opening facing forward. The three tap relief holes 1 a are all located in the opening end of the limiting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com