Clamp for turning irregular sleeve and machining method for same

An irregular, turning technique used in the manufacture of tools, metalworking equipment, metalworking machine parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation will be described in detail below in conjunction with the accompanying drawings.

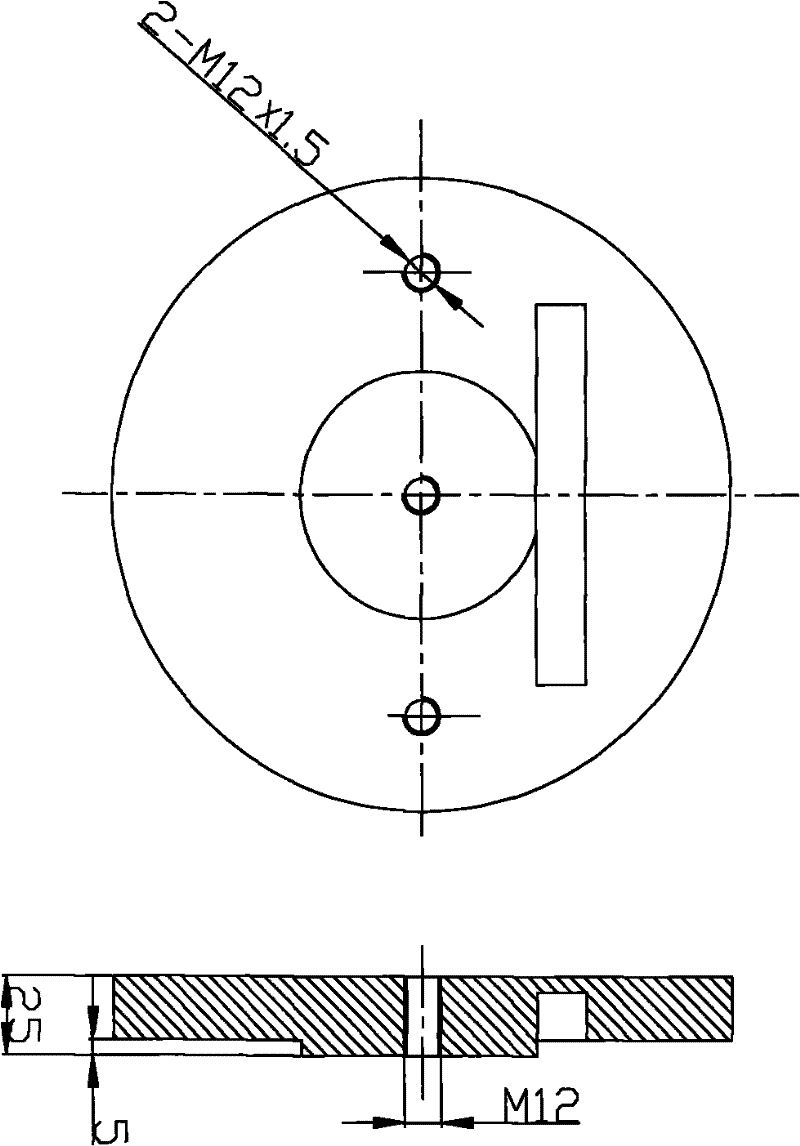

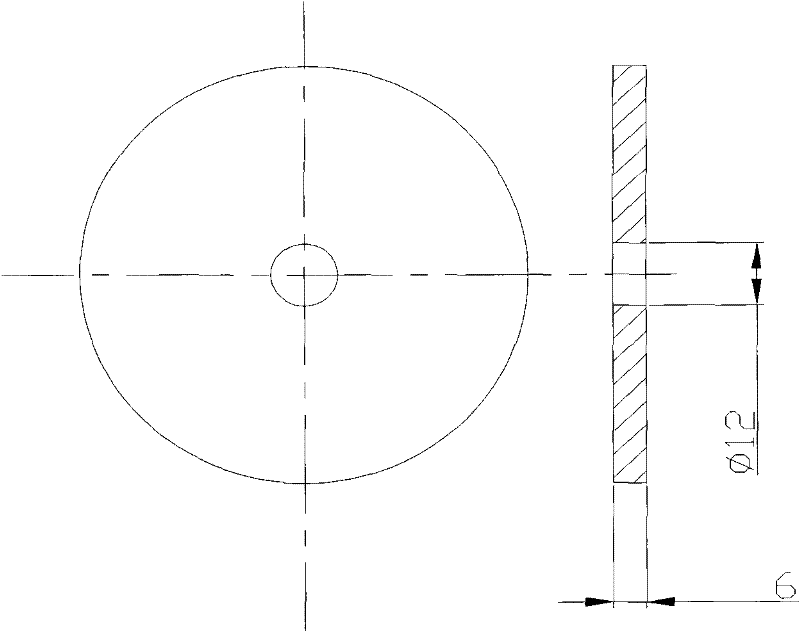

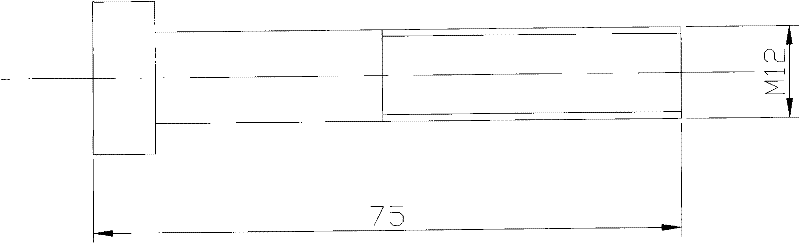

[0014] Such as Figure 1 to Figure 6 As shown, the present invention includes: a reference positioning plate 1, a large washer 2, a screw 3, a double-ended screw 4, a cover plate 5, and a nut 6. Process a cylindrical boss matching the inner hole of the part on the positioning reference plate 1; drill and tap M12 thread in the center; and open a rectangular relief groove above the boss; drill and tap 2-M12×1.5 thread to ensure a certain center distance. When clamping, an inner hole of the part cooperates with the cylindrical boss on the positioning reference plate, and the matching clearance meets the processing requirements of the part. A mounting rib on the part is placed in the relief groove, and the bottom surface of the part fits with the large end surface of the reference positioning plate. , so that the parts can achieve fast and accurate positioning in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com