Foundation bolt pre-burying auxiliary welding device

A technology of anchor bolts and auxiliary devices, which is applied in the direction of auxiliary devices, welding/cutting auxiliary equipment, welding equipment, etc., can solve the problems that the top is not on the same plane, the length of the thread is uneven, and the working time is long, etc., to meet the requirements of the construction process requirements, the overall structure is simple, and the welding quality is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

[0036] The anchor bolt pre-embedded welding auxiliary device provided by the embodiment of the present invention includes a base plate 1, a plurality of positioning sleeves 2, a plurality of sliders 3 matched with the positioning sleeves, and a plurality of locking screws for locking the sliders on the base plate. parts and a series of adjusting sleeves 5 that cooperate with anchor bolts of different specifications.

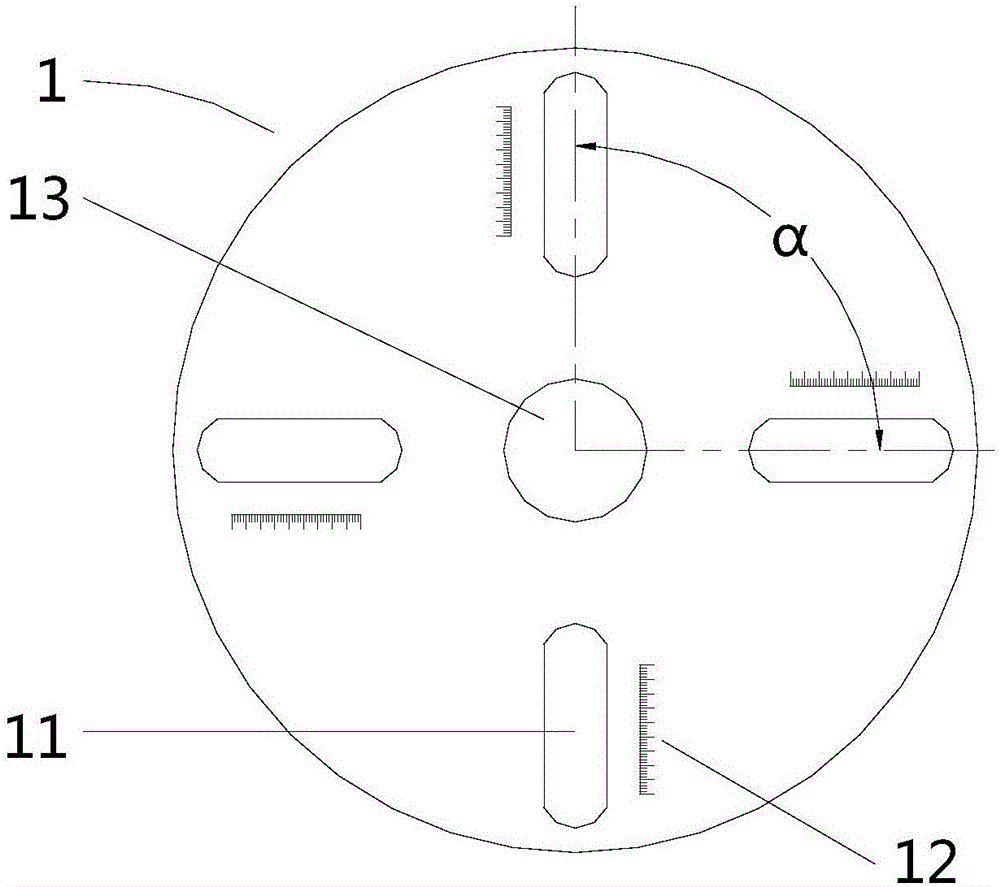

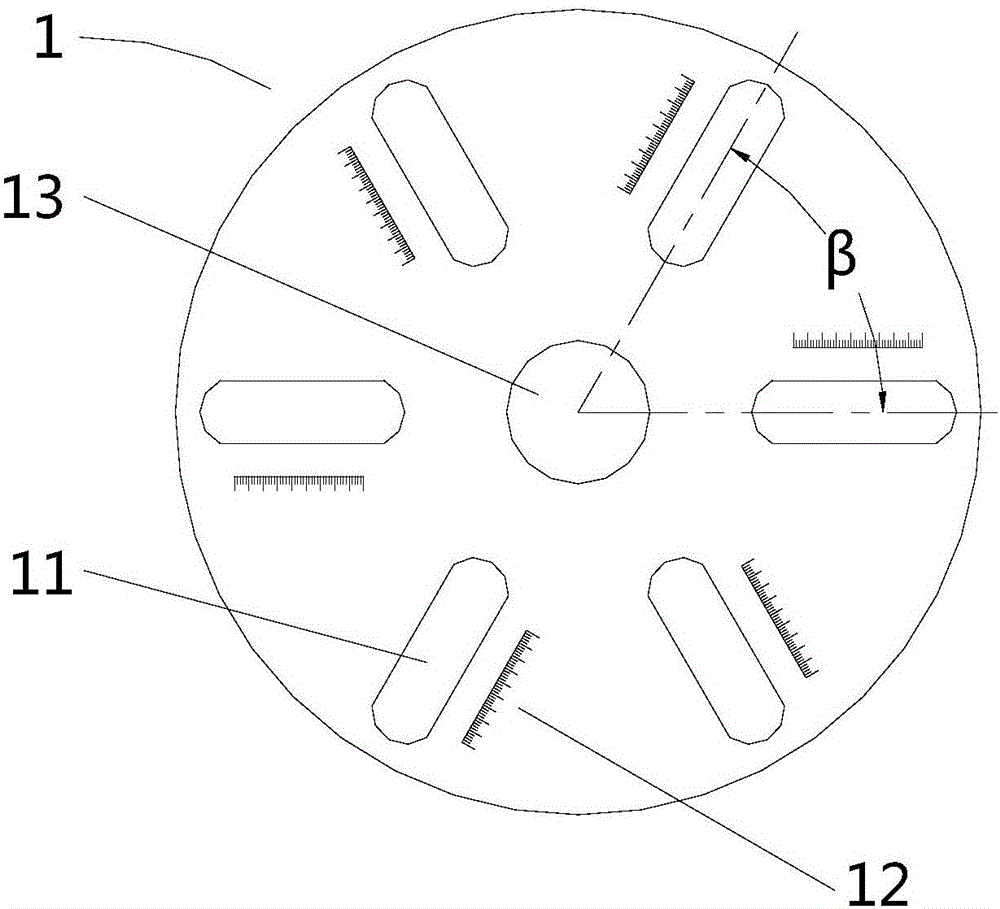

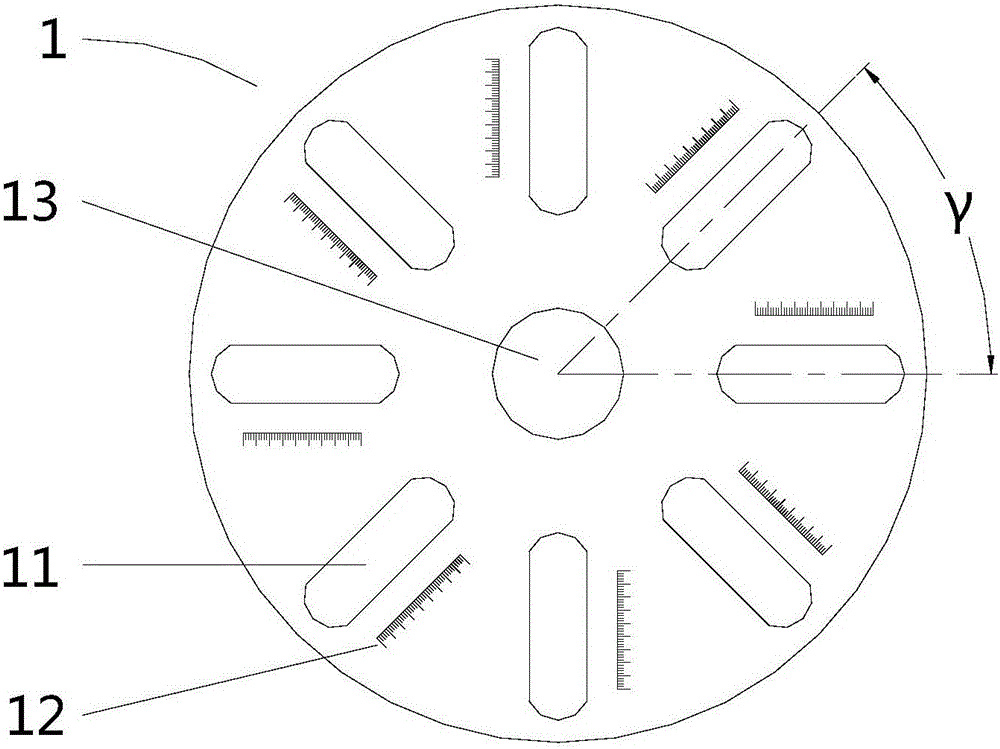

[0037] Such as figure 1 , 2 , 3, base plate 1 is provided with some chute 11, each chute is arranged on the base plate radially with the center point of the base plate as the center of circle, and the center angles between adjacent chute length directions are all equal, the base plate A scale line 12 corresponding to the length of the chute is provided on at least one side in the length direction of the chute.

[0038] figure 1 Among them, four chutes 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com