Tight-lock coupler body mechanical manufacturing processes

A mechanical processing and close-contact technology, applied in railway car body parts, railway couplings, transportation and packaging, etc., can solve the problems affecting the center distance of the front convex cone and the concave cone, unstable quality, large linear error, etc. Achieve the effect of eliminating positioning error, shortening clamping time and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

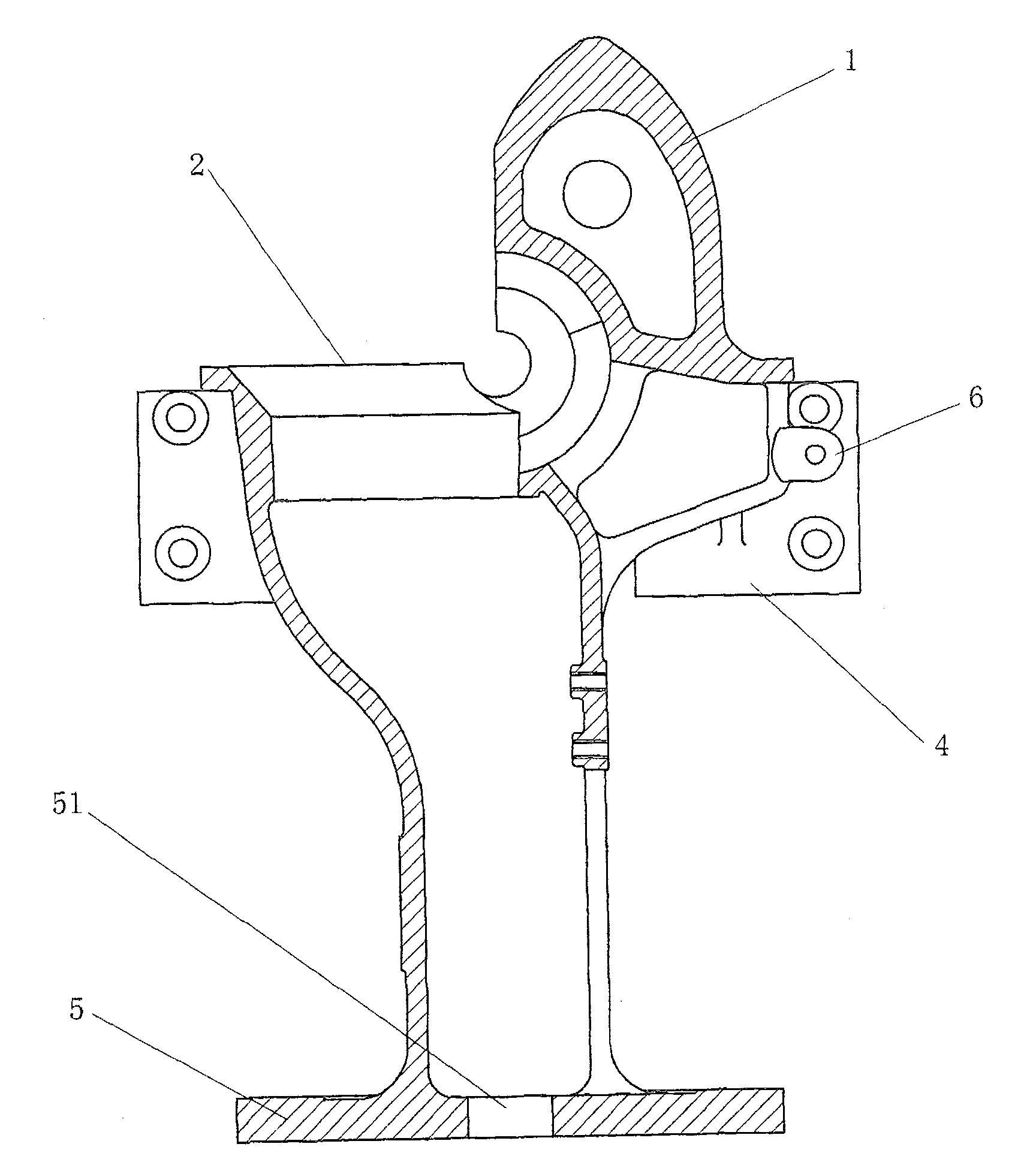

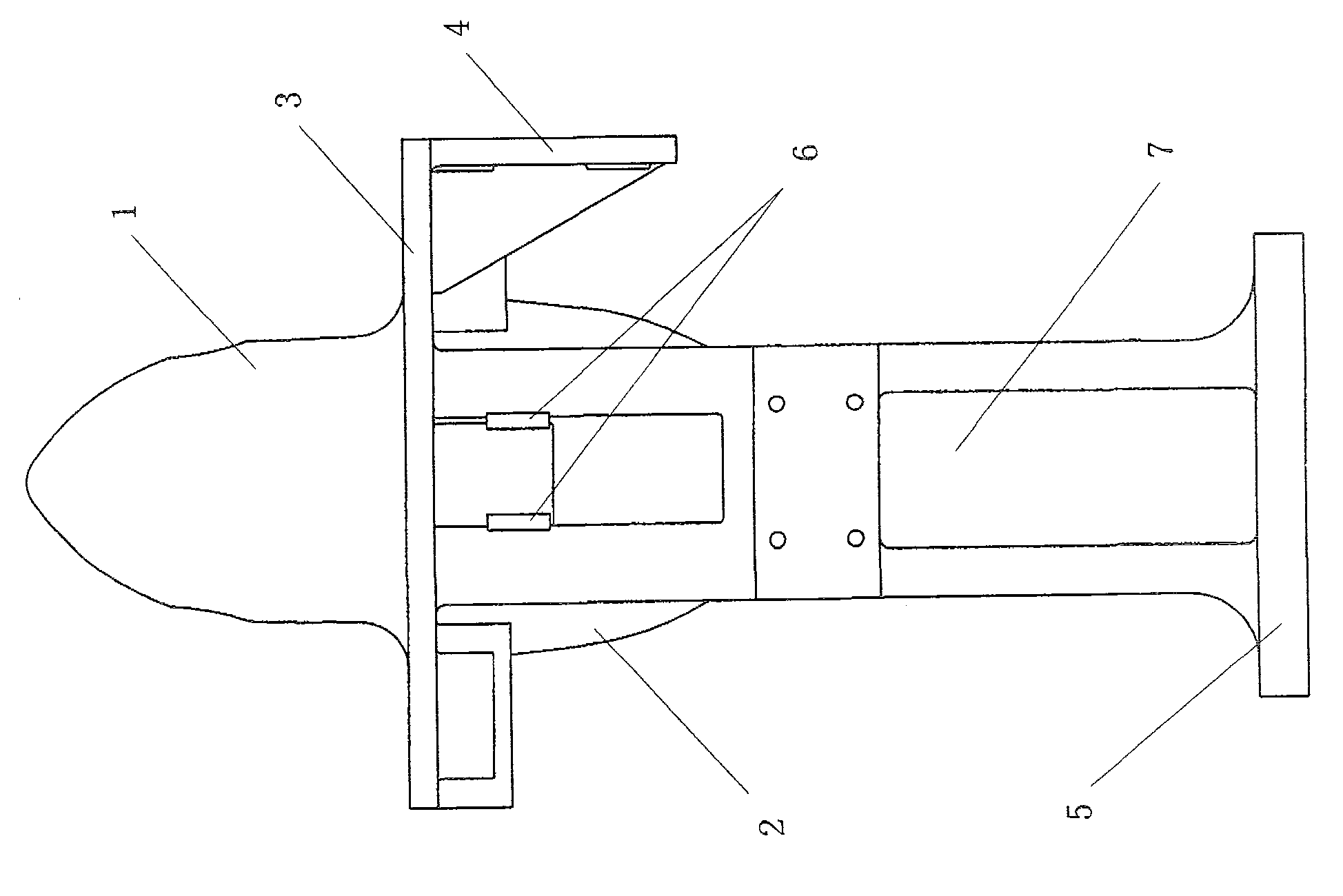

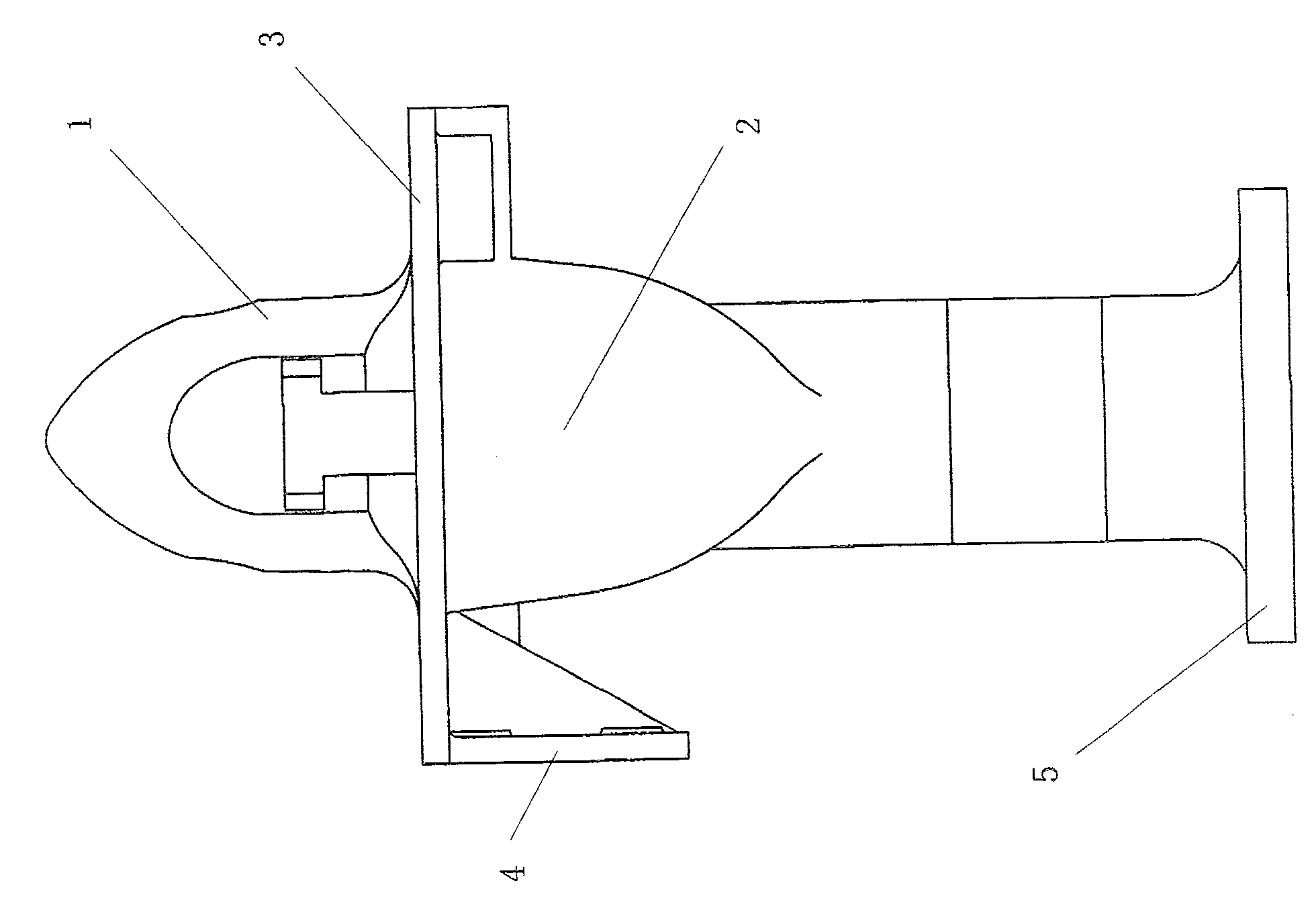

Embodiment 1

[0031] A mechanical processing technology for close-connected coupler body, the blank is cast with E-grade steel, and the heat treatment hardness is HB241-291; when processing, first mark the overall line, taking into account each processing surface and calibration line, and then mill the bottom surface of the bracket 4 and mill the tail Φ320mm The upper and lower planes of the connecting flange 5, when milling the upper and lower planes of the connecting flange 5 at the tail, use the bottom surface of the bracket 4 as the reference plane; Then drill four Φ16.5 mm installation holes on the support 4, two of which are drilling and reaming positioning holes; and the bottom surface of the support 4 and the two holes are used as the two-pin positioning reference of the following process; then rough 1. Finish turning convex cone 1. Curved surface and plane. The finishing turning is processed by CNC lathe to improve work efficiency and processing quality; The thickness of the sub 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com