Worm gear screw

A worm gear screw and worm gear technology, applied in the direction of gear transmission, belt/chain/gear, hoisting device, etc., can solve the problems of insufficient transmission efficiency, unreliable transmission, and small thread lift angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

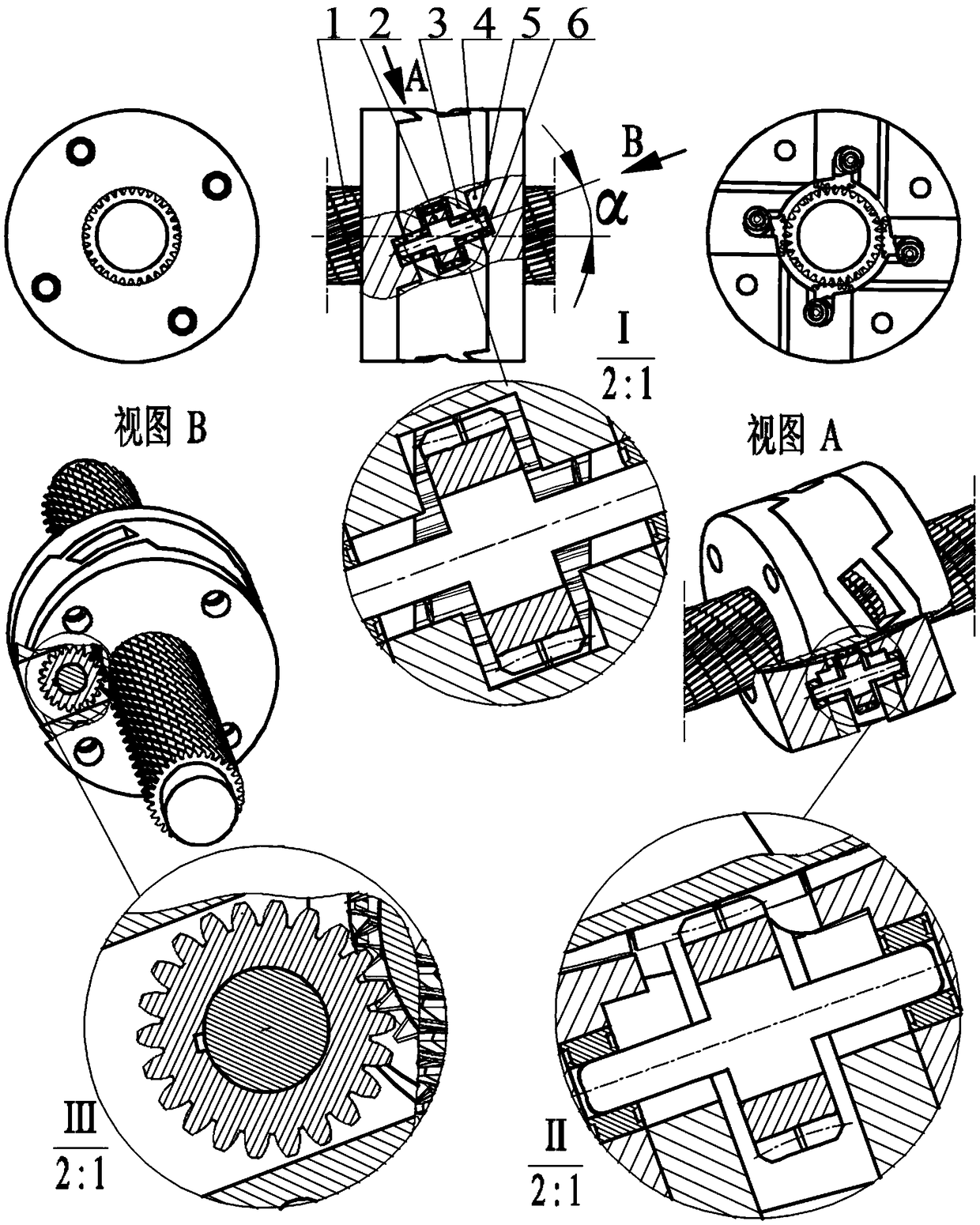

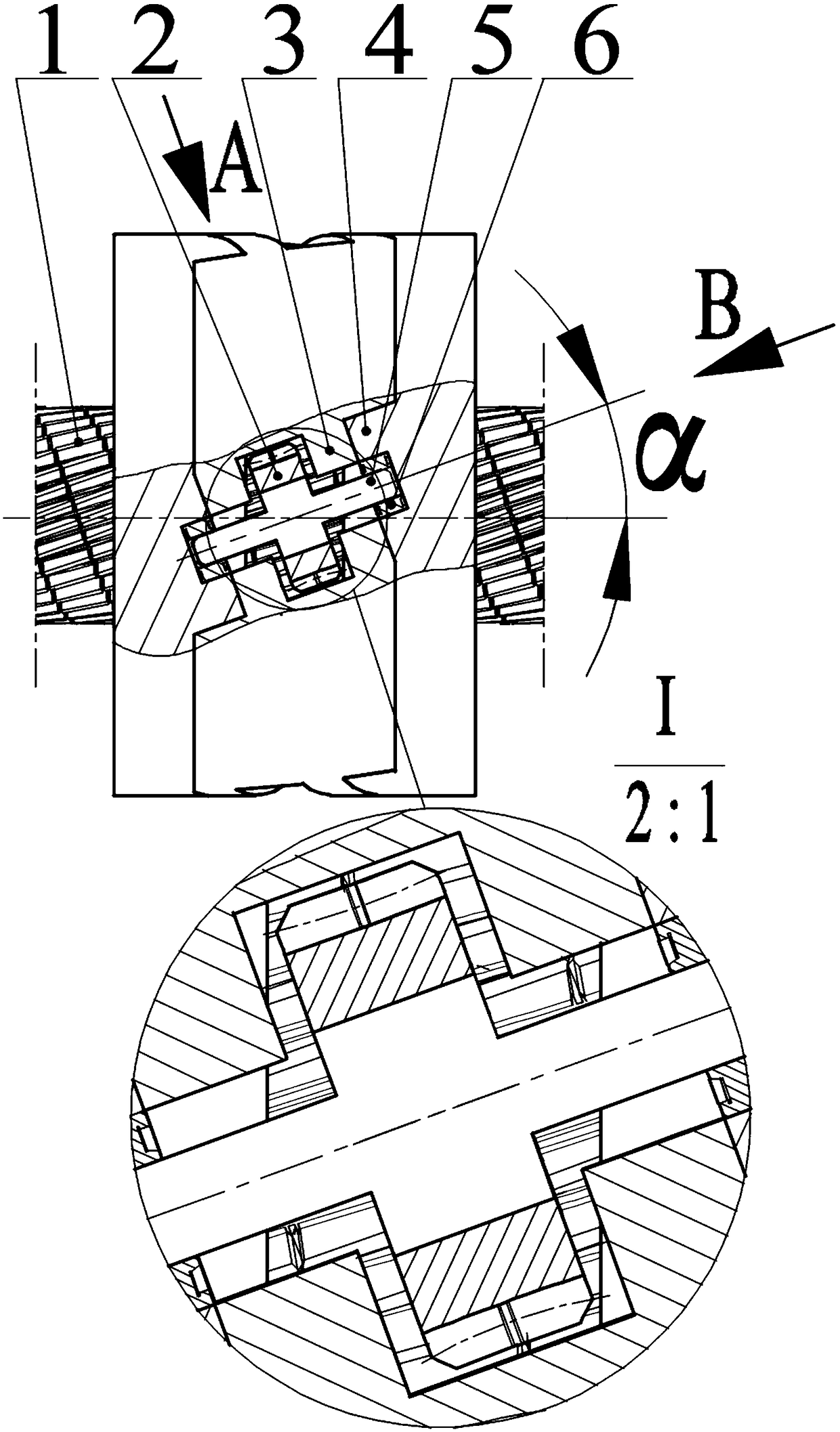

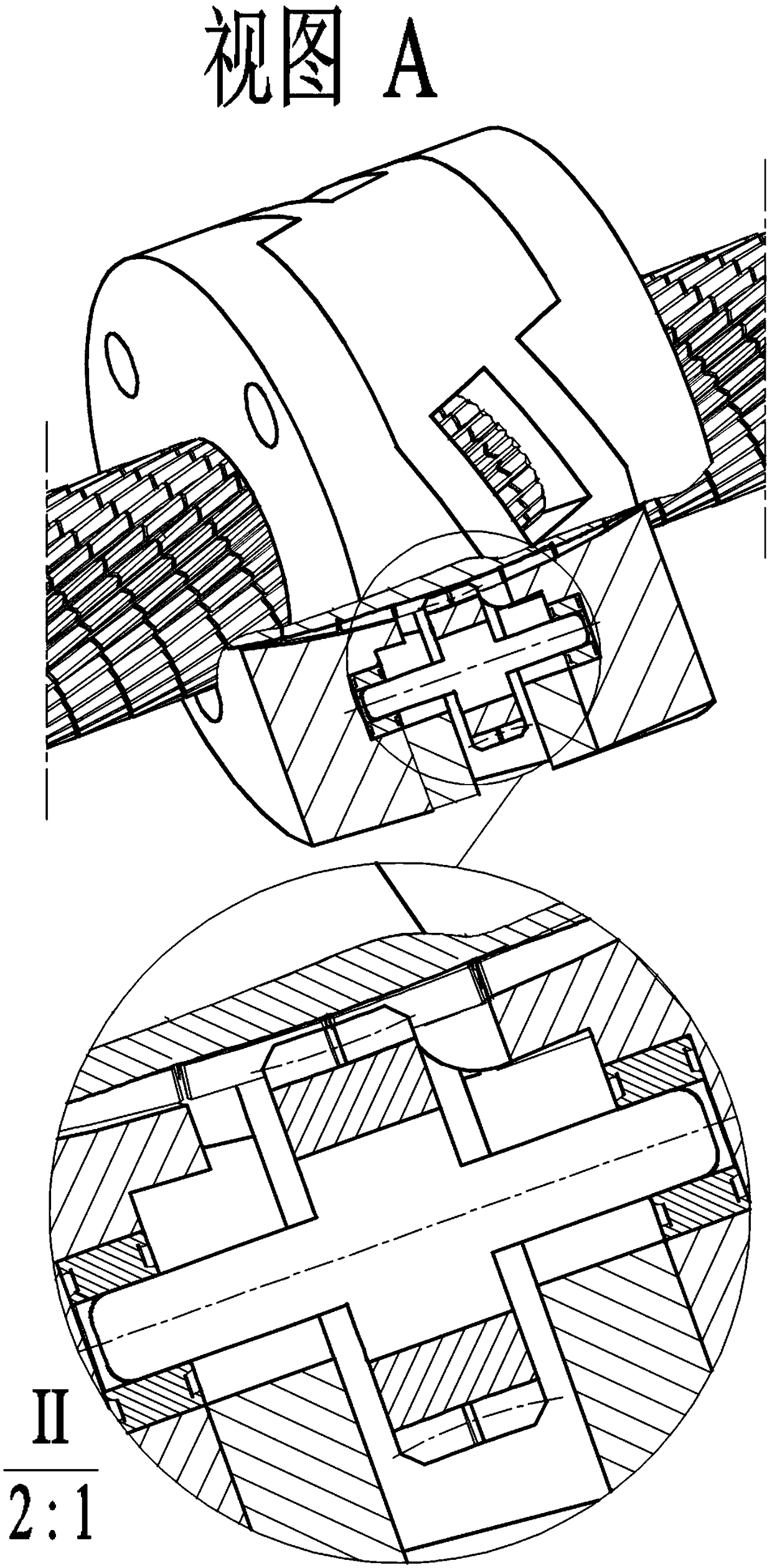

[0025] like Figure 1-Figure 5 Shown: both ends of the sleeve (3) are connected and fixed with the end cover (4), and the worm gear shaft (5) passes through the U-shaped hole on the square hole on the sleeve (3) inclined at an angle α with the axis of the sleeve (3). The groove is installed on the blind hole coaxial with the U-shaped groove on the end cover (4) through a rolling bearing (6).

[0026] like Figure 1-Figure 5 Shown: the new worm gear (2) is fixed on the worm gear shaft (5), the new worm gear (2) meshes with the new helical gear shaft (1), the boss of the new worm gear (2) and the helical teeth of the new helical gear shaft (1) The alignment and fit of the cutouts prevents the original possible relative sliding. The worm gear shaft (5) is fixed on the rolling bearing (6), and the rolling bearing (6) is fixed on the end cover (3). The worm gear shaft (5) together with the The new worm gear (2) is distributed in a circular array of 4 units at equal intervals along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com