Belt conveyor headstock and manufacturing method thereof

A head frame and belt conveyor technology, applied in the field of conveyor racks, can solve problems affecting work progress, reducing work efficiency, affecting transportation efficiency, etc., to achieve the effects of ensuring transmission efficiency, improving work efficiency, and avoiding belt deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

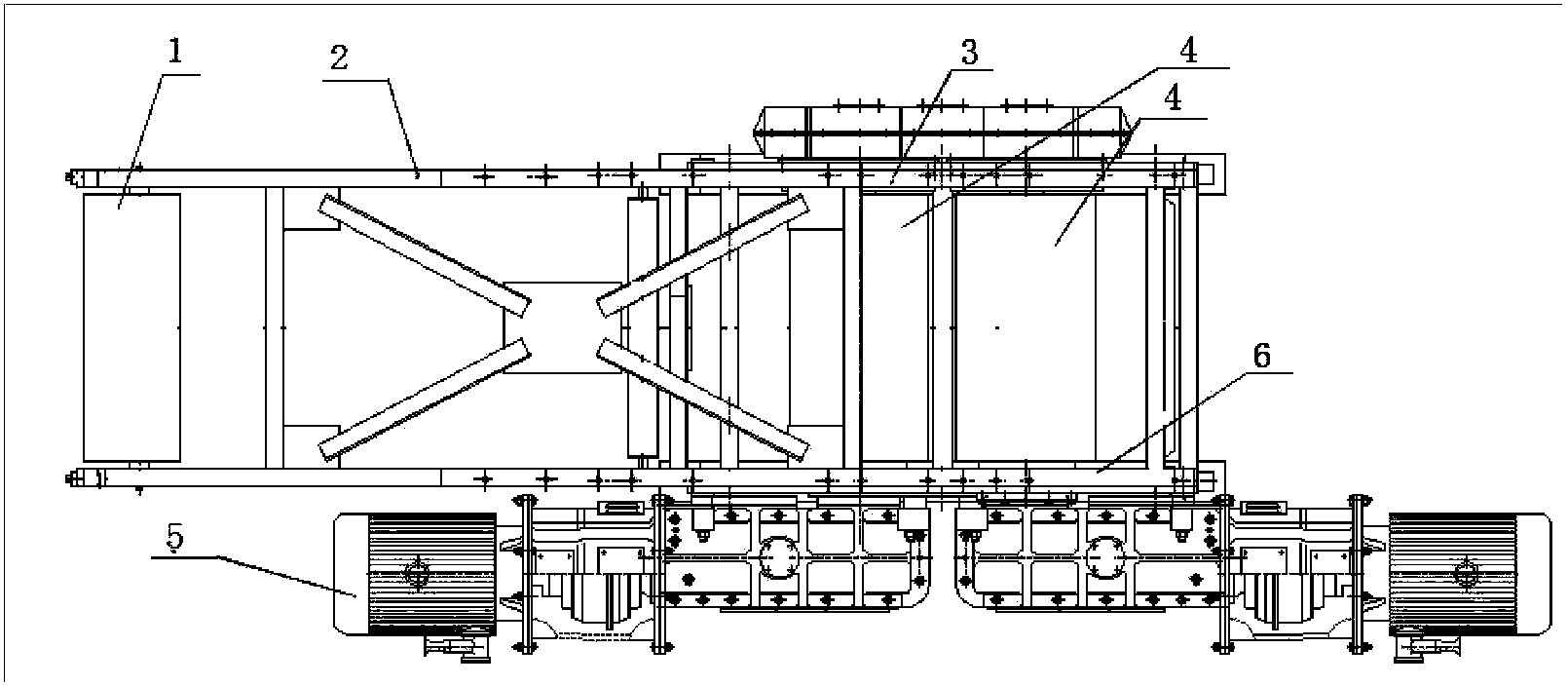

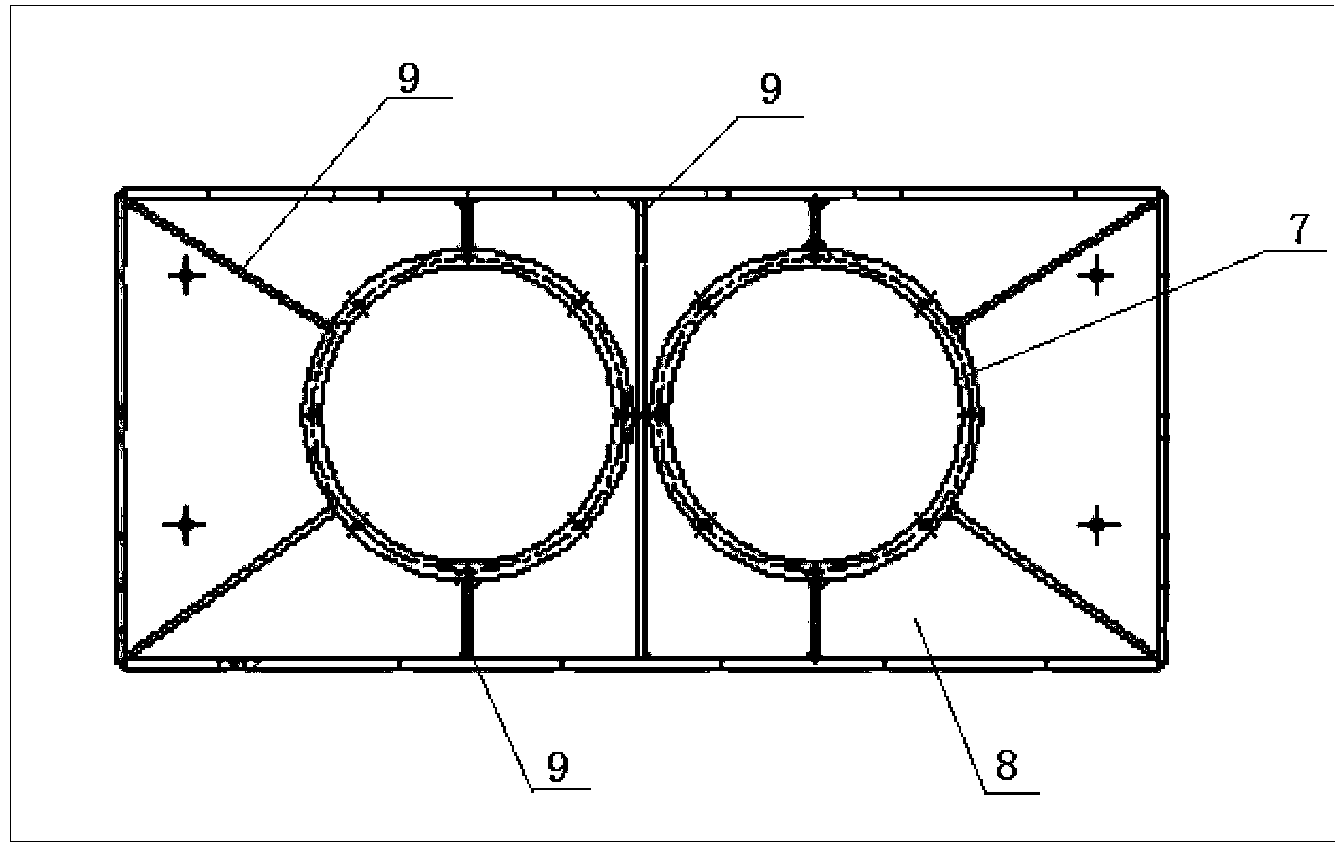

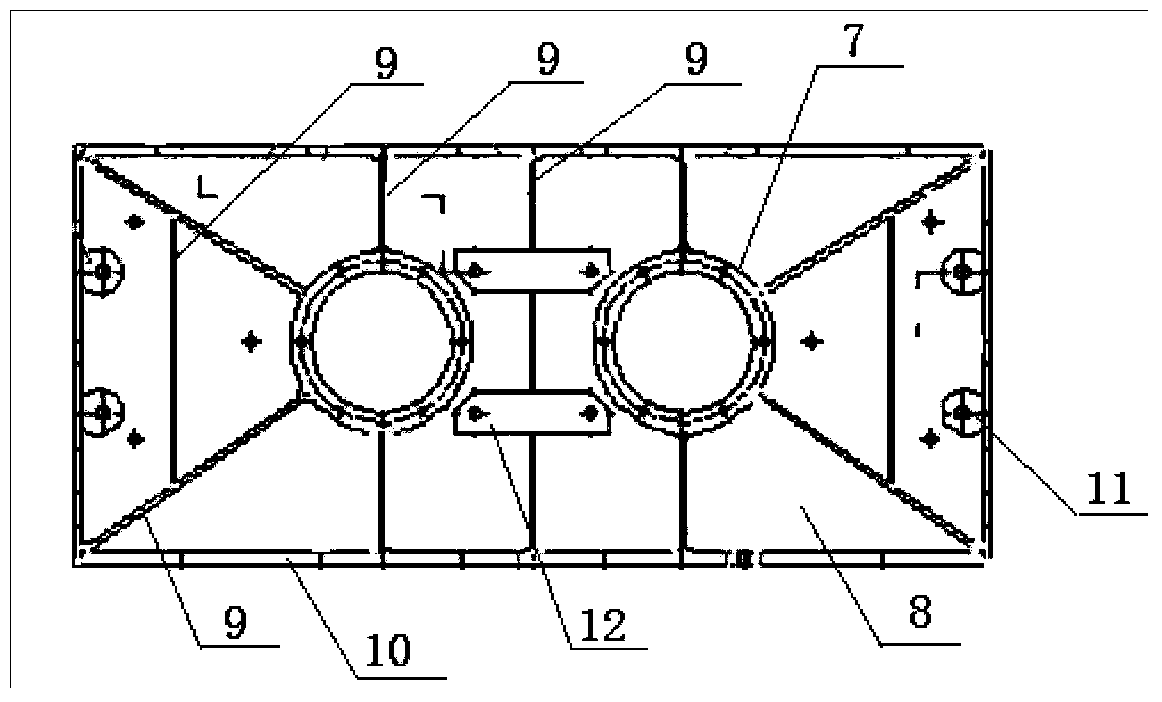

[0018] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a belt conveyor head frame includes an extension frame 2, an unloading drum 1 arranged at the front end of the extension frame 2, and a left side plate 6 and a right side plate are respectively arranged on the left and right sides of the rear end of the extension frame 2. The side plate 3 is provided with a transmission part 5 on the side of the left side plate 6; The reducer block 12 is composed of; the right side plate 3 is composed of the sleeve 7, the rib plate 9 and the side plate 10 arranged on the side plate 8, and it is characterized in that: the sleeve 7 on the left side plate 6 and the right side plate The center distance of the upper sleeve 7 is consistent, which ensures the coaxiality of the main drum, ensures that the large gears can be meshed correctly, and improves work efficiency.

Embodiment 2

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a method for preparing the head frame of a belt conveyor uses tooling to install the left side plate and the right side plate. Specifically, when installing the left side panel, first use tooling to insert the sleeve on the left side panel on the small circle, and determine the position and center distance of the sleeve before installing the left side panel other boards on the right side board; when installing the right side board, first use tooling to set the sleeve on the right side board on the big circle, and after confirming the position and center distance of the sleeve, install other boards on the right side board In this way, the left and right side plates processed on the same tooling can effectively ensure the position and center distance of the sleeve. After installing the main drive pulley, the coaxiality of the main pulley can also be guaranteed to ensure transmission efficiency and prevent ...

Embodiment 3

[0022] Such as figure 1 , figure 2 , image 3 or Figure 4 As shown, the side plate of the head frame of the side plate belt conveyor is divided into left and right side plates, and two driving rollers are installed between the two side plates. The driving rollers pass through the sleeves on both sides of the plate. , the two gears mesh with each other to achieve the synchronous operation of the two main rollers and improve the transportation efficiency; if the coaxiality of the two main rollers is not high, it will cause the belt conveyor belt to deviate, and the large gears cannot be meshed correctly, which will affect the synchronous rotation , therefore, in order to ensure the coaxiality of the two main rollers and the correct meshing of the large gears, the position and center distance of the sleeves on the left and right side plates must be ensured. Therefore, the technical solution of the present invention adopts tooling to weld the left and right side plates , effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com