Processing method of case body and case cover of gear case

A processing method and technology of a gearbox, applied in the field of gearboxes, can solve the problems of low centering accuracy, high accuracy, inability to guarantee center distance, etc., and achieve the effect of convenient and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

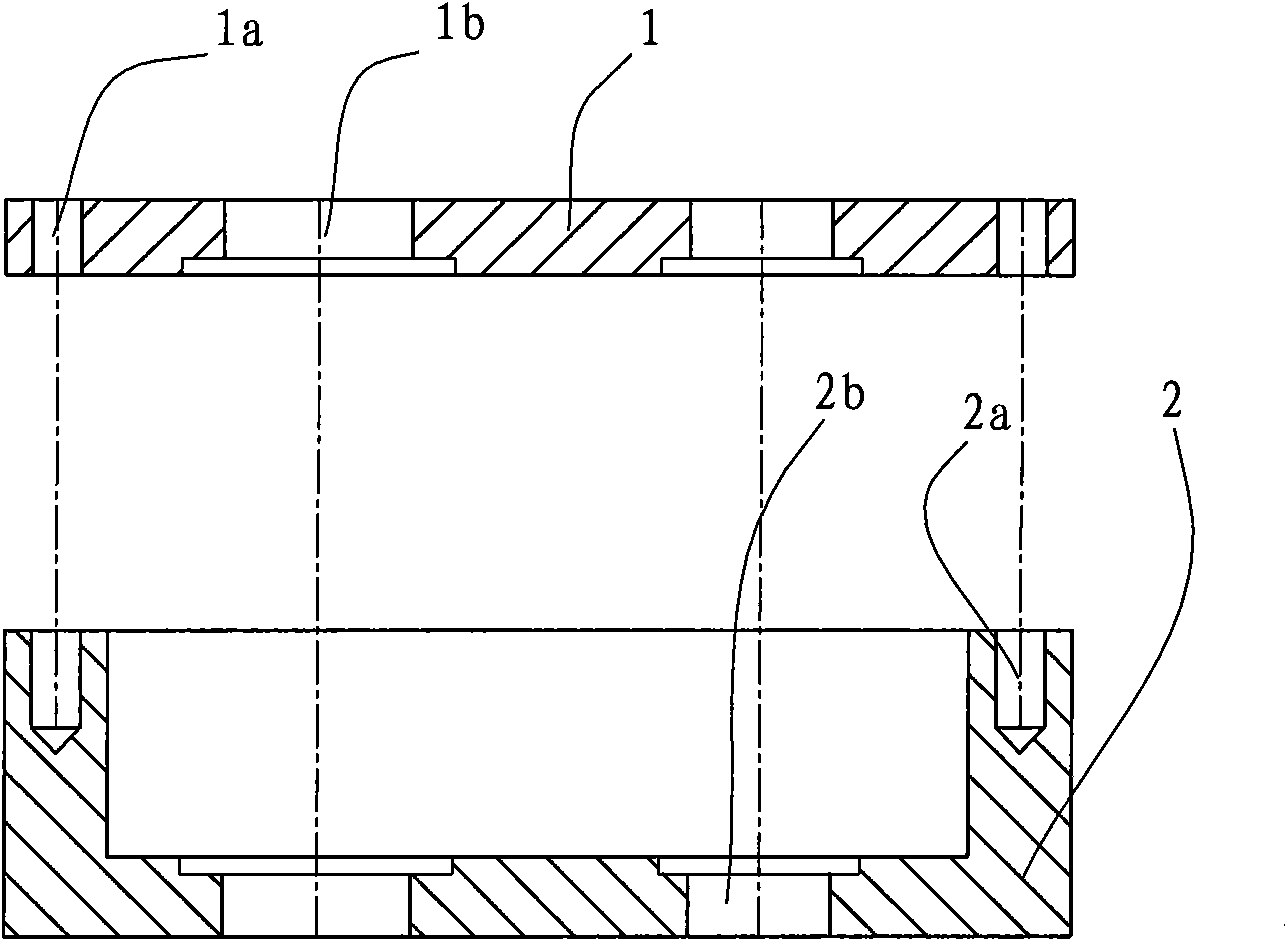

[0013] Embodiment 1: as figure 1 As shown, the processing method of the gearbox includes the following steps:

[0014] a. Process the box cover: According to the drawing, strictly follow the size marked on the drawing, use a vertical machining center for processing, and center the drilling process at the four corners of the rectangular box cover 1 and the middle of the box cover 1 respectively. Then carry out the boring process, the four corners of the box cover 1 are processed to obtain the box cover pin hole 1a, the middle part of the box cover 1 is processed to obtain the box cover bearing hole 1b, when the boring process box cover bearing hole 1b, the whole box The cover bearing hole 1b is processed in two sections, one section is bored with a larger diameter, and the other section is bored with a small diameter, so that the case cover bearing hole 1b is a stepped hole;

[0015] b. Machining the box body: Use a three-coordinate measuring instrument to detect the center di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com