Chain wear test device and chain wear test method

A wear test and chain technology, applied in measuring devices, testing wear resistance, instruments, etc., can solve problems such as increased energy consumption and complex structure

Pending Publication Date: 2019-02-26

SUZHOU UNIVERSAL GRP TECH CO LTD

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of this application is to provide a chain wear test device and chain wear test method, to solve the existing in the prior art by applying reverse torque to two sprockets in each set of sprockets of t

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

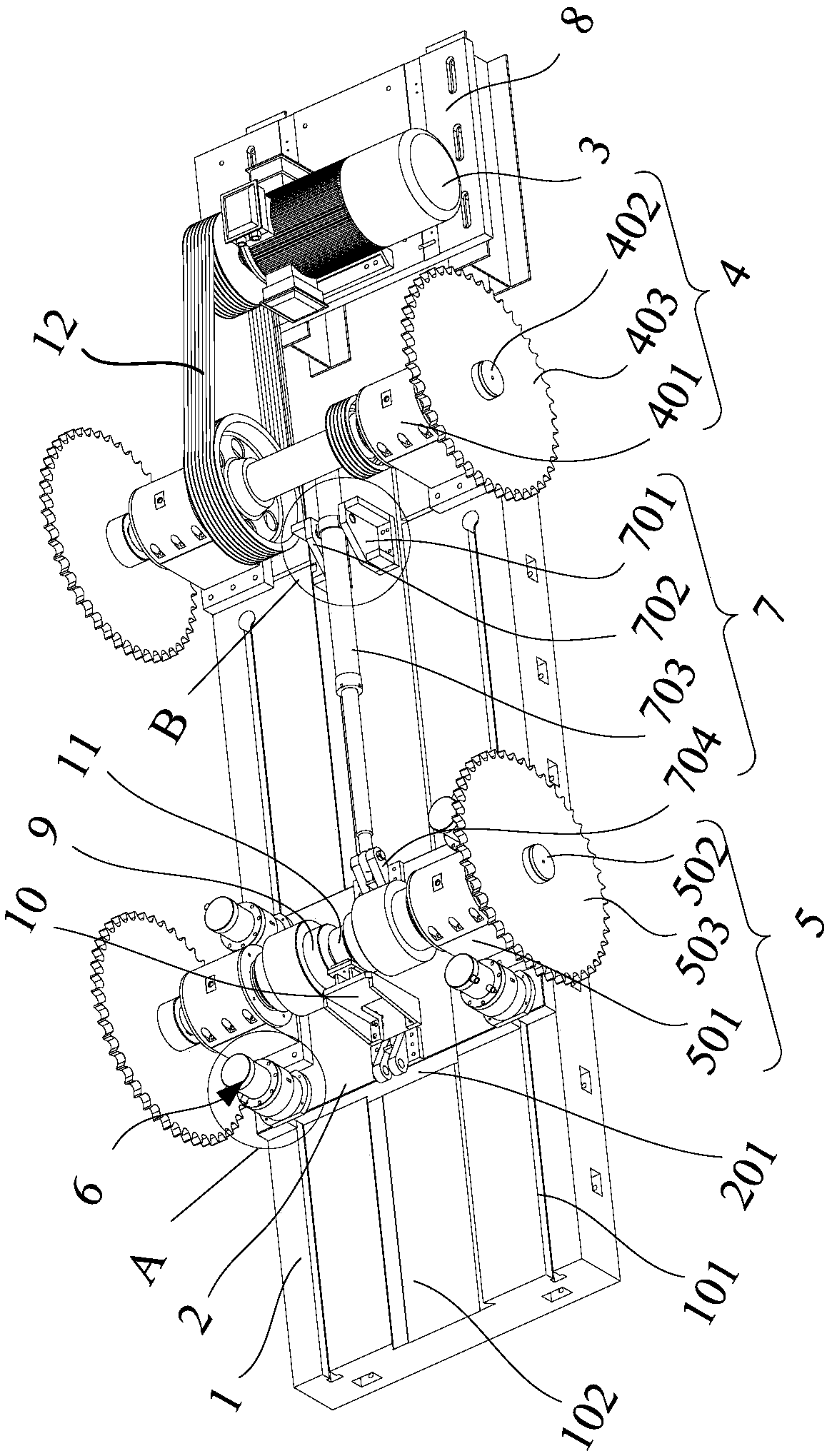

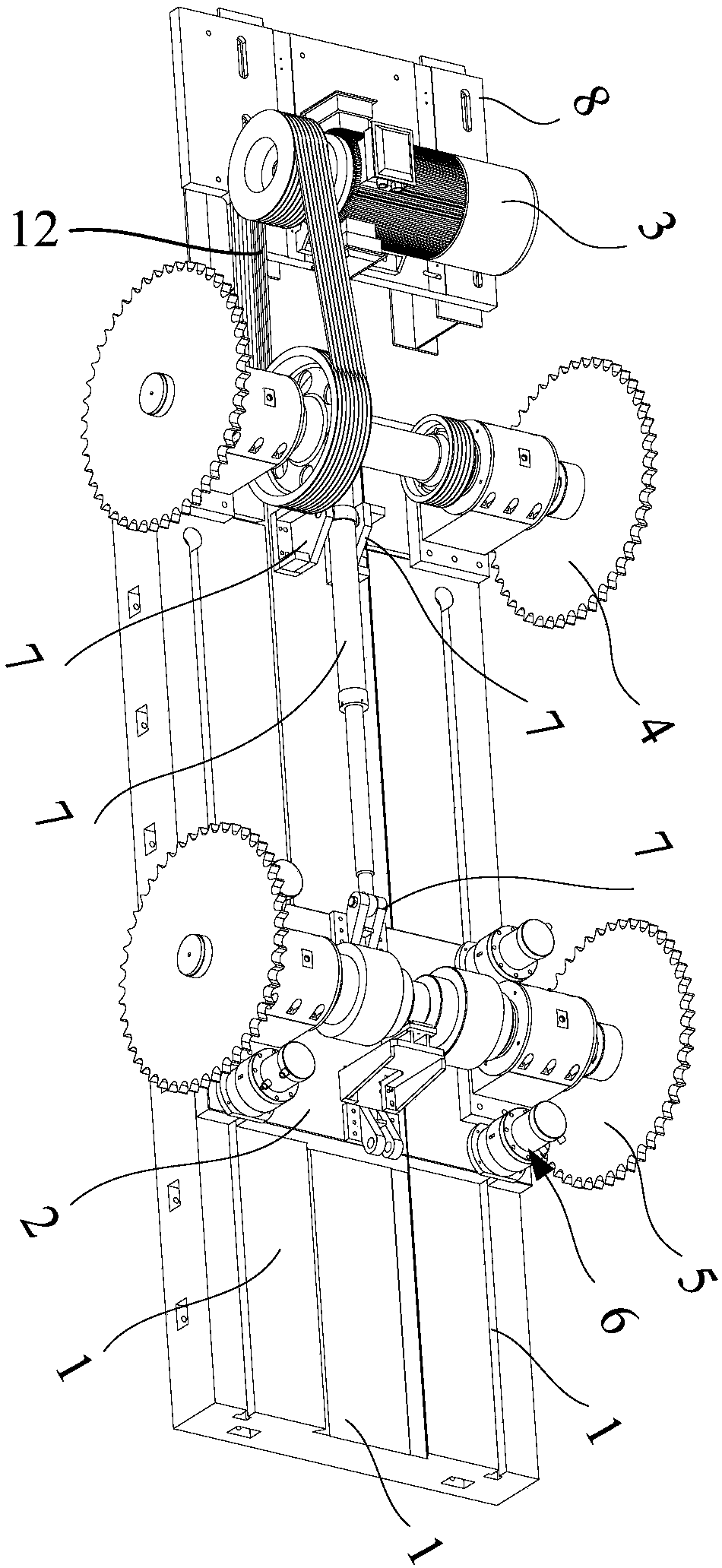

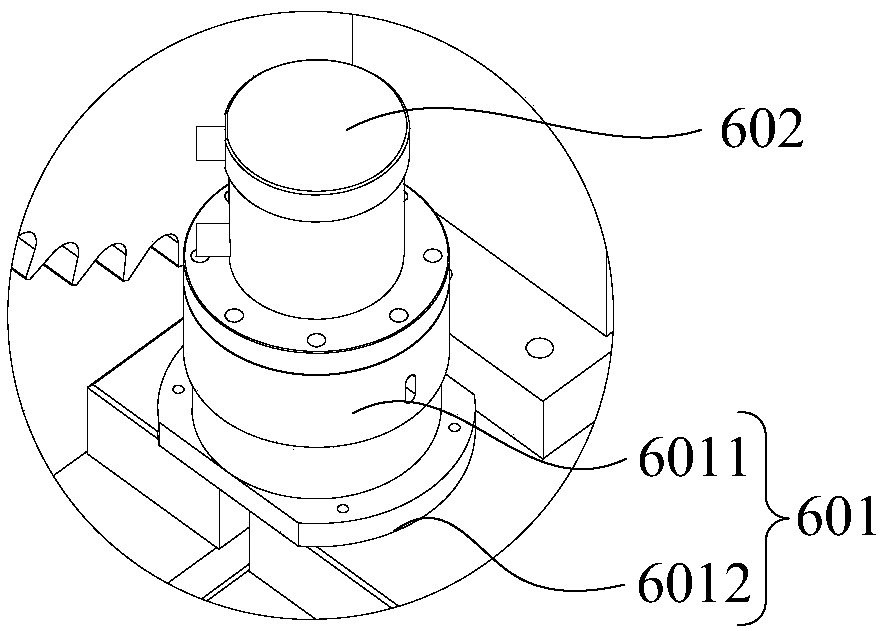

Theapplication relates to the technical field of chain wear test, in particular to a chain wear test device and a chain wear test method. The chain wear test device comprises a fixed plate, a movableplate, a driving device, a driving sprocket mechanism, a driven sprocket mechanism, a fixing component and a tensioning component; a first bearing block of the driving sprocket mechanism is arranged on the fixed plate; a driving shaft of the driving sprocket mechanism is inserted in the first bearing block, two ends of the driving shaft are sleeved with first sprockets, and the projections of thetwo first sprockets in a direction perpendicular to the axis of the driving shaft coincide with each other; the driving device drives the driving shaft to rotate; the movable plate can slide relativeto the fixed plate; the tensioning assembly is used for adjusting the distance between the movable plate and the fixed plate; the fixing component is used for fixing the movable plate to the fixed plate; and the driven sprocket mechanism comprises a second bearing block, a driven shaft and a second sprocket. The test device can simulate the real operation of a chain, and achieves the purpose of applying a large torque to the chain while saving energy.

Description

technical field [0001] The present application relates to the technical field of chain wear test, in particular to a chain wear test device and a chain wear test method. Background technique [0002] At present, the chain wear test bench is used to test the elongation of the chain under test conditions and within a certain time range. The existing chain wear tester applies reverse torque to the two sprockets in each set of sprockets, so that a part of the chain hanging on each set of sprockets is in a tensioned state, and the other part is in a loose state, and then Simulate the actual operation of the chain, but add a hydraulic torque loading system, the structure is complicated, and the energy consumption is increased. Contents of the invention [0003] The purpose of this application is to provide a chain wear test device and chain wear test method, to solve the existing in the prior art by applying reverse torque to two sprockets in each set of sprockets of the chain ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/56

CPCG01N3/56G01N2203/0282

Inventor 黄伟达刘家强黄千益胡清

Owner SUZHOU UNIVERSAL GRP TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com