Coaxial large strided distance ear base hole boring auxiliary device and boring process method

An auxiliary device and large-span technology, applied in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve the problems of large assembly workload, low work efficiency, large fit clearance, etc., and achieve high assembly accuracy, Improve the efficiency of installation work and the effect of small fit clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below by taking the machining of the coaxial large-span lug hole boring pin on the base of the heavy-duty skid-mounted drilling rig as an example, in conjunction with the accompanying drawings.

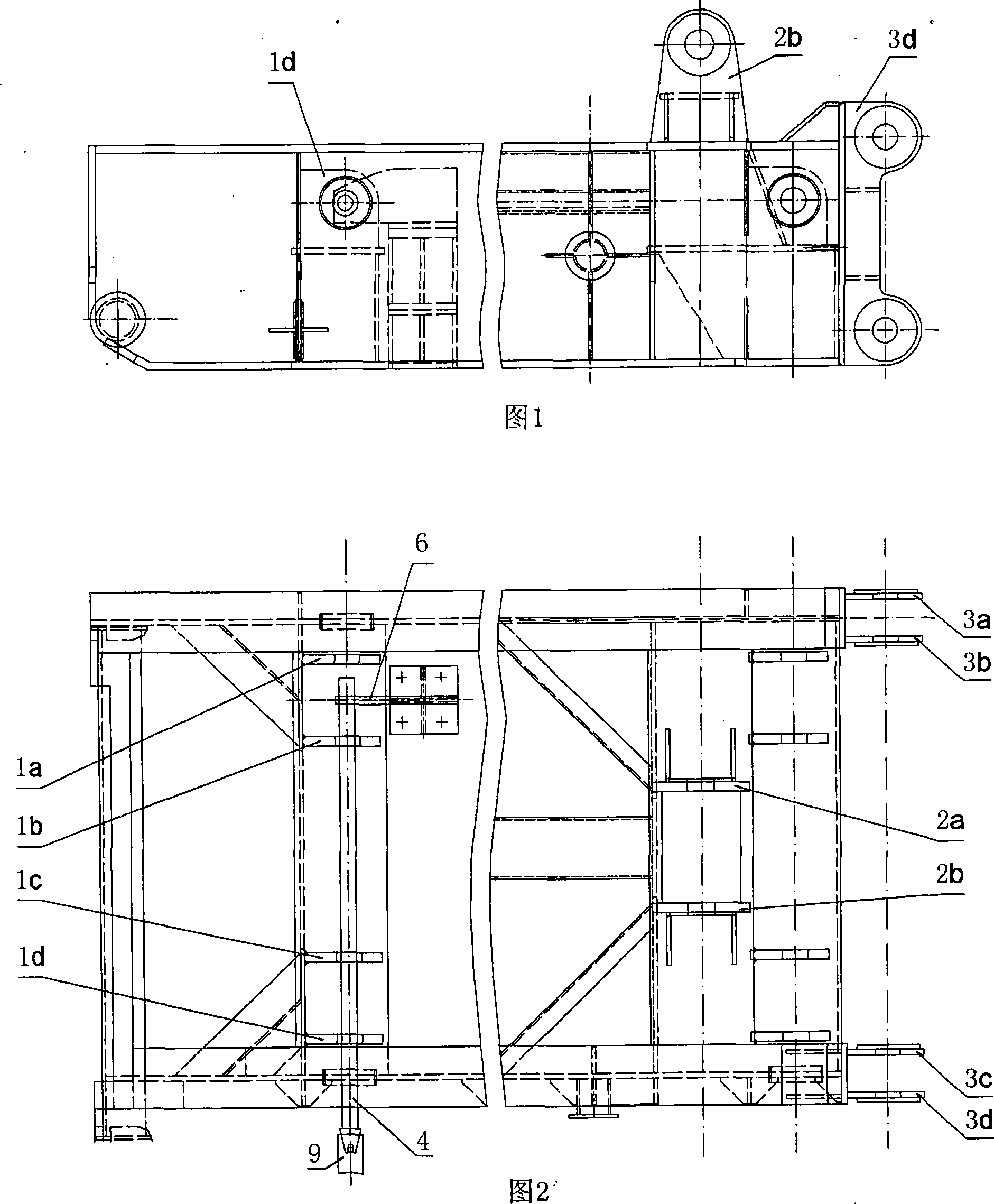

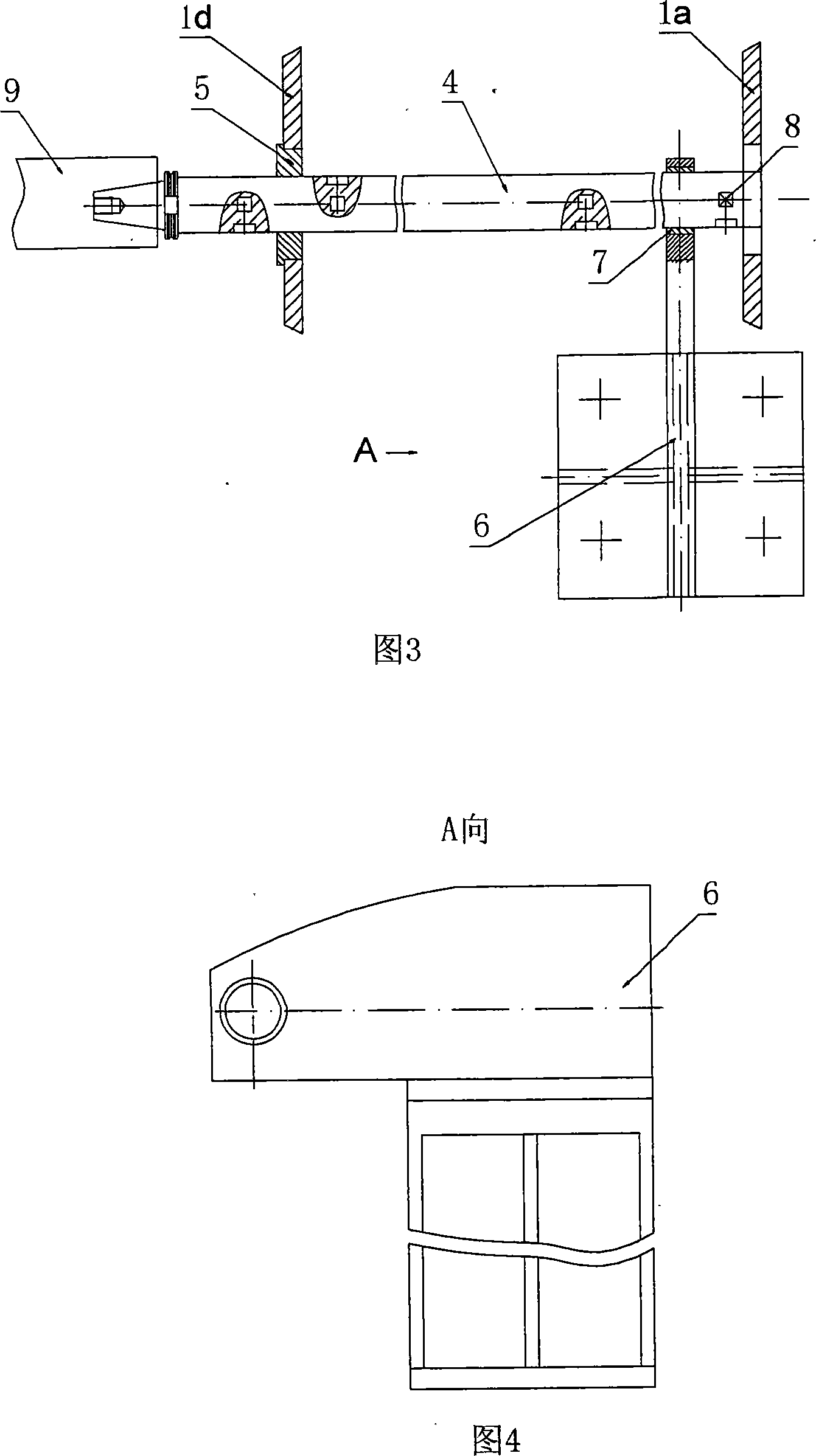

[0020] Figure 1 and Figure 2 are schematic diagrams of the foundation seat structure of the heavy-duty skid-mounted drilling rig. The foundation seat is about 13 meters long and 2.2 meters wide. There are several groups of ear seats on it, which are used to connect the ear seats and ear plates between the derrick and the drilling floor , in order to ensure that the derrick and the drill floor can be freely rotated and lifted relative to the foundation base, there is a high coaxiality requirement between a set of coaxial lug holes, and there is a center distance between the centerlines of each set of lug holes with parallel axes Size requirements and parallelism requirements. The following takes the boring pin processing of a group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com