Large low-temperature fatigue experimental device for bolt

A fatigue experiment and bolt technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of liquid nitrogen temperature fatigue, large bolt size parameters, and inability to test low temperature fatigue, etc., to achieve accurate temperature and save liquid nitrogen The effect of refrigerant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

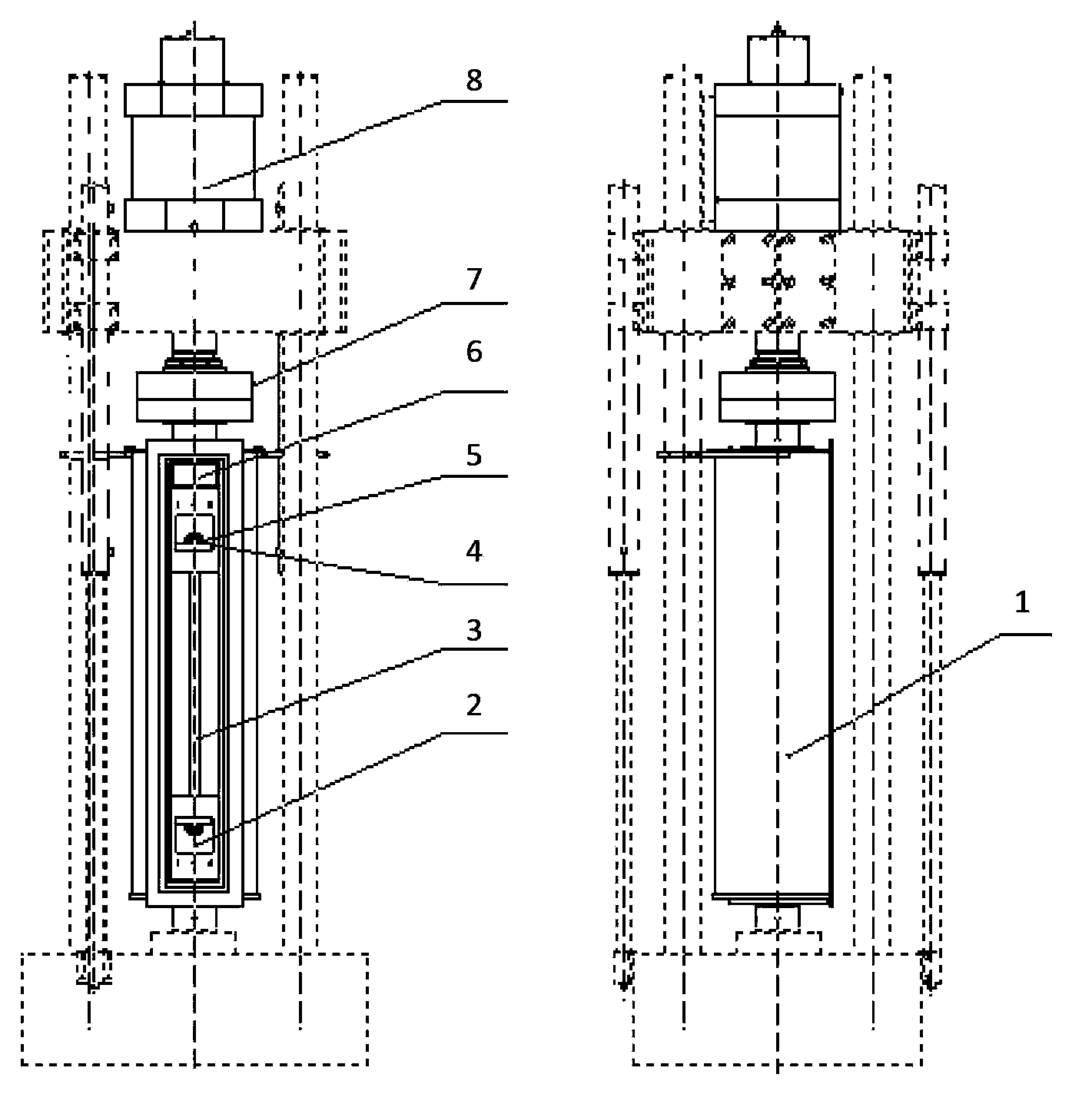

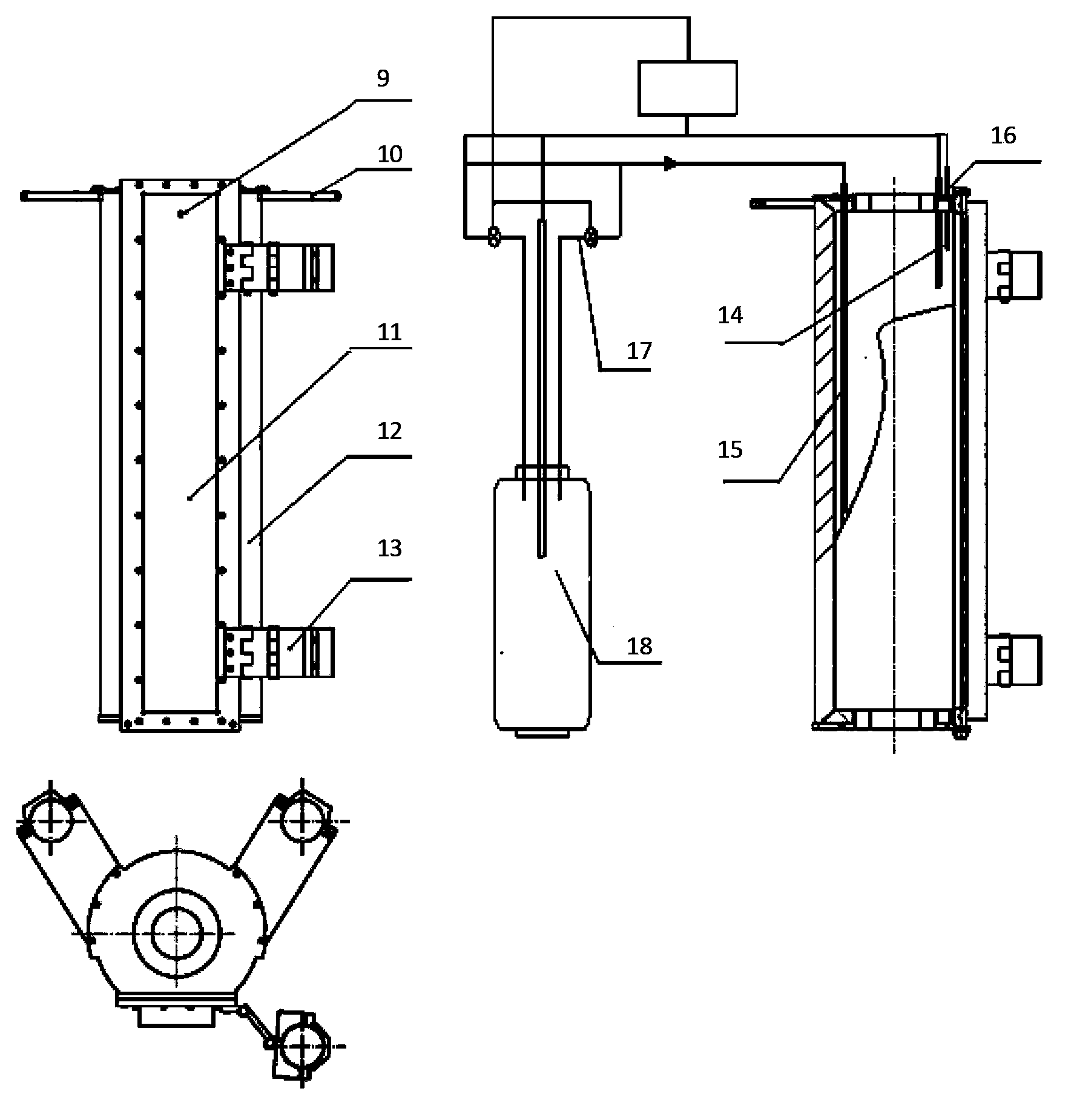

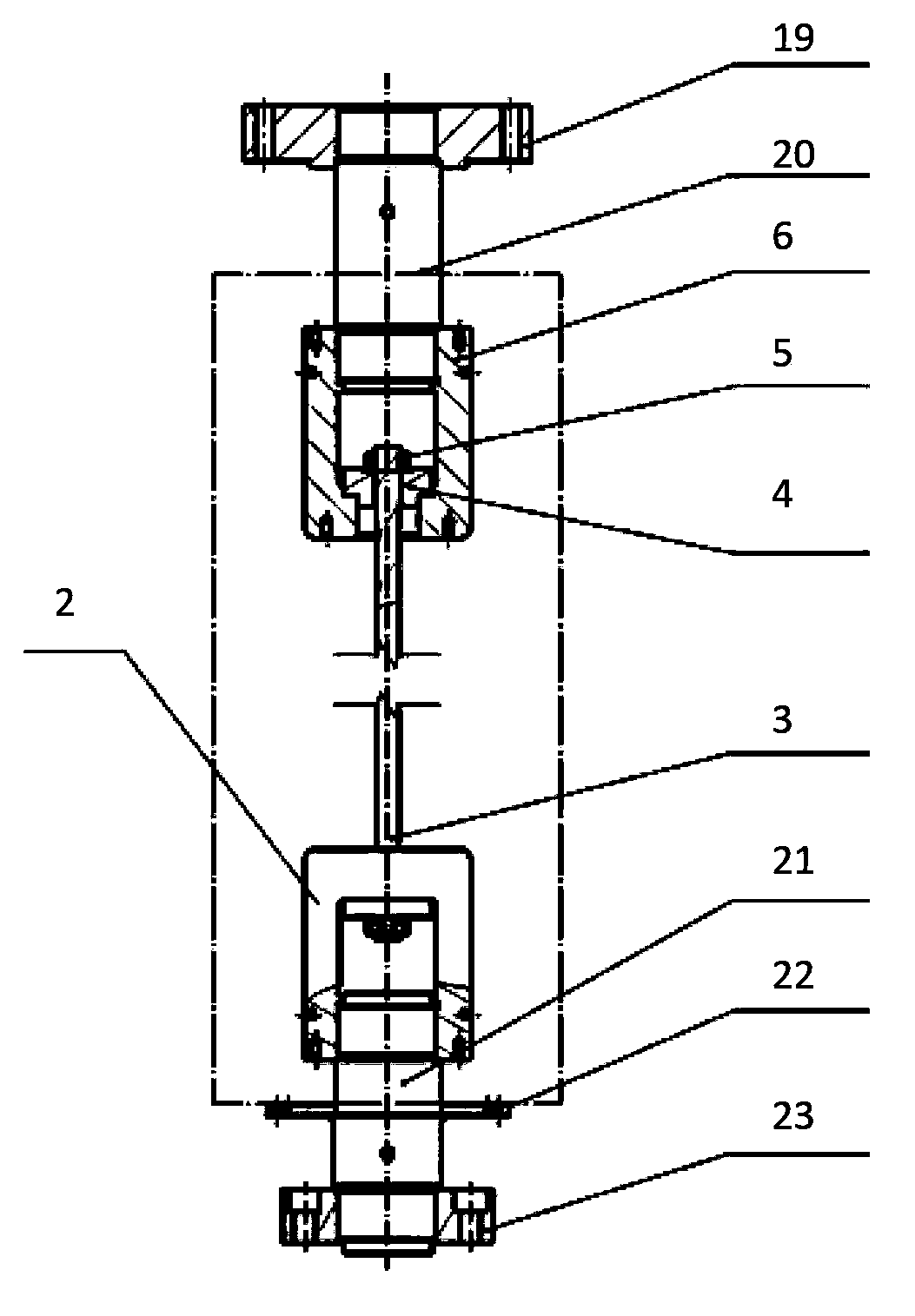

[0013] A low-temperature fatigue test device for bolts mainly includes: a low-temperature environment chamber, a special fixture for low-temperature fatigue of bolts, a low-temperature environment control system, a servo actuator, an electric control system, and the like. The low temperature fatigue test of large bolts can be performed by connecting the experimental device to a conventional fatigue machine.

[0014] The low-temperature environment box is composed of a hollow cylindrical special-shaped vertical Dewar, and its upper and lower ends each have a coaxial through hole, so that the upper and lower rods can be connected with the fixture inside through them. The low-temperature environment box is divided into two parts: the main body of the tank and the front door. A sealing ring groove is designed between them, and the low-temperature sealing material in the ring groove is compressed by the fastening bolts on the front door to seal. The bolt fastening method directly a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com