Hydraulic clamp for processing spindle taper hole

A technology for processing spindles and hydraulic fixtures, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., to achieve uniform pressure transmission, improve manufacturing accuracy, and meet the effects of elastic deformation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] The purpose of the present invention is to provide a hydraulic clamp with radial clamping function using an external expansion type to solve the problem of high-efficiency machining of the small taper hole of the spindle. In order to achieve the above-mentioned objective, the present invention proposes a hydraulic clamp with radial clamping function using an expansion type, which realizes the use of a car instead of grinding and solves the problem of high-efficiency machining of the small taper hole of the main shaft.

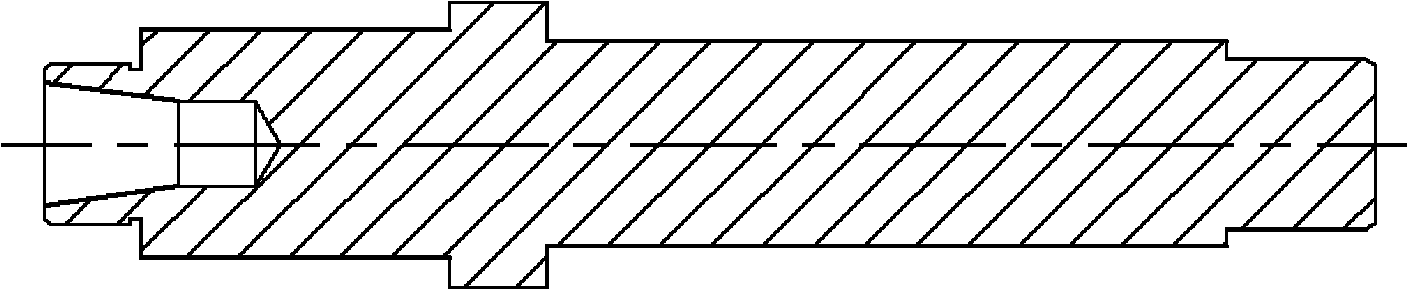

[0024] figure 1 It is a schematic diagram of the parts to be processed in the present invention. The hole size of the spindle taper hole is Φ11±0.05, the angle is 16°±30″, the surface roughness is required to be Ra0.8, and the coaxiality of the taper hole to the bearing gear is less than 0.002.

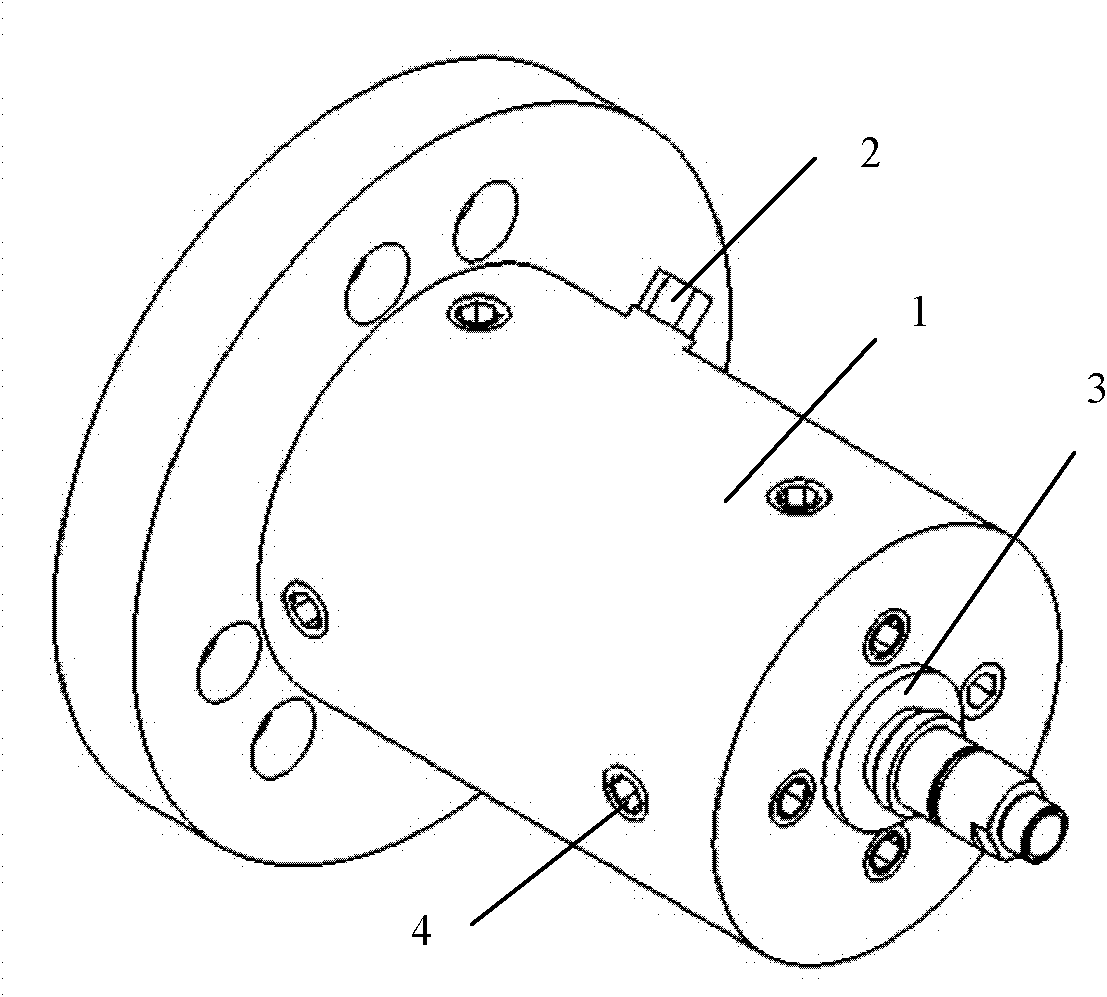

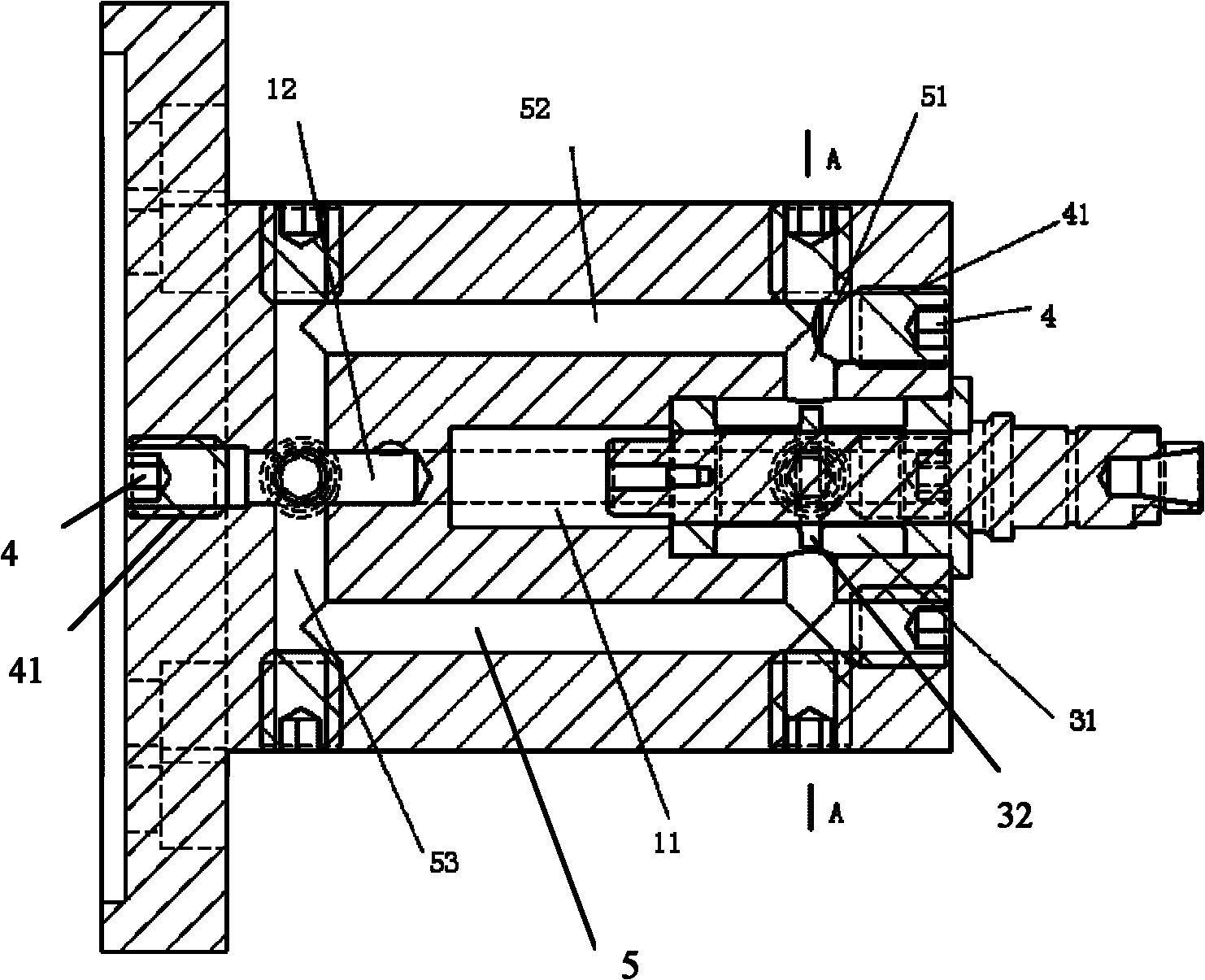

[0025] Such as figure 2 , image 3 , Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com