A double-fed wind driven generator novel seam allowance assembling structure and an assembling method

A technology for wind turbines and assembly structures, which is applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve the problems of difficult maintenance of wind farms, difficult maintenance and reassembly, and scratches on the edge of bearings. The effect of running, good consistency and not easy to scratch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

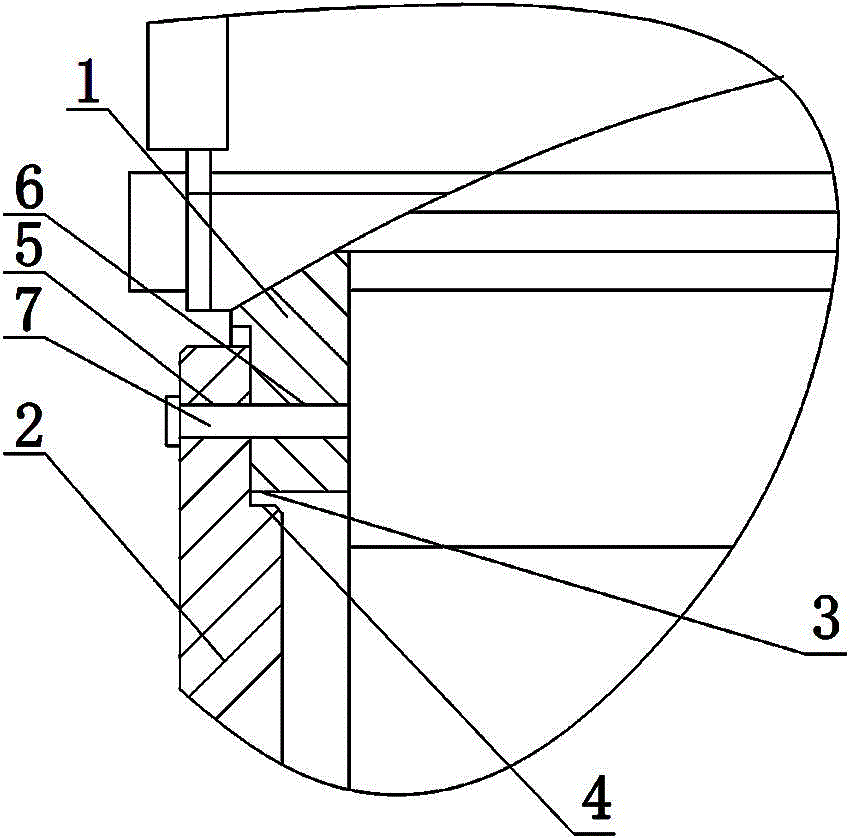

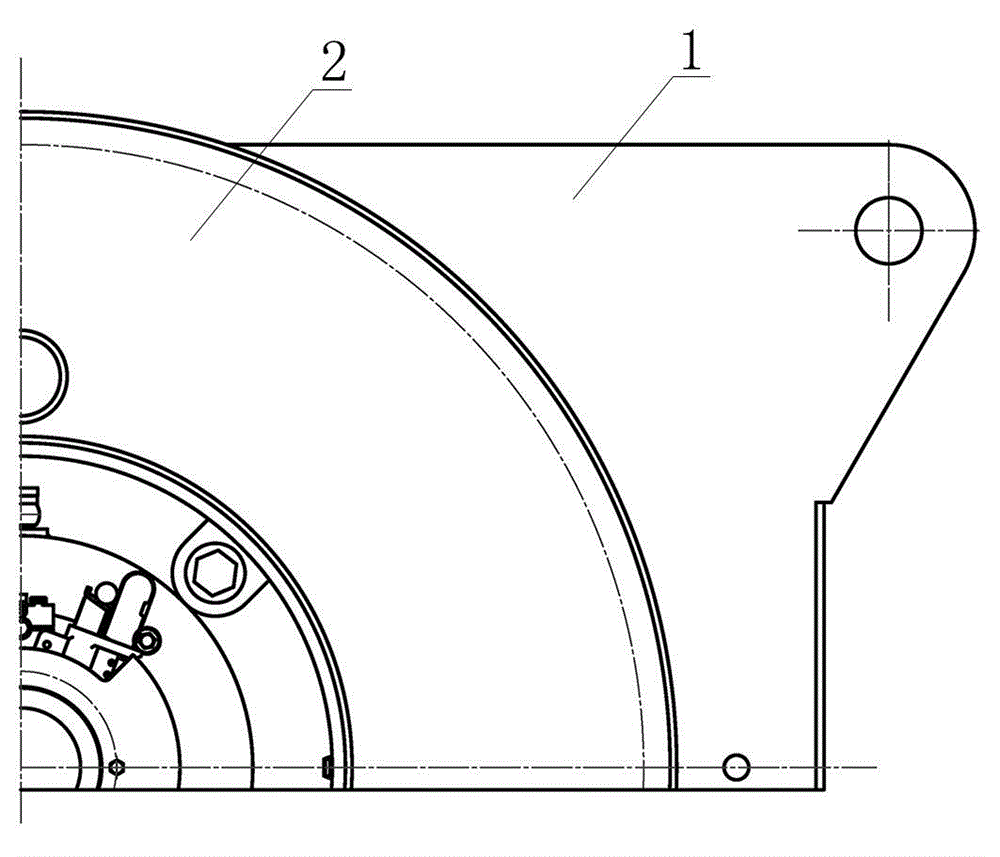

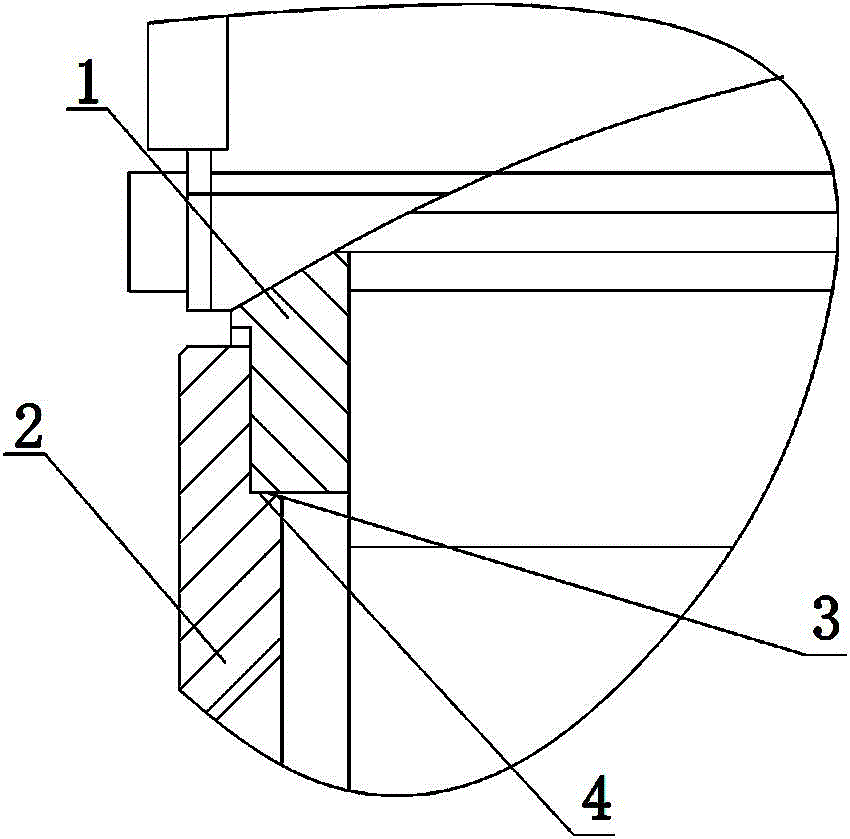

[0018] Such as figure 1 As shown, a new spigot assembly structure of a doubly-fed wind power generator, which includes a base 1 and an end cover 2 installed on the base 1, the base 1 is provided with an inner spigot 3, and the end cover 2 There is a gap between the outer peripheral surface of the outer lip 4 of the end cover 2 and the inner peripheral surface of the inner lip 3 of the machine base 1, and the end cover 2 and the machine base 1 are respectively provided with a step The positioning holes A5 on the end cover 2 and the positioning holes B6 on the machine base 1 are processed and synchronously prepared. The end cover 2 is evenly provided with several positioning holes A5 along the circumference, and the machine base 1 is provided with The positioning hole B6 matched with the positioning h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com