Stepped annular part high-precision butt joint circular welding inner supporting tool and design method and welding method thereof

A ring-shaped part and design method technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of easy misalignment, concentricity, roundness and other problems, so as to facilitate assembly and debugging and improve assembly accuracy , The effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

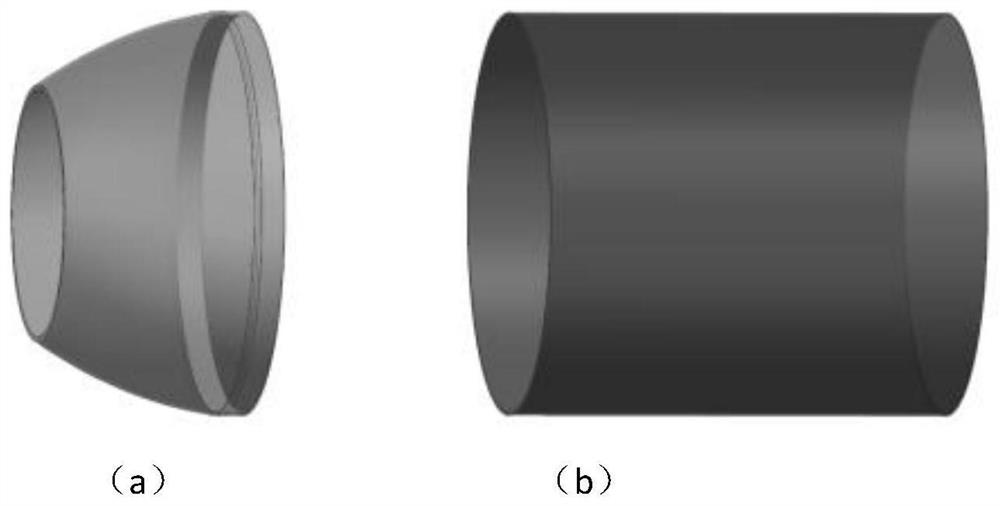

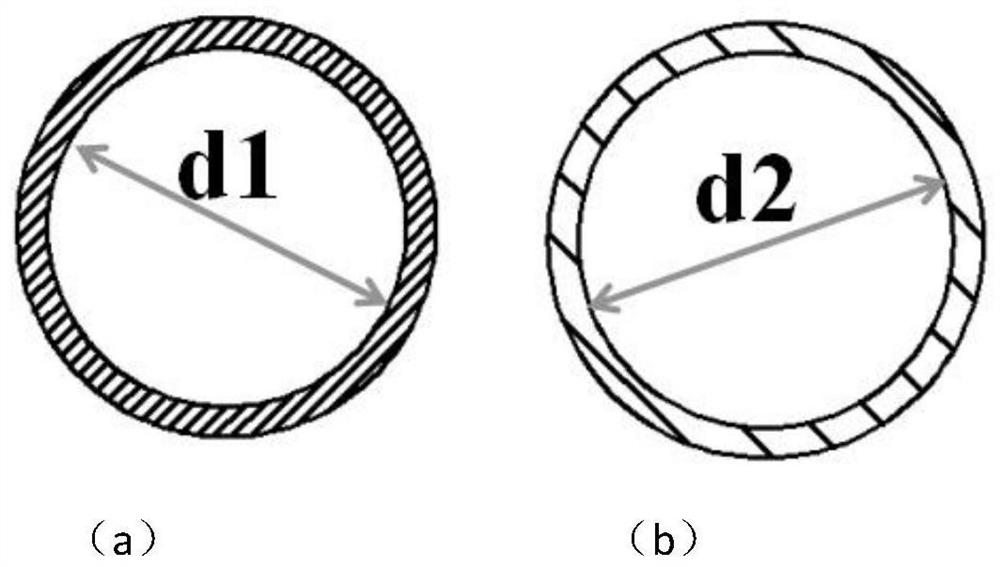

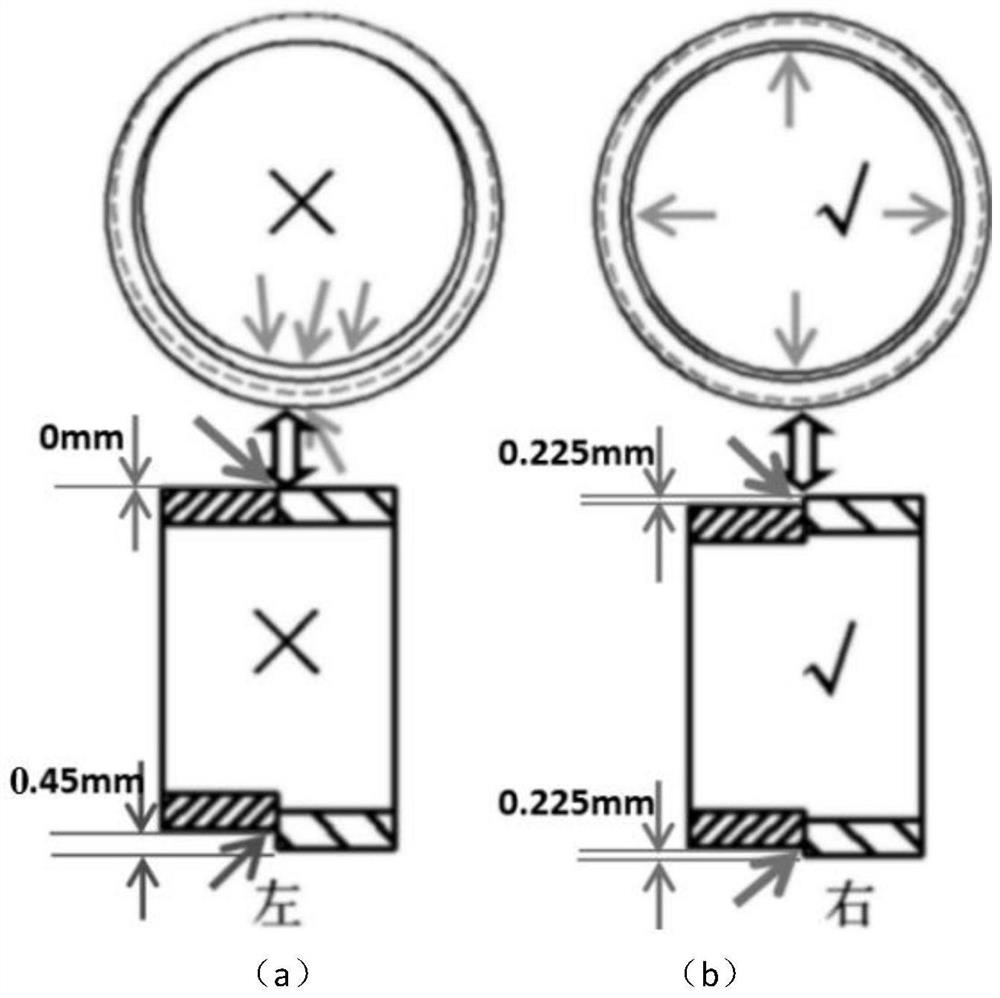

[0064] Specific implementation mode one: see Figure 6-8 This embodiment will be described. The high-precision butt ring welding inner support tooling of stepped ring parts in this embodiment mainly includes a main shaft 0, two forward and backward rotating shafts 2, two transmission rods 3, two dowel rods 4, two wedge-shaped transmission shafts and Support petal combination, the support petal combination includes two sets of support petals,

[0065] The two ends of the main shaft are respectively equipped with forward and backward rotating shafts 2, and each advancing and retreating rotating shaft 2 is connected with a transmission rod 3, and the end of each transmission rod 3 is vertically installed with a dowel 4, which transmits force to the wedge A transmission shaft, the outer periphery of each wedge-shaped transmission shaft is equipped with a support flap.

[0066] The supporting petal assembly includes a No. 1 supporting petal 11 and a No. 2 supporting petal 12, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com